"hey GRUMPY?

Just bought a 427 long motor. Stock except .040" over. eng casting no is 3999294. Got some heads for it, casting no 3986133. Heads are mentioned in a few different chevy numbers lists, but half say closed chamber and the others say open?!?! What should I measure to confirm? I want +400 hp at the wheels, with a stage 3 shift kitted Turbo Hydro 400 trans. Wondering what cam to go with? solid or hydraulic? roller rockers? Going to run Quaddie carby, cos I love them. Making our own sheetmetal intake too. Want to try and reverse the water flow, to keep heads colder and bottom end hotter. Anyone got experience with this? Sorry for all the newbie questions."

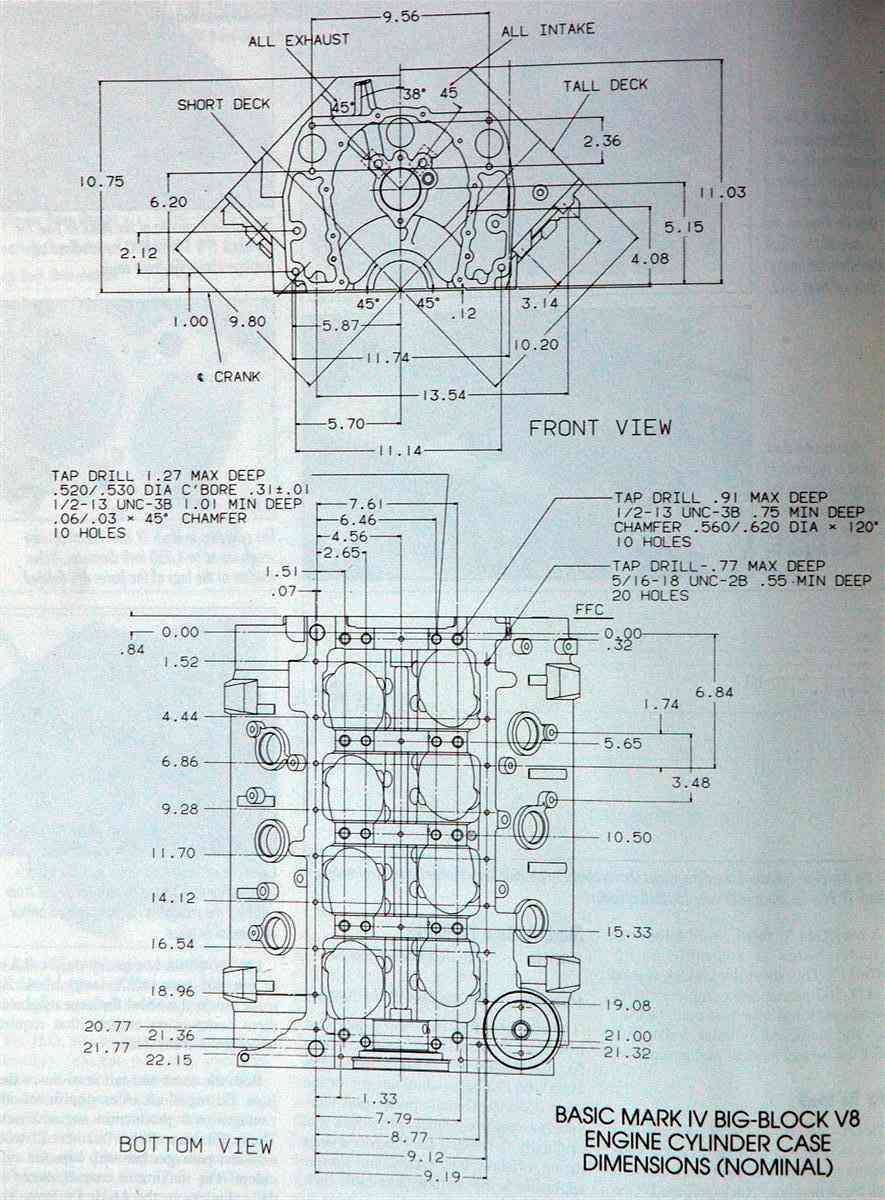

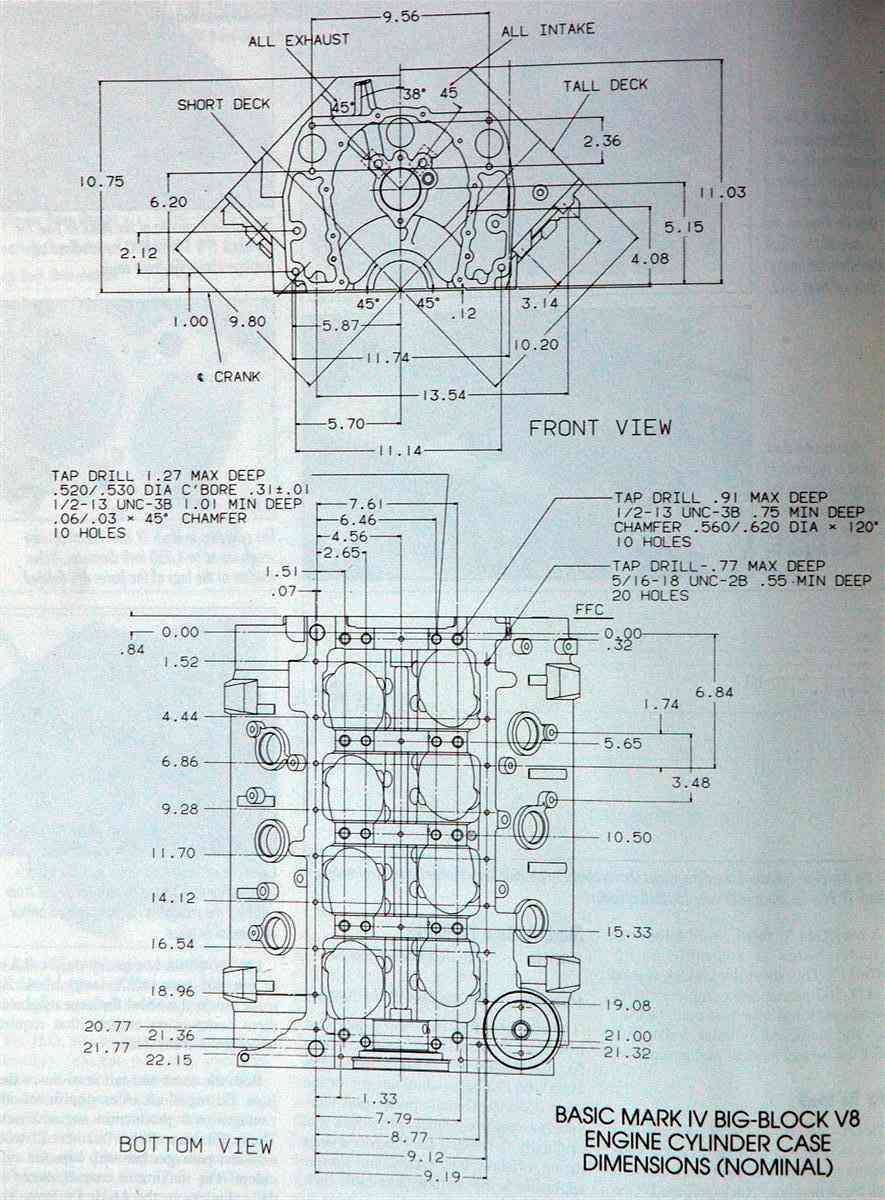

the tall deck 427 block you have is a good place to start from, the heads are far less desirable, most guys building the tall deck blocks build a 496 stroker with a longer 6.385" connecting rod, and 4.25" stroker crank, and much lighter forged pistons,to take full advantage of the taller deck height, the current pistons are far too heavy to make high rpm power, the tall deck block used a heavy flat top low compression piston with 4 rings , not three like most car pistons ,requiring a taller piston and resulting taller block deck, its designed for low rpm torque.

the cam you select will depend on the heads, and intake, and compression ratio, and final displacement and your cars gearing, generally, youll want a fairly tight LSA around 108 and about a 10:1 cpr on a street car, duration and lift will be dictated by the other factors mentioned, obviously if you stay with a stock low cpr 427 it takes a smaller cam that a 10:1 cpr 496

3999294....427T......68-84...4-bolt

3986133....68-85...oval...OPEN...366T, 427T, 454 Truck

heads like these will far out perform your current heads easily worth an additional 100 plus hp

http://www.summitracing.com/parts/BRO-2061010/

http://gearheadgeek.com/ghgj/index.php/ ... -s?start=1

a properly designed 496 can easily make 550-600 hp with minor mods on off the shelf parts

the key is getting the head flow ,compression ,and cam timing to match the intended power curve

a properly built 496 can easily produce far more horsepower and torque that the heavy rotating assembly in your current 427 designed for low rpm torque and long term durability only

READ THE LINKS AND SUB LINKS,it could easily save you weeks of work and hundreds of dollars, and if you take the effort youll be far ahead of those guys that glance thru and don,t take the time to understand the concepts

viewtopic.php?f=69&t=3153

viewtopic.php?f=69&t=916

viewtopic.php?f=52&t=3960&p=10600&hilit=open+oval#p10600

viewtopic.php?f=69&t=170

http://www.edelbrock.com/automotive_new ... 0/2916.pdf

viewtopic.php?f=51&t=93&p=9023&hilit=mortec#p9023

viewtopic.php?f=51&t=2692&p=13225&hilit=tall+deck+intake#p13225

viewtopic.php?f=44&t=101

viewtopic.php?f=69&t=6132&p=19023#p19023

Thanks for your informative replys and links. I need all the help I can get! The engine is for a 1938 Bedford truck cabin rod I am building, body built by GM Holden, pre-world war II, in Melbourne. I am building a chassis for it, to mainly street it, but also for the odd Sunday at my local drag strip. Am currently estimating under 2500 lb for the car. 427T, TH400 box, 3.9-ish gears (9"), 4 link, air bags all round, flat bed tray. Power to weight should be ok

What does this look like to you, in terms of overall package, for about US$2600? I am unsure about the rods' ProComp brand, it being so new on the scene in Australia. Appreciate any feedback.

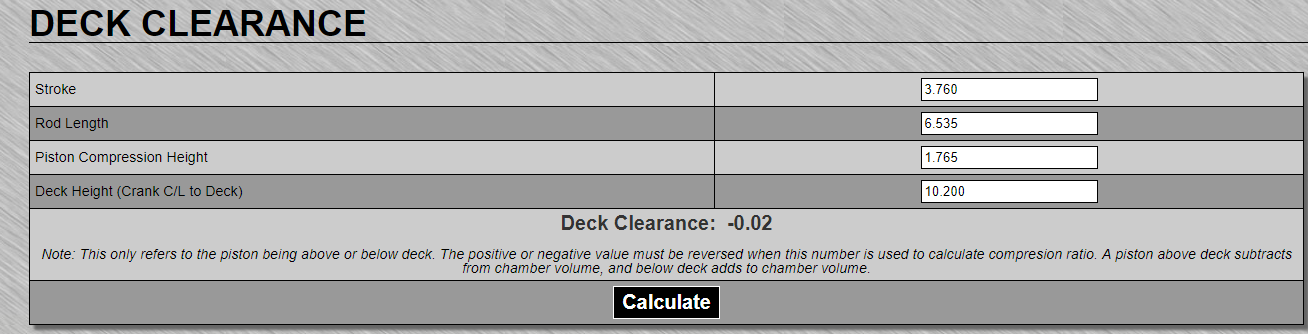

Scat Manufacturing 1-42390BI BBC 10.200 Deck 4340 Forged Competition Rotating Assembly with I-Beam Rods, 4.500" Bore x 4.500" Stroke x 6.535" Rod

4340 Forged Standard Weight Crank, Pro Comp I-Beam Connecting Rods with 7/16†Cap Screws, 1.395" Compression Ht. Premium Forged Pistons, Rings, Rod Bearings & Main Bearings

Internally Balanced

Crank:4-454-4500-6535

Rods:2-454-6535-2200

Stroke:4.500"

Rod:6.535"

Piston remium Forged Dish

remium Forged Dish

Bore:4.500"

Compression 58cc:8.8

Compression 64 cc:8.5

Compression 70cc:8.2

your going to need to have that block checked again, if its a tall deck 427 block your NEVER going to be able to bore it past about 4.310 and maintain a rigid cylinder wall that will maintain a good ring seal, and 4.375 is about the max stroke if you very carefully machine clearances, most guys go with a 4.25" stroke and a 4.310 bore and build a 496 displacement big block with 6.385 rods.

btw most BBC head have 100cc-122cc combustion chamber sizes and those CC quoted are SMALL BLOCK HEAD SIZES

main_page=calculators&zenid=823ce2c9e2ffa691864d832c10107df0

the best solution from a performance perspective is to do the required calculations to select the longest length connecting rod and the lowest weight piston,

of a decent design that will reduce the reciprocating mass significantly more.

the tall deck has a 10.2" deck height, a good dual plane aluminum high rise intake manifold will tend to provide the best compromise if you use a low compression and mild cam duration,

while it might seem like a waste of time, now, reading the links and sub-links will provide a good base to work from, later and save you a great deal of wasted time and money

you have a choice, you can slap the components you own together, now and live with what you have built regardless of the results , or you can put some real thought into making the result perform and carefully select parts and significantly boost power... yes that routes more expensive up front, but in the long term it tends to get better results and cost LESS.

common BB CHEVY piston compression heights are

1.270"

1.395"

1.520"

1.645"

1.765"

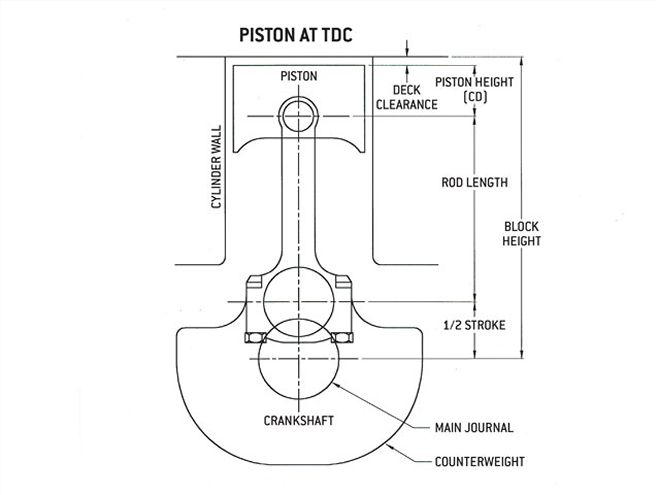

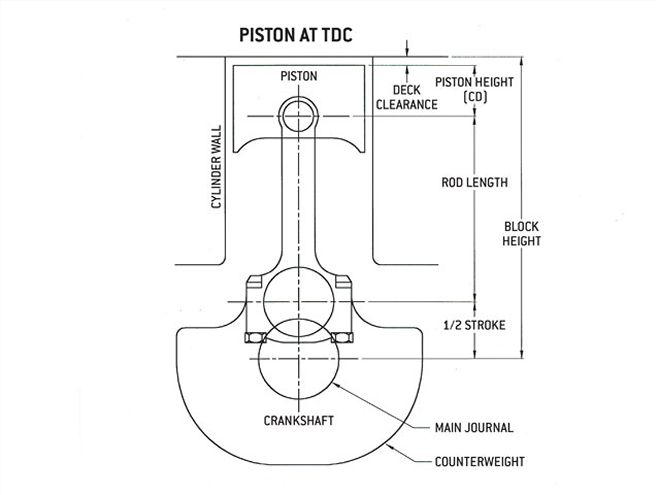

remember the blocks deck height, minus the piston pin height minus 1/2 the crank stroke will equal the required connecting rod length

OR

the blocks deck height, minus the connecting rod length, minus 1/2 the crank stroke. will equal the required piston pin height

if you wonder why I suggest using SCAT (H) beam style cap screw connecting rods vs stock or most (I) beam designs this picture should show the increased cam to connecting rod clearance

notice the pin height in the pistons pictured above allow a longer or shorter connecting rod length

heres a selection of commonly available big block chevy connecting rod lengths

https://www.uempistons.com/index.ph...e=deck&zenid=823ce2c9e2ffa691864d832c10107df0

https://www.uempistons.com/index.php?main_page=calculators&zenid=823ce2c9e2ffa691864d832c10107df0

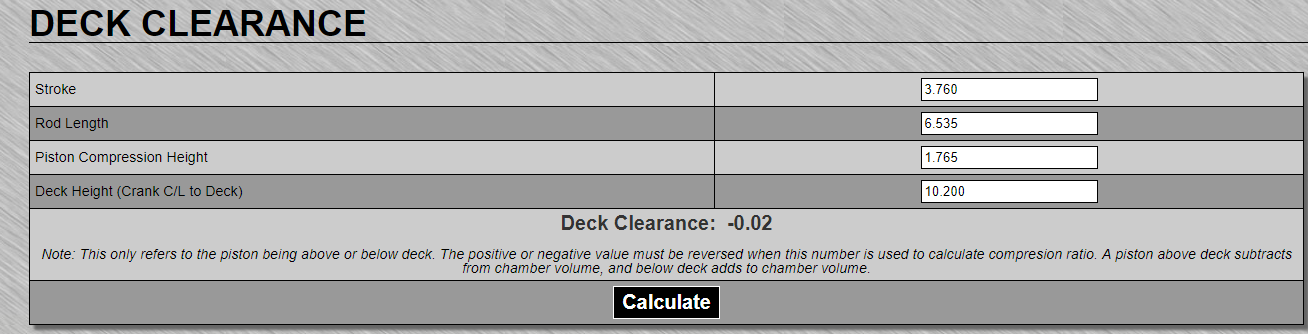

1.765 compression height, pistons in standard 9.8" deck block, a 10.2" tall deck requires a longer connecting rod

most likely a 6.535" aftermarket connecting rod

threads you should read through carefully,and the sub links in them are below,

the tall deck block is put to much better use building a 496 with a 4.25" stroke and a .060 over bore and 6.385" connecting rods

http://garage.grumpysperformance.com/index.php?threads/another-496bbc.5123/

http://garage.grumpysperformance.co...g-block-head-comparison.319/page-2#post-61658

http://www.maliburacing.com/patrick_budd_article.htm

http://garage.grumpysperformance.com/index.php?threads/427-tall-deck-bbc.14451/

http://garage.grumpysperformance.com/index.php?threads/big-block-chevy-info.710/#post-60299

http://garage.grumpysperformance.co...-displacement-street-engine.10961/#post-50668

Grumpy, what is this required number likely to be, on most of the cams you like to use? (Intake Closing Point (degrees)ABDC @ 0.050 lift plus 15 degrees) This is required in this calculator I am using to consider compression ratios. I think it's one you've recommended.

address to calculator here:

http://kb-silvolite.com/calc.php?action=comp

Looking at using a 4.25" crank, 6.8" 'H' rods and a piston compression height of 1.27". Gives me a rod/stroke ratio of 1.6:1. What sort of pistons should I be looking for, using Brodix "Big Brodie" heads, with a 119cc chamber and 300cc intake runners, 2.25 intakes and 1.88 exh. Want between 10:1 and 11:1 compression. Waiting for deck height confirmation, but if its a stock 10.2", then I have .005" clearance with this combo, plus .040" for the gasket! Appreciate your help and suggestions!

in an ideal world you want the cylinder walls on cylinders to be at least .180 thick at the THINNEST, point, if they are thinner than .140 Id seriously consider either buying an aftermarket block with a thicker casting or filling the block water passages up to the lower edge of the freeze plugs to add a good deal more rigidity to the cylinder walls to reduce flex and increase ring seal.

READ THESE

viewtopic.php?f=51&t=588&p=764&hilit=sonic#p764

viewtopic.php?f=51&t=976&p=1827#p1827

HERES A CHART to find the intake valve close point at .050 lift, you then add 15 degrees to use that particular calculator

viewtopic.php?f=52&t=4299

If the rest of you figures are correct youll want about a 20cc-24cc dome on the piston and a cam with about a 55 degree intake valve close point at .050 lift

but most un-milled blocks will have a .023 deck height not .005

now for best power a cam with a 104-108 LSA is about correct but you can afford to use a wider 110-112 LSA, and loose a few hp but make the combo easier to drive and tune on the street, and have a wider torque curve

viewtopic.php?f=52&t=82

viewtopic.php?f=52&t=1070

viewtopic.php?f=52&t=727

Grumpy,

So, I did some homework with the info you have offered me.

I have tentatively chosen a piston with 24cc top, and a Comp Cams 11-450-8 cam.

It has IVC @.050 of 44 deg.

Power is in the region of 600hp (using the numbers for a 454) The Comp Cams calculator would not consider the 4.31 bore, so could not refer to 496 cu. in.

I used a 'domestic dual plane' for carb. with an 850 cfm

I then ran all the effective number in the compression calc you offered:

COMPRESSION RATIO CALCULATOR

Static and Dynamic Compression Ratio

(Considers Cam Timing and Rod Ratio)

ENTER YOUR DATA CALCULATED DATA

Cylinder Head Volume (cc) 199

Cylinder Head Vol (cubic in.) 7.259

Piston Head Volume (cc) -24

Piston Head Vol (cubic in.) -1.464

Gasket Thickness (in.) .040

Swept Volume (cubic in.) 62.006

Gasket Bore (in.) 4.31

T.D.C. Volume (cubic in.) 6.715

Cylinder Bore Diameter (in.) 4.31

Gasket Volume (cubic in.) 0.584

Deck Clearance (in.) .023 Note: Neg. nubmer above deck, Pos. number below deck

Deck Volume (cubic in.) 0.336

Stroke (in.) STATIC COMPRESSION RATIO 10.234

OPTIONAL DATA

Rod Length (in.) 6.8

Adjusted Stroke (in.) 3.468

Intake Closing Point (degrees)ABDC @ 0.050 lift plus 15 degrees 59

DYNAMIC EFFECTIVE COMPRESSION RATIO 8.535

What are your thoughts on this combo?

Darn you know some serious stuff. I am loving the resource you are for me.

Id suggest a thinner head gasket to get the quench distance a bit closer and retarding this cam

http://www.summitracing.com/parts/CCA-11-460-8/

4 degrees as a better match to your application

Just bought a 427 long motor. Stock except .040" over. eng casting no is 3999294. Got some heads for it, casting no 3986133. Heads are mentioned in a few different chevy numbers lists, but half say closed chamber and the others say open?!?! What should I measure to confirm? I want +400 hp at the wheels, with a stage 3 shift kitted Turbo Hydro 400 trans. Wondering what cam to go with? solid or hydraulic? roller rockers? Going to run Quaddie carby, cos I love them. Making our own sheetmetal intake too. Want to try and reverse the water flow, to keep heads colder and bottom end hotter. Anyone got experience with this? Sorry for all the newbie questions."

the tall deck 427 block you have is a good place to start from, the heads are far less desirable, most guys building the tall deck blocks build a 496 stroker with a longer 6.385" connecting rod, and 4.25" stroker crank, and much lighter forged pistons,to take full advantage of the taller deck height, the current pistons are far too heavy to make high rpm power, the tall deck block used a heavy flat top low compression piston with 4 rings , not three like most car pistons ,requiring a taller piston and resulting taller block deck, its designed for low rpm torque.

the cam you select will depend on the heads, and intake, and compression ratio, and final displacement and your cars gearing, generally, youll want a fairly tight LSA around 108 and about a 10:1 cpr on a street car, duration and lift will be dictated by the other factors mentioned, obviously if you stay with a stock low cpr 427 it takes a smaller cam that a 10:1 cpr 496

3999294....427T......68-84...4-bolt

3986133....68-85...oval...OPEN...366T, 427T, 454 Truck

heads like these will far out perform your current heads easily worth an additional 100 plus hp

http://www.summitracing.com/parts/BRO-2061010/

http://gearheadgeek.com/ghgj/index.php/ ... -s?start=1

a properly designed 496 can easily make 550-600 hp with minor mods on off the shelf parts

the key is getting the head flow ,compression ,and cam timing to match the intended power curve

a properly built 496 can easily produce far more horsepower and torque that the heavy rotating assembly in your current 427 designed for low rpm torque and long term durability only

READ THE LINKS AND SUB LINKS,it could easily save you weeks of work and hundreds of dollars, and if you take the effort youll be far ahead of those guys that glance thru and don,t take the time to understand the concepts

viewtopic.php?f=69&t=3153

viewtopic.php?f=69&t=916

viewtopic.php?f=52&t=3960&p=10600&hilit=open+oval#p10600

viewtopic.php?f=69&t=170

http://www.edelbrock.com/automotive_new ... 0/2916.pdf

viewtopic.php?f=51&t=93&p=9023&hilit=mortec#p9023

viewtopic.php?f=51&t=2692&p=13225&hilit=tall+deck+intake#p13225

viewtopic.php?f=44&t=101

viewtopic.php?f=69&t=6132&p=19023#p19023

Thanks for your informative replys and links. I need all the help I can get! The engine is for a 1938 Bedford truck cabin rod I am building, body built by GM Holden, pre-world war II, in Melbourne. I am building a chassis for it, to mainly street it, but also for the odd Sunday at my local drag strip. Am currently estimating under 2500 lb for the car. 427T, TH400 box, 3.9-ish gears (9"), 4 link, air bags all round, flat bed tray. Power to weight should be ok

What does this look like to you, in terms of overall package, for about US$2600? I am unsure about the rods' ProComp brand, it being so new on the scene in Australia. Appreciate any feedback.

Scat Manufacturing 1-42390BI BBC 10.200 Deck 4340 Forged Competition Rotating Assembly with I-Beam Rods, 4.500" Bore x 4.500" Stroke x 6.535" Rod

4340 Forged Standard Weight Crank, Pro Comp I-Beam Connecting Rods with 7/16†Cap Screws, 1.395" Compression Ht. Premium Forged Pistons, Rings, Rod Bearings & Main Bearings

Internally Balanced

Crank:4-454-4500-6535

Rods:2-454-6535-2200

Stroke:4.500"

Rod:6.535"

Piston

Bore:4.500"

Compression 58cc:8.8

Compression 64 cc:8.5

Compression 70cc:8.2

your going to need to have that block checked again, if its a tall deck 427 block your NEVER going to be able to bore it past about 4.310 and maintain a rigid cylinder wall that will maintain a good ring seal, and 4.375 is about the max stroke if you very carefully machine clearances, most guys go with a 4.25" stroke and a 4.310 bore and build a 496 displacement big block with 6.385 rods.

btw most BBC head have 100cc-122cc combustion chamber sizes and those CC quoted are SMALL BLOCK HEAD SIZES

main_page=calculators&zenid=823ce2c9e2ffa691864d832c10107df0

the best solution from a performance perspective is to do the required calculations to select the longest length connecting rod and the lowest weight piston,

of a decent design that will reduce the reciprocating mass significantly more.

the tall deck has a 10.2" deck height, a good dual plane aluminum high rise intake manifold will tend to provide the best compromise if you use a low compression and mild cam duration,

while it might seem like a waste of time, now, reading the links and sub-links will provide a good base to work from, later and save you a great deal of wasted time and money

you have a choice, you can slap the components you own together, now and live with what you have built regardless of the results , or you can put some real thought into making the result perform and carefully select parts and significantly boost power... yes that routes more expensive up front, but in the long term it tends to get better results and cost LESS.

common BB CHEVY piston compression heights are

1.270"

1.395"

1.520"

1.645"

1.765"

remember the blocks deck height, minus the piston pin height minus 1/2 the crank stroke will equal the required connecting rod length

OR

the blocks deck height, minus the connecting rod length, minus 1/2 the crank stroke. will equal the required piston pin height

if you wonder why I suggest using SCAT (H) beam style cap screw connecting rods vs stock or most (I) beam designs this picture should show the increased cam to connecting rod clearance

notice the pin height in the pistons pictured above allow a longer or shorter connecting rod length

heres a selection of commonly available big block chevy connecting rod lengths

https://www.uempistons.com/index.ph...e=deck&zenid=823ce2c9e2ffa691864d832c10107df0

https://www.uempistons.com/index.php?main_page=calculators&zenid=823ce2c9e2ffa691864d832c10107df0

1.765 compression height, pistons in standard 9.8" deck block, a 10.2" tall deck requires a longer connecting rod

most likely a 6.535" aftermarket connecting rod

threads you should read through carefully,and the sub links in them are below,

the tall deck block is put to much better use building a 496 with a 4.25" stroke and a .060 over bore and 6.385" connecting rods

http://garage.grumpysperformance.com/index.php?threads/another-496bbc.5123/

http://garage.grumpysperformance.co...g-block-head-comparison.319/page-2#post-61658

http://www.maliburacing.com/patrick_budd_article.htm

http://garage.grumpysperformance.com/index.php?threads/427-tall-deck-bbc.14451/

http://garage.grumpysperformance.com/index.php?threads/big-block-chevy-info.710/#post-60299

http://garage.grumpysperformance.co...-displacement-street-engine.10961/#post-50668

Grumpy, what is this required number likely to be, on most of the cams you like to use? (Intake Closing Point (degrees)ABDC @ 0.050 lift plus 15 degrees) This is required in this calculator I am using to consider compression ratios. I think it's one you've recommended.

address to calculator here:

http://kb-silvolite.com/calc.php?action=comp

Looking at using a 4.25" crank, 6.8" 'H' rods and a piston compression height of 1.27". Gives me a rod/stroke ratio of 1.6:1. What sort of pistons should I be looking for, using Brodix "Big Brodie" heads, with a 119cc chamber and 300cc intake runners, 2.25 intakes and 1.88 exh. Want between 10:1 and 11:1 compression. Waiting for deck height confirmation, but if its a stock 10.2", then I have .005" clearance with this combo, plus .040" for the gasket! Appreciate your help and suggestions!

in an ideal world you want the cylinder walls on cylinders to be at least .180 thick at the THINNEST, point, if they are thinner than .140 Id seriously consider either buying an aftermarket block with a thicker casting or filling the block water passages up to the lower edge of the freeze plugs to add a good deal more rigidity to the cylinder walls to reduce flex and increase ring seal.

READ THESE

viewtopic.php?f=51&t=588&p=764&hilit=sonic#p764

viewtopic.php?f=51&t=976&p=1827#p1827

HERES A CHART to find the intake valve close point at .050 lift, you then add 15 degrees to use that particular calculator

viewtopic.php?f=52&t=4299

If the rest of you figures are correct youll want about a 20cc-24cc dome on the piston and a cam with about a 55 degree intake valve close point at .050 lift

but most un-milled blocks will have a .023 deck height not .005

now for best power a cam with a 104-108 LSA is about correct but you can afford to use a wider 110-112 LSA, and loose a few hp but make the combo easier to drive and tune on the street, and have a wider torque curve

viewtopic.php?f=52&t=82

viewtopic.php?f=52&t=1070

viewtopic.php?f=52&t=727

Grumpy,

So, I did some homework with the info you have offered me.

I have tentatively chosen a piston with 24cc top, and a Comp Cams 11-450-8 cam.

It has IVC @.050 of 44 deg.

Power is in the region of 600hp (using the numbers for a 454) The Comp Cams calculator would not consider the 4.31 bore, so could not refer to 496 cu. in.

I used a 'domestic dual plane' for carb. with an 850 cfm

I then ran all the effective number in the compression calc you offered:

COMPRESSION RATIO CALCULATOR

Static and Dynamic Compression Ratio

(Considers Cam Timing and Rod Ratio)

ENTER YOUR DATA CALCULATED DATA

Cylinder Head Volume (cc) 199

Cylinder Head Vol (cubic in.) 7.259

Piston Head Volume (cc) -24

Piston Head Vol (cubic in.) -1.464

Gasket Thickness (in.) .040

Swept Volume (cubic in.) 62.006

Gasket Bore (in.) 4.31

T.D.C. Volume (cubic in.) 6.715

Cylinder Bore Diameter (in.) 4.31

Gasket Volume (cubic in.) 0.584

Deck Clearance (in.) .023 Note: Neg. nubmer above deck, Pos. number below deck

Deck Volume (cubic in.) 0.336

Stroke (in.) STATIC COMPRESSION RATIO 10.234

OPTIONAL DATA

Rod Length (in.) 6.8

Adjusted Stroke (in.) 3.468

Intake Closing Point (degrees)ABDC @ 0.050 lift plus 15 degrees 59

DYNAMIC EFFECTIVE COMPRESSION RATIO 8.535

What are your thoughts on this combo?

Darn you know some serious stuff. I am loving the resource you are for me.

Id suggest a thinner head gasket to get the quench distance a bit closer and retarding this cam

http://www.summitracing.com/parts/CCA-11-460-8/

4 degrees as a better match to your application

Last edited by a moderator: