Grumpy, I just bought a nearly flawless (interior & exterior) 1986 C4 coupe. When I drove it home from the dealership, I noticed a slightly rough idle but still good performance out of the engine. First thing my son and I did was replace the plugs, wires, distributor, and rotor... started her up and she purred like a kitten until it kicked down into low idle ~600rpm. The engine then lost rpm until it finally died.

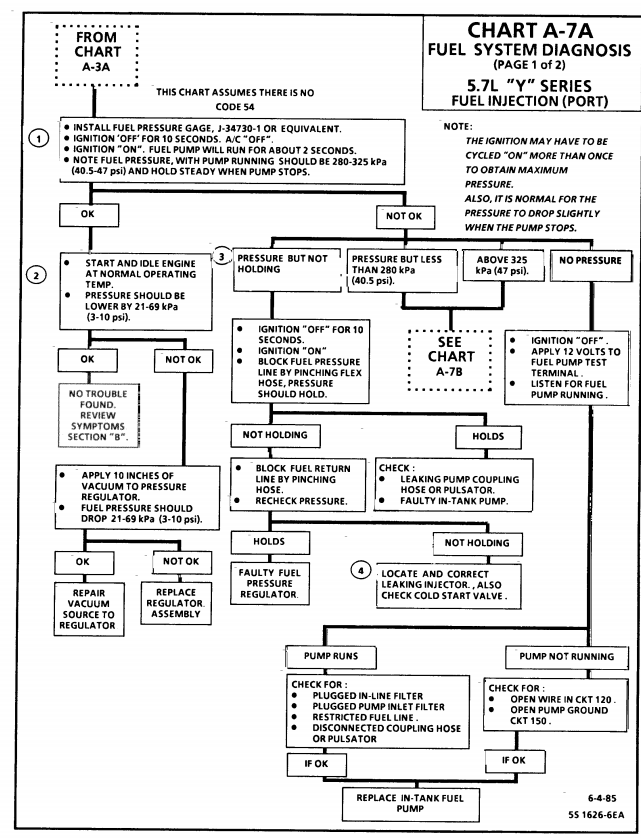

I'm thinking the problem might be in the throttle body somewhere... I'm also going to check the full pressure as well in order to rule out a fuel problem. I'm just trying to zero in on a possible culprit as quickly as possible since I really want to drive it this weekend. Also, the "Service Engine Soon" light has come on a couple of times while driving today BUT I got no codes out of the computer when I jumpered the terminals this evening! It just keeps blinking "12" continuously...

Car only has 66k miles on it, by the way.

Thanks!

Derek

I'm thinking the problem might be in the throttle body somewhere... I'm also going to check the full pressure as well in order to rule out a fuel problem. I'm just trying to zero in on a possible culprit as quickly as possible since I really want to drive it this weekend. Also, the "Service Engine Soon" light has come on a couple of times while driving today BUT I got no codes out of the computer when I jumpered the terminals this evening! It just keeps blinking "12" continuously...

Car only has 66k miles on it, by the way.

Thanks!

Derek