I bought and use this press and so far ITS never had the slightest difficulty doing any of the jobs you listed and several more like U-joints

this is cheap and slow

http://www.harborfreight.com/cpi/ctaf/displayitem.taf?Itemnumber=38335

below a better tool

http://www.harborfreight.com/cpi/ctaf/displayitem.taf?Itemnumber=33497

the money saved on a single u-joint swap on a corvette will pay for the press

the local machine shop wanted $20 EACH just to press out and re-install the U-joints, with ME suppling the u-joints or $40 each if they supplied the u-joints, keep in mind thiers 6 u-joints in a corvette, two on the drive shaft and two on EACH half shaft, and if ones bad thru normal wear and mileage then the others have significant mileage on them and should be replaced at the same time

the press cost was $129 when I purchased mine several years ago, its far more than paid for itself since then, and its far easiet to use than the screw thread hand held c-clamp type

http://neapco.mycarparts.net/ (American made u-joints)

heres helpfu info , read thru the links below

http://personal.tmlp.com/scorp/vette/images/ujoints/index.html

http://www.corvettemagazine.com/2005/december/u-joint/u-joint.asp

http://www.digitalcorvettes.com/forums/showthread.php?t=76752

http://www.corvettemagazine.com/2005/november/arms/arms.asp

http://www.micro-controls.com/article-ujoints.html

http://www.micro-controls.com/cartools-ujoint.html

http://www.dennysdriveshaft.com/html/faq.html

http://personal.tmlp.com/scorp/vette/images/ujoints/index.html

first Ill point out that the U-joints made in china are JUNK, so get the AMERICAN MADE u-joints WITHOUT the grease nipples as that design is stronger

next , many machine shops charge $15-20 to remove and instal EACH u-joint with a press, thats 4 u-joints on the half shafts and two on the drive shaft (TOTAL 6) so it can EASILLY run you $90-120 in just labor IF YOU PULL THE SHAFTS and REINSTALL THEM (99% of the LABOR) and have a shop remove/reinstall the u-joints themselfs, thats INSANE if you are doing it on a regular basis, when you can buy a decent press for about the same cost as a single series of replacements

[http://www.harborfreight.com/cpi/ctaf/displayitem.taf?Itemnumber=38335

http://www.harborfreight.com/cpi/ctaf/displayitem.taf?Itemnumber=33497

this is a differant year but most of the info applies

http://www.corvettemagazine.com/2005...nt/u-joint.asp

http://www.micro-controls.com/article-ujoints.html

http://www.corvetteamerica.com/cf/di...ategoryid=X935

basically youll need a shop manual or similar instructions like the HAYNES manual,

you jack up the rear, place the frame on sturdy jack stands, remove the tires and youll need a long 1/4" extension with a universal and a 10 mm socket to reach the straps retaining the u-joints on the inner ends and a shorter extension and box end wrench for the outer ends and the use of the floor jack to reduce the pressure on the rear suspension as you work on each side

BTW once you get familiar with the process you can replace ALL six u-joints in UNDER 4 hours, only need to do the 1/2 shafts, great youll complete that in under 2 hours with practice (WITHOUT AIR TOOLS) (under an hour WITH THEM)

any time your required to weld, or paint or use gasket cement or gasket sealers , on your car, parts prep is critical to doing the job correctly,

you'll need to carefully clean and de-grease carefully re-clean and dry the surfaces.

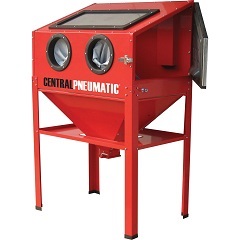

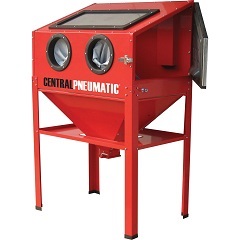

this can require several steps before a parts clean enough to be used.for smaller parts this is a sand blast cabinet I have in my shop, for small things like alternator brackets and crank pulleys it does a good job

http://www.harborfreight.com/abrasive-blast-cabinet-62144.html

http://www.harborfreight.com/5-hp-60-gallon-165-psi-two-stage-air-compressor-93274.html

this is slow but if your patient it does a reasonable job on many larger parts like differentials that won,t fit in the blast cabinet

http://www.harborfreight.com/21-oz-hopper-gravity-feed-spot-blaster-gun-95793.html

HAVING A SOLVENT WASH SINK SURE HELPS

http://www.gregsmithequipment.com/40-Gallon-Parts-Washer

RELATED INFO

http://garage.grumpysperformance.com/index.php?threads/compressor-info.24/

http://garage.grumpysperformance.com/index.php?threads/parts-prep-cleaning.6255/#post-41064

this is cheap and slow

http://www.harborfreight.com/cpi/ctaf/displayitem.taf?Itemnumber=38335

below a better tool

http://www.harborfreight.com/cpi/ctaf/displayitem.taf?Itemnumber=33497

the money saved on a single u-joint swap on a corvette will pay for the press

the local machine shop wanted $20 EACH just to press out and re-install the U-joints, with ME suppling the u-joints or $40 each if they supplied the u-joints, keep in mind thiers 6 u-joints in a corvette, two on the drive shaft and two on EACH half shaft, and if ones bad thru normal wear and mileage then the others have significant mileage on them and should be replaced at the same time

the press cost was $129 when I purchased mine several years ago, its far more than paid for itself since then, and its far easiet to use than the screw thread hand held c-clamp type

http://neapco.mycarparts.net/ (American made u-joints)

heres helpfu info , read thru the links below

http://personal.tmlp.com/scorp/vette/images/ujoints/index.html

http://www.corvettemagazine.com/2005/december/u-joint/u-joint.asp

http://www.digitalcorvettes.com/forums/showthread.php?t=76752

http://www.corvettemagazine.com/2005/november/arms/arms.asp

http://www.micro-controls.com/article-ujoints.html

http://www.micro-controls.com/cartools-ujoint.html

http://www.dennysdriveshaft.com/html/faq.html

http://personal.tmlp.com/scorp/vette/images/ujoints/index.html

first Ill point out that the U-joints made in china are JUNK, so get the AMERICAN MADE u-joints WITHOUT the grease nipples as that design is stronger

next , many machine shops charge $15-20 to remove and instal EACH u-joint with a press, thats 4 u-joints on the half shafts and two on the drive shaft (TOTAL 6) so it can EASILLY run you $90-120 in just labor IF YOU PULL THE SHAFTS and REINSTALL THEM (99% of the LABOR) and have a shop remove/reinstall the u-joints themselfs, thats INSANE if you are doing it on a regular basis, when you can buy a decent press for about the same cost as a single series of replacements

[http://www.harborfreight.com/cpi/ctaf/displayitem.taf?Itemnumber=38335

http://www.harborfreight.com/cpi/ctaf/displayitem.taf?Itemnumber=33497

this is a differant year but most of the info applies

http://www.corvettemagazine.com/2005...nt/u-joint.asp

http://www.micro-controls.com/article-ujoints.html

http://www.corvetteamerica.com/cf/di...ategoryid=X935

basically youll need a shop manual or similar instructions like the HAYNES manual,

you jack up the rear, place the frame on sturdy jack stands, remove the tires and youll need a long 1/4" extension with a universal and a 10 mm socket to reach the straps retaining the u-joints on the inner ends and a shorter extension and box end wrench for the outer ends and the use of the floor jack to reduce the pressure on the rear suspension as you work on each side

BTW once you get familiar with the process you can replace ALL six u-joints in UNDER 4 hours, only need to do the 1/2 shafts, great youll complete that in under 2 hours with practice (WITHOUT AIR TOOLS) (under an hour WITH THEM)

any time your required to weld, or paint or use gasket cement or gasket sealers , on your car, parts prep is critical to doing the job correctly,

you'll need to carefully clean and de-grease carefully re-clean and dry the surfaces.

this can require several steps before a parts clean enough to be used.for smaller parts this is a sand blast cabinet I have in my shop, for small things like alternator brackets and crank pulleys it does a good job

http://www.harborfreight.com/abrasive-blast-cabinet-62144.html

http://www.harborfreight.com/5-hp-60-gallon-165-psi-two-stage-air-compressor-93274.html

this is slow but if your patient it does a reasonable job on many larger parts like differentials that won,t fit in the blast cabinet

http://www.harborfreight.com/21-oz-hopper-gravity-feed-spot-blaster-gun-95793.html

HAVING A SOLVENT WASH SINK SURE HELPS

http://www.gregsmithequipment.com/40-Gallon-Parts-Washer

RELATED INFO

http://garage.grumpysperformance.com/index.php?threads/compressor-info.24/

http://garage.grumpysperformance.com/index.php?threads/parts-prep-cleaning.6255/#post-41064

Last edited by a moderator: