MikeB

Member

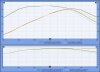

My 327 has a CompCams XS262S cam with advertised duration specified at .015" tappet rise. With .016" lash and 1.5 rockers, the valve starts moving at .011" tappet rise. So, the 262 degree intake spec is equal to a zero lash 262 cam being spec'd at .004" tappet rise right? Of course, Comp specifies their hydraulic cams at .006". Go figure.

Now the .050" duration spec gets strange because it's really more like a .039" spec. But I won't even go there, because thinking about it makes my head hurt! Needless to say, my 224 @ .050" solid cam probably acts more like a 220 or even 218 hydraulic cam, although I realize the lobe shape may be more aggressive. Is there a way to determine what a comparable hydraulic duration would be?

I just got a Lunati hydraulic cam with 268 advertised duration (at unknown tappet rise) and 218 @ .050â€. Just trying to get a feel for how it compares to my current cam. I think it may still be on the big side of what I’m looking for to work with the 3.08 axle I’m building.

Now the .050" duration spec gets strange because it's really more like a .039" spec. But I won't even go there, because thinking about it makes my head hurt! Needless to say, my 224 @ .050" solid cam probably acts more like a 220 or even 218 hydraulic cam, although I realize the lobe shape may be more aggressive. Is there a way to determine what a comparable hydraulic duration would be?

I just got a Lunati hydraulic cam with 268 advertised duration (at unknown tappet rise) and 218 @ .050â€. Just trying to get a feel for how it compares to my current cam. I think it may still be on the big side of what I’m looking for to work with the 3.08 axle I’m building.