With the manual transmission, the low vacuum of this engine, and the emphasis on street driving, would I be better off with a mechanical secondary carb? I also have an issue with this engine dieseling on shutdown, which I have researched as best that I can, to getting two much fuel past the carb on shutdown. I cannot increase the timing to reduce the idle setting without risking detonation. Would a smaller carb with mechanical secondaries be a better choice? I agree with your idea of getting a good Holley tuner, but we do not have one within 3 hours drive of this chunk of the middle of nowhere. Thank you for your expertise. I have spent a LOT of time reading on your site and it has helped solve many problems.

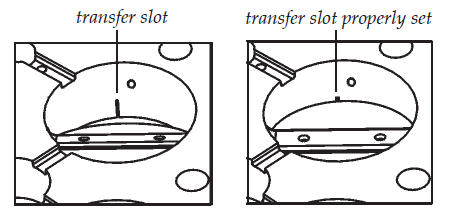

in many or most cases engine dieseling after the ignition is turned off is caused by a combination of a bit too rich of a fuel/air mix being drawn in and a bit too much heat in the combustion chambers this is common when a holley carbs ESPECIALLY IF transfer slot is badly adjusted to expose too much slot at idle or carbs OR with the float level set too high, or a fuel pressure regulator pressure set too high or a blocked return line on the fuel pressure regulator, or at times indicates a vacuum leak

Tuning Tips for Holley Carburetors

Q: Holley 2300/4150 Tuning Tips

A: Float Level ? The fuel level in the bowls should be set at the bottom of the sight hole so that you have to jostle the car to get the fuel to come out the sight hole when running. We set the floats in the shop to a particular setting; but fuel pressure dictates fuel level. Therefore you must set this when you first install the carburetor. Finally, after setting the floats, always give the carburetor time to burn off enough fuel to reopen the needle/seat so that your new setting is really what you are seeing. Many times people lower the floats too much because they haven?t waited a sufficient amount of time for the fuel to burn off and the new setting to take.

Throttle Blade Adjustment ? The throttle blades should be set at an rpm that is as low as possible to keep the transfer slots covered at closed throttle position. Keep the primary and secondary throttle blades adjusted equally. If you should lose your setting just back it completely off, put 1 round in the primary and 1 round in the secondary and start there.

both front and rear float levels on holley carbs with site plugs should be adjusted to the level that just allows the lower edge of the site plug threads to get damp with fuel at idle

Idle Mixture Screws ? Always adjust the 4 idle mixture screws evenly. The settings on all 4 should be the same. Our original setting is 1 1/2 turns out. If for some reason your engine absolutely needs a different setting on one side or corner you can just about bet something is wrong with the engine causing it to have a different signal/vacuum on that side/corner.

Fuel Pressure ? 6.0 to 6.5 pounds. You should absolutely know what your fuel pressure is! Many racers have no clue what their fuel pressure is, and they chase engine problems for weeks when a simple fuel pressure gauge would have indicated the problem straight away.

btw if your not already registered on my home web site it would be to your advantage to do so