93chevyz71 said:Grumpy, Im building a 350 sbc engine using vortec heads and using the stock pan and was wondering if I should just buy a stock oil pump or buy a high volume one?

http://www.melling.com/Aftermarket/Tech-Tip-Videos

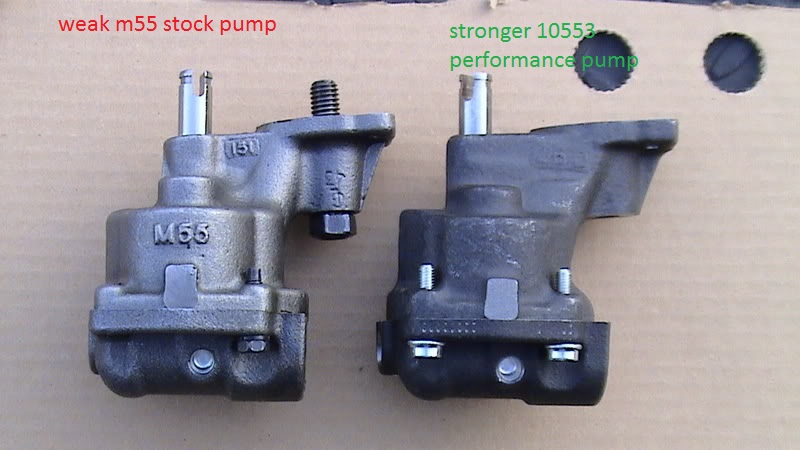

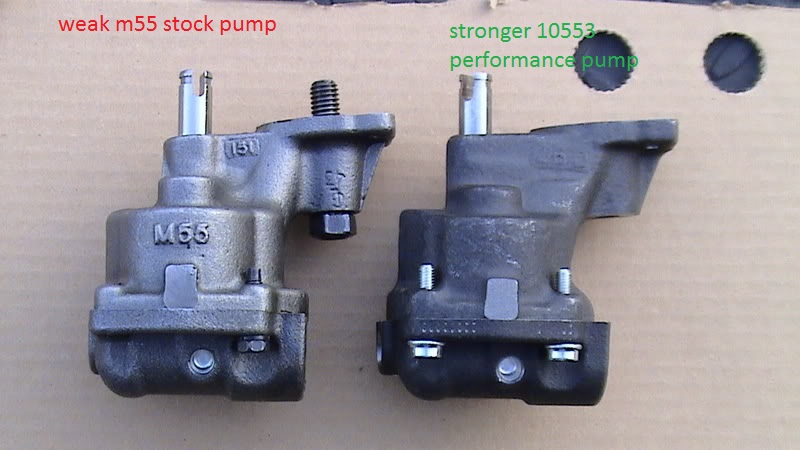

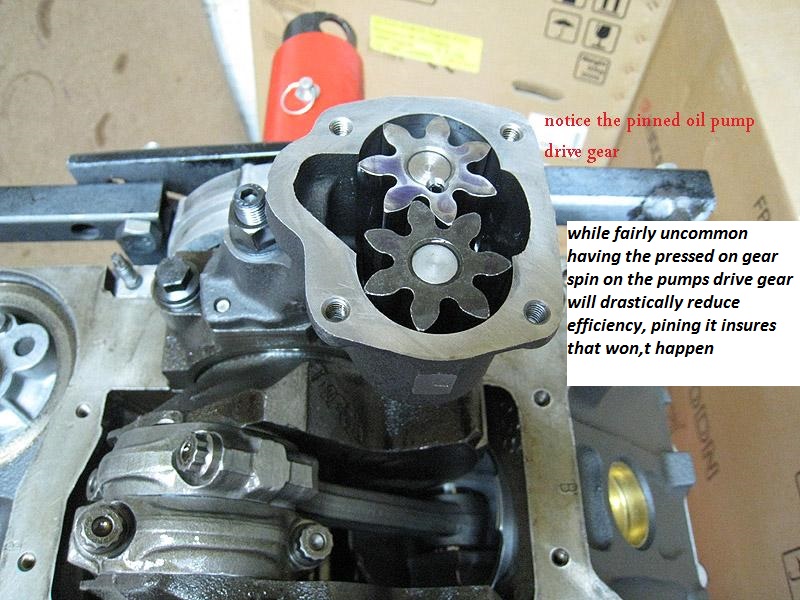

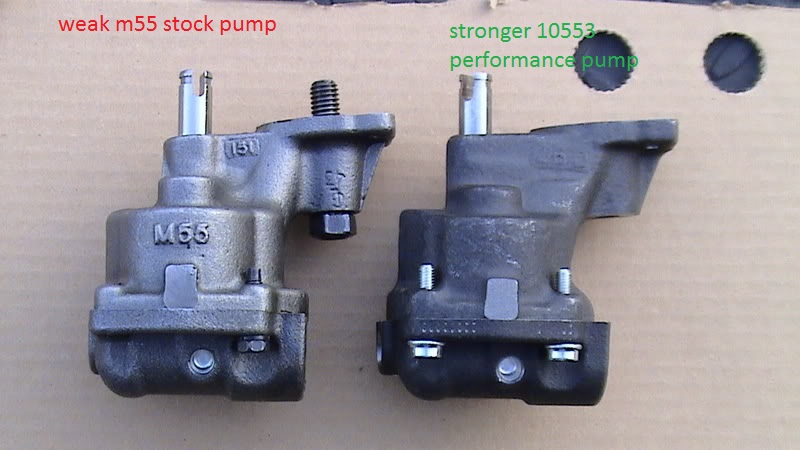

about 1993 or so melling changed the standard chevy SB oil pump casting to a MUCH WEAKER CASTING on the standard M55 pumps , THIS MANDATED the use of the stronger and thicker casting 10553 pump in performance applications

http://www.milodon.com/oil-system/oil-pumps.asp

http://www.melling.com/Aftermarket/High-Performance/Cast-Iron-Aluminum-Oil-Pumps

bracing the oil pump with a milodon vibration brace can increase durability

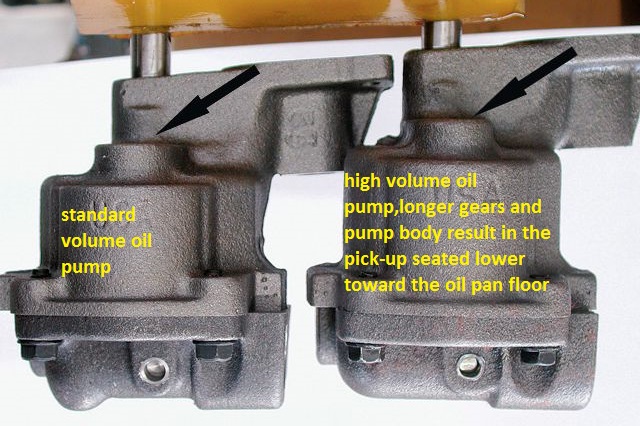

short answer, use this oil pump(link below) in most stock SBC builds, as it produces a 10% increase in oil volume and standard pressure which is just fine , but obviously check your bearing clearances and oil pump to oil pan floor clearances and braze the CORRECT MATCHING pick-up to the pump, and I,d also suggest if you have the room, for clearance that you look into one of the less expensive 7 quart baffled oil pans as they provide a good deal more potential protection and durability to your bearings longevity. be very sure you verify the oil pump pick-up to oil pan floor clearance, and braze the pick-up to the pump body.

yes theres less expensive oil pumps that will work, but thats a good value, in a well made pump.

first choice

http://www.summitracing.com/parts/mel-10552/overview/ SBC

or

http://www.jegs.com/i/Melling/689/10778C/10002/-1 BBC

second choice

http://www.summitracing.com/parts/mil-18750/overview/ SBC

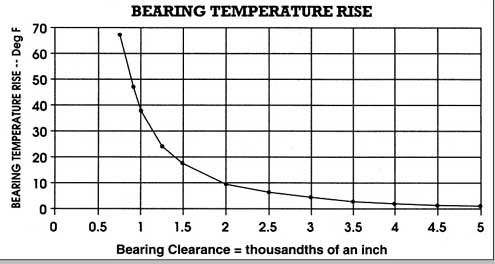

Id point out up front that oil pressure on the gauge is the result of the resistance the engines clearances cause to oil flow rates,and the viscosity and temperature of the oil.

if your having any problem, maintaining oil pressure you can either increase the flow rate , of viscosity of the oil used or decrease the engines clearances, increasing the oil flow or viscosity is treating a symptom, decreasing the clearances is treating the problem,both approaches will work if done correctly withing reasonable limits and both approaches have points in their favor, and potential problems, IF THE CORRECT PARTS ARE USED, but controlling the oil flow is key to success. a standard z28 sbc oil pump will provide enough oil for most applications

ITS always a good idea to verify the oil pan floor to oil pump pick-up clearance and to braze the pick-up to the oil pump, to reduce the potential for it to come loose.

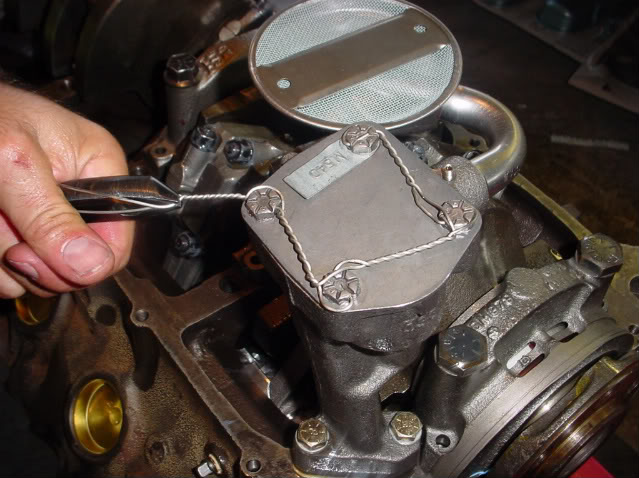

yes you can MIG ,TIG or TORCH WELD the pick-up but I found BRAZING works the best and is less likely to warp or crack the pump or pick-up

"how in hell do those twisty, safety wire pliers work?"

well a video should be helpful here! Id also point out that you can buy the wire in several diameters and the thicker sizes are far more difficult to use, home depot sells the 22 gauge and 18 gauge, the 22-24 gauge is what youll use far more commonly, as its much easier to use,both stainless (PREFERED) and galvanized are used, and will work on 95% of the applications on a car your likely to use.

while helical cut gears will run smoother ,

( ESPECIALLY WITH THE STOCK 7 tooth SBC oil pump)

as you potentially have 2 or three gear teeth in various stages of gear tooth contact

(depends on the angle of tooth engagement)

and yes the design will reduce a tendency to produce a pressure pulse, I have not seen this as a major issue.

simply swapping to the standard volume and pressure BIG BLOCK 12 tooth oil pump in a SBC engine all but eliminates the pulse and pressure and volume issues a sbc oil pump has.

as a general rule as your engine oil viscosity is reduced the effort required to pump the oil thru clearances is lower and the pressure reading on the gauge drops, thats not necessarily an indication of lower bearing protection, as thats generally a function of oil quality and its formula, and basic components used, in its design, and generally its increased flow rate increases bearing cooling, a good quality 10w30 should ideally provide 20-22 psi at 800rpm idle (anything over 15-17 psi at 800rpm is fine) and 60-65psi by 5000rpm which is all you can use

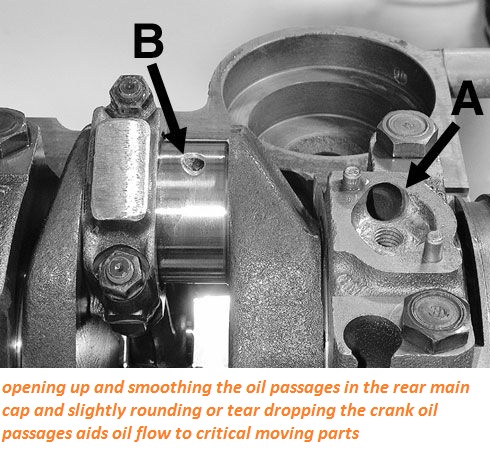

Id also point out that, if you properly set up a performance engine with the proper after market oil control components,the stock engine's oil system, can be vastly improved upon, youll want too, open the oil drain holes and use the proper oil pan, windage screen and crank scraper, its virtually impossible , in a well designed engine to run the engine "long enough to pump all the oil upstairs."

as with a properly designed baffled oil pan, with a carefully fitted and clearanced windage screen and crank scraper, the oil pump simply reaches a flow rate pumping oil out of about 100 or so potential lubricant flow leakage points

http://garage.grumpysperformance.com/index.php?threads/whats-a-windage-tray-do.64/

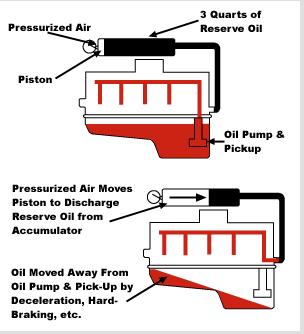

theres zero doubt an accusump oil feed is a good insurance policy to maintain oil pressure at the bearings, but simply having a 7-8 quart baffled oil pan,properly clearanced, windage screen and crank scraper will insure the oil pressure remains consistent , mostly due to the fact that theres always going to be enough oil over the oil pump pick-up, simply because theres really no room to pack most of the available oil volume in the upper engine ,plus the fact that hot oil flows well.

OIL PRESSURE read on the oil pressure gauge is a MEASURE of RESISTANCE to oil flow, you can REDUCE the pressure the gauge reads by either increasing the engine clearances or REDUCING the oil viscosity (thickness) so it flows thru the clearances faster with less resistance.(OR INSTALLING A SLIGHTLY WEAKER OIL PUMP BYE_PASS SPRING,that limits the pump pressure before it allows some oil to re-circulate back through the bye-pass valve ,from the high pressure back to the low pressure side of the pump impellers, but only the max pressure you reach is limited by the bye-pass spring,in your oil pressure bye pass circuit and its that spring resistance determines the point where the bye-pass circuit, opens and limits max oil pressure, but the bye-pass circuit has zero to do with anything else, if its functioning correctly,

there are many oil leakage points(100) in a standard Chevy engine.

16 lifter to push rod points

16 push rod to rocker arm points

32 lifter bores 16 x 2 ends

10 main bearing edges

9 cam bearing edges

16 rod bearing edges

2 distributor shaft leaks

1 distributor shaft to shim above the cam gear(some engines that have an oil pressure feed distributor shaft bearing.)

once oil exits the bearings or valve train it flows mostly by gravity back to the oil pan sump, but a properly designed windage screen and crank scraper correctly clearanced allows the spinning crank/rotating assembly to act like a directional pump that drags the vast majority of the oil flow back to the sump, by design.

http://garage.grumpysperformance.com/index.php?threads/whats-a-windage-tray-do.64/

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/

http://garage.grumpysperformance.com/index.php?threads/basic-info-on-your-v8-lube-system.52/

adding "ST" to the end of the existing melling SBC OIL PUMP part number denotes the helical gear set option

using anti-seize paste on bolt or stud threads helps prevent future problems

using safety wire pliers

but in a 400 block it will need a narrowed waist area to bypass the 400 sbc larger diam. main bearing so the

ARP part # 134-7901 is used, there should be .050 minimum vertical slack/clearance once the oil pump drive shaft and distributor are assembled, obviously best verified with the engine on the engine stand and the oil pan removed with the intake and distributor temporarily assembled. a high capacity baffle oil pan equipped with a windage screen is highly advised, and verifying that the oil pump pick-up is correctly clearanced and brazed into place is mandatory

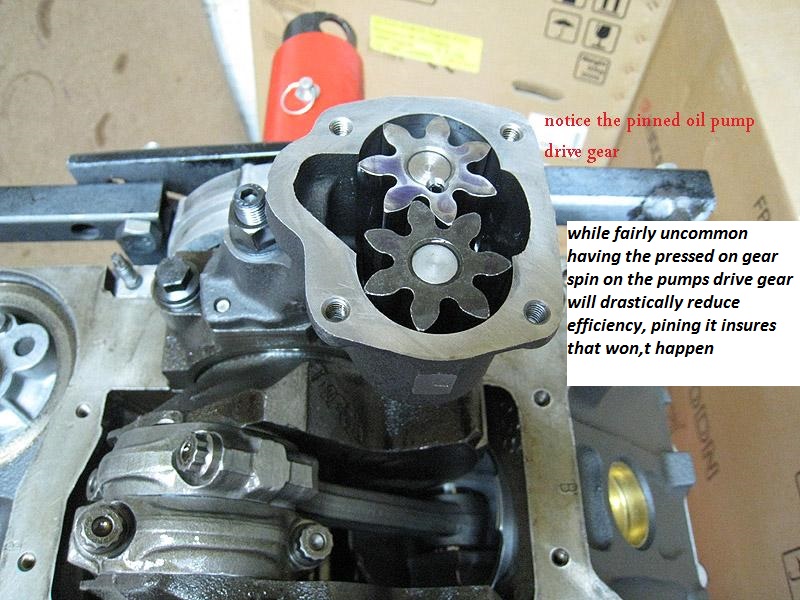

notice the welded tabs bracing the oil pump pick-up and that big block pumps have 5 cover screws unlike the small block pump with its 4 screw cover

read these links

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/

http://garage.grumpysperformance.co...l-pumps-pressure-bye-pass-circuit-works.3536/

http://garage.grumpysperformance.com/index.php?threads/installing-an-oil-pump-pick-up-tube.1800/

http://garage.grumpysperformance.com/index.php?threads/basic-info-on-your-v8-lube-system.52/

http://www.jegs.com/i/ARP/070/134-7901/10002/-1

the milodon 18770 pump is used

http://www.jegs.com/i/Milodon/697/18770/10002/-1

the 3/4" oil pan pick up that fits your oil pan is used

http://www.milodon.com/oil-pans/circle- ... -chevy.asp

Chevrolet Performance 14091563

Left (Driver Side) Dipstick Plug

Chevrolet Performance 9421743

Right (Passenger Side) Dipstick Plug

example

#31504 oil pan

LATE MODEL & SPRINT -

COMPETITION SERIES, 7" DEEP

Designed for Dirt or Asphalt racing in Late Models, Modifieds, Sprint Cars that don't use a stock cross member location. The highly effective tray door system and the quick release windage tray assembly that is fastened into the pan provide 100% oil control at all times. This results in consistent oil pressure both in and out of the corners, as well as increases power output. Accepts stock large diameter flywheels. A sealed, dirt proof, screw in style dipstick and temperature sender bung are also welded into the pan.

Pan will fit a 4" stroke crank and Carillo or Eagle style rod.

Pan Capacity is 7 Quarts Plus Filter -

12" Sump Length, 7" Sump Depth

Left Hand, without dipstick 31504

Left Hand, with dipstick 31525

Oil Pump and Pick-Up Required:

Pickup with Milodon 18770 or Melling M99HV 18305

Pickup with Milodon 18750 or Melling M55HV / 10550 18306

Oil Pump 18750

Pump Drive Shaft 23050

Oil Pan Gasket 40100

Oil Pan Gasket, 1 piece, 41000

Rear Pan Baffle 32500

Oil Pan Bolts, vibration resistant 85000

related info, you'll want to read thru

viewtopic.php?f=54&t=1800

viewtopic.php?f=54&t=2187

viewtopic.php?f=54&t=2080

viewtopic.php?f=60&t=1948&p=5176&hilit=braze#p5176

keep in mind the sbc oil pump has 7 tooth gears and the big block pumps have 12 teeth making the oil flow smoother and less pulsed, plus having larger gears they tend to supply more oil at lower rpms

look closely and youll see the big block oil pump has a 5 bolt lower cover and the oil pump pick-up with its 3/4" feed seats into the main pump casting while the small block oil pump has a 4 bolt cover and the sbc oil pump pick-up with its 5/8" feed seats into the pumps cover plate

look at the picture below, the restrictive stock O.E.M. pickup if placed to close to the oil pan floor becomes a HUGE restriction to oil flow rates

as many of you gentlemen know MELLING CHANGED the casting on their standard M55 high volume oil pumps making them weaker and thinner

http://www.hotrod.com/articles/ccrp-0911-small-block-chevy-oil-pumps/

like the thin casting on the left

but I understand that it caused a good deal of bad press and they are currently changing back to the thicker castings, but theres still thousands of the thin casting pumps in inventory that should not be use in high performance applications

did you replace the oil pump drive shaft?

theres three common lengths in those oil pump drive shafts

theres a difference in length between the drive shaft used for a common sbc oil pump,

the drive shaft used for a BIG BLOCK oil pump in a SMALL BLOCK APPLICATION,

and a BIG BLOCK oil pump drive shaft length

all can be placed in a small block,or a big block but only the correct length will function in each application

theres a difference between the sbc and bbc drive shaft designs so don,t mix them up

theres MARK IV and MARK V BBC oil pump drive shafts that differ also

theres both BBC and SBC oil pump drives and a less common oil pump drive shaft designed for using a BBC oil pumps in a SBC application thats length is between those lengths

oil pump drive shafts can be custom machined, to gain clearance, you should have about .050 clearance with the distributor seated

The oil pump drive shaft on the left fits any

Gen. I smallblock except the 400. The 400

shaft on the right is necked down in the center

portion to clear the wider main caps found on

the 400.

the aftermarket drive shafts are held to a much higher strength tolerance, and a steel collar and and the reduced mid section are both good features, for the very low price Id strongly suggest pitching the stock drive shaft in the dumpster

be sure you select the correct oil pump drive shaft

SB - is a bit shorter about 5.75"

BB - is a bit longer about - 6.50" or so

there should be about .050 vertical movement, of the oil pump, oil pump drive shaft between the oil pump and lower distributor gear with the manifold and distributor seated correctly

Small Block Chevy Oil & Lubrication Systems

The Chevy smallblock lubrication system is very reliable and presents no design defects to worry

about. Just keep everything clean. Change the oil and filter on a regular basis, and it will provide good

service for more than one hundred thousand miles. If the recommended main and rod bearing and

rod side clearances are maintained, a stock volume oil pump is all that is required. A high-volume or

high-pressure pump or an oil pump from a bigblock Chevy are not needed in most street applications.

These other pumps take additional horsepower to run and add more strain on the cam/distributor

drive gears and drive shaft. Checking the operating clearances on the stock oil pump and optimizing

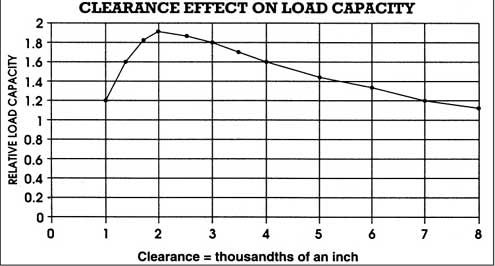

them if necessary, will ensure adequate oil pressure. The clearance between the pump gears and the

pump gear cover should be .002" to .0025". If there is more clearance, take a sheet of 400-grit

sandpaper and some oil, then move the main pump body in a figure-8 motion over the wet sandpaper

to remove material until the clearance is correct. If there is less than the minimum clearance, you can

sand the pump gears. Remember to Loctite the pump cover bolts when you put the pump back

http://www.summitracing.com/search?keyword=5556F&dds=1

(chevy small block oil pump bye-pass springs)

http://www.summitracing.com/parts/mel-77060

(chevy big block oil pump bye-pass springs)

GM Small Block Performance Pumps

10550

High volume performance upgrade for M-55HV.

25% increase in volume over stock oil pump.

The 10550 housing and cover are CNC machined and phosphate coated.

The lower pressure spring is included to reduce pressure if desired.

Includes intermediate shaft with steel guide. Uses 5/8” press in screen.

10551

High volume performance upgrade for M155HV.

25% increase in volume over stock oil pump.

The 10551 housing and cover are CNC machined and phosphate coated.

The lower pressure spring is included to reduce pressure if desired.

Includes intermediate shaft with steel guide. Uses 3/4” press in screen.

10552

High volume performance oil pump.

10% increase in volume over stock oil pump.

The 10552 is manufactured with the drive and idler shafts extended to allow for additional support in the cover eliminating dynamic shaft deflection at increased RPM levels.

The cover is doweled to the pump housing to assure alignment of the shaft bores.

Screw in plug retains relief valve spring instead of pin.

Relief hole in cover uses screw in plug instead of pressed cup plug.

All bolts are self locking socket heads, with the wrench supplied.

The housing and cover are CNC machined and phosphate coated.

Includes intermediate shaft with steel guide. Uses both 3/4” bolt on or press in screen.

The lower pressure spring is included to reduce pressure if desired.

Patent No. 5,810,571.

10552C (Anti-Cavitation)

10552CHigh volume performance oil pump.

10% increase in volume over stock oil pump.

Same as the 10552 with the addition of grooves machined in the body and cover. The grooves reduce cavitation effects in high RPM applications.

Includes intermediate shaft with steel guide.

Uses both 3/4” bolt on or press in screen.

Using this oil pump will reduce pressure at idle.

The 10552C uses the high pressure spring only.

Racing Applications Only.

Patent No. 5,810,571.

10553

10553High pressure performance upgrade for M-55 & M-55A.

Standard volume oil pump.

The 10553 housing and cover are CNC machined and phosphate coated.

Manufactured with pink spring installed for higher pressure (M-55A).

To change pump to lower pressure (M-55) install the supplied yellow spring.

Includes intermediate shaft with steel guide.

The 10553 uses a 5/8” press in screen.

10554

Performance upgrade for M155. Standard volume oil pump.

The 10554 housing and cover are CNC machined and manganese phosphate coated.

Manufactured with pink spring installed for higher pressure.

To change pump to lower pressure install the supplied yellow spring.

Includes intermediate shaft with steel guide.

The 10554 uses a 3/4” press in screen.

10555

High Volume performance upgrade for the 10550 oil pump.

25% increase in volume over stock oil pump.

The 10555 is manufactured with the drive and idler shafts extended to allow for additional support in the cover eliminating dynamic shaft deflection at increased RPM levels.

The cover is doweled to the pump housing to assure alignment of the shaft bores.

Screw in plug retains relief valve spring instead of pin.

Relief hole in cover uses screw in plug instead of pressed cup plug.

All bolts are self locking socket heads, with the wrench supplied.

The housing and cover are CNC machined and manganese phosphate coated.

Includes intermediate shaft with steel guide.

Uses both 3/4” bolt on or press in screen.

The lower pressure spring is included to reduce pressure if desired.

Patent No. 5,810,571

10555C (Anti-Cavitation)

High volume performance upgrade for the 10550 oil pump.

25% increase in volume over stock oil pump.

Same as the 10555 with the addition of grooves machined in the body and cover. The grooves reduce cavitation effects in high RPM applications.

Includes intermediate shaft with steel guide.

Uses both 3/4” bolt on or press in screen.

Using this oil pump will reduce pressure at idle.

The 10555C uses the high pressure spring only.

Racing Applications Only.

Patent No. 5,810,571

10990

High volume performance upgrade for the M-99HV-S. ($144 price is outrageous in my opinion)

Increase in volume of 25% over stock oil pump.

The 10990 is a Big Block style oil pump made to fit the Small Block applications.

The drive and idler shafts have been extended to allow for additional support in the cover. Additional support eliminates dynamic shaft deflection at increased RPM levels.

The cover is doweled to the pump housing to assure alignment of the shaft bores.

The relief valve has a screw-in plug instead of a pin.

The housing and cover are CNC machined and phosphate coated.

An additional spring, the original stock replacement is supplied which will reduce bypass pressure if needed.

Includes intermediate shaft with steel guide.

Uses 3/4” press in screen.

Patent No. 5,810,571.

10990C (Anti-Cavitation)

High volume performance upgrade for the M-99HV-S.

Increase in volume of 25% over stock oil pump.

The same as the 10990 except with the addition of grooves machined in the housing and cover. The grooves reduce cavitation effects in high RPM applications.

Using this oil pump will reduce pressure at idle.

Includes intermediate shaft with steel guide.

Uses 3/4” press in screen.

Racing applications only.

Patent No. 5,810,571.

GM B.B. Performance Pumps

10770

High volume performance upgrade for M-77HV.

25% increase in volume over stock pump.

The housing and cover are CNC machined and phosphate coated.

The lower pressure spring is included to reduce pressure if desired.

Includes intermediate shaft with steel guide.

Uses 3/4” press in screen.

10774

10774Standard volume performance upgrade for M-77.

The housing and cover are CNC machined and phosphate coated.

The lower pressure spring is included to reduce pressure if desired.

Includes intermediate shaft with steel guide.

Uses 3/4” press in screen.

10778

High volume performance upgrade for the 10770.

Increase in volume of 25% over stock oil pump.

The drive shaft has been manufactured from chrome-moly steel.

The drive and idler shafts have been extended to allow for additional support in the cover. Additional support eliminates dynamic shaft deflection at increased RPM levels.

The cover is doweled to the pump housing to assure alignment of the shaft bores.

The relief valve has a screw-in plug instead of a pin.

The housing and cover are CNC machined and phosphate coated.

An additional spring, the original stock replacement is supplied which will reduce bypass pressure if needed.

Includes intermediate shaft with steel guide.

Uses 3/4” press in screen.

Patent No. 5,810,571.

10778C (Anti-Cavitation)

High volume performance upgrade for the 10770.

Increase in volume of 25% over stock oil pump.

The same as the 10778 except with the addition of grooves machined in the housing and cover. The grooves reduce cavitation effects in high RPM applications.

Using this oil pump will reduce pressure at idle.

Includes intermediate shaft with steel guide.

Uses 3/4” press in screen.

Racing applications only.

Patent No. 5,810,571

RELATED INFO

viewtopic.php?f=54&t=2598

http://www.hotrod.com/how-to/engine/ccrp-0911-small-block-chevy-oil-pumps/

together.

READ THRU THE LINKS FOR A GREAT DEAL MORE DETAILED INFO, failure to install the pump correctly WILL CAUSE problems

READ THIS LINK

viewtopic.php?f=54&t=1800

viewtopic.php?f=53&t=852

viewtopic.php?f=53&t=2726

viewtopic.php?f=54&t=2294

viewtopic.php?f=54&t=52

viewtopic.php?f=54&t=3536

viewtopic.php?f=54&t=2187

viewtopic.php?f=54&t=6479&p=20555&hilit=pump+drive+shaft#p20555

viewtopic.php?f=54&t=4966&p=13781&hilit=pump+drive+shaft#p13781

viewtopic.php?f=54&t=4966&p=13778&hilit=melling+oil+pump#p13778

Last edited by a moderator: