being truthful with yourself during intake manifold selection is usually rather difficult for many newer guys in the hobby of hot rodding,and even for some of the older more experience guys, the problem is that most of us drive our cars 97% of the time on the street, but think about racing our cars about 50% of the time, we read all the magazine dyno tests and we go to the local track and look at what the fastest cars engines look like, and we tend to sub-consciously think , we should select the same components.

so when it comes down to selecting the correct intake manifold we frequently select an intake thats more correctly matched to the cars IMAGINED use or what we wish we could be doing vs what we really do with the car.

an intake designed to maximize power in the 5000rpm-7000rpm range on a 12.5:1 compression ,nitrous equipped 377-406 SBC race engine, that is used 90% of the time at wide open throttle, is very unlikely to maximize results on a daily driven 383 with 9:1-10:1 compression that very rarely exceeds 6000rpm , and spends 90% of its time below 4000rpm

this was brought home to me recently when one of the neighbors kids was asking me which intake to buy for his car,with its mild 350 and a stock cam, hes seen me build 383 sbc engines and use both edelbrock performer RPM AIR GAP, and a wieand keith darton intake on sbc 383 combos

he asked me which intake potentially makes the best hp.

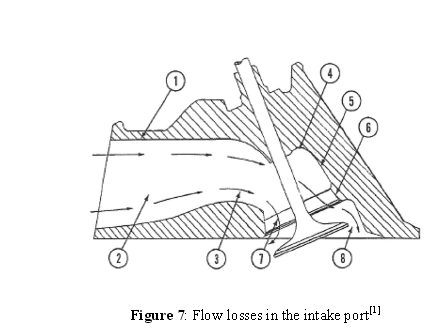

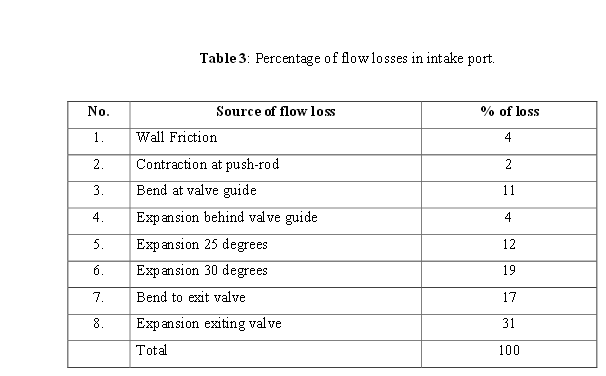

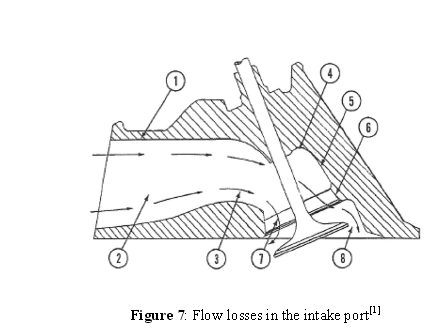

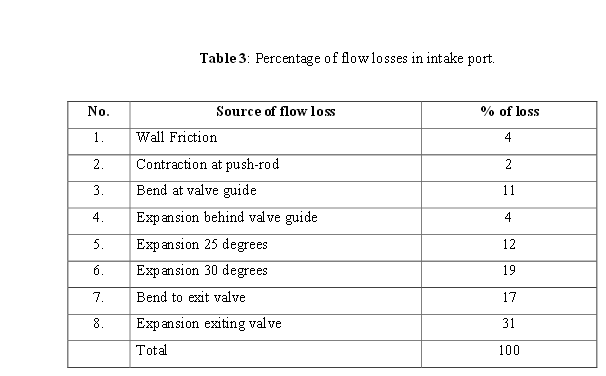

both the runner design and runner length and cross sectional area effects your potential power range, the plenum and carburetor will also effect your results so you need to calculate whats required, you maximize efficiency by selecting an intake that won,t restrict flow into the cylinders but also by keeping the port air speeds as high as you can to provide max inertial ram effect to maximize cylinder fill rates

if the runner cross sectional areas too large for the application, port air flow rates drop, volumetric efficiency is significantly reduced, and power drops..the goal is to keep air flow rates high, to maximize the inertial ram effect and maximize volumetric efficiency, without having the runner cross sectional area,so small, it will become restrictive in the upper rpm range.

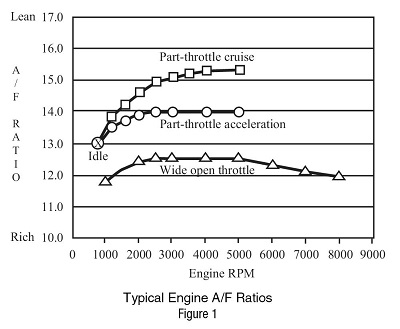

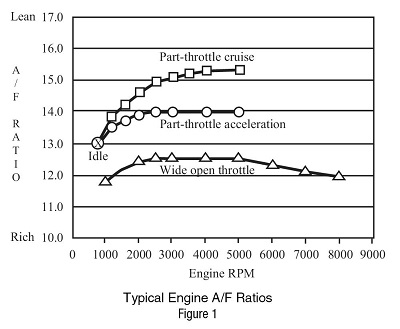

keep in mind that the fuel air ratio will need to change with the rpms and load on the engine, max mileage is generally found near 15:1 while max torque is generally reach at ratios closer to 12.5:1 on the fuel air ratio, youll generally set the engine up to run a bit lean under 3000rpm to enhance average mileage and tune it to transition to significantly richer under higher rpms and max loads, to reduce the tendency to get into detonation, and over heating under load.

you can get into the correct ball park range , for a high performance 4 barrel carburetor selection, by simply multiplying your engine displacement in cubic inches by 2.09, IE if you multiply 383 x 2.09=800 cfm

or 2.09x 454=950cfm.this may not be ideal in all applications but it will get you close if you want muscle car as a a weekend toy to race occasionally and drive on the street, and your more concerned with maximizing power than mileage

viewtopic.php?f=55&t=624&p=11495&hilit=calculate+runner#p11495

viewtopic.php?f=52&t=322&p=10973&hilit=calculate+runner#p10973

http://www.chevyhiperformance.com/techa ... 0_cfm.html

right then I could see myself back about 45 years ago.

now at his age I probably would not have taken the advise I gave him, but I tried hard to explain that hes not running an engine combo that can come close to using the flow potential of the keith darton single plane intake , and that even the RPM air gap had far more potential flow than his current cylinder heads and cam could ever use.

if he selected the single plane intake he was sure to kill off a significant amount of low and mid rpm torque, the rpm air gap was even a bit larger than ideal for a car with a stock cam and rear gear and stock heads.

i asked him if he had priced the intakes yet?

he said they generally cost in the $200-$300 range, I suggested he save some cash, and buy the wieand intake below,and some cheap headers, as the combo was much more likely to produce far more impressive gains.

when were talking about a 350-400 sbc

http://www.summitracing.com/parts/WND-8120/

this intakes great between idle and about 5800rpm, headers help. its a great choice for a street car with stock heads and a mild cam.

http://www.summitracing.com/parts/EDL-7501/

this intakes great between about 1500rpm and about 6300rpm. but really likes to have a bit better cam and head flow than stock, or your not going to get nearly its full potential benefits and of course a low restriction exhaust and headers

http://www.summitracing.com/expertadvic ... Calculator

http://www.summitracing.com/parts/HLY-300-110/

this intakes great between about 3700rpm and about 6800rpm, but its pretty much wasted with out a decent cam with at least 240 dur at .050 lift and killer heads,that flow at least 250cfm at .500 lift or with a supercharger with killer heads that flow at least 250cfm at .500 lift and a decent cam with at least 220 dur. at .050 lift and of course a low restriction exhaust and headers

if you ever have doubts, about any component in a certain application, the first reasonable step is to carefully read the advertizing and spec sheet info, AND THEN CALL the manufacturer for more detailed info if you can., you might be surprised but a lot of times asking for a transfer to the engineer department vs the sales guys is also a much better course of action when looking for confirmation on component use. info.

READ THESE LINKS

viewtopic.php?f=55&t=58&p=10819#p10819

viewtopic.php?f=55&t=1038

http://victorylibrary.com/mopar/intake-tech-c.htm#new

viewtopic.php?f=55&t=109

viewtopic.php?f=55&t=211

http://www.racingheadservice.com/rhs/in ... -chevyhtml

viewtopic.php?f=55&t=8485&p=29767#p29767

viewtopic.php?f=55&t=635

viewtopic.php?f=55&t=1790

viewtopic.php?f=55&t=1639

viewtopic.php?f=55&t=5229

so when it comes down to selecting the correct intake manifold we frequently select an intake thats more correctly matched to the cars IMAGINED use or what we wish we could be doing vs what we really do with the car.

an intake designed to maximize power in the 5000rpm-7000rpm range on a 12.5:1 compression ,nitrous equipped 377-406 SBC race engine, that is used 90% of the time at wide open throttle, is very unlikely to maximize results on a daily driven 383 with 9:1-10:1 compression that very rarely exceeds 6000rpm , and spends 90% of its time below 4000rpm

this was brought home to me recently when one of the neighbors kids was asking me which intake to buy for his car,with its mild 350 and a stock cam, hes seen me build 383 sbc engines and use both edelbrock performer RPM AIR GAP, and a wieand keith darton intake on sbc 383 combos

he asked me which intake potentially makes the best hp.

both the runner design and runner length and cross sectional area effects your potential power range, the plenum and carburetor will also effect your results so you need to calculate whats required, you maximize efficiency by selecting an intake that won,t restrict flow into the cylinders but also by keeping the port air speeds as high as you can to provide max inertial ram effect to maximize cylinder fill rates

if the runner cross sectional areas too large for the application, port air flow rates drop, volumetric efficiency is significantly reduced, and power drops..the goal is to keep air flow rates high, to maximize the inertial ram effect and maximize volumetric efficiency, without having the runner cross sectional area,so small, it will become restrictive in the upper rpm range.

keep in mind that the fuel air ratio will need to change with the rpms and load on the engine, max mileage is generally found near 15:1 while max torque is generally reach at ratios closer to 12.5:1 on the fuel air ratio, youll generally set the engine up to run a bit lean under 3000rpm to enhance average mileage and tune it to transition to significantly richer under higher rpms and max loads, to reduce the tendency to get into detonation, and over heating under load.

you can get into the correct ball park range , for a high performance 4 barrel carburetor selection, by simply multiplying your engine displacement in cubic inches by 2.09, IE if you multiply 383 x 2.09=800 cfm

or 2.09x 454=950cfm.this may not be ideal in all applications but it will get you close if you want muscle car as a a weekend toy to race occasionally and drive on the street, and your more concerned with maximizing power than mileage

viewtopic.php?f=55&t=624&p=11495&hilit=calculate+runner#p11495

viewtopic.php?f=52&t=322&p=10973&hilit=calculate+runner#p10973

http://www.chevyhiperformance.com/techa ... 0_cfm.html

right then I could see myself back about 45 years ago.

now at his age I probably would not have taken the advise I gave him, but I tried hard to explain that hes not running an engine combo that can come close to using the flow potential of the keith darton single plane intake , and that even the RPM air gap had far more potential flow than his current cylinder heads and cam could ever use.

if he selected the single plane intake he was sure to kill off a significant amount of low and mid rpm torque, the rpm air gap was even a bit larger than ideal for a car with a stock cam and rear gear and stock heads.

i asked him if he had priced the intakes yet?

he said they generally cost in the $200-$300 range, I suggested he save some cash, and buy the wieand intake below,and some cheap headers, as the combo was much more likely to produce far more impressive gains.

when were talking about a 350-400 sbc

http://www.summitracing.com/parts/WND-8120/

this intakes great between idle and about 5800rpm, headers help. its a great choice for a street car with stock heads and a mild cam.

http://www.summitracing.com/parts/EDL-7501/

this intakes great between about 1500rpm and about 6300rpm. but really likes to have a bit better cam and head flow than stock, or your not going to get nearly its full potential benefits and of course a low restriction exhaust and headers

http://www.summitracing.com/expertadvic ... Calculator

http://www.summitracing.com/parts/HLY-300-110/

this intakes great between about 3700rpm and about 6800rpm, but its pretty much wasted with out a decent cam with at least 240 dur at .050 lift and killer heads,that flow at least 250cfm at .500 lift or with a supercharger with killer heads that flow at least 250cfm at .500 lift and a decent cam with at least 220 dur. at .050 lift and of course a low restriction exhaust and headers

if you ever have doubts, about any component in a certain application, the first reasonable step is to carefully read the advertizing and spec sheet info, AND THEN CALL the manufacturer for more detailed info if you can., you might be surprised but a lot of times asking for a transfer to the engineer department vs the sales guys is also a much better course of action when looking for confirmation on component use. info.

READ THESE LINKS

viewtopic.php?f=55&t=58&p=10819#p10819

viewtopic.php?f=55&t=1038

http://victorylibrary.com/mopar/intake-tech-c.htm#new

viewtopic.php?f=55&t=109

viewtopic.php?f=55&t=211

http://www.racingheadservice.com/rhs/in ... -chevyhtml

viewtopic.php?f=55&t=8485&p=29767#p29767

viewtopic.php?f=55&t=635

viewtopic.php?f=55&t=1790

viewtopic.php?f=55&t=1639

viewtopic.php?f=55&t=5229