the real basics, (off ebays site)-------------------------------------------------------------------------------

"

This guide is intended to help you sort out the more major differences among Big Block Chevrolet engines produced since 1958. Chevrolet has designed and produced several different "big block" engine families. Within each family, there can be evolutionary changes, and special parts designed for competition use which may not be directly interchangeable with the regular production items. I don't intend to cover every possible variation. For practical purposes, all big block Chevrolet engines use a cylinder bore spacing of 4.84 inches although note the one exception below.

Early engines were designated as Mark I, (Mk I) Mk II, Mk III, and Mk IV. Later engines continued the numbering system as Generation 5 (Gen 5), Gen 6, Gen 7. There are some conflicting theories as to the reason for the change from "Mark" to "Generation". My first guess: "Gen 5" sounds much more modern, hi-tech, and trendy than "Mk V".

Mark I: The original "Big Block Chevy", also called the "W" engine perhaps because of the layout of the valves and therefore the shape of the valve covers--although another possibility is that GM chose the "W" prototype for production rather than the competing "X" or "Y" prototypes, and therefore it's a convenient coincidence that the valve layout is in the shape of a "W". It should be noted that this engine became "Mark I" only after the Mark II was being designed years after the "W" was introduced. Whatever the origin of the name, this engine family was installed in vehicles beginning in 1958, as a 348. In 1961, it went to 409 cubic inches, (as immortalized in the Beach Boys song "She's so fine, my 409") and for one year only (1963) a few well-connected racers could buy a car with a 427 cubic inch version called the Z-11. The 427 version was all about performance, and had special parts which were not directly interchangeable with the 348/409. While production of the 427 was severely limited, both the 348 and 409 were offered in passenger cars and light- and medium-duty trucks. The truck blocks were somewhat different from the passenger car blocks, having slightly different water jackets and of course, lower compression achieved by changes in the piston in addition to more machining of the top of the cylinder. A novel feature of this engine is that the top of the cylinders are not machined at a 90 degree angle to the bore centerline. The top of the cylinder block is machined at a 16 degree angle, and the cylinder head has almost no "combustion chamber" cast into it. The combustion chamber is the top wedge-shaped section of the cylinder. Ford also introduced an engine family like that in '58--the Mercury/Edsel/Lincoln "MEL" 383/410/430/462. The "W" engine ended it's automotive production life part way through the 1965 model year, when the 409 Mk I was superseded by the 396 Mk IV engine.

Mark II: This is more of a prototype than a production engine. It is the 1963-only "Mystery Engine" several of which ran the Daytona 500 race, and in fact won the 100-mile qualifier setting a new record. It is largely the result of engineering work by Dick Keinath. Produced mainly as a 427 but with a few 396 and 409 cubic inch versions, all in VERY limited numbers. Even though it was intended as a NASCAR-capable engine, it had 2-bolt main caps. This engine was never installed in a production-line vehicle by GM, it only went to racers. And even though it was available in 1963, it has very little resemblance to the 427 Mark I "W" engine of the same year. The Mark II was a "breakthrough" design using intake and exhaust valves that are tilted in two planes--a canted-valve cylinder head, nicknamed the "Semi-Hemi" or "Porcupine" because it is "almost" a hemi head, and the valve stems stick out of the head casting at seemingly random angles. The engine was the subject of an extensive article in the May, 1963 Hot Rod Magazine. Because of NASCAR politics, Chevrolet was forced to sell two 427 Mark II engines to Ford after the '63 Daytona race, (to "prove" that it was a production engine, and therefore eligible to race in NASCAR events) and so this engine is not only the grandfather of the Mark IV and later big block Chevies, it's also the grandfather of the canted-valve Ford engines: Boss 302, 351 Cleveland and variants, and the 429/460 big block Ford. The bore and stroke of the 427 MK II is not the same as the 427 MK IV.

Mark III: Never released for production. This was rumored to be the result of GM/Chevrolet's proposed buyout of the tooling and rights to the Packard V-8 engine of the mid-to-late '50's. The Packard engine was truly huge, having 5" bore centers. The former president of Packard wound up at Ford after Packard folded, perhaps because of that, Ford was also interested in this engine. Ford wanted to make a V-12 variant from it just as Packard had once envisioned. One way or another, neither GM nor Ford actually went forward with the purchase.

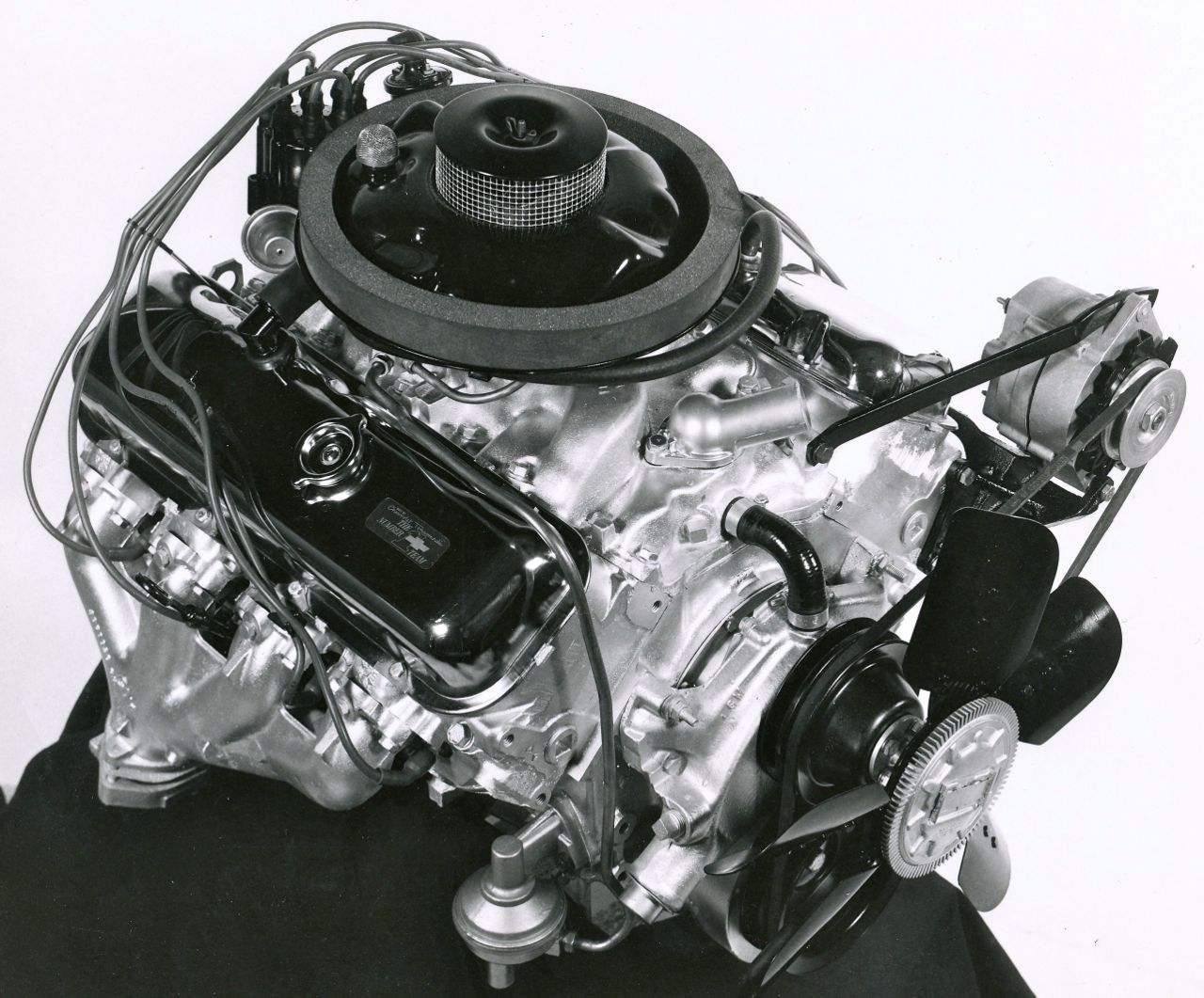

Mark IV: The engine that most people think of as the "big block Chevy". Released partway into the 1965 model year as a 396, superseding the older 409. It is a development of the Mark II and using similar but not identical canted valve (semi-hemi/porcupine) cylinder heads. It was later expanded to 402 (often still labeled as a 396, or even a 400,) a 427, a 454, and a few "special" engines were produced in the late '60's for offshore boat racing as a 482. There was a 366 and a 427 version that each had a .400 taller deck height to accommodate .400 taller pistons using four rings instead of the more usual three rings. These tall-deck engines were used only in medium-duty trucks (NOT in pickup trucks--think in terms of big farm trucks, garbage trucks, dump trucks, school busses, etc.) The tall-deck blocks all had 4-bolt main caps, forged crankshafts, and the strongest of the 3/8 bolt connecting rods. All-out performance engines used 7/16 bolt connecting rods, along with other changes. This engine family was discontinued in 1990, with the Gen 5 appearing in 1991.

Gen 5: General Motors made substantial revisions to the Mark IV engine, and the result was christened "Gen 5" when it was released for the 1991 model year as a 454. There were 502 cu. in. versions, but never installed in a production vehicle, the 502s were over-the-parts-counter only. Changes to the Gen 5 as compared to the Mk IV included, but are not limited to: rear main seal (and therefore the crankshaft and block) were changed to accept a one-piece seal, oiling passages were moved, the mechanical fuel pump provisions were removed from the block casting, the machined boss for a clutch bracket was eliminated, the cylinder heads lost the ability to adjust the valve lash, and the coolant passages at the top of the cylinder block were revised. The changes to the coolant passage openings meant that installing Mk IV cylinder heads on a Gen 5 block could result in coolant seepage into the lifter valley. Frankly, the changes (except for the one-piece rear main seal) were all easily recognized as cost-cutting measures which also removed some quality and/or utility. All told, the Gen 5 engine was not well regarded by the Chevy enthusiasts because of the changes to the coolant passages and the lack of an adjustable valvetrain. As always, the aftermarket has provided reasonable fixes for the problems. The Gen 5 lasted only until 1995 Gen 6: GM recognized that it did not make any friends when it designed the Gen 5, and so they chose to revise the coolant passages again when designing the Gen 6, allowing the older heads to be used without coolant seepage problems. The boss for the clutch bracket returned, but was generally not drilled and tapped. The non-adjustable valvetrain remained, as did the one-piece rear main seal. Some but not all Gen 6 454 (and not 502) blocks regained a mechanical fuel pump provision. Production engines installed in pickup trucks got a high-efficiency cylinder head, still canted-valve, but with a modern heart-shaped combustion chamber of about 100cc. The intake port has a "ski jump" cast into it to promote swirling of the intake air flow. All production vehicles with a Gen 6 used a 454 version, but over-the-counter 502s are available. The Gen 6 is sometimes referred to as the "Gen Fix" because it fixed a number of issues that disappointed enthusiasts when the Gen 5 was released. As an added bonus, most if not all Gen 6 engines use hydraulic roller lifters.

Gen 7: A very major revision of the previous engines resulted in the 8.1 liter/ 8100/ 496 cubic inch Gen 7 in 2001. The block gained .400 in deck height so it is the same height as the previous "Tall Deck" truck blocks, wider oil pan rails, and the cylinder heads have symmetrical port layouts instead of the previous 4 long/4 short port layout. Very little interchanges between the 8.1 liter engine and the previous Mark IV/Gen 5/Gen 6 engines. The head bolt pattern and even the firing order of the cylinders has been changed. There are some things that remained true to the previous Mk IV/Gen 5/Gen 6--the bellhousing bolt pattern, the side motor mount bolt pattern, the flywheel bolt pattern, and the exhaust manifold bolt pattern are the same. Note that the bolt holes are threaded for metric fasteners. The 8.1 is internally balanced, so you could install a flywheel/flexplate from a 396/427 Mk IV provided you use the correct bolts to suit the 8.1 crankshaft.

I have had a chance to compare Mark IV, Gen 5/6 and Gen 7 head gaskets. It seems to be possible--but very difficult--to install IV/5/6 heads on the Gen 7 block. GM did this on one show vehicle, it IS possible. You must move three head bolt holes in the block; and as the holes only move about 1/2 their diameter it would be difficult to plug the existing holes, re-drill the new holes, and still have enough strength in the deck surface. There are cooling system differences as well that must be addressed. I have NOT done this conversion; but I do have comparison photos of the head gaskets.

Specifications:

(sorry if this table loses it's formatting: I don't know how to fix it. It looks "ok" at full screen width on my computer)

Engine family Displacement Bore Stroke Rod length

MK I 348 4.125 3.25 6.135

MK I 409 4.31 3.5 6.010

MK I 427 4.31 3.65 6.135

MK II 427 4.31 3.65 6.135

MK IV 366 3.938 3.76 6.135 (Only offered as a medium duty truck engine)

MK IV 396 4.094 3.76 6.135

MK IV 402 4.125 3.76 6.135

MK IV 427 4.250 3.76 6.135 (Offered in passenger car and medium duty truck versions)

MK IV/Gen 5/6 454 4.250 4.0 6.135

MK IV 482 4.250 4.25 6.405 (very rare, made only for offshore boat races. Used tall-deck block)

Gen 5/6 502 4.466 4.0 6.135 (Over the parts-counter only; not installed in production vehicles)

Gen 7 496/8.1 4.25 4.37

Specials: GM has sold many special-purpose engines, partial engines, blocks, cylinder heads, etc., "over the parts counter" that were never installed in production line vehicles. It is very difficult to track all the various items--suffice to say that heavy-duty "Bowtie" blocks and cylinder heads in various configurations--Mark IV, Gen 5, etc, have been produced. Oldsmobile used the Big Block Chevy as a baseline when designing the first of the Drag Race Competition Engines (DRCE) so that the early DRCE engines have an Olds Rocket emblem cast into the block, but it's Chevy parts that fit inside. There are special high performance blocks and heads, in either iron or aluminum, produced by GM and by aftermarket suppliers to suit almost any racing need.

Coolant Routing Mk IV/Gen 5/Gen 6

There are two different ways that coolant can be routed through the engine: series flow and parallel flow. Both ways work just fine. There may be a slight preference for parallel flow, but it is not a big deal. Series flow has the water exiting the water pump, flowing through the block to the rear, it then transfers through the head gasket and into the cylinder head through two large passages on each cylinder bank at the rear of the block. The coolant then travels from the rear of the head, forward to the front of the head, into the intake manifold water passage and out past the thermostat and thermostat housing. The water cools the block first, then it cools the head. The coldest water (coming out of the water pump) is directly below the hottest water (having already picked up the heat of the block and the head) as the hot water transfers into the intake manifold. By contrast, parallel flow has the water exiting from the water pump into the block, where a portion "geysers" up into the head between the first and second cylinder, another portion "geysers" up to the head between the second and third cylinders, another portion geysers up to the head between the third and fourth cylinder, and the remainder transfers to the head at the rear of the block. The coolant temperature inside the engine is more even that way. The differences in coolant routing is having (or not having) the three additional coolant transfer holes in each block deck, and three matching holes in the head gasket. The heads have passages for either system, and are not different based on coolant flow.

Be aware that gaskets that DO have the three extra holes between the cylinders often have restricted coolant flow at the rear--instead of having two large coolant transfer holes at the rear, there is only one, and it's the smaller of the two holes that remains. This is important because if you use a parallel flow head gasket on a series flow block, you can have massive overheating and there's NOTHING that will cure the problem except to replace the head gaskets with ones that don't restrict flow at the rear of the block, or to drill the block decks to allow the coolant to flow into the head between the cylinders. Here's why they can overheat: A series-flow block doesn't have the openings between the cylinders, no coolant can flow up to the head there. The gasket may only have the single, smaller opening at the rear, so the amount of water that gets through that opening is greatly reduced from what the block designers intended. The result is that the coolant flow through the engine is only a fraction of what is needed.

Most, but NOT all Mk IV engines are Series Flow. ALL Gen 5 and Gen 6 engines are Parallel Flow. A series flow block can be converted to parallel flow by drilling 3 holes in each deck surface, and then use parallel flow head gaskets. You can use the parallel flow gaskets as templates for locating the additional holes. It's really easy: Put the parallel flow gaskets on the block, mark the location and size of the three extra holes. Remove the gasket. Grab a 1/2" drill and a drill bit of the correct size, and pop the extra holes in the block. There is NO modification needed on the head castings. Some blocks have one of the holes already, but it needs to be ground oblong to properly match the gasket. Again, very easy with a hand held die grinder and rotary file.

Please check out my guides to GM small block engines , and Olds, Pontiac, and Buick big block engines, Mopar V-8 engine families, Ford V-8 engine families since 1932 or HEI distributors , too.

"

"

This guide is intended to help you sort out the more major differences among Big Block Chevrolet engines produced since 1958. Chevrolet has designed and produced several different "big block" engine families. Within each family, there can be evolutionary changes, and special parts designed for competition use which may not be directly interchangeable with the regular production items. I don't intend to cover every possible variation. For practical purposes, all big block Chevrolet engines use a cylinder bore spacing of 4.84 inches although note the one exception below.

Early engines were designated as Mark I, (Mk I) Mk II, Mk III, and Mk IV. Later engines continued the numbering system as Generation 5 (Gen 5), Gen 6, Gen 7. There are some conflicting theories as to the reason for the change from "Mark" to "Generation". My first guess: "Gen 5" sounds much more modern, hi-tech, and trendy than "Mk V".

Mark I: The original "Big Block Chevy", also called the "W" engine perhaps because of the layout of the valves and therefore the shape of the valve covers--although another possibility is that GM chose the "W" prototype for production rather than the competing "X" or "Y" prototypes, and therefore it's a convenient coincidence that the valve layout is in the shape of a "W". It should be noted that this engine became "Mark I" only after the Mark II was being designed years after the "W" was introduced. Whatever the origin of the name, this engine family was installed in vehicles beginning in 1958, as a 348. In 1961, it went to 409 cubic inches, (as immortalized in the Beach Boys song "She's so fine, my 409") and for one year only (1963) a few well-connected racers could buy a car with a 427 cubic inch version called the Z-11. The 427 version was all about performance, and had special parts which were not directly interchangeable with the 348/409. While production of the 427 was severely limited, both the 348 and 409 were offered in passenger cars and light- and medium-duty trucks. The truck blocks were somewhat different from the passenger car blocks, having slightly different water jackets and of course, lower compression achieved by changes in the piston in addition to more machining of the top of the cylinder. A novel feature of this engine is that the top of the cylinders are not machined at a 90 degree angle to the bore centerline. The top of the cylinder block is machined at a 16 degree angle, and the cylinder head has almost no "combustion chamber" cast into it. The combustion chamber is the top wedge-shaped section of the cylinder. Ford also introduced an engine family like that in '58--the Mercury/Edsel/Lincoln "MEL" 383/410/430/462. The "W" engine ended it's automotive production life part way through the 1965 model year, when the 409 Mk I was superseded by the 396 Mk IV engine.

Mark II: This is more of a prototype than a production engine. It is the 1963-only "Mystery Engine" several of which ran the Daytona 500 race, and in fact won the 100-mile qualifier setting a new record. It is largely the result of engineering work by Dick Keinath. Produced mainly as a 427 but with a few 396 and 409 cubic inch versions, all in VERY limited numbers. Even though it was intended as a NASCAR-capable engine, it had 2-bolt main caps. This engine was never installed in a production-line vehicle by GM, it only went to racers. And even though it was available in 1963, it has very little resemblance to the 427 Mark I "W" engine of the same year. The Mark II was a "breakthrough" design using intake and exhaust valves that are tilted in two planes--a canted-valve cylinder head, nicknamed the "Semi-Hemi" or "Porcupine" because it is "almost" a hemi head, and the valve stems stick out of the head casting at seemingly random angles. The engine was the subject of an extensive article in the May, 1963 Hot Rod Magazine. Because of NASCAR politics, Chevrolet was forced to sell two 427 Mark II engines to Ford after the '63 Daytona race, (to "prove" that it was a production engine, and therefore eligible to race in NASCAR events) and so this engine is not only the grandfather of the Mark IV and later big block Chevies, it's also the grandfather of the canted-valve Ford engines: Boss 302, 351 Cleveland and variants, and the 429/460 big block Ford. The bore and stroke of the 427 MK II is not the same as the 427 MK IV.

Mark III: Never released for production. This was rumored to be the result of GM/Chevrolet's proposed buyout of the tooling and rights to the Packard V-8 engine of the mid-to-late '50's. The Packard engine was truly huge, having 5" bore centers. The former president of Packard wound up at Ford after Packard folded, perhaps because of that, Ford was also interested in this engine. Ford wanted to make a V-12 variant from it just as Packard had once envisioned. One way or another, neither GM nor Ford actually went forward with the purchase.

Mark IV: The engine that most people think of as the "big block Chevy". Released partway into the 1965 model year as a 396, superseding the older 409. It is a development of the Mark II and using similar but not identical canted valve (semi-hemi/porcupine) cylinder heads. It was later expanded to 402 (often still labeled as a 396, or even a 400,) a 427, a 454, and a few "special" engines were produced in the late '60's for offshore boat racing as a 482. There was a 366 and a 427 version that each had a .400 taller deck height to accommodate .400 taller pistons using four rings instead of the more usual three rings. These tall-deck engines were used only in medium-duty trucks (NOT in pickup trucks--think in terms of big farm trucks, garbage trucks, dump trucks, school busses, etc.) The tall-deck blocks all had 4-bolt main caps, forged crankshafts, and the strongest of the 3/8 bolt connecting rods. All-out performance engines used 7/16 bolt connecting rods, along with other changes. This engine family was discontinued in 1990, with the Gen 5 appearing in 1991.

Gen 5: General Motors made substantial revisions to the Mark IV engine, and the result was christened "Gen 5" when it was released for the 1991 model year as a 454. There were 502 cu. in. versions, but never installed in a production vehicle, the 502s were over-the-parts-counter only. Changes to the Gen 5 as compared to the Mk IV included, but are not limited to: rear main seal (and therefore the crankshaft and block) were changed to accept a one-piece seal, oiling passages were moved, the mechanical fuel pump provisions were removed from the block casting, the machined boss for a clutch bracket was eliminated, the cylinder heads lost the ability to adjust the valve lash, and the coolant passages at the top of the cylinder block were revised. The changes to the coolant passage openings meant that installing Mk IV cylinder heads on a Gen 5 block could result in coolant seepage into the lifter valley. Frankly, the changes (except for the one-piece rear main seal) were all easily recognized as cost-cutting measures which also removed some quality and/or utility. All told, the Gen 5 engine was not well regarded by the Chevy enthusiasts because of the changes to the coolant passages and the lack of an adjustable valvetrain. As always, the aftermarket has provided reasonable fixes for the problems. The Gen 5 lasted only until 1995 Gen 6: GM recognized that it did not make any friends when it designed the Gen 5, and so they chose to revise the coolant passages again when designing the Gen 6, allowing the older heads to be used without coolant seepage problems. The boss for the clutch bracket returned, but was generally not drilled and tapped. The non-adjustable valvetrain remained, as did the one-piece rear main seal. Some but not all Gen 6 454 (and not 502) blocks regained a mechanical fuel pump provision. Production engines installed in pickup trucks got a high-efficiency cylinder head, still canted-valve, but with a modern heart-shaped combustion chamber of about 100cc. The intake port has a "ski jump" cast into it to promote swirling of the intake air flow. All production vehicles with a Gen 6 used a 454 version, but over-the-counter 502s are available. The Gen 6 is sometimes referred to as the "Gen Fix" because it fixed a number of issues that disappointed enthusiasts when the Gen 5 was released. As an added bonus, most if not all Gen 6 engines use hydraulic roller lifters.

Gen 7: A very major revision of the previous engines resulted in the 8.1 liter/ 8100/ 496 cubic inch Gen 7 in 2001. The block gained .400 in deck height so it is the same height as the previous "Tall Deck" truck blocks, wider oil pan rails, and the cylinder heads have symmetrical port layouts instead of the previous 4 long/4 short port layout. Very little interchanges between the 8.1 liter engine and the previous Mark IV/Gen 5/Gen 6 engines. The head bolt pattern and even the firing order of the cylinders has been changed. There are some things that remained true to the previous Mk IV/Gen 5/Gen 6--the bellhousing bolt pattern, the side motor mount bolt pattern, the flywheel bolt pattern, and the exhaust manifold bolt pattern are the same. Note that the bolt holes are threaded for metric fasteners. The 8.1 is internally balanced, so you could install a flywheel/flexplate from a 396/427 Mk IV provided you use the correct bolts to suit the 8.1 crankshaft.

I have had a chance to compare Mark IV, Gen 5/6 and Gen 7 head gaskets. It seems to be possible--but very difficult--to install IV/5/6 heads on the Gen 7 block. GM did this on one show vehicle, it IS possible. You must move three head bolt holes in the block; and as the holes only move about 1/2 their diameter it would be difficult to plug the existing holes, re-drill the new holes, and still have enough strength in the deck surface. There are cooling system differences as well that must be addressed. I have NOT done this conversion; but I do have comparison photos of the head gaskets.

Specifications:

(sorry if this table loses it's formatting: I don't know how to fix it. It looks "ok" at full screen width on my computer)

Engine family Displacement Bore Stroke Rod length

MK I 348 4.125 3.25 6.135

MK I 409 4.31 3.5 6.010

MK I 427 4.31 3.65 6.135

MK II 427 4.31 3.65 6.135

MK IV 366 3.938 3.76 6.135 (Only offered as a medium duty truck engine)

MK IV 396 4.094 3.76 6.135

MK IV 402 4.125 3.76 6.135

MK IV 427 4.250 3.76 6.135 (Offered in passenger car and medium duty truck versions)

MK IV/Gen 5/6 454 4.250 4.0 6.135

MK IV 482 4.250 4.25 6.405 (very rare, made only for offshore boat races. Used tall-deck block)

Gen 5/6 502 4.466 4.0 6.135 (Over the parts-counter only; not installed in production vehicles)

Gen 7 496/8.1 4.25 4.37

Specials: GM has sold many special-purpose engines, partial engines, blocks, cylinder heads, etc., "over the parts counter" that were never installed in production line vehicles. It is very difficult to track all the various items--suffice to say that heavy-duty "Bowtie" blocks and cylinder heads in various configurations--Mark IV, Gen 5, etc, have been produced. Oldsmobile used the Big Block Chevy as a baseline when designing the first of the Drag Race Competition Engines (DRCE) so that the early DRCE engines have an Olds Rocket emblem cast into the block, but it's Chevy parts that fit inside. There are special high performance blocks and heads, in either iron or aluminum, produced by GM and by aftermarket suppliers to suit almost any racing need.

Coolant Routing Mk IV/Gen 5/Gen 6

There are two different ways that coolant can be routed through the engine: series flow and parallel flow. Both ways work just fine. There may be a slight preference for parallel flow, but it is not a big deal. Series flow has the water exiting the water pump, flowing through the block to the rear, it then transfers through the head gasket and into the cylinder head through two large passages on each cylinder bank at the rear of the block. The coolant then travels from the rear of the head, forward to the front of the head, into the intake manifold water passage and out past the thermostat and thermostat housing. The water cools the block first, then it cools the head. The coldest water (coming out of the water pump) is directly below the hottest water (having already picked up the heat of the block and the head) as the hot water transfers into the intake manifold. By contrast, parallel flow has the water exiting from the water pump into the block, where a portion "geysers" up into the head between the first and second cylinder, another portion "geysers" up to the head between the second and third cylinders, another portion geysers up to the head between the third and fourth cylinder, and the remainder transfers to the head at the rear of the block. The coolant temperature inside the engine is more even that way. The differences in coolant routing is having (or not having) the three additional coolant transfer holes in each block deck, and three matching holes in the head gasket. The heads have passages for either system, and are not different based on coolant flow.

Be aware that gaskets that DO have the three extra holes between the cylinders often have restricted coolant flow at the rear--instead of having two large coolant transfer holes at the rear, there is only one, and it's the smaller of the two holes that remains. This is important because if you use a parallel flow head gasket on a series flow block, you can have massive overheating and there's NOTHING that will cure the problem except to replace the head gaskets with ones that don't restrict flow at the rear of the block, or to drill the block decks to allow the coolant to flow into the head between the cylinders. Here's why they can overheat: A series-flow block doesn't have the openings between the cylinders, no coolant can flow up to the head there. The gasket may only have the single, smaller opening at the rear, so the amount of water that gets through that opening is greatly reduced from what the block designers intended. The result is that the coolant flow through the engine is only a fraction of what is needed.

Most, but NOT all Mk IV engines are Series Flow. ALL Gen 5 and Gen 6 engines are Parallel Flow. A series flow block can be converted to parallel flow by drilling 3 holes in each deck surface, and then use parallel flow head gaskets. You can use the parallel flow gaskets as templates for locating the additional holes. It's really easy: Put the parallel flow gaskets on the block, mark the location and size of the three extra holes. Remove the gasket. Grab a 1/2" drill and a drill bit of the correct size, and pop the extra holes in the block. There is NO modification needed on the head castings. Some blocks have one of the holes already, but it needs to be ground oblong to properly match the gasket. Again, very easy with a hand held die grinder and rotary file.

Please check out my guides to GM small block engines , and Olds, Pontiac, and Buick big block engines, Mopar V-8 engine families, Ford V-8 engine families since 1932 or HEI distributors , too.

"