great! thanks for getting back and posting, so few people do that and its usually a P.I.T.A. to find out what happened in unfinished threads

I think it is 80 & up mark IV big block engines that has the later improved cooling with the three extra holes.

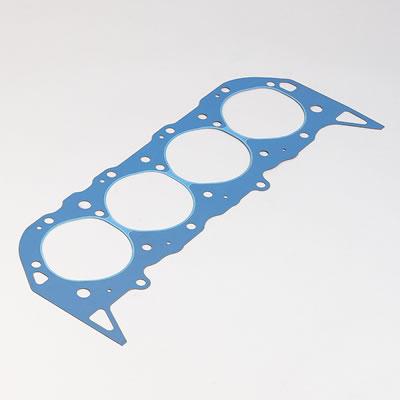

(look at the gasket info below)

ITS Real easy to drill the holes in the earlier blocks if you don,t have then with a 3/8" drill , using the gasket as a pattern as it was found to increase cooling.

BTW fritz1990 posted this info

Top gasket pic is one with the extra cooling holes. Can use this gasket as a template to drill these 1/2" holes in the deck of the block. All heads already have these holes just some blocks don't.

The holes are the three on the bottom side of the gasket right below the ones between the cyls. The ends of the gasket are also different.

Just don't use the top gasket on your block without drilling the holes. I have to run to work and I can explain the difference later. The top setup is suppose to give you a lil' better cooling but there are many like yours running around, not a real big issue, just better to do it now.

If you have the three holes in the block you can run either gasket.

The bottom gasket is the one you will need to use if you don't drill the holes.

BBC HEAD GASKETS READ THIS LINK

http://www.cartechbooks.com/vstore/show ... apter=7174

Three types of gasket materials are generally available, steel shim, composition and copper gaskets. Cast iron heads can use all three types of gasket materials. Aluminum cylinder heads require the use of composition or copper gaskets. Various compressed gasket thicknesses are offered. Remember that you should have a minimum clearance of .035"-.040" between the top of the piston deck and the deck of the cylinder head when using steel rods. Aluminum connecting rods typically require a larger clearance.

Fel-Pro composition head gasket (PN-8180-PT) for 4.250" bore Mark IV engines. It has two additional holes for head bolts that go into the lifter valley found on some high performance Bowtie and aftermarket blocks.

Different head gasket bore sizes are offered. Mark IV head gaskets have different coolant core hole passages than gaskets for Gen.V engines, blocking some passages and opening other coolant passages. Some block deck coolant core holes are round, while on Gen.V production blocks the holes are irregularly shaped on the block deck. Mark IV heads and head gaskets should be used on Mark IV blocks. Likewise Gen.V style cylinder heads and gaskets should be used on Gen.V blocks. There are exceptions. Mark IV heads can be used on Gen.V "Bowtie" and on Gen.VI HO blocks because the core holes in these block decks will seal the water core holes found on Mark IV heads. If you build this combination then use a Mark IV style head gasket and plug the core hole in the Gen.V "Bowtie" block deck located near the front head dowel pin location (see photo). Otherwise coolant entering the front of the block can bypass the rest of the block and exit out thru the head and intake manifold.

Steel shim gaskets and copper gaskets require the use of head gasket sealant. Composition gaskets do not require sealant.

Head bolts should be completely cleaned and then torqued down in the proper sequence and to the correct torque values. Head bolts or studs, used on aluminum heads, need to have a hardened steel flat washer (PN-3899696) under each bolt head or nut, to prevent damage to the aluminum head surface. Head bolt threads going into water passages should be coated with sealant and head bolts going into blocks with "blind" holes should be coated with moly lube or oil. Some head gaskets do not need retorquing, but it is a good practice to retorque all of the head bolts after the motor has been heated up the first time and allowed to cool down. Remember, do not try to put Mark IV heads on a production Gen.V block and visa versa. You can use Mark IV heads on the new Gen.VI 454 and 502 HO blocks or on "Bowtie" blocks.