You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

block assembly and measurements

- Thread starter jteu2002

- Start date

Re: block assembly and mesurements

thats a good question most guys never think about!

but I wondered the same thing years ago, so, heres a reference

http://www.rbracing-rsr.com/squishcalc1.html

http://garage.grumpysperformance.com/index.php?threads/chevy-big-block-vi.9857/#post-37553

http://newcenturyperformance.com/Blocks.htm

https://www.globalindustrial.com/p/...tm_campaign=Calipers&infoParam.campaignId=T9Z

http://garage.grumpysperformance.co...piston-to-bore-clearance-on-your-block.14251/

he coefficient of linear thermal expansion is the ratio of the change in length per degree F (imperial) to the length.

Linear thermal expansion for some common metals can be found in the table below:

Cast Iron, gray expands between 5.8 micro inches to 11 micro inches between 32F - 212F, a MICRO INCH IS A MILLIONTH OF AN INCH thats (millionth of an inch, per inch, between 32F and 212 f) alloys of cast iron can slightly increase the rate but in no case will it be critical in the temperature ranges you'll encounter

reference

http://www.engineeringtoolbox.com/therm ... d_859.html

http://hyperphysics.phy-astr.gsu.edu/hb ... hexp2.html

http://www.engineeringtoolbox.com/linea ... -d_95.html

example

your normal SBC has a deck height of 9.023 inches so the expansion from lets say between 40F on a cold day to lets say 90F on a hot day ,with that 50 degree temperature swing,on the block deck height would be about 1.61-3.0 millions x 9.023 0r between .0000145 ,and .000029 or put a different way, your wasting your time worrying about it .

viewtopic.php?f=51&t=976&p=1706#p1706

http://circletrack.automotive.com/10913 ... index.html

http://www.chevyhiperformance.com/techa ... index.html

http://reviews.ebay.com/Big-Block-Chevy ... 0001563647

related links with lots of info

watch this video, but remember , if you intend to partially fill a block to add cylinder wall rigidity, the block should be filled at least 48 hours prior to any machine work being done on the block, as the fill in the coolant passages will generally expands slightly as it sets and will change the bore dimensions slightly.

Id also point out that a DART after market blocks significantly thicker and stiffer and made from a stronger alloy than the OEM production block casting

viewtopic.php?f=51&t=2692

viewtopic.php?f=44&t=752&p=13184#p13184

thats a good question most guys never think about!

but I wondered the same thing years ago, so, heres a reference

http://www.rbracing-rsr.com/squishcalc1.html

http://garage.grumpysperformance.com/index.php?threads/chevy-big-block-vi.9857/#post-37553

http://newcenturyperformance.com/Blocks.htm

https://www.globalindustrial.com/p/...tm_campaign=Calipers&infoParam.campaignId=T9Z

http://garage.grumpysperformance.co...piston-to-bore-clearance-on-your-block.14251/

he coefficient of linear thermal expansion is the ratio of the change in length per degree F (imperial) to the length.

Linear thermal expansion for some common metals can be found in the table below:

Cast Iron, gray expands between 5.8 micro inches to 11 micro inches between 32F - 212F, a MICRO INCH IS A MILLIONTH OF AN INCH thats (millionth of an inch, per inch, between 32F and 212 f) alloys of cast iron can slightly increase the rate but in no case will it be critical in the temperature ranges you'll encounter

reference

http://www.engineeringtoolbox.com/therm ... d_859.html

http://hyperphysics.phy-astr.gsu.edu/hb ... hexp2.html

http://www.engineeringtoolbox.com/linea ... -d_95.html

example

your normal SBC has a deck height of 9.023 inches so the expansion from lets say between 40F on a cold day to lets say 90F on a hot day ,with that 50 degree temperature swing,on the block deck height would be about 1.61-3.0 millions x 9.023 0r between .0000145 ,and .000029 or put a different way, your wasting your time worrying about it .

viewtopic.php?f=51&t=976&p=1706#p1706

http://circletrack.automotive.com/10913 ... index.html

http://www.chevyhiperformance.com/techa ... index.html

http://reviews.ebay.com/Big-Block-Chevy ... 0001563647

related links with lots of info

watch this video, but remember , if you intend to partially fill a block to add cylinder wall rigidity, the block should be filled at least 48 hours prior to any machine work being done on the block, as the fill in the coolant passages will generally expands slightly as it sets and will change the bore dimensions slightly.

Id also point out that a DART after market blocks significantly thicker and stiffer and made from a stronger alloy than the OEM production block casting

viewtopic.php?f=51&t=2692

viewtopic.php?f=44&t=752&p=13184#p13184

Last edited by a moderator:

Re: block assembly and mesurements

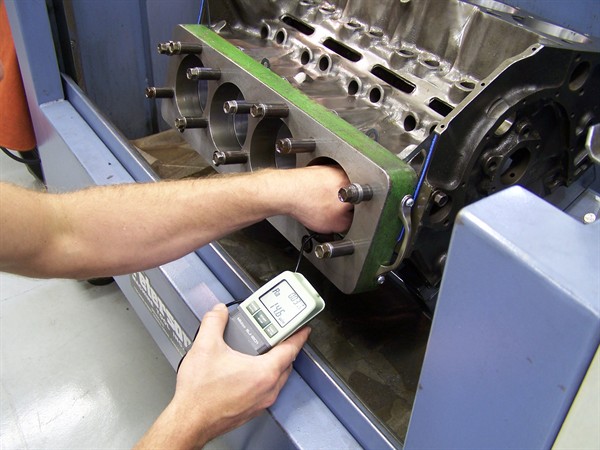

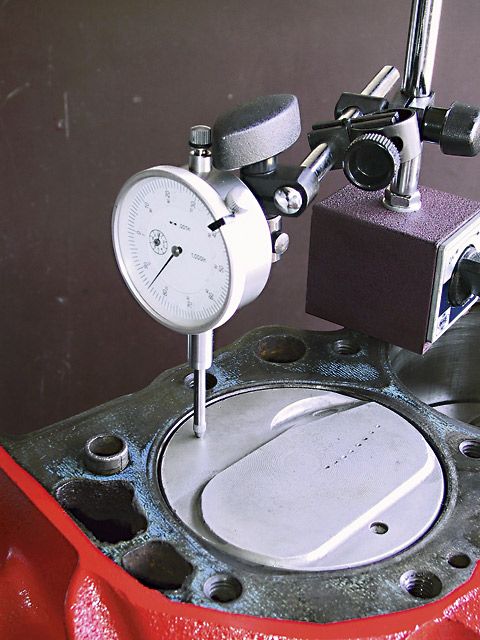

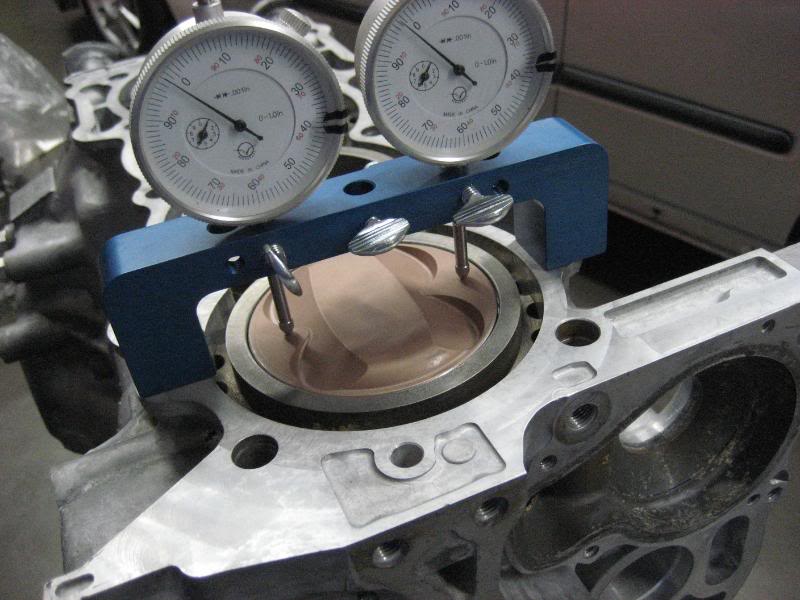

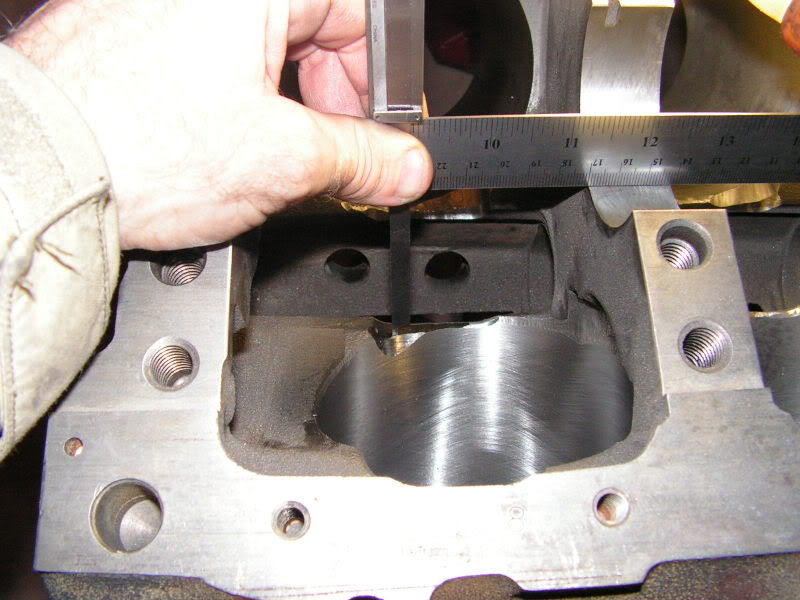

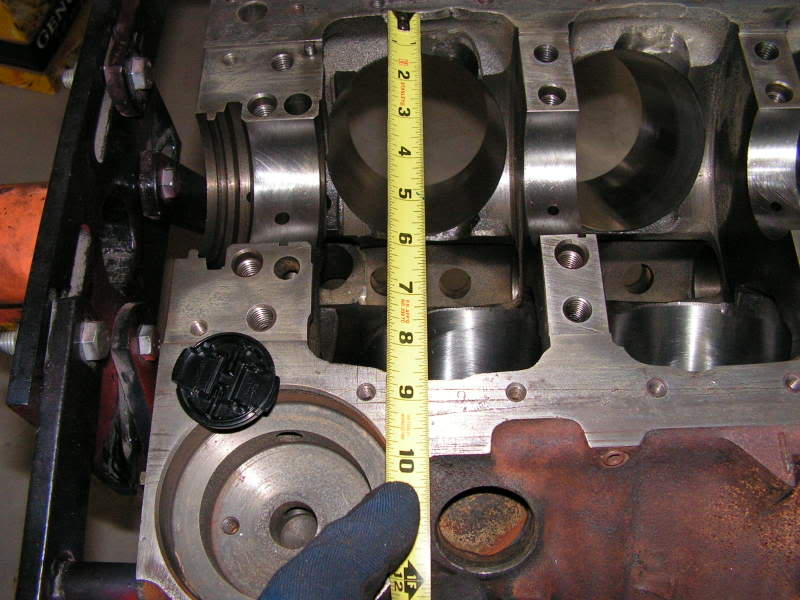

A question in ralation to block measurements, if one had a question about the deck heights being equal on both sides of a block. What would be the level of accuracy be if you mounted a piston/rod on a new crank and new bearings on one side of the block, measured the piston height, then mounted the same rod/piston on the same journal on the other side of the block and measured the piston height?

A question in ralation to block measurements, if one had a question about the deck heights being equal on both sides of a block. What would be the level of accuracy be if you mounted a piston/rod on a new crank and new bearings on one side of the block, measured the piston height, then mounted the same rod/piston on the same journal on the other side of the block and measured the piston height?

Re: block assembly and mesurements

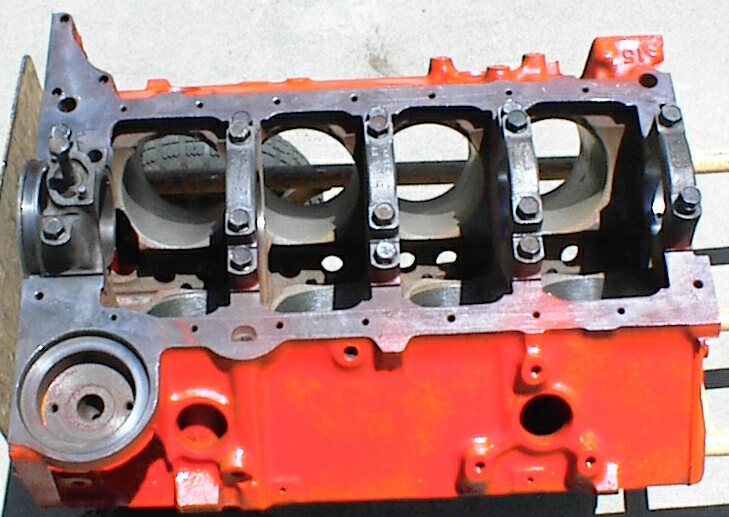

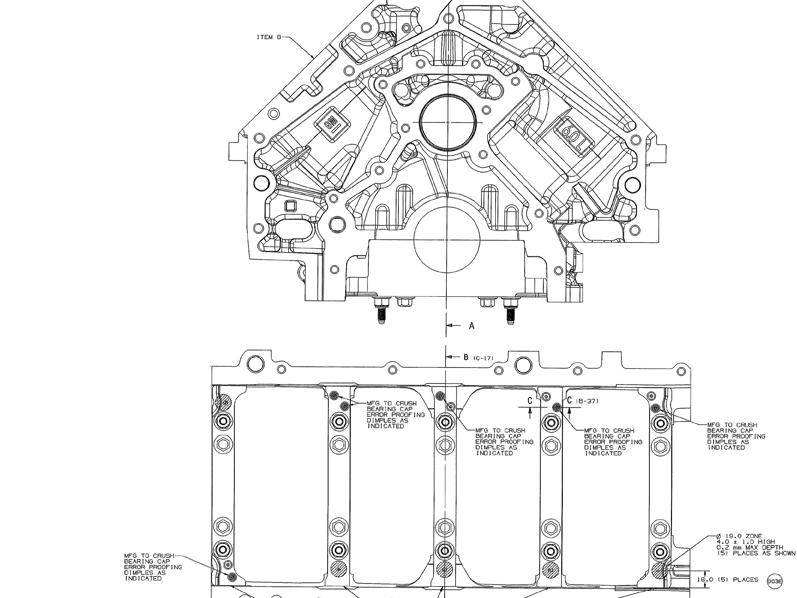

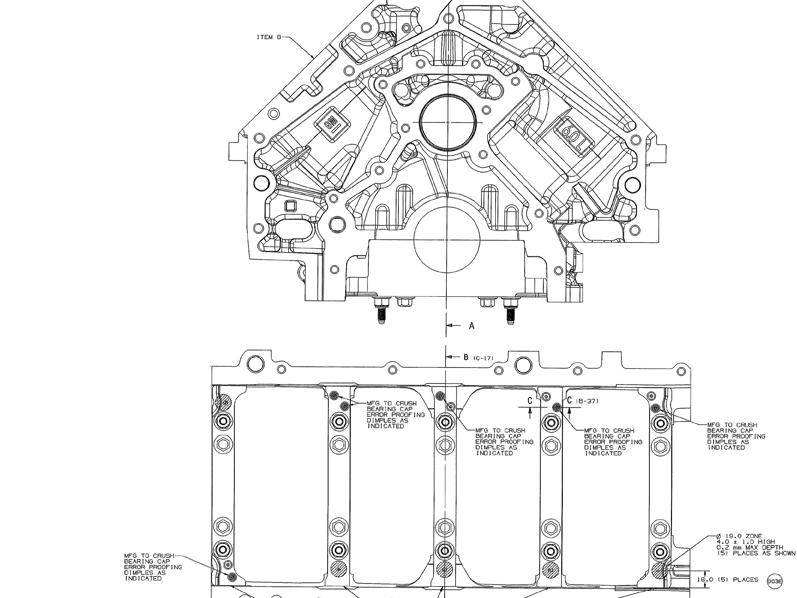

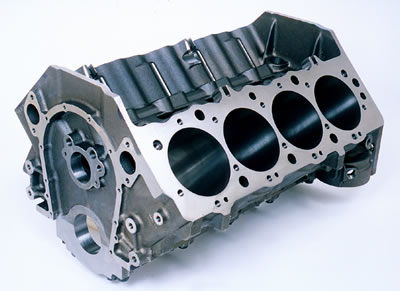

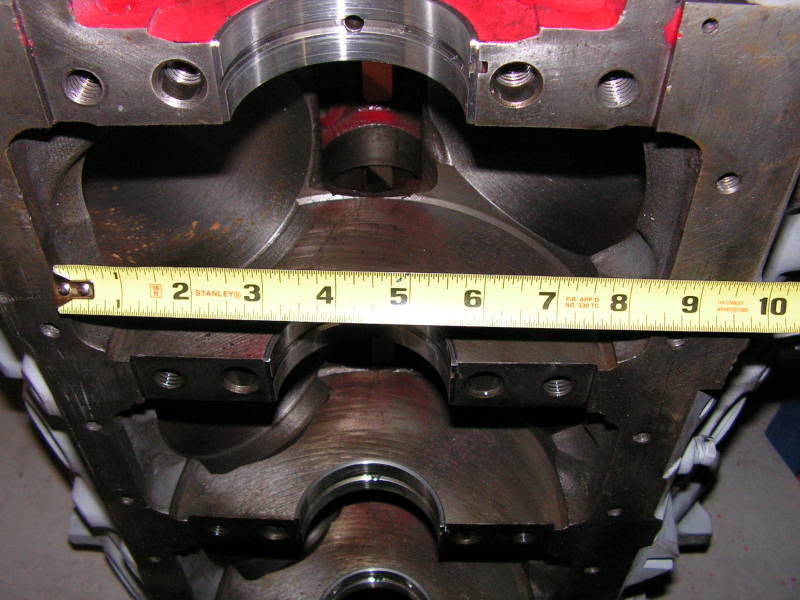

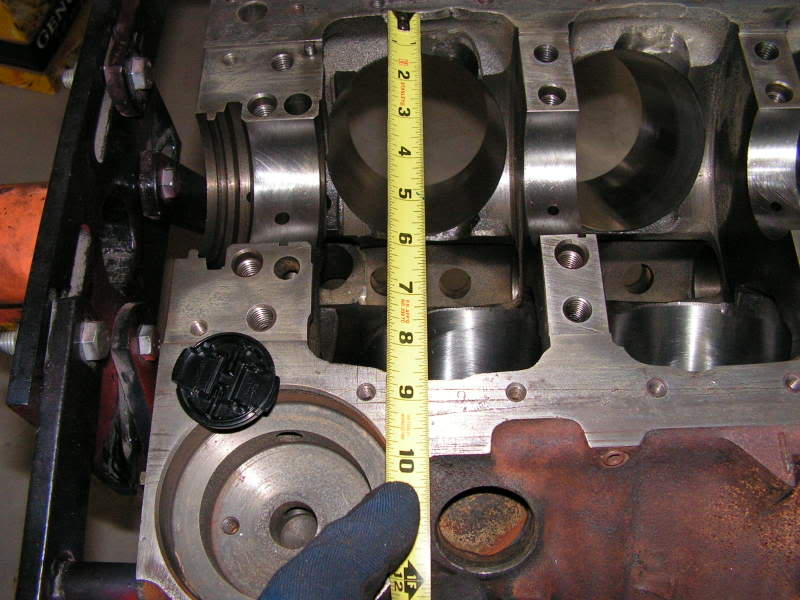

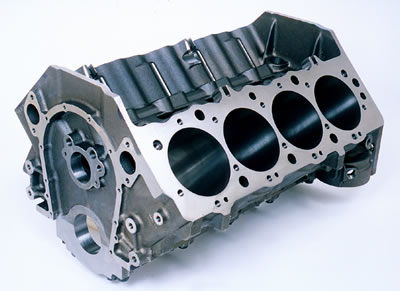

TWO BOLT MAIN CAP BLOCK

4 bolt SBC block

http://www.edelbrock.com/automotive_new ... 0/2916.pdf

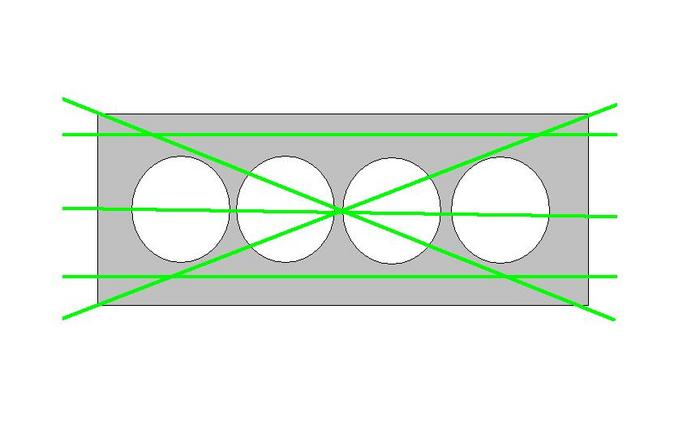

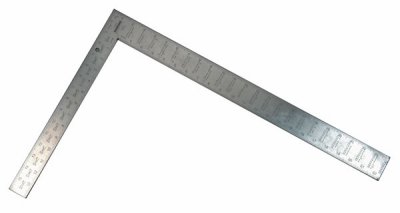

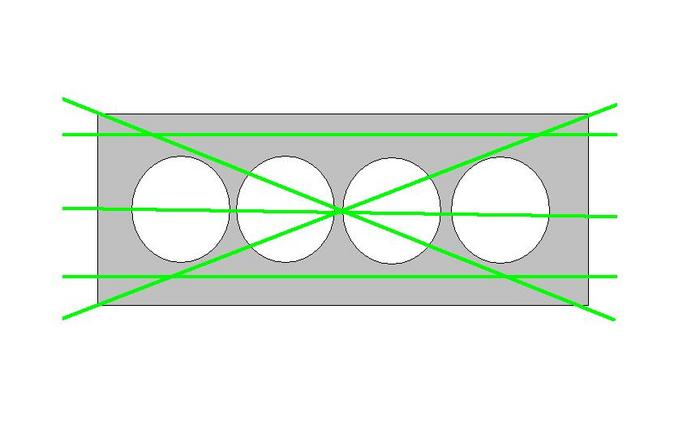

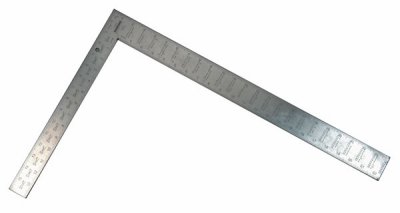

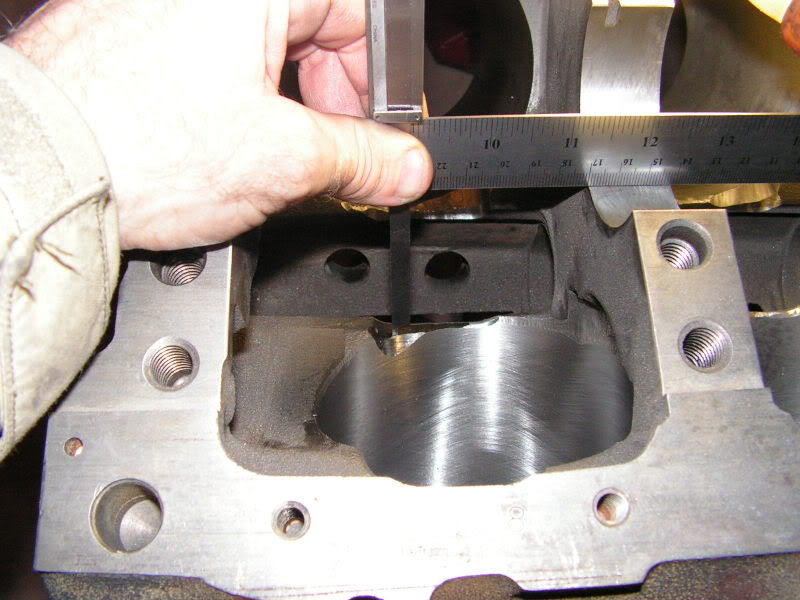

VERIFY THE BLOCK DECKS NOT WARPED

A CARPENTERS SQUARE , A BRIGHT LIGHT AND FEELER GAUGES CAN BE USED TO CHECK IF THE BLOCK DECK OR CYLINDER HEAD MATING SURFACE IS SQUARE AND NOT WARPED

at least in theory ,most block.deck,measurements are determined from the crank center-line, since the piston and crank throw don,t change the deck height will change only if the blocks measurements between the two decks is different, or if the bore center-lines are different.

keep in mind that the rods have one side designed to face outward to the crank throw counter weight and one side designed to ride facing the paired rod and that the intake and exhaust valve notches , force you to have both a left and right piston, so simply swapping the rod from cylinder to cylinder is going to place the valve notch and piston out ward side, facing the wrong way in one location, some pistons are designed to fit in either position, most are not, and must be correctly indexed

viewtopic.php?f=53&t=247&p=7191&hilit=installed+pistons#p7191

you may want to talk to these guys

http://www.nitrousdesigns.net/cncblocksne/index.htm

207-892-7215

or

http://www.lewisracingengines.com/

707-984-6103

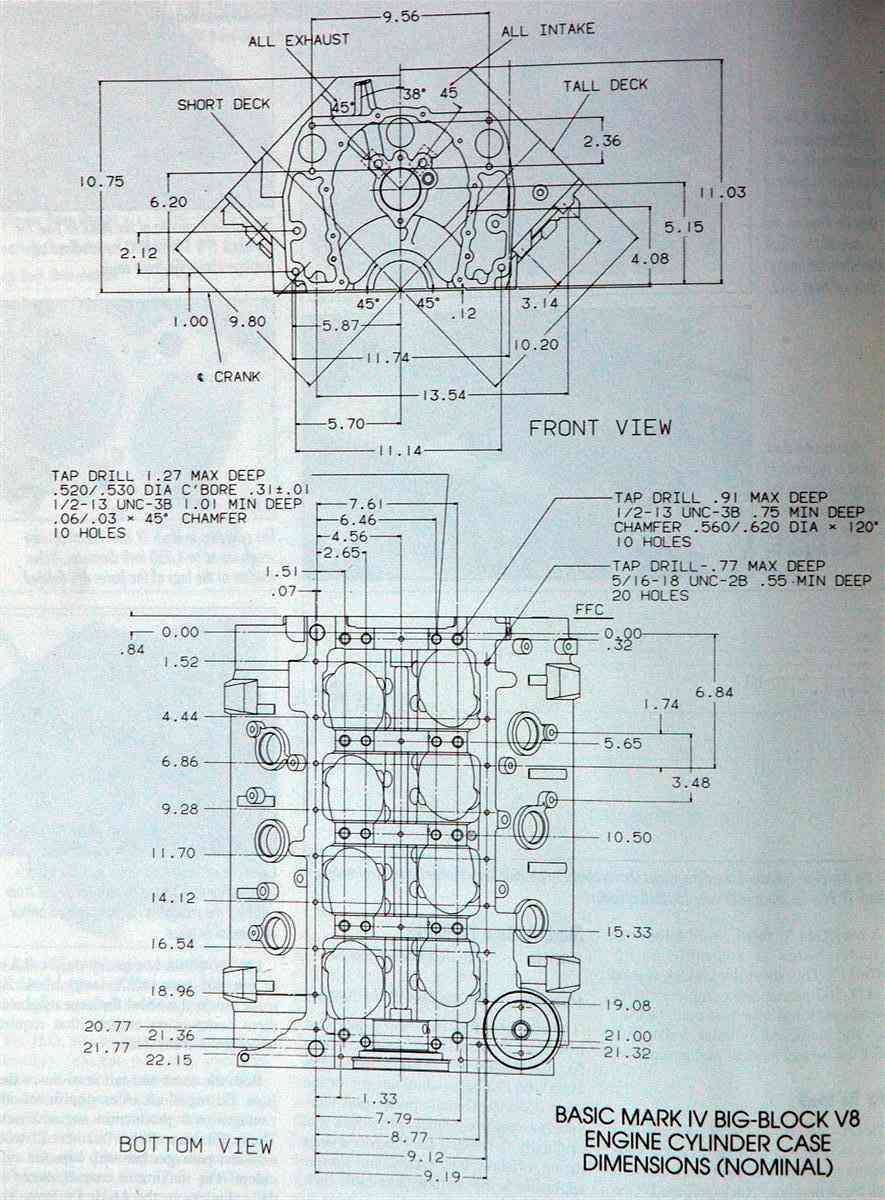

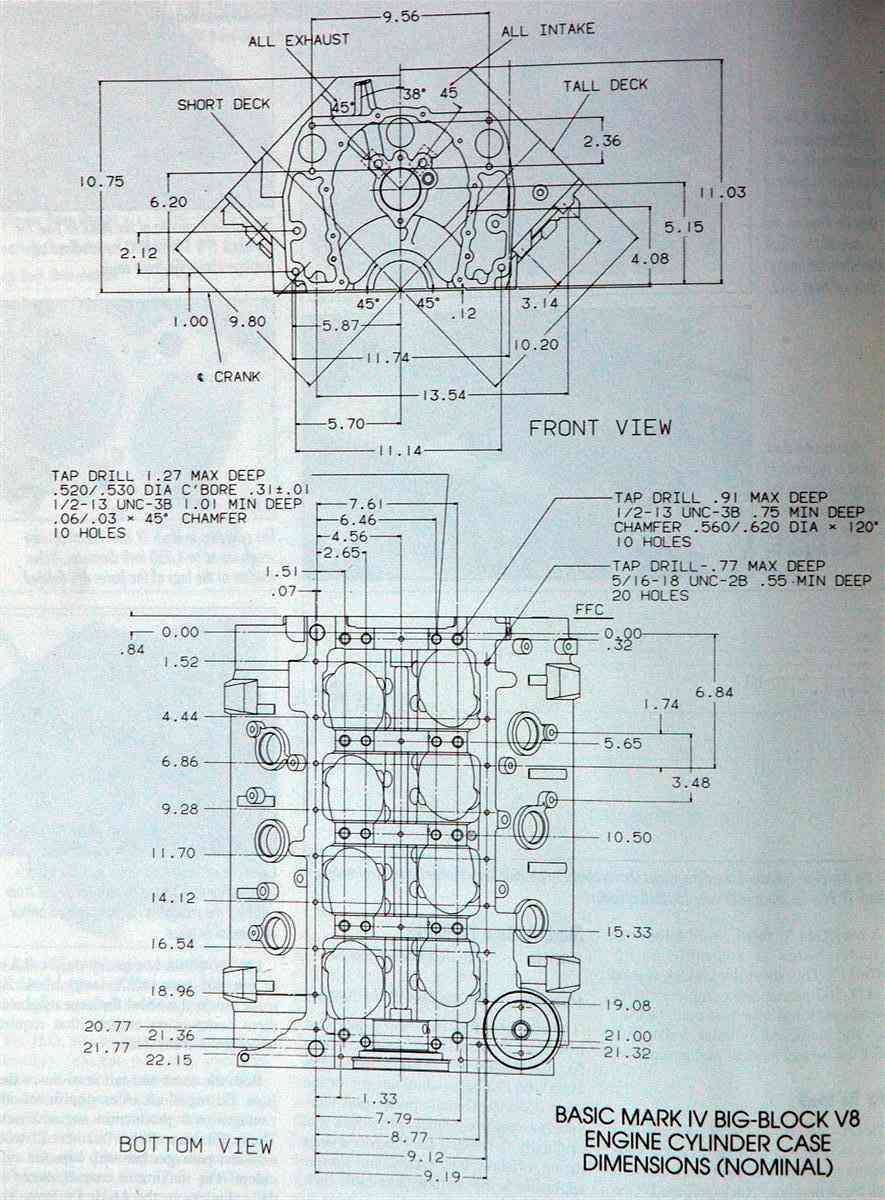

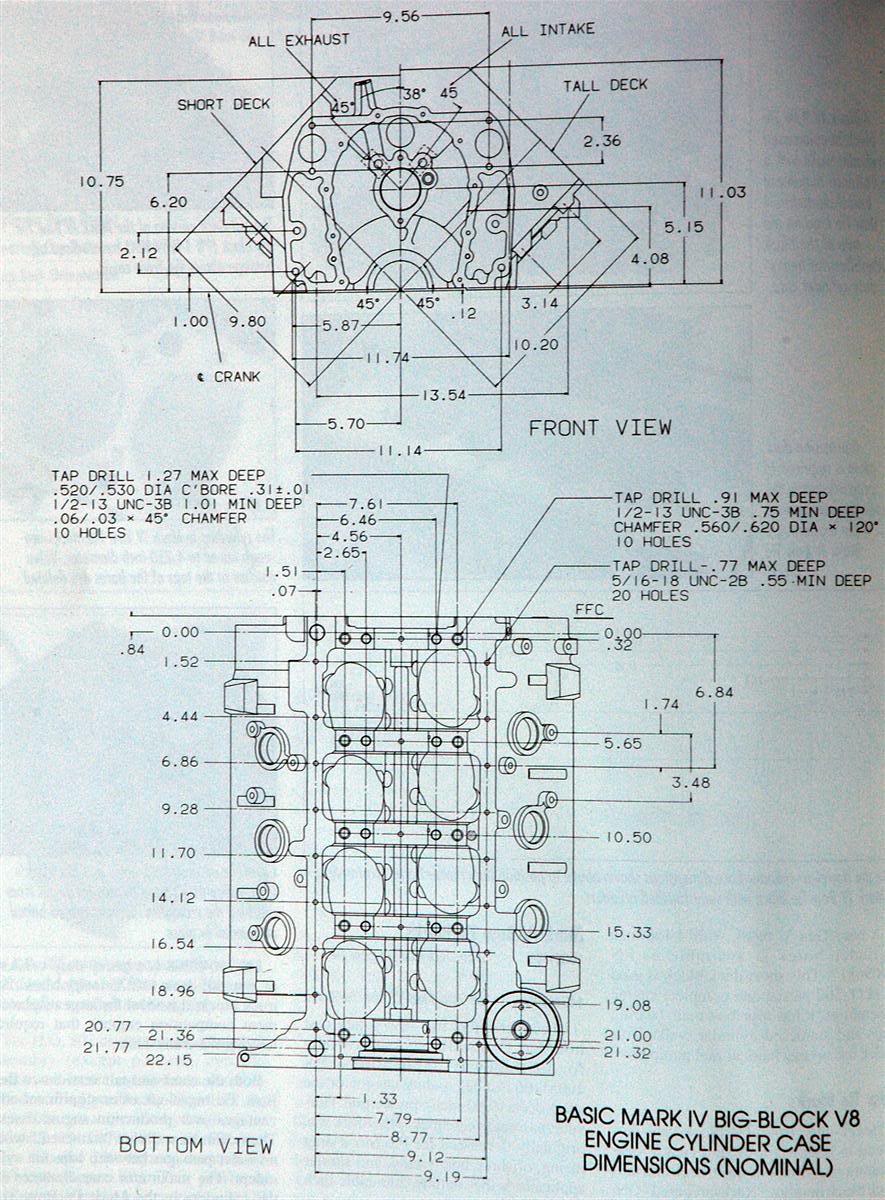

BTW if your building a BIG BLOCK CHEVY theres TWO common deck heights, most pass car and pick-up blocks have a 9.8" deck, some truck blocks have a 10.2" deck heights

READ THESE

viewtopic.php?f=51&t=93&p=10310&hilit=casting+numbers#p10310

viewtopic.php?f=51&t=93&p=9023&hilit=casting+numbers#p9023

Look at the casting number. Here's a list of 454's. Tall deck blocks are identified, all others are standard deck.

346236 454 1975 Two-bolt

361959 454 1978-1987 Two-bolt or four-bolt

364776 454 1977-1990 Four-bolt (tall-deck)

3963512 454 1968-1971 Two-bolt or four-bolt

3969854 454 1972 Two-bolt

3999289 454 1972-1979 Two-bolt

10114182 454 1992 Four-bolt (tall-deck)

14015445 454 1978-1987 Two-bolt or four-bolt

LS1

WOLFPLACE POSTED THIS INFO

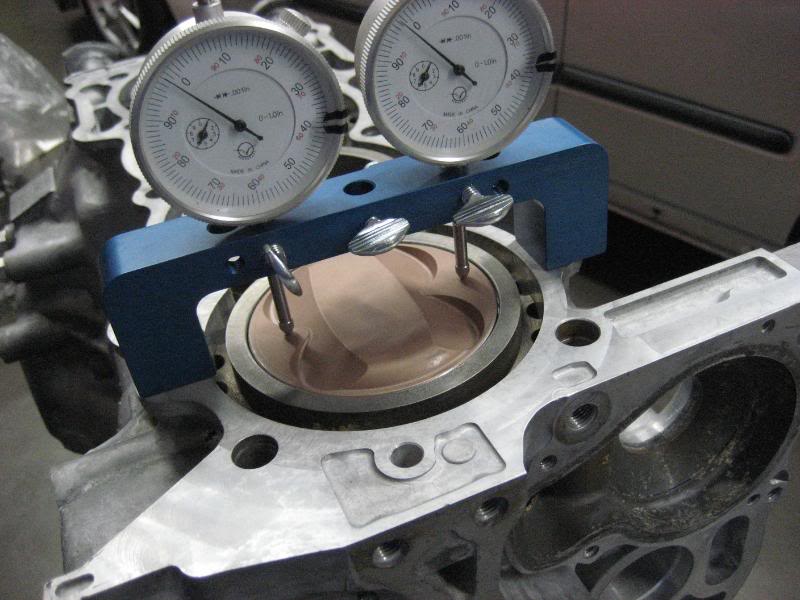

IF You are making the assumption that the block is both square & at a nominal 9.025,,,

Both are huge assumptions in my experience

The blocks vary, sometimes by a bunch from block to block & in the same block from corner to corner so I never build a performance engine without squaring the thing up from the mains.

Real life examples I have posted many times

Quote:

Four blocks recently that I have records in front of me for.

I kept them because they were all pretty bad & a good example of the reasons to square things up

Two were 400 small blocks & two were BB's

The nominal deck height for a SB is 9.025 & for a BB 9.800 for the standard deck

The two 400's

Worst one was 9.011 on one corner, 9.031 on the opposite end of the other side.

Sweeping this block from intake to exhaust was over .010 from a 45° using the cam as a datum.

The other was better, 9.019-9.027

One 454 was 9.797 to 9.815

The other was 9.786 to 9.801

This is why I don't build performance engines without decking the block square from the mains to whatever piston height I require.

Usually zero to .005 down.

The only exception would be a numbers matching block for a restoration but I have a program I wrote to leave the numbers now so I usually do these too.

This is also why almost all common combinations have a c/h of pistons that come out less then the nominal deck of the block.

It is a hell of a lot easier to adjust the block than to adjust the pistons

TWO BOLT MAIN CAP BLOCK

4 bolt SBC block

http://www.edelbrock.com/automotive_new ... 0/2916.pdf

VERIFY THE BLOCK DECKS NOT WARPED

A CARPENTERS SQUARE , A BRIGHT LIGHT AND FEELER GAUGES CAN BE USED TO CHECK IF THE BLOCK DECK OR CYLINDER HEAD MATING SURFACE IS SQUARE AND NOT WARPED

at least in theory ,most block.deck,measurements are determined from the crank center-line, since the piston and crank throw don,t change the deck height will change only if the blocks measurements between the two decks is different, or if the bore center-lines are different.

keep in mind that the rods have one side designed to face outward to the crank throw counter weight and one side designed to ride facing the paired rod and that the intake and exhaust valve notches , force you to have both a left and right piston, so simply swapping the rod from cylinder to cylinder is going to place the valve notch and piston out ward side, facing the wrong way in one location, some pistons are designed to fit in either position, most are not, and must be correctly indexed

viewtopic.php?f=53&t=247&p=7191&hilit=installed+pistons#p7191

you may want to talk to these guys

http://www.nitrousdesigns.net/cncblocksne/index.htm

207-892-7215

or

http://www.lewisracingengines.com/

707-984-6103

BTW if your building a BIG BLOCK CHEVY theres TWO common deck heights, most pass car and pick-up blocks have a 9.8" deck, some truck blocks have a 10.2" deck heights

READ THESE

viewtopic.php?f=51&t=93&p=10310&hilit=casting+numbers#p10310

viewtopic.php?f=51&t=93&p=9023&hilit=casting+numbers#p9023

Look at the casting number. Here's a list of 454's. Tall deck blocks are identified, all others are standard deck.

346236 454 1975 Two-bolt

361959 454 1978-1987 Two-bolt or four-bolt

364776 454 1977-1990 Four-bolt (tall-deck)

3963512 454 1968-1971 Two-bolt or four-bolt

3969854 454 1972 Two-bolt

3999289 454 1972-1979 Two-bolt

10114182 454 1992 Four-bolt (tall-deck)

14015445 454 1978-1987 Two-bolt or four-bolt

LS1

WOLFPLACE POSTED THIS INFO

IF You are making the assumption that the block is both square & at a nominal 9.025,,,

Both are huge assumptions in my experience

The blocks vary, sometimes by a bunch from block to block & in the same block from corner to corner so I never build a performance engine without squaring the thing up from the mains.

Real life examples I have posted many times

Quote:

Four blocks recently that I have records in front of me for.

I kept them because they were all pretty bad & a good example of the reasons to square things up

Two were 400 small blocks & two were BB's

The nominal deck height for a SB is 9.025 & for a BB 9.800 for the standard deck

The two 400's

Worst one was 9.011 on one corner, 9.031 on the opposite end of the other side.

Sweeping this block from intake to exhaust was over .010 from a 45° using the cam as a datum.

The other was better, 9.019-9.027

One 454 was 9.797 to 9.815

The other was 9.786 to 9.801

This is why I don't build performance engines without decking the block square from the mains to whatever piston height I require.

Usually zero to .005 down.

The only exception would be a numbers matching block for a restoration but I have a program I wrote to leave the numbers now so I usually do these too.

This is also why almost all common combinations have a c/h of pistons that come out less then the nominal deck of the block.

It is a hell of a lot easier to adjust the block than to adjust the pistons

Last edited by a moderator:

Re: block assembly and mesurements

Valve notch location notwithstanding, on a centered pin piston, only for the purpose of measuring, it should theoretically rise to the same height on either bank. Correct?

What is the do you consider the acceptable variation in deck height between cylinders on the same bank? Between banks?

TIA

Valve notch location notwithstanding, on a centered pin piston, only for the purpose of measuring, it should theoretically rise to the same height on either bank. Correct?

What is the do you consider the acceptable variation in deck height between cylinders on the same bank? Between banks?

TIA

Re: block assembly and mesurements

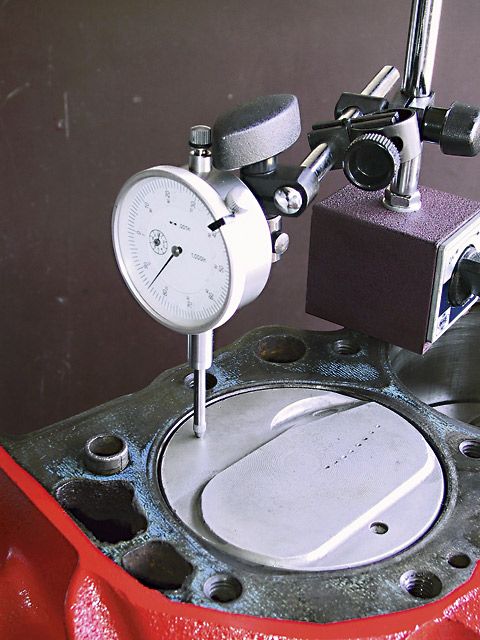

in the real world a difference between deck height on each of the two cylinder banks or between pistons in a bank of 3-5 thousands or more is common, and finding one thats out .020 or more is not all that rare (far from ideal, but common) but the deck should be perpendicular and square to the crank center-line, but its also common to have 2-3 thousands variation from end to end.(again , not ideal) all those should be at least in an ideal world,within .0015 or less in my opinion, on a correctly machined block.a good metal strait edge like a 2 foot long carpenters square and a .002 feeler gauge can give you some idea as to your blocks deck warpage .

Id be more concerned, with the deck measurement variations , end to end and your blocks deck warpage . than individual piston to deck measurements that can usually be minimized by juggling piston and rods during pre-assembly checks.

this is where it pays to spend money at a performance machine shop that specializes in precise work rather than your average local engine re-builders shop, thats usually not equipped to do precise machine work, and while its true you generally pay a bit more you also tend to get the closer tolerances that can make the difference between an average and an exceptional engine

obviously you may want to measure components like piston pin height

http://www.bhjproducts.com/bhj_download ... og_p25.pdf

http://www.auto-ware.com/combust_bytes/shortblock.htm

in the real world a difference between deck height on each of the two cylinder banks or between pistons in a bank of 3-5 thousands or more is common, and finding one thats out .020 or more is not all that rare (far from ideal, but common) but the deck should be perpendicular and square to the crank center-line, but its also common to have 2-3 thousands variation from end to end.(again , not ideal) all those should be at least in an ideal world,within .0015 or less in my opinion, on a correctly machined block.a good metal strait edge like a 2 foot long carpenters square and a .002 feeler gauge can give you some idea as to your blocks deck warpage .

Id be more concerned, with the deck measurement variations , end to end and your blocks deck warpage . than individual piston to deck measurements that can usually be minimized by juggling piston and rods during pre-assembly checks.

this is where it pays to spend money at a performance machine shop that specializes in precise work rather than your average local engine re-builders shop, thats usually not equipped to do precise machine work, and while its true you generally pay a bit more you also tend to get the closer tolerances that can make the difference between an average and an exceptional engine

obviously you may want to measure components like piston pin height

http://www.bhjproducts.com/bhj_download ... og_p25.pdf

http://www.auto-ware.com/combust_bytes/shortblock.htm

CNC BLOCKS

Member

Re: block assembly and mesurements

It would be best to wait till the temps come upt to at least 65 degrees as I have seen some build that were assembles in cold garages, We plate honed the block but you could see where things were not right when it was assembled in the cold.

jteu2002 said:the garage i am working is has no heating and the temp is about 45-50 F got no problem working in that temp

but what does it do to messurements to check my clearences on an engine build

ore is it bether to wait on higher temp ?

It would be best to wait till the temps come upt to at least 65 degrees as I have seen some build that were assembles in cold garages, We plate honed the block but you could see where things were not right when it was assembled in the cold.

Re: block assembly and mesurements

Grumpy,

I will tell you what we are working with and would be interested in your thoughts.

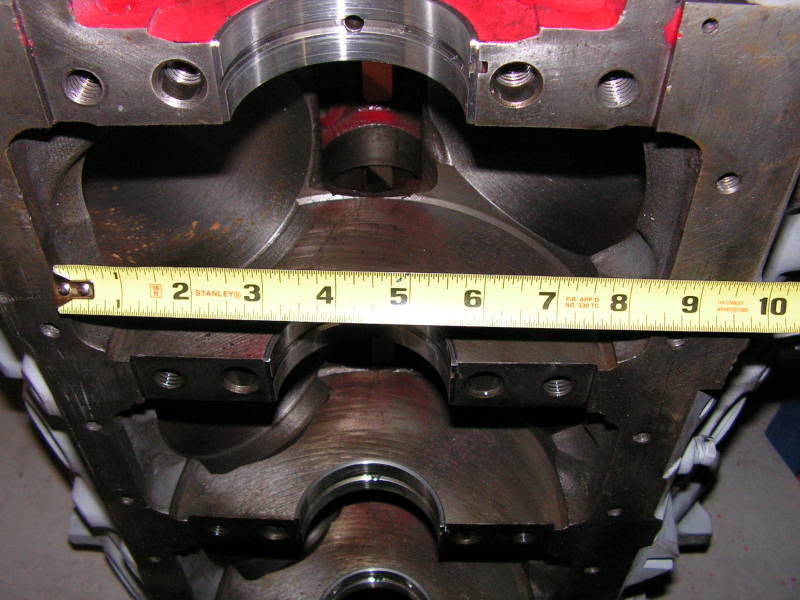

We have a pre prepped Summit 880 block that has supposedly been bored, plate honed (.030) aligned bored/honed and decked. An Enginekits new cast crank (3.75), reconditioned shotpeened rods with ARP stroker (6027) bolts with KB 134 flat top hyper 7cc relief pistons.

What we come up with deckwise is as follows:

1 .014 2 .008

3 .015 4 .0085

5 .0115 6 .005

7 .0145 8 .009

We seem to be good front to back on both banks, but have around .006 variance between banks. It would seem that .006 off the left bank would bring us to .004 max variation. We have plenty of P/V clearance so that would not be a problem. On cylinders 5 & 6 our inclination is that the crank may be off on that throw. It could be rod length or piston height, but both being on the same journal increases the odds of that possibility. We might be able to pick up a thousandth or two hole swapping. We are going to have the block inspected and see what is up. I'm not sure of the economic prudence of what it would cost to achieve an additional .0025 of conformity on 5 & 6, on a mid power, 90% street motor. Or for that matter what would be involved to achieve that gain.

Grumpy,

I will tell you what we are working with and would be interested in your thoughts.

We have a pre prepped Summit 880 block that has supposedly been bored, plate honed (.030) aligned bored/honed and decked. An Enginekits new cast crank (3.75), reconditioned shotpeened rods with ARP stroker (6027) bolts with KB 134 flat top hyper 7cc relief pistons.

What we come up with deckwise is as follows:

1 .014 2 .008

3 .015 4 .0085

5 .0115 6 .005

7 .0145 8 .009

We seem to be good front to back on both banks, but have around .006 variance between banks. It would seem that .006 off the left bank would bring us to .004 max variation. We have plenty of P/V clearance so that would not be a problem. On cylinders 5 & 6 our inclination is that the crank may be off on that throw. It could be rod length or piston height, but both being on the same journal increases the odds of that possibility. We might be able to pick up a thousandth or two hole swapping. We are going to have the block inspected and see what is up. I'm not sure of the economic prudence of what it would cost to achieve an additional .0025 of conformity on 5 & 6, on a mid power, 90% street motor. Or for that matter what would be involved to achieve that gain.

Re: block assembly and mesurements

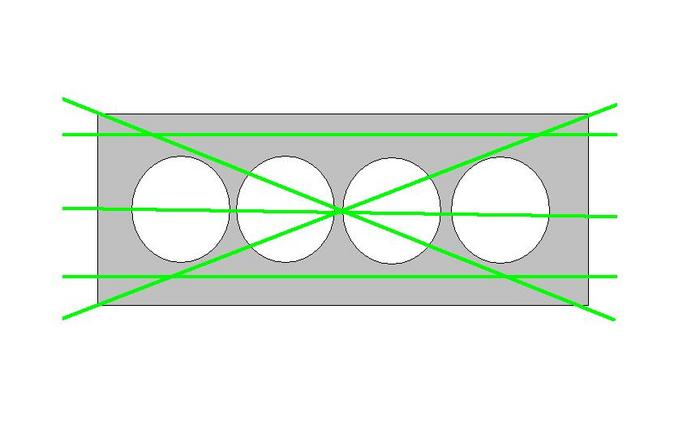

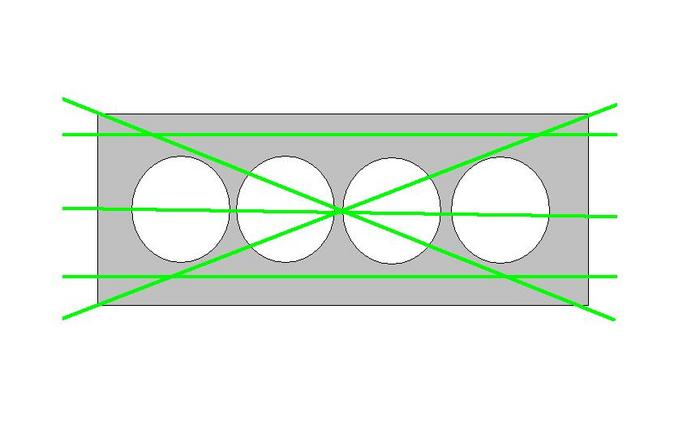

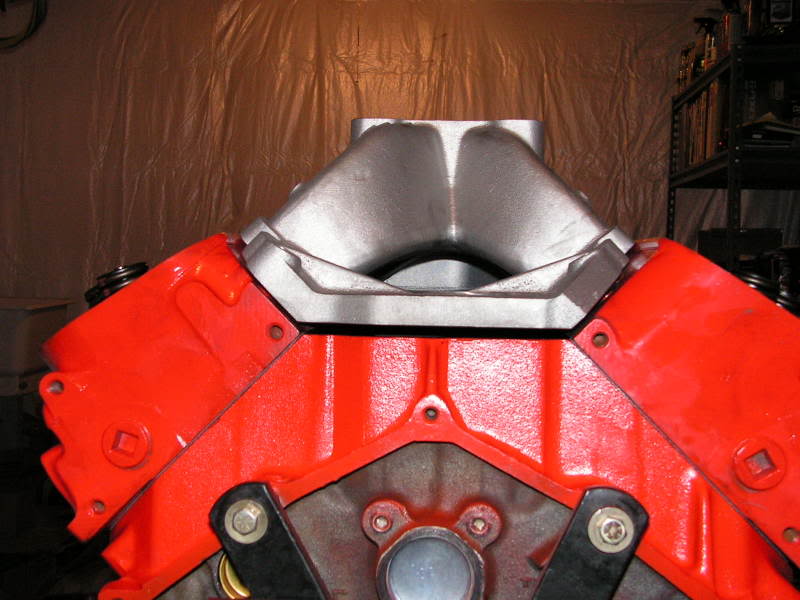

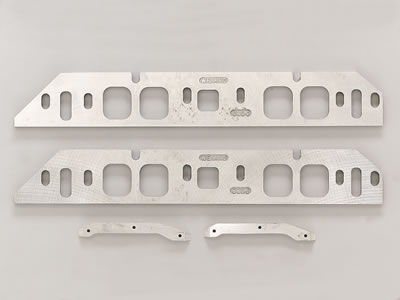

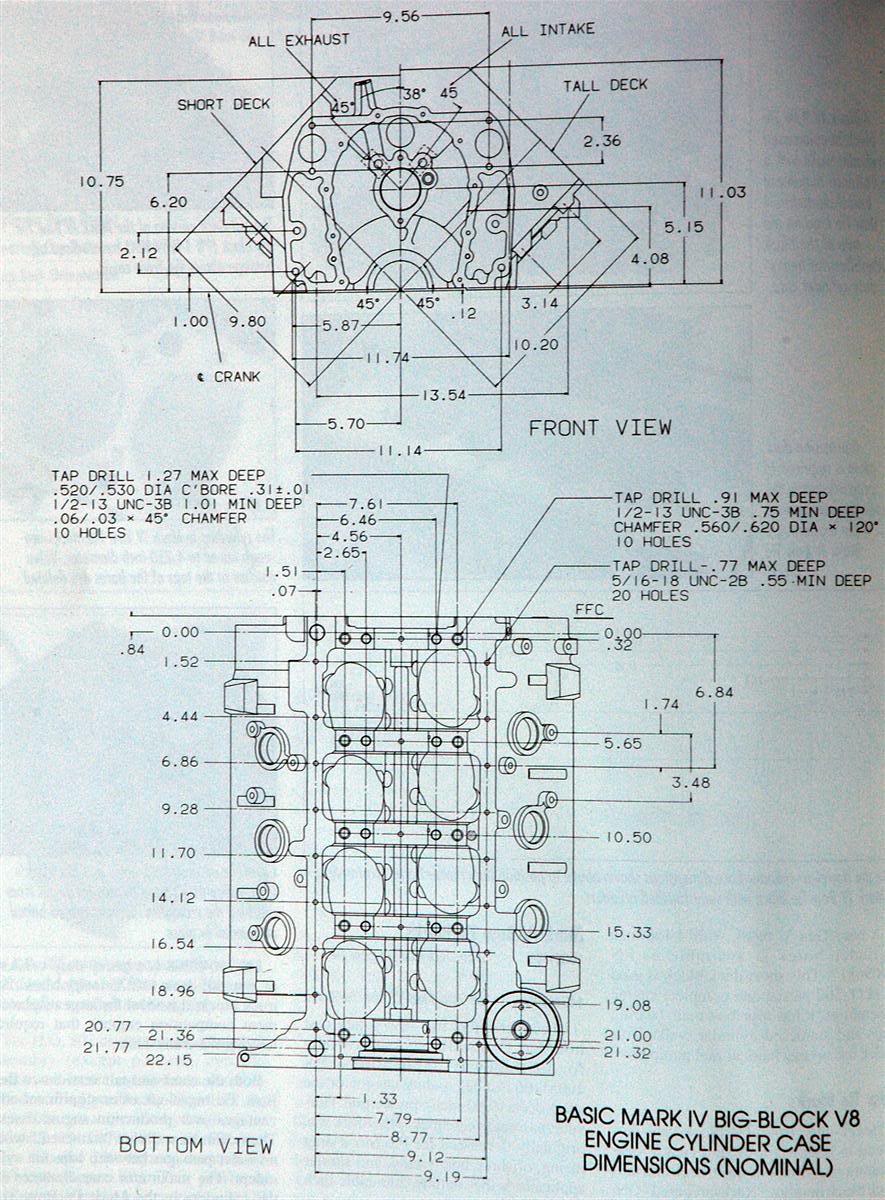

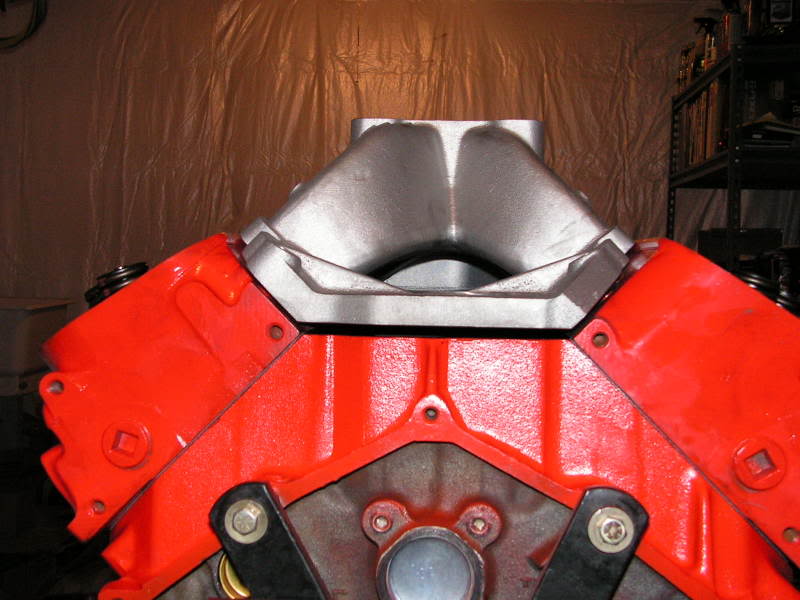

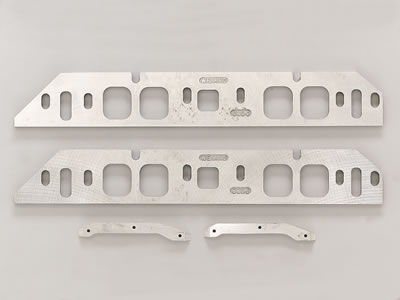

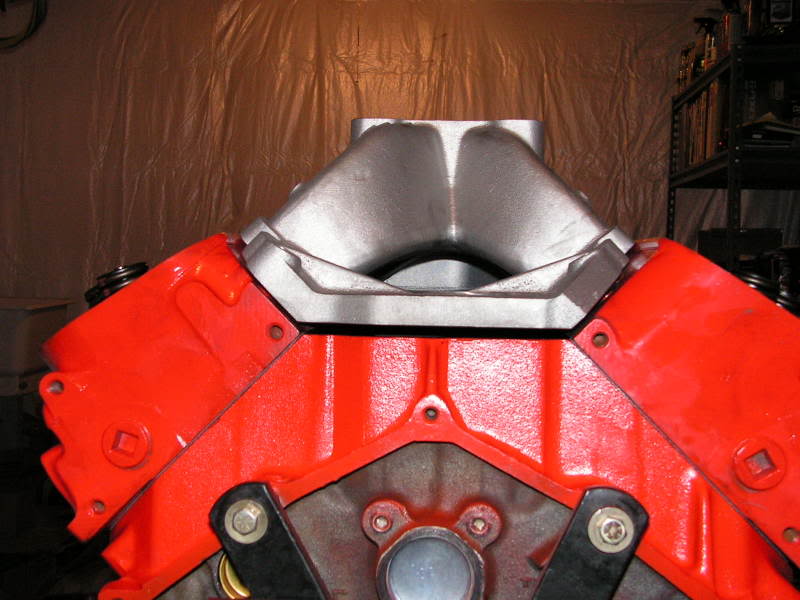

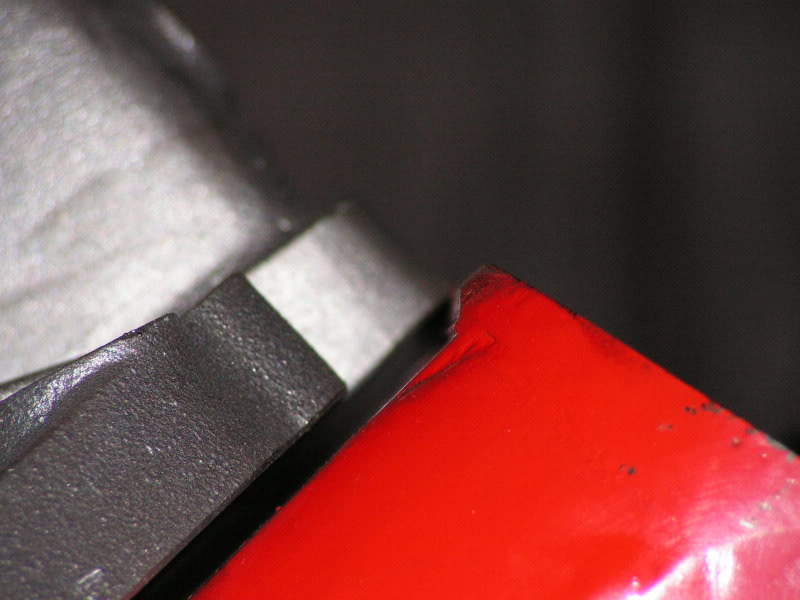

if your thinking of building a big block chevy, keep in mind theres two common block deck heights the standard pass car 9.8" and the taller truck block with its 10.2" deck height.pictures would help, but if its a tall deck block theres adapter plates

are used on a standard intake because of the greater distance between the gasket surfaces on the tall 10.2" tall deck block vs the standard 9.8" deck height, if the adapter plates look like these its a TALL TRUCK BLOCK, 427 based engine

why would anybody want to use adapter plates, if there are so many correct intakes available?

look here for tall deck intakes that should work

http://www.summitracing.com/search/?key ... take&dds=1

http://www.jegs.com/i/Edelbrock/350/2916/10002/-1

well its because the adapter plates allow you to use a standard intake on a tall deck block and the adapter plates are significantly less expensive than a tall deck intake which can ONLY be used on the tall deck block applications while the standard intake and adapter plate combo allows the intake to be used on either application

You tell the bare blocks apart by looking at the distance above the top water pump bolts to the block deck surface!

look very closely at the distance between the upper water-pump bolt holes, the standard block on the left is noticeably closer that the tall deck on the right

Shown on the diagram: 10.75" vs. 11.03" = .28" taller block china wall on the lifter gallery

thats true for the block china wall but not the intake

your forgetting the wider distance between the heads requires spacer plates and four intake gaskets, and end spacer plates each about 0.125" thick that raised the intake

trust me the intakes carb mount surface with the same intake used on a tall deck block sits about 5/8" higher on a tall deck application

read these links

viewtopic.php?f=54&t=4576

viewtopic.php?f=54&t=2187

viewtopic.php?f=54&t=64

viewtopic.php?f=53&t=204

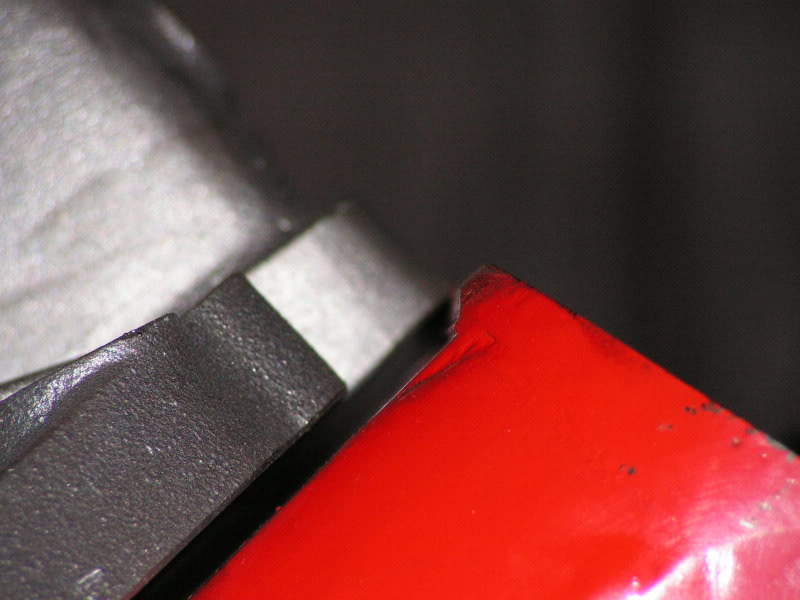

Tall deck blocks bolts are 3/4" from the bolt holes to the block decks while the more common pass blocks or standard deck blocks are about 3/8" from the upper water pump bolt holes from the block decks.

standard intake on tall deck block showing why spacers are required

standard block is clearanced for 8.5"

truck block for slightly wider 8 5/8"

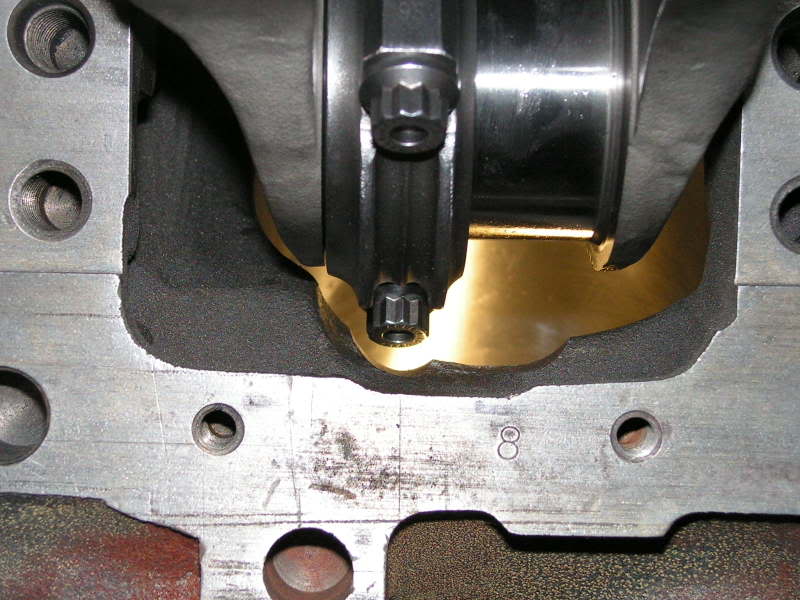

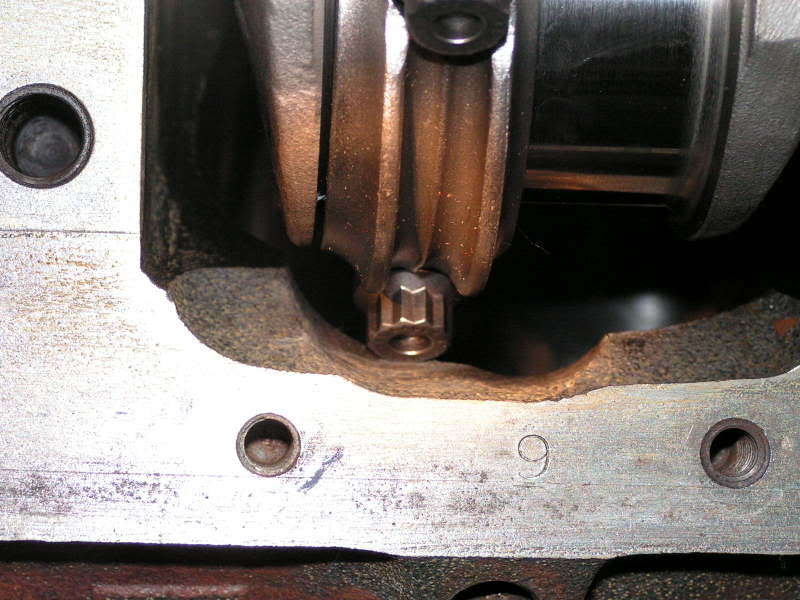

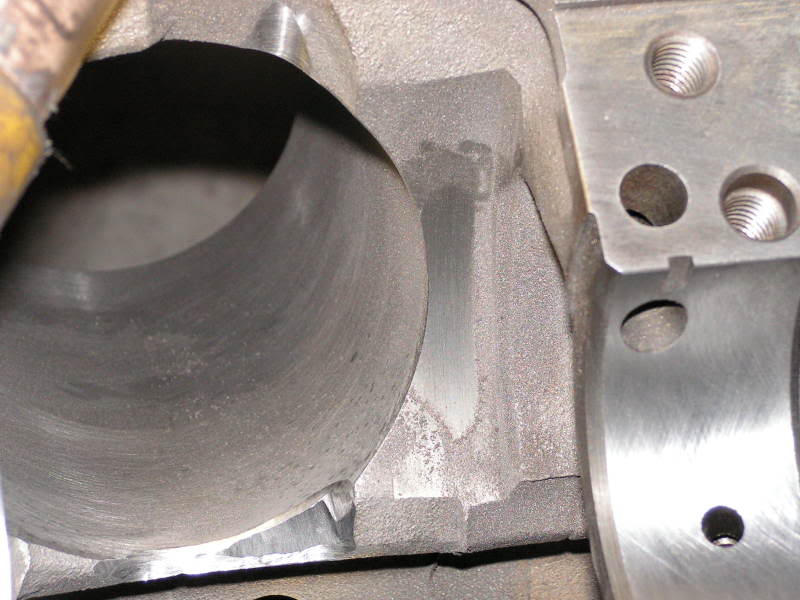

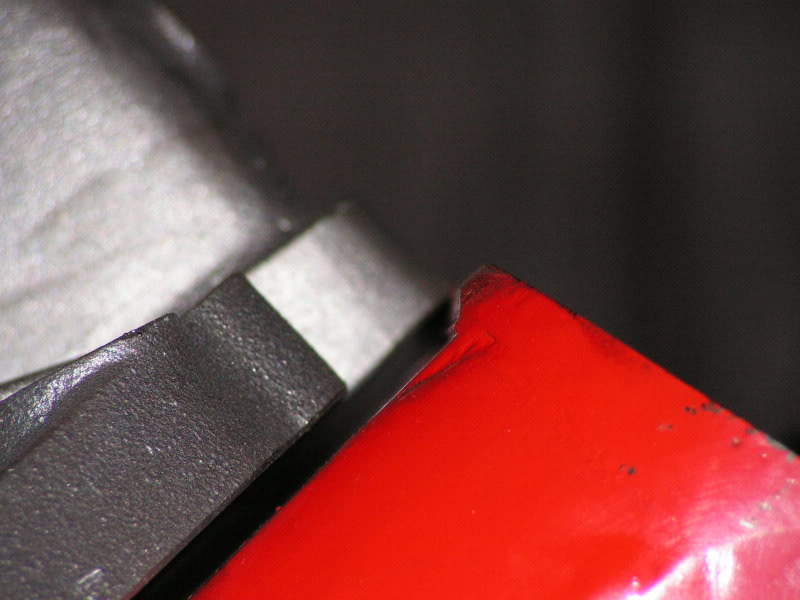

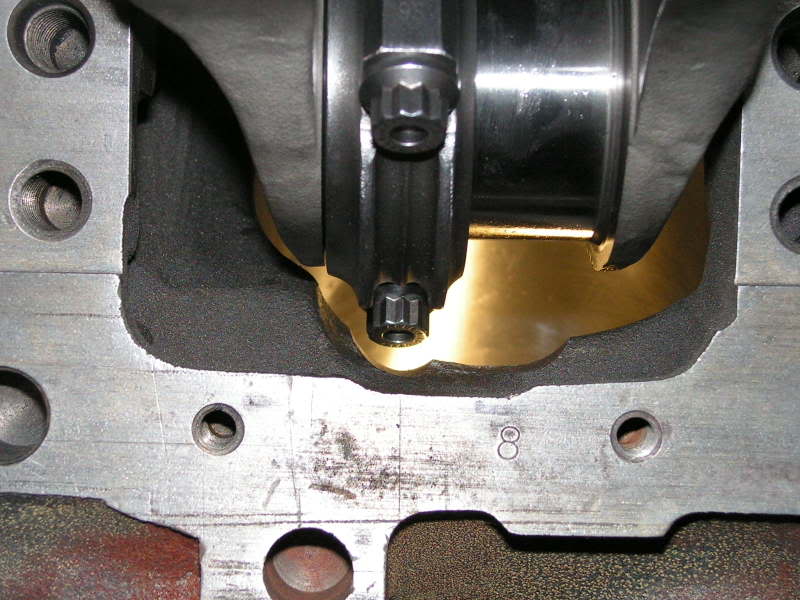

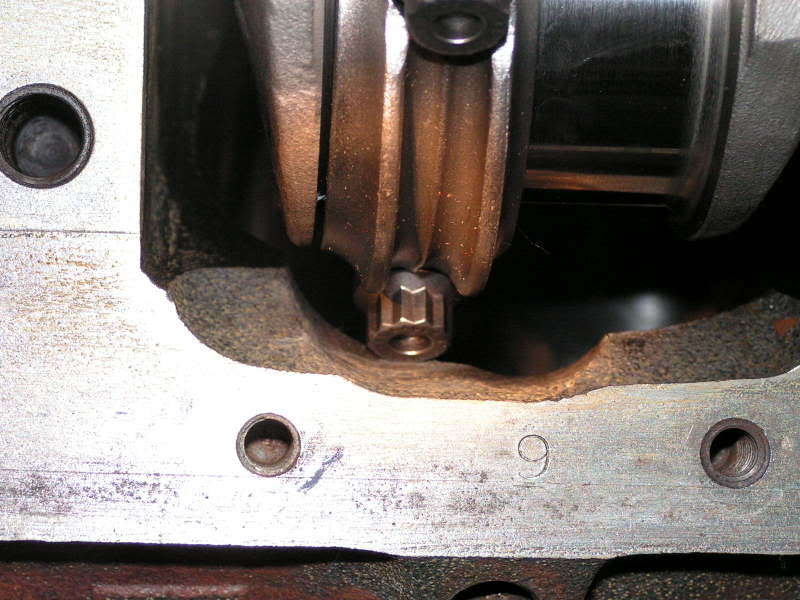

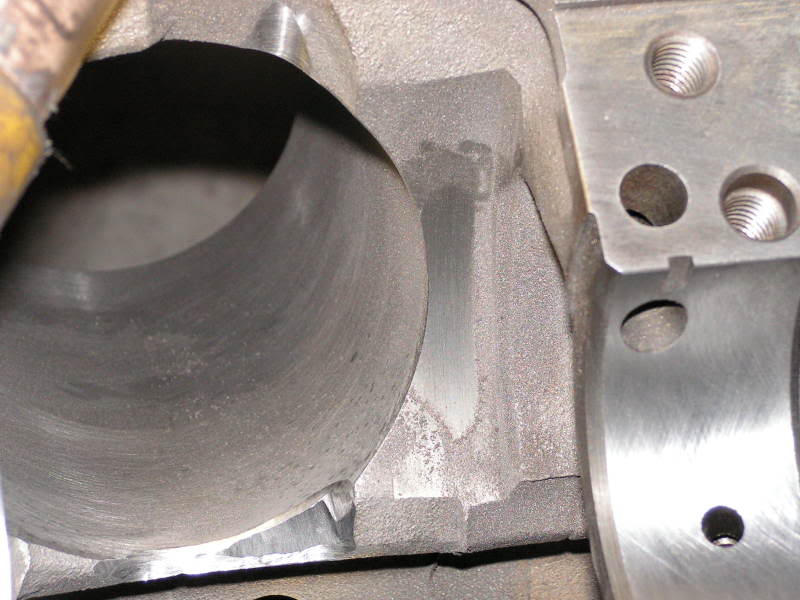

stroker cranks will frequently require the lower cylinder edges and outer block rails be clearanced ground to clear rod bolts and rods, but be very careful as the lower block casting is thin in some places

http://www.summitracing.com/parts/wnd-8206/overview/

http://www.summitracing.com/parts/mor-65090/overview/

I've frequently found these intake spacer plates that allow standard big block intakes to fit the tall deck blocks for $40-$80 at swap meets so look around before paying full ticket prices.

youll want a distributor with adjustable height locking collar

http://www.circletrack.com/techarticles ... tools.html

http://www.msdignition.com/Products/Dis ... butor.aspx

https://www.cpperformance.com/instructions/121-3560.pdf

http://www.smileysracing.com/shopping/p ... =20124&c=0

http://www.huntmagnetos.com/products/slip-collar.html

if you have access to a lathe, a lot of standard distributors can be modified to have a slide/slip locking height adjustment collar installed after the old fixed collars machined off

http://www.summitracing.com/parts/msd-85561

viewtopic.php?f=51&t=188&p=1634&hilit=tall+deck+block#p1634

viewtopic.php?f=51&t=2692&p=8174&hilit=tall+deck#p8174

viewtopic.php?f=69&t=5123

if your thinking of building a big block chevy, keep in mind theres two common block deck heights the standard pass car 9.8" and the taller truck block with its 10.2" deck height.pictures would help, but if its a tall deck block theres adapter plates

are used on a standard intake because of the greater distance between the gasket surfaces on the tall 10.2" tall deck block vs the standard 9.8" deck height, if the adapter plates look like these its a TALL TRUCK BLOCK, 427 based engine

why would anybody want to use adapter plates, if there are so many correct intakes available?

look here for tall deck intakes that should work

http://www.summitracing.com/search/?key ... take&dds=1

http://www.jegs.com/i/Edelbrock/350/2916/10002/-1

well its because the adapter plates allow you to use a standard intake on a tall deck block and the adapter plates are significantly less expensive than a tall deck intake which can ONLY be used on the tall deck block applications while the standard intake and adapter plate combo allows the intake to be used on either application

You tell the bare blocks apart by looking at the distance above the top water pump bolts to the block deck surface!

look very closely at the distance between the upper water-pump bolt holes, the standard block on the left is noticeably closer that the tall deck on the right

Shown on the diagram: 10.75" vs. 11.03" = .28" taller block china wall on the lifter gallery

thats true for the block china wall but not the intake

your forgetting the wider distance between the heads requires spacer plates and four intake gaskets, and end spacer plates each about 0.125" thick that raised the intake

trust me the intakes carb mount surface with the same intake used on a tall deck block sits about 5/8" higher on a tall deck application

read these links

viewtopic.php?f=54&t=4576

viewtopic.php?f=54&t=2187

viewtopic.php?f=54&t=64

viewtopic.php?f=53&t=204

Tall deck blocks bolts are 3/4" from the bolt holes to the block decks while the more common pass blocks or standard deck blocks are about 3/8" from the upper water pump bolt holes from the block decks.

standard intake on tall deck block showing why spacers are required

standard block is clearanced for 8.5"

truck block for slightly wider 8 5/8"

stroker cranks will frequently require the lower cylinder edges and outer block rails be clearanced ground to clear rod bolts and rods, but be very careful as the lower block casting is thin in some places

http://www.summitracing.com/parts/wnd-8206/overview/

http://www.summitracing.com/parts/mor-65090/overview/

I've frequently found these intake spacer plates that allow standard big block intakes to fit the tall deck blocks for $40-$80 at swap meets so look around before paying full ticket prices.

youll want a distributor with adjustable height locking collar

http://www.circletrack.com/techarticles ... tools.html

http://www.msdignition.com/Products/Dis ... butor.aspx

https://www.cpperformance.com/instructions/121-3560.pdf

http://www.smileysracing.com/shopping/p ... =20124&c=0

http://www.huntmagnetos.com/products/slip-collar.html

if you have access to a lathe, a lot of standard distributors can be modified to have a slide/slip locking height adjustment collar installed after the old fixed collars machined off

http://www.summitracing.com/parts/msd-85561

viewtopic.php?f=51&t=188&p=1634&hilit=tall+deck+block#p1634

viewtopic.php?f=51&t=2692&p=8174&hilit=tall+deck#p8174

viewtopic.php?f=69&t=5123

hey grumpy?

i do have a hiv rev performance built 498 stroker, based on a 427 tall deck in my chevelle.

it has hi-compression (11.5) rectangular iron heads, headers, solid lifter roller rocker cam, single plane intake ect. motor was built by the previous owner a few years ago.

problem: its consuming a considerably amount of oil, about 1 quart per 60 miles.

i just had the heads redone, with new umbrella style valve stems. still consumes that much.

but the engine does not burn oil when idling, nor leaks. i had a fellow driving behind, no blue smoke. no smell.

can´t get behind that issue. are the tall decks known for higher oil consumption in high rev situations? i have a 4.11 rear, so high rev situations are common.

any tips?

http://www.edelbrock.com/automotive_new ... 0/2916.pdf

if anything the tall decks tend to burn less oil, if you've had the car up on a lift and theres no leaks,Id check to see if the PVC is sucking oil, but it sounds like the piston to bore clearance or ring seal is a bit loose, it may be time for a bore job on the block, to the next larger bore size and hone with deck plates and new pistons,and rings

obviously a LEAK-DOWN TEST WOULD HELP prove or dis-prove THAT!

viewtopic.php?...

getting only 60 miles to the quart its obviously going some place,a common problem is defective intake gaskets that allow oil to be sucked from the lifter gallery, ID suggest carefully replacing the intake gaskets and inspecting the intake ports for evidence of oil leaks in the intake ports, ESPECIALLY if your using adapter plates

READ THRU THIS THREAD

viewtopic.php?f=69&t=5123

standard intake on tall deck block showing why spacers are required

can you post clear pictures of the spark plugs