Ok pulled the rotating assembly out today and had a good look at every thing

The block had the same wear in all the cylinders all about the same one with a little more, I dont think the rings was file fit, the bearings are toast and I think the crank might need to be turned it has some marks

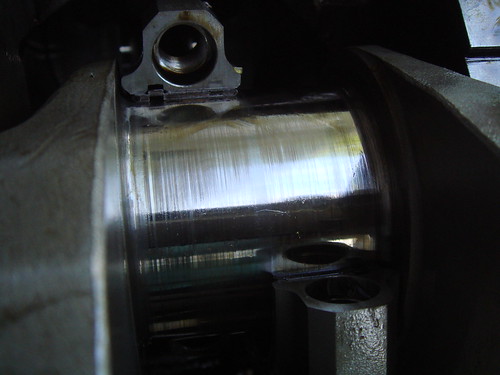

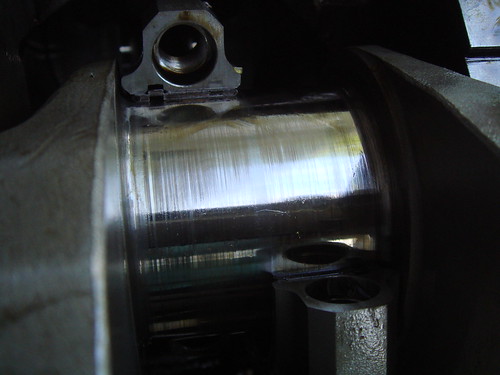

is this normal to have this wear in all the cylinders like this with low miles? I included one of the crank (the worst one)

The block had the same wear in all the cylinders all about the same one with a little more, I dont think the rings was file fit, the bearings are toast and I think the crank might need to be turned it has some marks

is this normal to have this wear in all the cylinders like this with low miles? I included one of the crank (the worst one)