there's not a thing wrong with almost any decent oil with a high concentration of wear additives for the break-in process, IM sure that royal purple oil would do its job just as designed

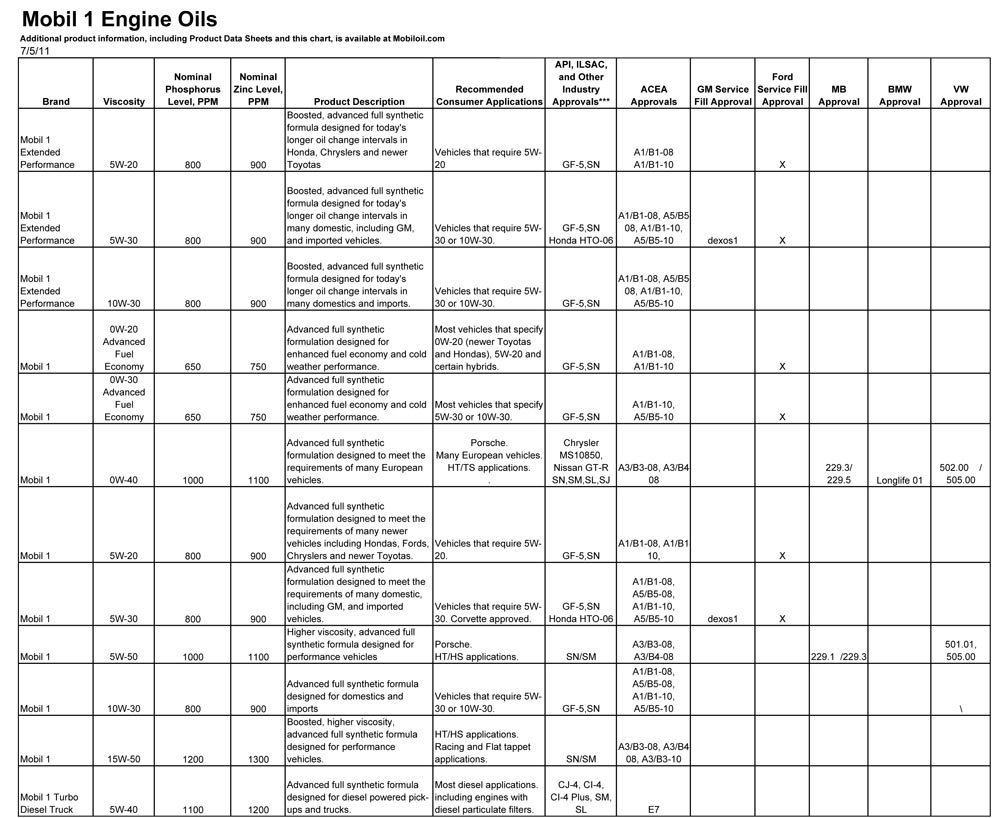

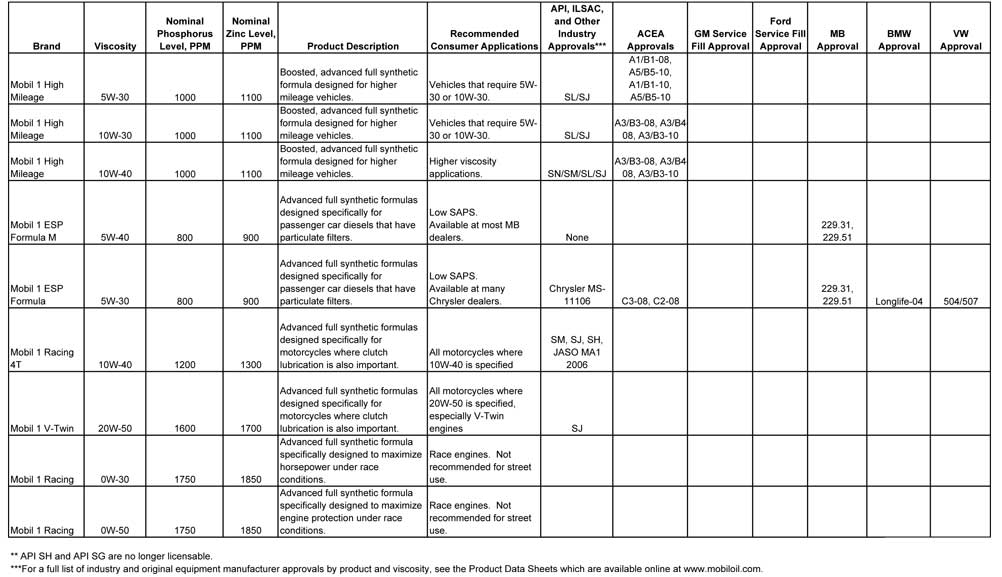

use logic, there's millions of new engines getting broken in, with standard 10w30 oils, just select one with a high concentration of wear additives (thats currently mostly the diesel rated oil, look at the chart posted below)

If you want to use that oil , it will be fine, your going to be dumping the break-in oil and filter in the first 3-4 hours of run time at most if your doing your best to prevent wear,

(THE BREAK-IN PROCESS,IS WHERE A NEW ENGINES PARTS MOVING SURFACES LAP INTO A COMPATIBLE,MATCHING SURFACE FINNISH)

the standard 10w 30 oils either synthetic or mineral base can be used, the synthetics have a reputation for taking longer for the components to seat correctly but the new corvettes are shipped full of synthetic oil so its hardly likely the manufacturer would do that if it would become a major problem.

OBVIOUSLY you need to use a good moly assembly lube on the bearings and cam and lifters in a flat tappet engine,

if you want to pay extra for a couple of quarts of oil and a filter that you should run, drain and replace within a few hundred miles use be my guest, but the standard HAVOLINE,VALVOLINE,TEXACO,SHELL, ETC 10w30 oil and a qt of MARVEL MYSTERY OIL and a CAN OF G.M. E. O.S. and a new oil filter, has worked just fine for hundreds of engines IVE built or seen broken in, now IN sure the break-in oil has more friction reducers added, like zinc, & phosphorus but that's a double edge sword, in that it will help cam lobe life but slow rings seating to the cylinder walls, and the E.O.S. has that in large amounts, the MARVEL MYSTERY OIL has solvents and detergents to remove crud quickly,if your running a flat tappet cam you should be running a oil with those in the formula like most diesel oils and the MOLY assembly lube you use on the cam and lifters has other friction reducers

Ive almost always used about 90% of a good brand of synthetic oil and 10% marvel mystery oil in my engines for MANY years, I generally change both the oil and oil filters in the 5000-7000 mile range and they always come apart during inspections looking like new, what many guys don,t realize is that M.M.O. is just a high quality light oil with a high percentage of solvents and detergents, its not an oil additive in the common sense of the word, just an oil that tends to dissolve crud effectively.

I usually drain the engines break-in oil for the first time after I break in a cam after about 3-6 hours of driving , because by that time the cam lube and any metallic trash is at least in theory trapped in the oil filter , I generally throw on a new oil filter and fill the cars engine with something like SHELL 10w30 , the $20-$30 in fresh oil being "WASTED" is dirt cheap insurance if it allows you to remove potentially destructive metallic debris, and run the engine that way for at least 300-1000 miles and change oil again, the idea is to drain and remove as much metallic dust that is generated during the rings and lifters lapping in process as possible, then from that time on, change oil and filter every 5000-7000 miles

BTW a few magnets, placed in the oil pan sump to trap metallic dust mixed in the oil is a big advantage, changing the oil and oil filter during the first 300 miles helps for the long engine life.

you really need to read thru these threads, and the sub linked info provided carefully, look at the oil heat ranges, zinc content and what moly assembly lube does to protect moving surfaces, what filters work, etc.

viewtopic.php?f=52&t=282&hilit=+break

http://www.bobistheoilguy.com/index.php ... &Itemid=62

http://people.msoe.edu/~yoderw/oilfilte ... study.html

http://www.hotrod.com/pitstop/hrdp_0702 ... index.html

http://micapeak.com/info/oiled.html

viewtopic.php?f=44&t=799&p=2048&hilit=+procedure#p2048

IT should be obvious that you'll need to pre-prime the blocks oil passages and adjust the rockers so oil flows from the rockers with the engine being pre-primed with a priming tool being used BEFORE trying to start any engine with a new cam to insure oil flow begins instantly on the engines start-up,you WON,T get oil to all lifters equally unless the engines crank & cam are spinning,(so during testing spin the engine slowly with a breaker bar or ratchet), because the oil passages feeding the lifters aligns differently at different lifts,your oil leak at the distributor base is normal, but the clearances and flow may be excessive, with a priming tool, some are not nearly to spec. ID measure the diam. of the oil pump primer and then measure the distributor base, Id bet the distributor base is larger and fits better, which reduces the potential for leakage.

those bottom two bands form a wall on the oil passage, some guys cut a rounded grove and install an O-RING so the upper band seals too the block, you don,t want to do that to the lower band simply because that's the oil flow source to the distributor /cam gear

20 psi is about normal for your typical 3/8 drill,max pressure is not nearly as important as checking flow, and for leaks where there should not be leaks, with an engine primer tool,Ive brazed a socket to the top of my oil pump primer and use the 1/2" drive air ratchet to drive it, it won,t heat up and burn up like a electric drill will.

don,t get alarmed if you get zero pressure or flow for a few seconds,(the oil filter and passages need to fill first) that's one reason WHY your pre-priming, to get oil flow to the bearings instantly on start up , you don,t want them running without oil flow if you can prevent it even for 20 seconds

a 1/2" drive air ratchet

will not heat up like an electric drill if your using either to spin the pre-lube tool.

http://www.amazon.com/Chicago-Pneumatic ... B000NOX2OY

READ THIS THREAD

viewtopic.php?f=54&t=985&p=3802#p3802

one common problem I see many guys go thru is the result of not understanding what visual clues, or obvious symptoms indicate, when they see them.

when your breaking in a new engine or cam, one common problem indicator is the headers running excessively hot

EXAMPLE

btw notice the front header tube seems to be a bit cooler and each header tube as you move to the rear looks a bit hotter, thats because the engine compartment air flow cools the headers less effectively as its heated as it moves from the radiator rear ward

the picture above is commonly the result of having Your ignition timing too retarded for the 2500rpm-3500rpm your supposed to be lapping a new cam in at for the first few minutes,or the ignition advance curve rpm is to slow with a light load. Under a light load combustion is a slower process. Some of the combustion is still taking place after the exhaust valve opens which will make the headers glow.

if your running a LEAN due to either jetting, tuning issues or a large vacuum leak....the overly lean fuel/air mix tends to raise the exhaust temps, obviously an IR temp gun can be very useful in spotting this condition early, but its even more useful because it can easily tell you if only one or two headers are running significantly hotter, usually indicating a vacuum leak or tuning issue rather than ignition timing where all the header tubes tend to run hot.

now obviously you should have verified the correct oil and coolant levels and verified your ignition timing and advance and firing order before starting it , or seeing the headers glow before letting the engine run very long