" HEY GRUMPY?, I wanted to get your thoughts on a engine combo, I race asphalt circle track with a stock car. we have a 360cu in motor rule, have to run a production cast iron block, and heads. Flat top pistons and 2 barrell 500cfm holly carb. everyone at the track is just punching a 350 60 over and has very similar motors. I want to think outside the box. So I'm planning to build a 353 cubic inch motor by using a 400 block and a 3.25 stroke. With the idea of turning it 8500-9000rpm keeping the motor in the power band all the time. any input on parts, or recommendations on the best way to make this work would be appreciated. "

well Im my opinion a great deal depends on a close reading of the CLASS AND TRACK RULES

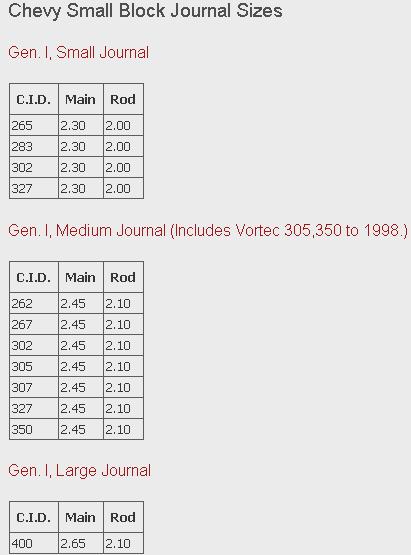

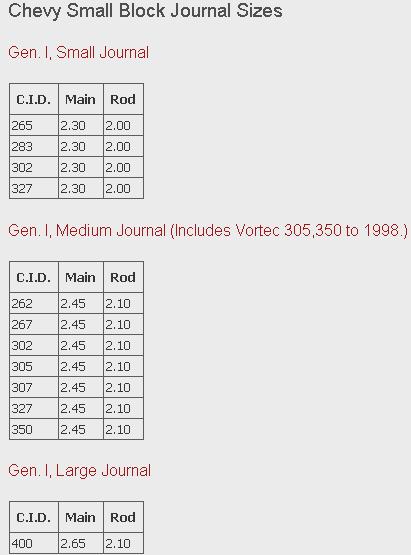

heres why, Ive built the 327 crank in a 400 block

usually requires bearing spacers that a good machine shop can fabricate

To align-bore the mains on a 400 block, the rear-main-seal journal must be cut from the stock 2.641-inch diameter to 2.841 so the tool can slip through. Afterwards, use Fel-Pro spacer seal kit PN 2909.

Read more: http://www.hotrod.com/techarticles/engi ... tml#photos#ixzz2862gPd9o

The 400 block has larger main-bearing bores than a 350 (2.650 versus 2.450). To use a 350 crank in a 400 block, install these Comp Cams PN 5620 spacers, then use conventional bearings. Jeff used Speed-Pro race bearings, PN M139-10.

Read more: http://www.hotrod.com/techarticles/engi ... z2861yRv2z

usually the 400 blocks bored .030 over size with spacer bearings. in the past Id be using 6.125" connecting rods

http://www.summitracing.com/parts/SCA-6612521/

http://www.kb-silvolite.com/kb_car/perf ... ls&P_id=74

, 1.261 compression height pistons

http://kb-silvolite.com/calc.php?action=piston_comp

this results in a 6.125 rod +1.261+compression height and 1.625 stroke length in a standard 9.023 un-decked block measuring 9.011, with the typical .032 head gasket and heads that flow at least 250 cfm at .500 lift you come out just fine

now reguarding the carb flow

you need a cam with decent overlap like a crane 110981, and compression near 10.5:1

a carb rated at 500 cfm is measured at 1.5: of mercury increase the vacuum and it easily flows 700 cfm

but having an intake thats not restrictive like

this

http://www.summitracing.com/parts/HLY-300-110/?rtype=10

helps flow

http://users.erols.com/srweiss/calcdchg.htm

next you'll ask is it worth it?, well if your restricted to 360 cid displacement and your allowed to use aftermarket heads and a solid lifter flat tappet cam, the answers very truly YES it will produce better hp than a standard 350, but if limited to a having a hydraulic cam, stock heads and intake its not likely to be worth the time and cash outlay

you might find this worth reading

http://www.airflowresearch.com/articles ... /A3-P1.htm

well Im my opinion a great deal depends on a close reading of the CLASS AND TRACK RULES

heres why, Ive built the 327 crank in a 400 block

usually requires bearing spacers that a good machine shop can fabricate

To align-bore the mains on a 400 block, the rear-main-seal journal must be cut from the stock 2.641-inch diameter to 2.841 so the tool can slip through. Afterwards, use Fel-Pro spacer seal kit PN 2909.

Read more: http://www.hotrod.com/techarticles/engi ... tml#photos#ixzz2862gPd9o

The 400 block has larger main-bearing bores than a 350 (2.650 versus 2.450). To use a 350 crank in a 400 block, install these Comp Cams PN 5620 spacers, then use conventional bearings. Jeff used Speed-Pro race bearings, PN M139-10.

Read more: http://www.hotrod.com/techarticles/engi ... z2861yRv2z

usually the 400 blocks bored .030 over size with spacer bearings. in the past Id be using 6.125" connecting rods

http://www.summitracing.com/parts/SCA-6612521/

http://www.kb-silvolite.com/kb_car/perf ... ls&P_id=74

, 1.261 compression height pistons

http://kb-silvolite.com/calc.php?action=piston_comp

this results in a 6.125 rod +1.261+compression height and 1.625 stroke length in a standard 9.023 un-decked block measuring 9.011, with the typical .032 head gasket and heads that flow at least 250 cfm at .500 lift you come out just fine

now reguarding the carb flow

you need a cam with decent overlap like a crane 110981, and compression near 10.5:1

a carb rated at 500 cfm is measured at 1.5: of mercury increase the vacuum and it easily flows 700 cfm

but having an intake thats not restrictive like

this

http://www.summitracing.com/parts/HLY-300-110/?rtype=10

helps flow

http://users.erols.com/srweiss/calcdchg.htm

next you'll ask is it worth it?, well if your restricted to 360 cid displacement and your allowed to use aftermarket heads and a solid lifter flat tappet cam, the answers very truly YES it will produce better hp than a standard 350, but if limited to a having a hydraulic cam, stock heads and intake its not likely to be worth the time and cash outlay

you might find this worth reading

http://www.airflowresearch.com/articles ... /A3-P1.htm