ENGINE BUILDING TOOL Shopping WISH LIST List

ENGINE STAND

Tapered Ring Compressor

THIS BEAM STYLE TORQUE WRENCH IS THE TYPE TORQUE WRENCH YOU WANT TO CHECK ROTATIONAL RESISTANCE

BUT NOT WHAT YOULL USE TO TIGHTEN HEAD BOLTS

HUSKY $88 (worked rather well, over all I was pleased)

http://www.homedepot.com/p/Husky-1-2-in-Click-Torque-Wrench-H2DTW/202916180?N=5yc1vZc6ev

FOR HEAD BOLTS AND MAIN CAP STUDS ETC.

youll need a good quality torque wrench

Piston Ring Squaring Tool

http://www.grumpysperformance.com/[/B]

ringsqtool.jpg

damper tool

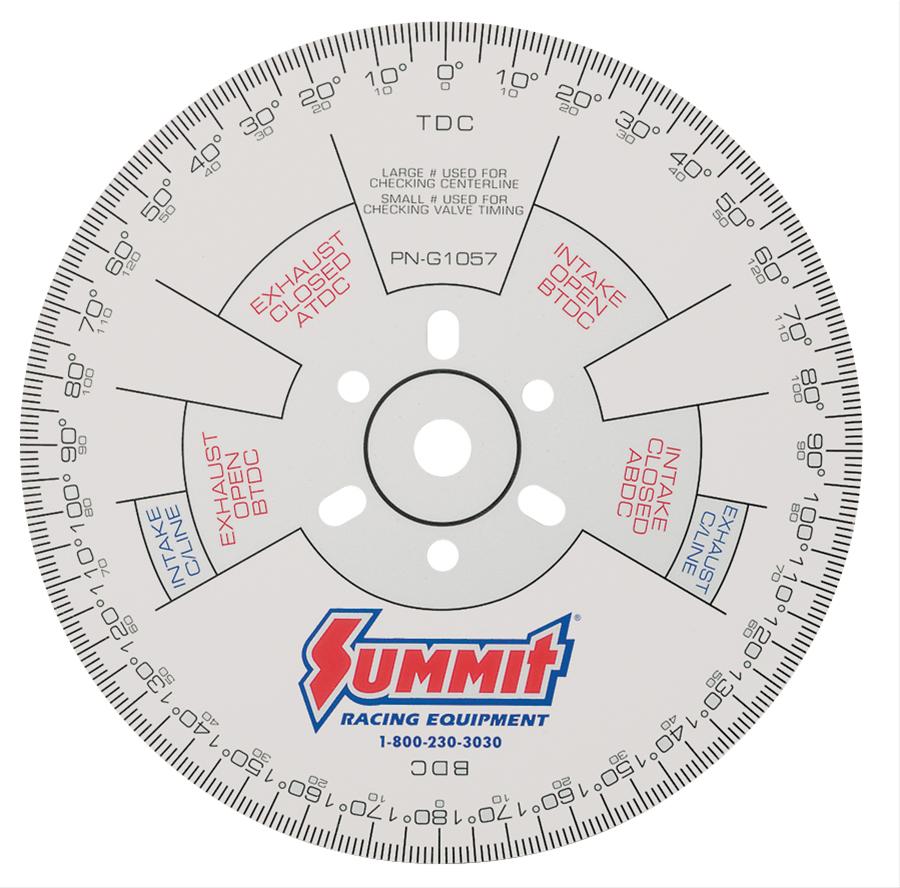

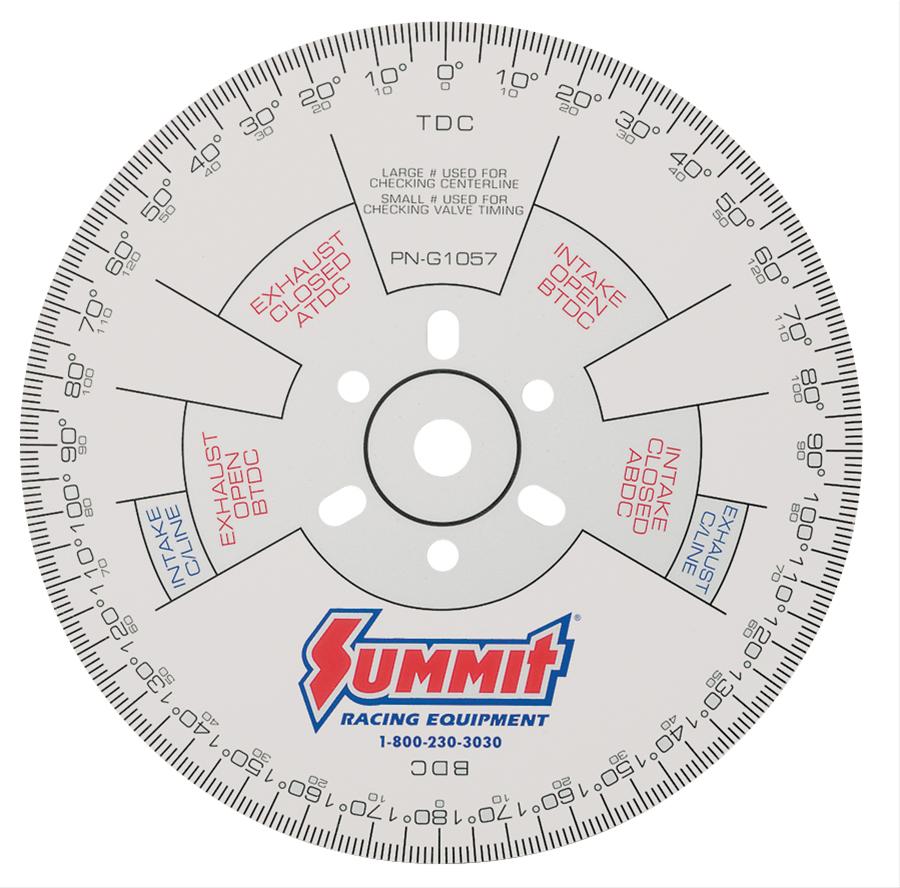

Degree Wheel

checking lifter

degree wheel

Dial Bore Gauge

Pushrod Length Checker

http://www.summitracing.com/search/...d-length-checkers?autoview=SKU&ibanner=SREPD5

Proform Pushrod Length Checkers 66789 SBC 3/8" rocker studs

Proform Pushrod Length Checkers 66790 SBC 7/16" rocker studs

Proform Pushrod Length Checkers 66806 BBC 7/16" rocker studs

Oil Pump Primer

http://www.harborfreight.com/36-piece-3 ... 60669.html

harbor freight has cheap and perfectly acceptable calipers

http://www.harborfreight.com/6-in-dial-caliper-62362.html

http://www.harborfreight.com/1-inch-travel-machinists-dial-indicator-623.html

http://www.harborfreight.com/multipositional-magnetic-base-with-fine-adjustment-5645.html

spring micrometers,

a crank snout, turning socket,

a dead blow mallet ,

a can of moly spray lube,

DECK BRIDGE

http://www.summitracing.com/parts/PRO-66797/

ring install pliers

piston ring filer,

GEAR PULLERS

http://www.hotrod.com/how-to/engine/ccrp-9901-affordable-engine-building-tools/

http://www.powerhouseproducts.com

https://www.proformtools.com/

http://www.bierbros.net/EngineBuildingAndPrecisionTools.html

http://www.superchevy.com/how-to/148-0505-engine-building-tools/

http://www.goodson.com/

ENGINE STAND

Tapered Ring Compressor

THIS BEAM STYLE TORQUE WRENCH IS THE TYPE TORQUE WRENCH YOU WANT TO CHECK ROTATIONAL RESISTANCE

BUT NOT WHAT YOULL USE TO TIGHTEN HEAD BOLTS

HUSKY $88 (worked rather well, over all I was pleased)

http://www.homedepot.com/p/Husky-1-2-in-Click-Torque-Wrench-H2DTW/202916180?N=5yc1vZc6ev

FOR HEAD BOLTS AND MAIN CAP STUDS ETC.

youll need a good quality torque wrench

Piston Ring Squaring Tool

http://www.grumpysperformance.com/[/B]

ringsqtool.jpg

damper tool

Degree Wheel

checking lifter

degree wheel

Dial Bore Gauge

Pushrod Length Checker

http://www.summitracing.com/search/...d-length-checkers?autoview=SKU&ibanner=SREPD5

Proform Pushrod Length Checkers 66789 SBC 3/8" rocker studs

Proform Pushrod Length Checkers 66790 SBC 7/16" rocker studs

Proform Pushrod Length Checkers 66806 BBC 7/16" rocker studs

Oil Pump Primer

http://www.harborfreight.com/36-piece-3 ... 60669.html

harbor freight has cheap and perfectly acceptable calipers

http://www.harborfreight.com/6-in-dial-caliper-62362.html

http://www.harborfreight.com/1-inch-travel-machinists-dial-indicator-623.html

http://www.harborfreight.com/multipositional-magnetic-base-with-fine-adjustment-5645.html

spring micrometers,

a crank snout, turning socket,

a dead blow mallet ,

a can of moly spray lube,

DECK BRIDGE

http://www.summitracing.com/parts/PRO-66797/

ring install pliers

piston ring filer,

GEAR PULLERS

http://www.hotrod.com/how-to/engine/ccrp-9901-affordable-engine-building-tools/

http://www.powerhouseproducts.com

https://www.proformtools.com/

http://www.bierbros.net/EngineBuildingAndPrecisionTools.html

http://www.superchevy.com/how-to/148-0505-engine-building-tools/

http://www.goodson.com/

Last edited: