You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Building a stand/dollie for the V8

- Thread starter DorianL

- Start date

mathd

solid fixture here in the forum

Hey, looks for a engine cradle.DorianL said:Hey All,

I searched around here but could not find it - do we have any blueprints on how to make a wooden stand for the SBC for transport in a trailer. Will add casters there after.

Thanks

D

All the guys here make they own using a welder and some backyard steel

Bolt on the back of the engine(where bellhousing bolt) and have the front/sides of the oil pan rail rest on some tubing.

I look for picture of mine on my computer and i will post it here.

http://www.summitracing.com/parts/SUM-910057/

at this price its barely worth plugging in the MIG and making a trip to the metal supply house

BTW most of my friends simply welded up their own stands using old motor mounts and 2" box steel and spare casters, but you might want to consider .. buying an engine stand and welding up a second temporary use,MUCH shorter center head holder so you can temporarily, remove the original one, and install the temporary short one for transport duty, so you can simply slide the head out of the original stand, swap to the lower custom center stand support bolted in its place, for transport than swap back, when the engine stands in use

adding much better quality casters increases the price considerably but will be making them far FAR more user friendly, because they roll far easier, and you can lock the wheels when working on the engine making torquing the bolts far safer and easier

http://www.harborfreight.com/8-inch-cus ... 46819.html

http://www.harborfreight.com/2000-lb-fo ... 67015.html

viewtopic.php?f=27&t=3724

making a second, bolt on,shorter modified, support section to swap out, and insert the existing engine holding tool head into for transport use, something similar to this would make it nearly impossible to tip over during transport in the back of a pick-up truck for example

(IF you transport engines frequently both the short replaceable center stand and welding on 4 to 6 d-rings to the engine stand base to simplify the tie down procedure would be a good idea on a stand used for engine transportation, these rings welded to both the front and rear engine stand frame corners for ease of transport, and security on the trailer or in the pick-up bed add security,at times)

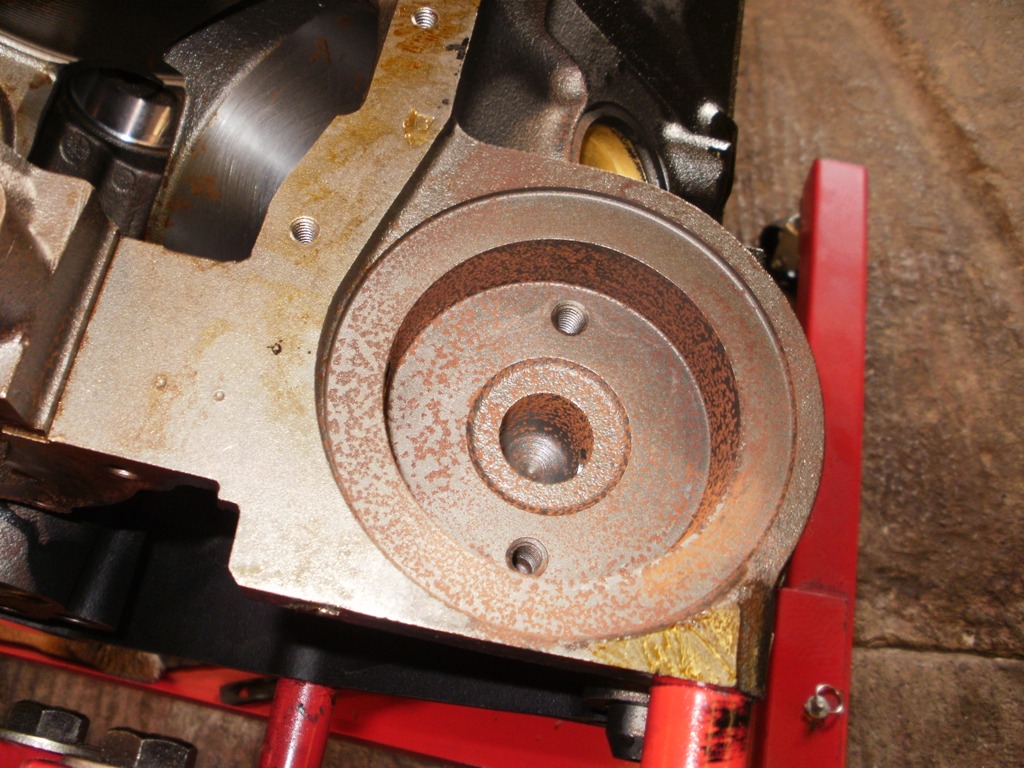

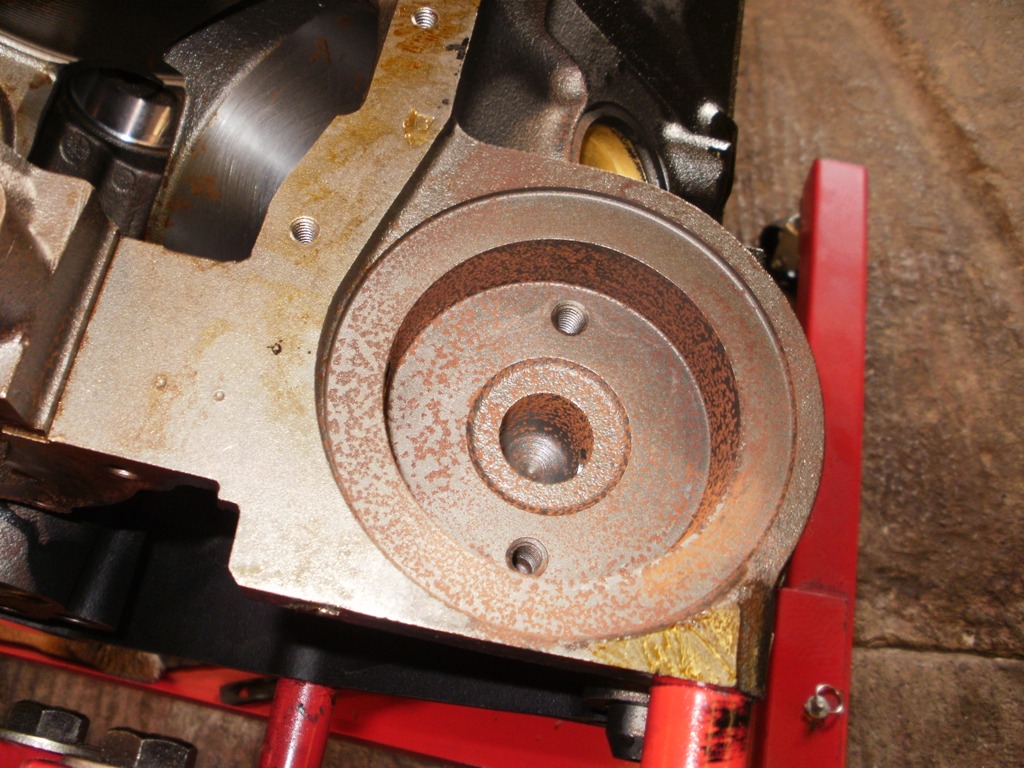

heres an example of a newly machined block that was shipped without proper rust proofing

its a shame the block was not carefully rust proof barrier coated before it was packed and shipped, but from the pictures it appears to be cosmetic rather than functional damage, to the block surface, that should clean up with machine oil and emery cloth, just be sure to clean the internal oil passages and degrease and paint the blocks non-machined surfaces to prevent further oxidation and lock in micro crud, its always a good idea to paint the non-machined surfaces and clean the oil passages, and coat the machined surfaces with a rust protection barrier oil,and store the block in sealed plastic bag with some desiccant, hanging below the engine in a separate package not in contact with the block during even short term storage.

LPS #3 leaves a grease/wax barrier that lasts for years on a well sealed engine block or crank machined surfaces

http://www.summitracing.com/parts/MOR-99400/

http://forum.grumpysperformance.com/viewtopic.php?f=51&t=125

http://garage.grumpysperformance.com/index.php?threads/engine-storage-frame-for-your-shop.16499/

at this price its barely worth plugging in the MIG and making a trip to the metal supply house

BTW most of my friends simply welded up their own stands using old motor mounts and 2" box steel and spare casters, but you might want to consider .. buying an engine stand and welding up a second temporary use,MUCH shorter center head holder so you can temporarily, remove the original one, and install the temporary short one for transport duty, so you can simply slide the head out of the original stand, swap to the lower custom center stand support bolted in its place, for transport than swap back, when the engine stands in use

adding much better quality casters increases the price considerably but will be making them far FAR more user friendly, because they roll far easier, and you can lock the wheels when working on the engine making torquing the bolts far safer and easier

http://www.harborfreight.com/8-inch-cus ... 46819.html

http://www.harborfreight.com/2000-lb-fo ... 67015.html

viewtopic.php?f=27&t=3724

making a second, bolt on,shorter modified, support section to swap out, and insert the existing engine holding tool head into for transport use, something similar to this would make it nearly impossible to tip over during transport in the back of a pick-up truck for example

(IF you transport engines frequently both the short replaceable center stand and welding on 4 to 6 d-rings to the engine stand base to simplify the tie down procedure would be a good idea on a stand used for engine transportation, these rings welded to both the front and rear engine stand frame corners for ease of transport, and security on the trailer or in the pick-up bed add security,at times)

heres an example of a newly machined block that was shipped without proper rust proofing

its a shame the block was not carefully rust proof barrier coated before it was packed and shipped, but from the pictures it appears to be cosmetic rather than functional damage, to the block surface, that should clean up with machine oil and emery cloth, just be sure to clean the internal oil passages and degrease and paint the blocks non-machined surfaces to prevent further oxidation and lock in micro crud, its always a good idea to paint the non-machined surfaces and clean the oil passages, and coat the machined surfaces with a rust protection barrier oil,and store the block in sealed plastic bag with some desiccant, hanging below the engine in a separate package not in contact with the block during even short term storage.

LPS #3 leaves a grease/wax barrier that lasts for years on a well sealed engine block or crank machined surfaces

http://www.summitracing.com/parts/MOR-99400/

http://forum.grumpysperformance.com/viewtopic.php?f=51&t=125

http://garage.grumpysperformance.com/index.php?threads/engine-storage-frame-for-your-shop.16499/

Last edited by a moderator: