theres several obvious and a couple less obvious things to check,start by pulling trouble codes, checking for loose electrical connections and vacuum lines.

A steady rhythmic surging,or pulse in the engine idle normally suggests a vacuum leak, or air fuel mixture imbalance issue, a random surging or cutting out at idle generally indicates a electrical or mechanical issue, especially if it tends to kick in as you apply throttle, Keep in mind the word "GENERALLY" as this can and will be only good as basic a guide line to think about. I would check all your vacuum lines,move them around and replace any that are suspect, do the propane torch test to locate vacuum leaks and look carefully at the air filter to throttle body clamps and tubes for splits and clamps for loose or improper alinement , obviously youll want to check see if there are any stored trouble codes, and loose electrical connectors and test sensors resistance or voltage values.

lots of guys , make the big mistake of overlooking partly clogged catalytic converters or defective oxygen sensors because getting under the cars not always easy.

Id start with checking the injector resistance and verify pulse with NOID LIGHTS , check the fuel rail pressure and ignition timing and advance, , ALL SHOULD BE OBVIOUS PLACES THAT COULD CAUSE PROBLEMS , loose electrical connections and grounds are always suspect, the most common cause I find for the lag,well (after verifying its not injector or fuel pressure or OXYGEN SENSOR RELATED or ignition , or knock sensor related,problem )obviously those should be checked , is problems related too the manifold and engine and air heat sensors, those sensors seem to be able to function well enough not to throw trouble codes but not always well enough to allow the engine to run perfectly

THESE THREADS AND SUB LINKS MAY HELP

grab a multi meter and check the sensor resistance and for a good electrical connection

http://www.harborfreight.com/5-in-1-dig ... 98674.html

having a fluke multi meter and an assortment of test leads helps

FLUKE is the brand of choice but they are expensive, shop around, Ive still got the original fluke multi meter I bought in HIGH SCHOOL and it STILL WORKS Ive purchase several imported multi meters from harbor freight , in the last 10 years alone and only one still works

http://www.fluke-direct.com/shop/itemDe ... urer=FLUKE

http://www.fluke-direct.com/shop/catego ... TERS&path=

viewtopic.php?f=80&t=728&p=43477&hilit=camaro+sensors#p43477

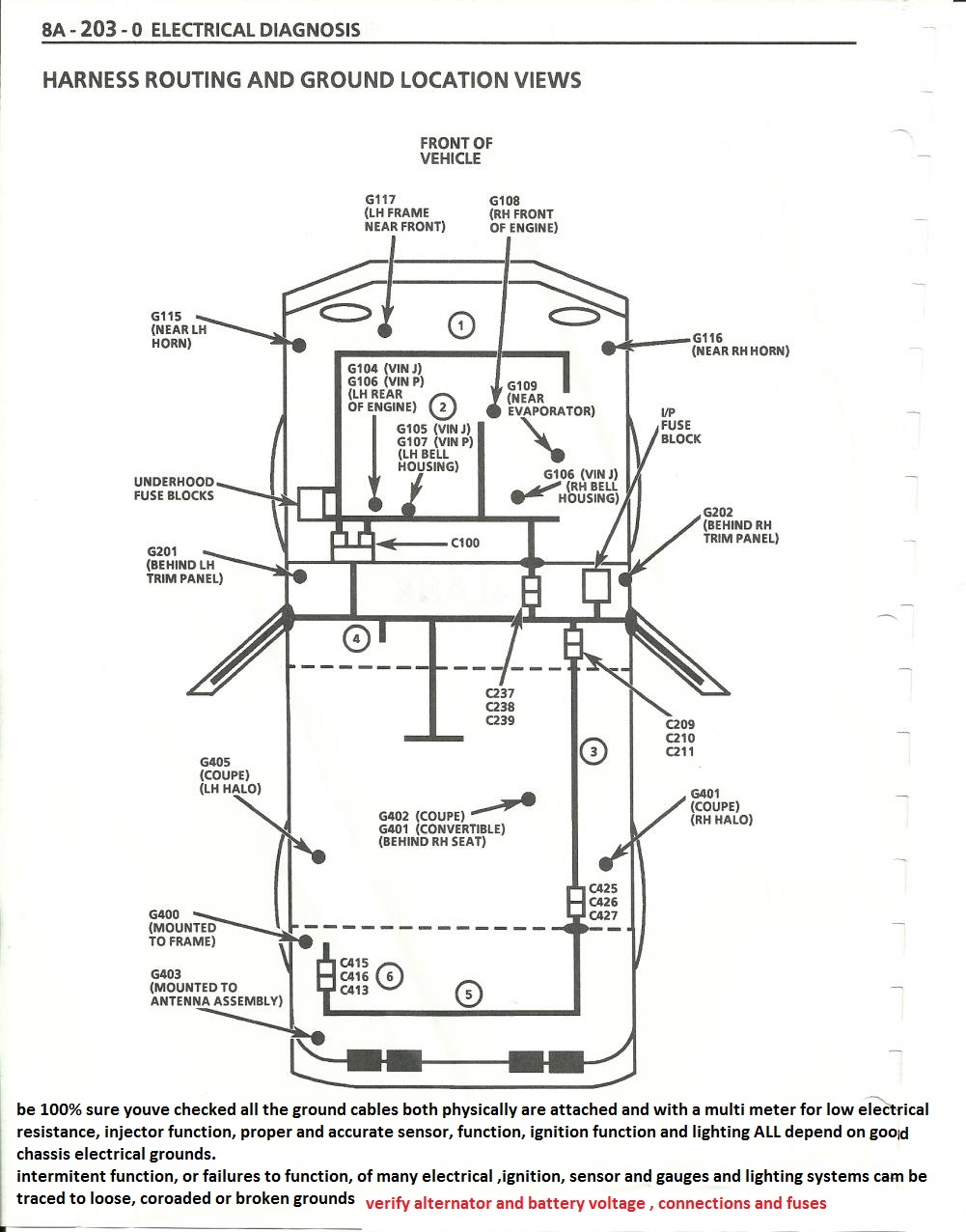

viewtopic.php?f=50&t=9478&p=34812&hilit=grounds#p34812

viewtopic.php?f=32&t=9778&p=36976&hilit=camaro+sensors#p36976

viewtopic.php?f=32&t=2697

viewtopic.php?f=32&t=596

viewtopic.php?f=32&t=10349

viewtopic.php?f=32&t=2697&p=29270&hilit=vacuum+lines#p29270

Re: C4 sensor and relay/switch locations and info

http://www.corvettebuyers.com/c4vettes/ ... mation.htm

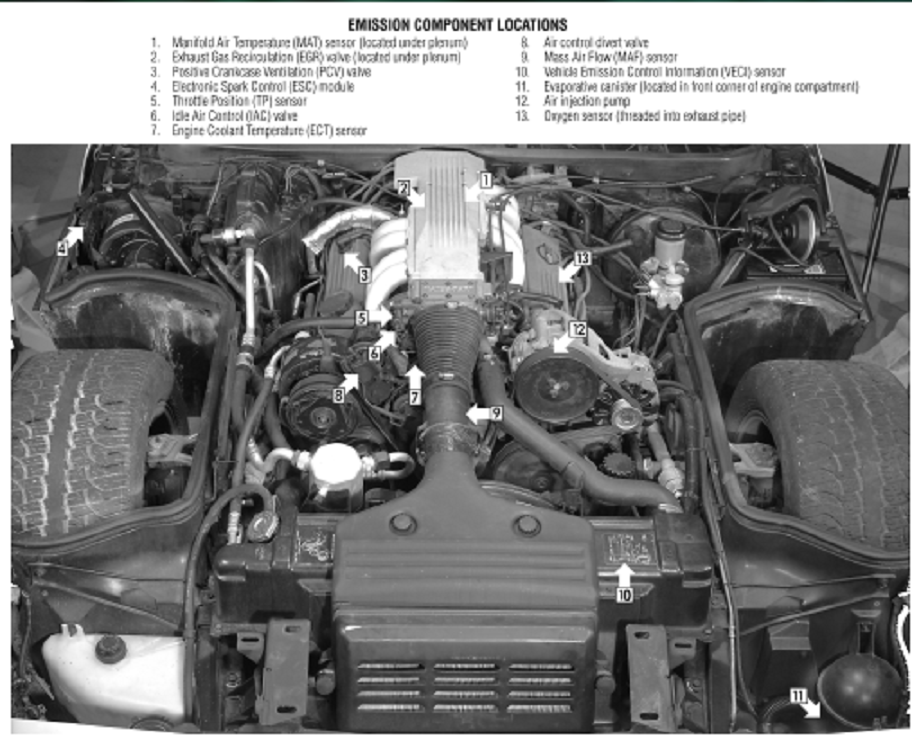

EMISSION COMPONENT LOCATIONS

Measured Value

Engine Coolant Temperature Sensor. 185 Ohms @ 210F, 3400 Ohms @ 68F, 7,500 Ohms @ 39 F.

Engine Oil Temperature Sensor. 185 Ohms @ 210 F, 3400 Ohms @ 68 F, 7,500 Ohms @39 F.

Oil Pressure Sender/Switch. 1 Ohms @ 0 PSI, 43 Ohms @ 30 PSI, 86 Ohms @ 60 PSI.

Fuel Quantity Sender. 0 Ohms @ Empty, 45 Ohms @ 1/2 Full, 90 Ohms @ Full.

MAT (Manifold Absolute Temperature Sensor). 185 Ohms @ 210 F, 3400 Ohms @ 70 F, 15,000 Ohms @ 40 F.

Outside Temperature Sensor. 4400 Ohms @ 60 F, 2200 Ohms @ 85 F.

In Car Temp Temperature Sensor. 4400 Ohms @ 60 F, 2200 Ohms @ 85 F.

MAF (Mass Air Flow) Sensor. .4 Volts @ idle, 5 Volts @ Full Throttle.

Oxygen (O2) Sensor. .1 Volt Lean Mixture, .9 Volt Rich Mixture.

TPS (Throttle Position Sensor). .54 Volts Idle, ~ 5 Volts Full Throttle.

Sensor Locations

Sensor

Location

Engine Coolant Temperature Sensor. Front of engine, below Throttle Body.

Engine Oil Temperature Sensor. Left rear of engine, just above the oil filter.

Oil Pressure Sender/Switch. Top, left hand rear of engine.

Fuel Quantity Sender. Top of fuel tank, beneath filler pipe escutcheon panel.

MAT (Manifold Absolute Temperature Sensor). Underside of manifold air plenum at rear.

Outside Temperature Sensor. Right side of engine, top right corner of radiator.

In Car Temp Temperature Sensor. Coupe: above left seat near interior courtesy light, Convertible: center of cargo compartment lid.

MAF (Mass Air Flow) Sensor. Front of engine ahead of throttle body.

Oxygen (O2) Sensor. Left side of engine, in exhaust pipe.

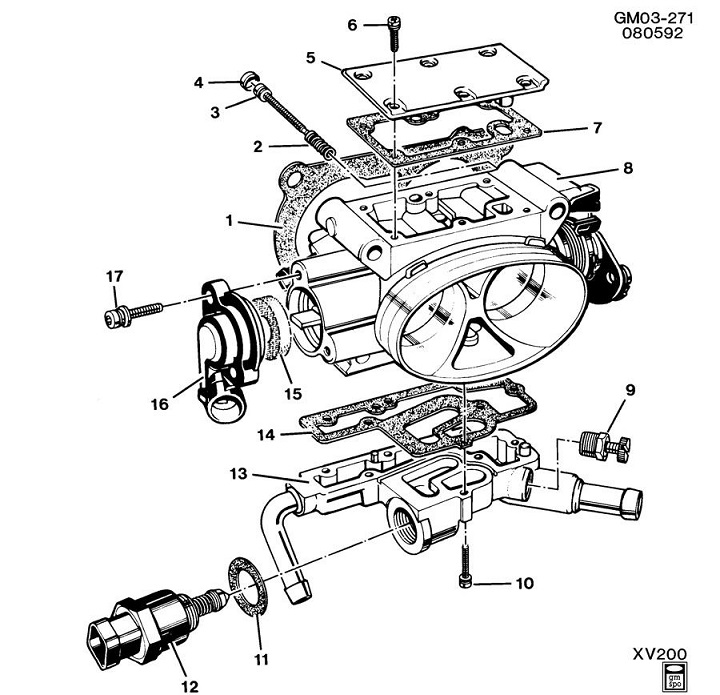

TPS (Throttle Position Sensor). Right side of throttle body at the front.