Carburetor Air Flow Ratings:

What Do They Really Mean?

RATINGS ARE CONSTANTLY QUOTED AND COMPARED, BUT ARE ACTUALLY ONE OF THE LEAST UNDERSTOOD AND MOST CONFUSING AREAS OF RACING DESIGN.

. The basis for most cubic feet per minute (C.F.M.) air flow ratings such as those used by Holley and other carburetor manufacturers was established long ago by the Society of Automotive Engineers (S.A.E.).

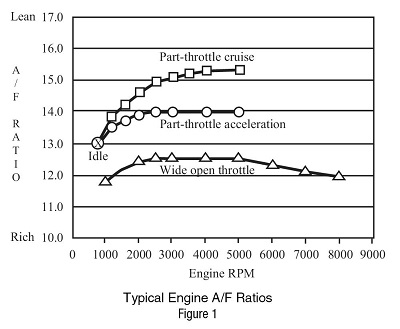

Standard test vacuum was 1-1/2 inches of mercury for 4 barrel carburetors and 3 inches of mercury “Vacuum” for 1 barrel and 2 barrel carburetors. This was reasonable as it was about what a passenger car would develop. Of course, for the numbers to mean anything, tests would have to be run at a certain temperature and barometric pressure. Or be corrected to standard temperature and pressure. If not otherwise stated, ratings in cubic feet per minute are at standard temperature and pressure.

This system is confusing for racing applications for several reasons. Some racing engines actually develop much more or less vacuum than these ratings, so are difficult to compare. For example, a Nascar 390, 4 barrel equipped car might have 3 times the 1-1/2 inches of mercury standard or a very large 2 barrel equipped car might have only 1-1/2 inches of mercury vacuum.

Even more confusing is the fact that most flow benches in the racing industry measure dry air at low pressure drops, commonly 10 inches of water column (W.C.), one bore or venturi at a time. This result is multiplied by a factor to arrive at what that bore would flow at a higher vacuum (i.e. 1-1/2 or 3 inches of mercury), then that figure is multiplied (by four, in the case of a 4 barrel carburetor) to get the C.F.M. rating. This rating is usually much higher than it actually is.

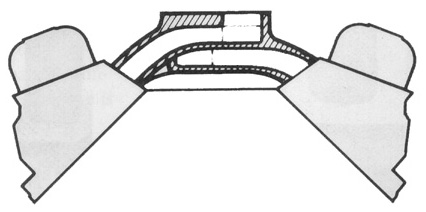

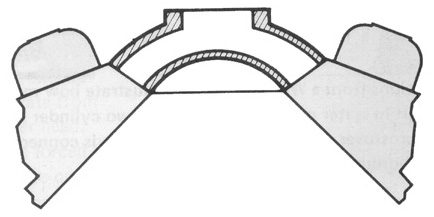

Besides previously mentioned airflow calculations, multiplying, reading and measuring errors, four bores will not flow four times what one bore will flow when they are close together, as in a 4 barrel carburetor. The bores are actually “fighting” for the same air. Another factor is no provision is made for fuel flow. The actual air flow will be 8% to 16% less “wet” than dry flow rating. Two reasons for this are, fuel takes up space so it uses up space for air. The second reason is fuel has more mass than air so “Hollow Cone” of vaporized fuel slows down flow velocity. This can be easily observed on large wet flow benches such as the custom C&S facility (shown in photo) which will flow wet or dry. Alcohol carbs will lose more air flow than gas simply because there is more fuel to handle.

In order to properly specify or compare carburetors much more must be known than simply a number. Not to mention the dishonest practice of inflating ratings to increase sales.

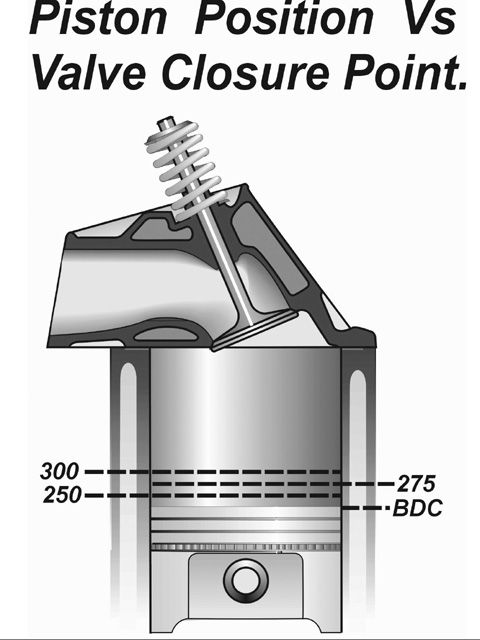

Another common pitfall is using widely published carburetor size selector charts that use parameters such as engine size, lowest RPM at wide open throttle etc. Drawing a line across the selector indicates maximum recommended carburetor size. These calculations are for Street Cars. If used for racing, the engine would be expected to develop 1-1/2 inches of mercury vacuum at wide open throttle (W.O.T.) unless prohibited by rules, using a larger carburetor will result in much improved racing performance.

Engines that need a broad RPM range such as Road Racing or Circle Track currently work best generating about .8 to 1 inch of mercury. Heavy drag cars will work at .6 to 1 inch depending on weight to horsepower ratio. Some light drag cars such as Pro Stock and Dragsters have C&S carburetors so large they generate only .1 to .2 inches of mercury vacuum and work very well at the high RPM narrow RPM range for these cars.

In conclusion, the general trend is larger and larger carburetors for every application. The carburetor that wouldn’t work several years ago for a certain application wasn’t too big, it just wasn’t good enough!

The C&S technical line is available to consult on your application free of charge. Call Mon. thru Fri., 7 a.m. to 5 p.m. at (636) 723-4996.