B

bob

Guest

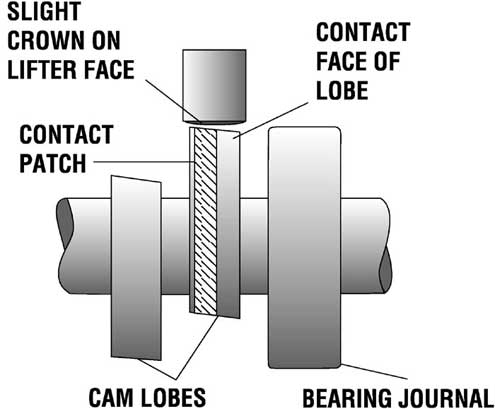

I was reading on a different site that its a good idea to throw a couple extra quarts of oil into an engine during the initial ring and cam/lifter break-in period, the theory being that the higher level of oil gaurantees a great deal more oil getting thrown on the cam and lifter contact area,by the spinning crank assembly, during the break-in process thus at least in theory keeping the lifter bases and cam lobe contact area much cooler and better lubricated?

now the first thing that I thought of is won,t that over power the oil rings?

and will it really provide any more lubrication?

now the first thing that I thought of is won,t that over power the oil rings?

and will it really provide any more lubrication?