Highveelocity said:I just took down my 383, never was happy with the power it had, and I'm looking for a cam recommendation. I will say that before I took this thing back apart, I added AFR 195 street heads with a Howards cam that was wiped out in 30, yes 30 miles(wondering if the spring pressure was too much for a flat tappet.). Yes, I added the zinc additive and followed proper break in procedures. Anyway, my combo is a .030 over 4 bolt block, nitrided 400 Chevy crank, Scat I beam rods, Probe forged flat top pistons, zero decked, .038 quench dimension and approximately 10.5 DCR, with the 75 cc AFR's milled down. Quadrajet marine carb with Edelbrock performer and 1 3/4 headers My Jeep is 4700 lbs, 35 inch tires, 4:56 gears, turbo 400. It's not a daily driver, and I want it to sound AND BE bad ass. I want the most power I can get out of it with a 2800 stall or lower, a flat tappet solid lifter cam, and Oh, BTW, I have no minimum vacuum requirements, I have hydroboost brakes

many more modern oil formulations lack the correct additives for flat tappet lifters, so be very sure you check to see what oil your using and if its designed for flat tappet lifter applications

obviously you would or should talk to the manufacturer before purchasing any cam, about your combo, and how well the cam selected matches your needs but this comes close to what your asking for

http://www.jegs.com/i/Lunati/638/301205 ... 7AodNyIA-Q

http://www.summitracing.com/parts/pro-66830/overview/

https://www.harborfreight.com/multipositional-magnetic-base-with-fine-adjustment-5645.html

https://www.harborfreight.com/catal...atured+Weight,f,Sale+Rank,f&q=indicator+stand

if the cam lost a lobe in 30 miles chances are EXCELLENT your dealing with a CLEARANCE issue in the valve train and/or significantly more spring loads than desirable for the application.

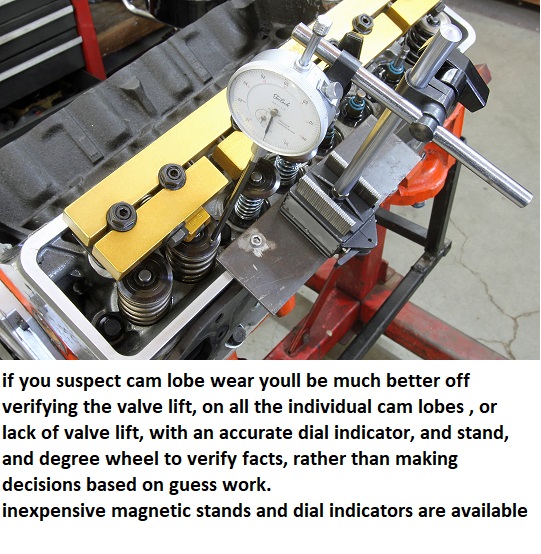

just because the heads are listed as allowing a .600 lift thats no reason to ignore verifying the valve train clearances or rocker geometry, or fail to degree in the cam. most guys blame a cam lobe failure on lack of lubrication or the wrong oil, but the truth is that the vast majority of issues that cause cam lobes to fail are related to valve train clearance issues, or the use of the wrong spring load rates or mismatched components, or in a few cases failure to install and degree in the cam correctly.

i can assure you guys regularly fail to verify rocker are not binding, and valve springs are not binding, in most cases because until some component fails they never even considered the possibility and bolted the parts on with the belief they would work flawlessly, right out of the packaging.

Even with roller valve train there is a break in period where the metals have to "mate". on flat tappet valve trains and non-roller rocker valve trains use of a good moly assembly lube is critical, Break in oils and assembly lubes have high pressure additives to help protect these new surfaces while this "mating" is taking place. Regular motor oil does not, always have the required additives or enough of them. thus using a good moly based assembly lube on lifters and bearings helps reduce wear , on roller rockers and roller lifter a mix of 50% assembly lube and 50% MARVEL MYSTERY OIL, thins this moly mix viscosity allowing it to penetrate roller bearings far faster

I can tell you what Ive done for DECADES and Ive never had any problems,I have assembled engines using crane cams or similar moly based assembly lube,on the lifters and cam lobes, then

get some 5 quarts of VALVOLINE 10W30 RACE oil (preferred) but I have used SHELL, HAVOLINE and EVEN MOBILE 1 oil,

http://www.jegs.com/p/Valvoline-Racing/ ... e=90&pno=1

add a quart of MARVEL MYSTERY OIL to the mix, if you have a can of wear additive it won,t hurt but its generally not needed,and fill the engine prime it and turn it manually until all the rockers bleed oil, and set the valves a bit loose, then start it up and keep the rpms in the 2500rpm range with a garden hose running over the radiator to help it cool, watch your oil pressure and obviously check your ignition timing and engine temps constantly.

READ THRU THESE LINKS AND SUB LINKS

yes you can just skip over or ignore that advice but chances are AGAIN EXCELLENT that youll be replacing a second "defective" cam and wondering what went wrong if you do

READ THESE THREADS

viewtopic.php?f=52&t=181

viewtopic.php?f=52&t=528

viewtopic.php?f=54&t=985&p=18690&hilit=prime+distributor#p18690

viewtopic.php?f=52&t=7716&p=29813&hilit=busted+spring#p29813

viewtopic.php?f=44&t=4712&p=12798&hilit=busted+spring#p12798

viewtopic.php?f=52&t=689&p=7416&hilit=busted+spring#p7416

viewtopic.php?f=52&t=399

viewtopic.php?f=52&t=1489

Last edited by a moderator: