yes IM well aware that theres a great deal of info in the links and it takes some time to read.....its worth the effort

http://www.hashmarks.com/techtips/hot_cam.htm

viewtopic.php?f=52&t=282

viewtopic.php?f=52&t=181

viewtopic.php?f=44&t=799&p=1161#p1161

viewtopic.php?f=52&t=90

http://www.pbm-erson.com/uploads/cat%5B ... CEDURE.pdf

viewtopic.php?f=52&t=126&p=1270&hilit=+roller+rockers#p1270

http://www.gnttype.org/techarea/engine/cam_tips.html

http://www.classicinlines.com/caminstall.asp

http://www.howardscams.com/tips_&_techniques.htm

http://www.fierolt1.com/lt1_CamHeadinstall.htm

http://www.amotion.com/tech/caminst.html

http://www.compcams.com/Technical/Instr ... es/145.pdf

http://www.northernautoparts.com/Produc ... elId=14795

http://www.iskycams.com/techinfo_index.html

http://www.cranecams.com/pdf/Page212.pdf

notice the approximate location and relationship between the cam pin and crank key

http://www.superchevy.com/technical/eng ... index.html

(btw when using a spark plug in the cylinder head style piston stop tool

if your standard strait probe/stop tool is not touching the piston due to the shallow enterance angle

youll want to remove ALL the spark plugs and back off ALL the rockers

on not only cylinder number one ,

but all the cylinders ,

so you can feel the engine as it moves/rotates

yes youll need to adjust valve when your done finding TDC

http://garage.grumpysperformance.com/index.php?threads/adjusting-valves.196/

and make sure the cars not in gear so that the engine can be rotated much more easily when done manually,

this prevents the valves in cylinder number one from opening and removing the other spark plugs greatly reduces resistance due to compression.

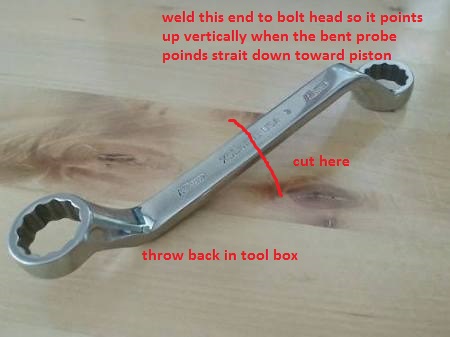

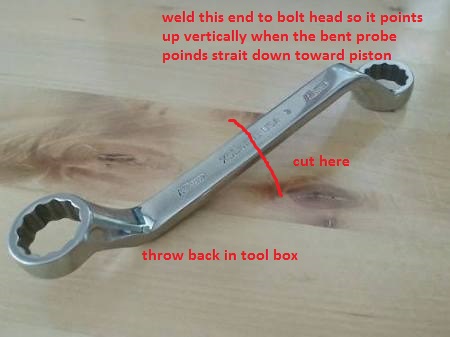

yes your problem, is FAR from rare and in fact its very common most guys simply take an old spark plug,

put it in a vise and bust out the old porcilian center and re-thread the interior of the remaining metal hex.

or buy a tool like comps

https://www.summitracing.com/parts/...-_-comp-cams&gclid=CJ3wuuyJ8tACFYOFswodCKYKvw

you then buy a 6" threaded bolt, screw it into the plug body

with similar thread pitch and thread that fully threaded bolt about 3" of that bolt entending past the spark plug base,

and heat and bend it with your propane or acetolene torch in a shallow curve,

now BRAZE or weld a cheap socket head wrench to the bolt head so it can,t move off the bolt and indexed so ,

its pointing strait up when the bent internal part of the piston stop points strait down ward

RELATED THREADS

http://garage.grumpysperformance.com/index.php?threads/cam-degreeing.9010/#post-35474

http://garage.grumpysperformance.co...et-it-to-last-cam-install-info.90/#post-31431

http://garage.grumpysperformance.co...ter-1-for-timing-ignition-cam.966/#post-18999

http://garage.grumpysperformance.com/index.php?threads/turning-your-crank-manually.5933/#post-18274

http://garage.grumpysperformance.com/index.php?threads/cam-degree-equipment-tools.1759/#post-4441

now you can stick the bent bolt into the cylinder, thread the bolt body into the head and once its seated in the head,

you can easily index the bent part to point down into the cylinder where it will contact the piston as it rotates

which a strait bolt would not do due to the shallow enterance angle

be aware that you need to be able to feel the engine stop when it contacts the probe tip, if you don,t manually turn the engine fter first removing the other spark plugs ,

and backing off the rockers the resistannce to rotation the valve train and compression have will make felling the piston contacting the piston stop difficult,

and you damn sure don,t want to bend or break the piston stop.

watch this

DROPPING THE DISTRIBUTOR BACK IN

viewtopic.php?f=50&t=54

http://www.hashmarks.com/techtips/hot_cam.htm

viewtopic.php?f=52&t=282

viewtopic.php?f=52&t=181

viewtopic.php?f=44&t=799&p=1161#p1161

viewtopic.php?f=52&t=90

http://www.pbm-erson.com/uploads/cat%5B ... CEDURE.pdf

viewtopic.php?f=52&t=126&p=1270&hilit=+roller+rockers#p1270

http://www.gnttype.org/techarea/engine/cam_tips.html

http://www.classicinlines.com/caminstall.asp

http://www.howardscams.com/tips_&_techniques.htm

http://www.fierolt1.com/lt1_CamHeadinstall.htm

http://www.amotion.com/tech/caminst.html

http://www.compcams.com/Technical/Instr ... es/145.pdf

http://www.northernautoparts.com/Produc ... elId=14795

http://www.iskycams.com/techinfo_index.html

http://www.cranecams.com/pdf/Page212.pdf

notice the approximate location and relationship between the cam pin and crank key

http://www.superchevy.com/technical/eng ... index.html

(btw when using a spark plug in the cylinder head style piston stop tool

if your standard strait probe/stop tool is not touching the piston due to the shallow enterance angle

youll want to remove ALL the spark plugs and back off ALL the rockers

on not only cylinder number one ,

but all the cylinders ,

so you can feel the engine as it moves/rotates

yes youll need to adjust valve when your done finding TDC

http://garage.grumpysperformance.com/index.php?threads/adjusting-valves.196/

and make sure the cars not in gear so that the engine can be rotated much more easily when done manually,

this prevents the valves in cylinder number one from opening and removing the other spark plugs greatly reduces resistance due to compression.

yes your problem, is FAR from rare and in fact its very common most guys simply take an old spark plug,

put it in a vise and bust out the old porcilian center and re-thread the interior of the remaining metal hex.

or buy a tool like comps

https://www.summitracing.com/parts/...-_-comp-cams&gclid=CJ3wuuyJ8tACFYOFswodCKYKvw

you then buy a 6" threaded bolt, screw it into the plug body

with similar thread pitch and thread that fully threaded bolt about 3" of that bolt entending past the spark plug base,

and heat and bend it with your propane or acetolene torch in a shallow curve,

now BRAZE or weld a cheap socket head wrench to the bolt head so it can,t move off the bolt and indexed so ,

its pointing strait up when the bent internal part of the piston stop points strait down ward

RELATED THREADS

http://garage.grumpysperformance.com/index.php?threads/cam-degreeing.9010/#post-35474

http://garage.grumpysperformance.co...et-it-to-last-cam-install-info.90/#post-31431

http://garage.grumpysperformance.co...ter-1-for-timing-ignition-cam.966/#post-18999

http://garage.grumpysperformance.com/index.php?threads/turning-your-crank-manually.5933/#post-18274

http://garage.grumpysperformance.com/index.php?threads/cam-degree-equipment-tools.1759/#post-4441

now you can stick the bent bolt into the cylinder, thread the bolt body into the head and once its seated in the head,

you can easily index the bent part to point down into the cylinder where it will contact the piston as it rotates

which a strait bolt would not do due to the shallow enterance angle

be aware that you need to be able to feel the engine stop when it contacts the probe tip, if you don,t manually turn the engine fter first removing the other spark plugs ,

and backing off the rockers the resistannce to rotation the valve train and compression have will make felling the piston contacting the piston stop difficult,

and you damn sure don,t want to bend or break the piston stop.

watch this

DROPPING THE DISTRIBUTOR BACK IN

viewtopic.php?f=50&t=54

Last edited by a moderator: