the more modern cam lobe designs have more aggressive ramps resulting in the valve being off the seat longer and more air flow,and in theory have superior materials, the older designs tended to value long term durability as more of an asset during the design,so low spring load rates were preferred and the lobe designs compensated for the lower strength materials, and lower spring load rates used by at least in theory inducing lower stress levels so the cams would last far longer, and be easier on the valve train.

but from what Ive seen several of the newer designs have reached or surpassed the reasonable limits on long term durability, having gone to the extreme edge of useful deceleration rates on the lobe designs, that added to the changes in the oils formulation recently to increase the life of the catalytic converters on emission systems that sacrificed some of the high load wear additives in the oil, and reduction in zinc and phosphates in the oil can and do cause failures.

each manufacturer tends to have a different philosophy, on exactly how much durability is reasonably required in their cam designs.

Ive had the best results from

CRANE,

ERSON,

CROWER,

ISKY

now as to your combo, your current cam is well matched to the rest of your current combo of components, yes you could change to a cam with more duration, but that would require a higher stall converter speed and a 3.73:1 rear gear to take full advantage of the increased duration, and it would kill off a bit of the drive ability in the lower rpm range.

I had the same choice to make in my combo in my corvette, I could (AND DID AT ONE TIME) install a larger cam, but because I use the car 90% of the time for cruising that quickly proved to be " a bit too much of a good thing "

in that I traded a bit more street manors than I personally wanted too to gain some extra upper rpm horsepower, and while the extra hp was definitely there , I didn,t feel in my case the compromise was worth it......the answer was found in my case in adding a

WET NITROUS KIT , and swapping back to a slightly milder cam, designed for nitrous, it allowed me to drive with the better street manors of the milder combo yet have the killer massive torque on the rare occasions I wanted more power than the standard combo provided.

installed correctly nitrous is both safe, and amazingly impressive and if tuned correctly its no big strain on a properly set up engine, Its been my experience that 99% of the guys that have problems, with nitrous either used a dry nitrous system,failed to have the ignition or nitrous jets or fuel system set up correctly, failed to use a nitrous controller,or either failed to carefully read or follow detailed instructions during the install process or tune the car correctly.

ID suggest you start with no more than a 100 hp system and jetting and set it up for the first few weeks with settings for a 50hp shot until you get a good grasp on nitrous tuning

BTW WET NITROUS KITS supply BOTH FUEL AND NITROUS to the engine in a fog/mist, so thru the use of jets you control the fuel/nirous ratio, dry nitrous systems flow only nitrous and relies totally on the computer and sensors to add the required fuel increase, to prevent melting pistons etc. the problem is that theres a small delay in time when its working correctly, between the nitrous plume and the fuel being added, which results in temps in the cylinders skyrocketing for an instant......"WHEN IT WORKS" if the sensors and injectors don,t respond almost instantly its like using a oxy-acetylene torch on your rings and pistons

btw you'll need to retard your ignition timing per the kits instructions during nitrous use so having an adjustable ignition advance with a switch connected to the nitrous controller is a great idea

ID strongly suggest you read thru the links and sub links below carefully

viewtopic.php?f=55&t=2372

http://www.ws6.com/mod-13.htm

viewtopic.php?f=55&t=59&p=72&hilit=+nitrous#p72

http://www.carcraft.com/techarticles/di ... index.html

viewtopic.php?f=55&t=211

very easy to install and good power

http://www.summitracing.com/parts/NOS-0 ... mage=large

While more complex, to set up and install, but with more hp potential and control over your results, a system with individual foggers for each intake port allows far more precise fuel/air mixture control

http://www.summitracing.com/parts/NOS-0 ... mage=large

heres free cam selection software to narrow your choices

http://www.compcams.com/Pages/409/camquest-6.aspx

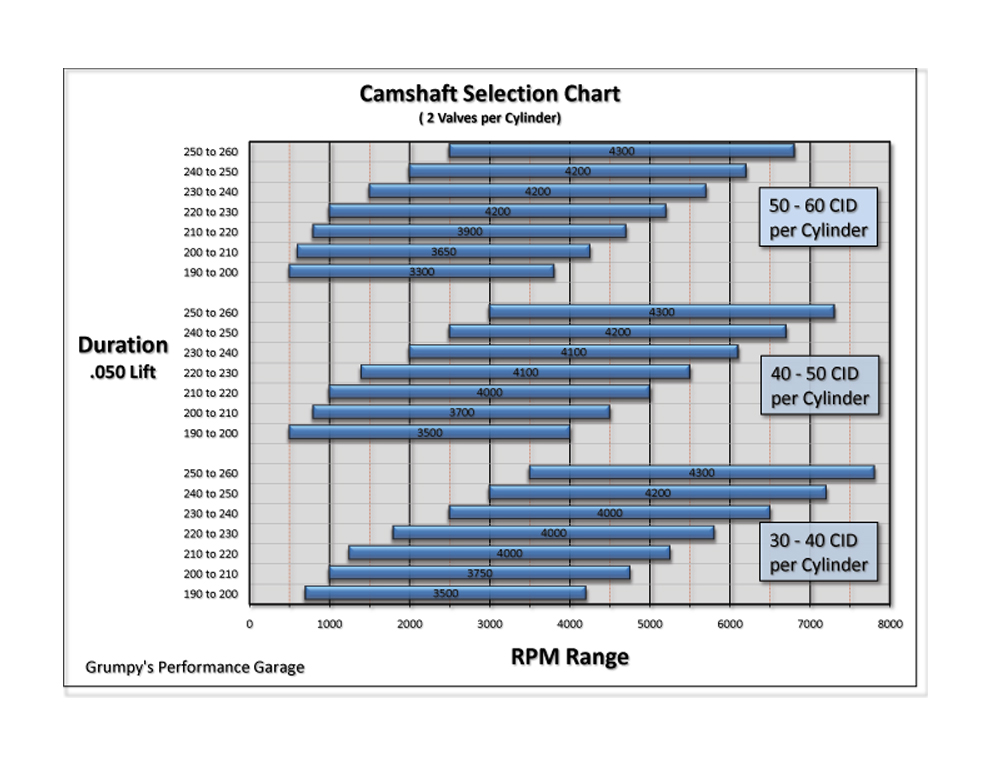

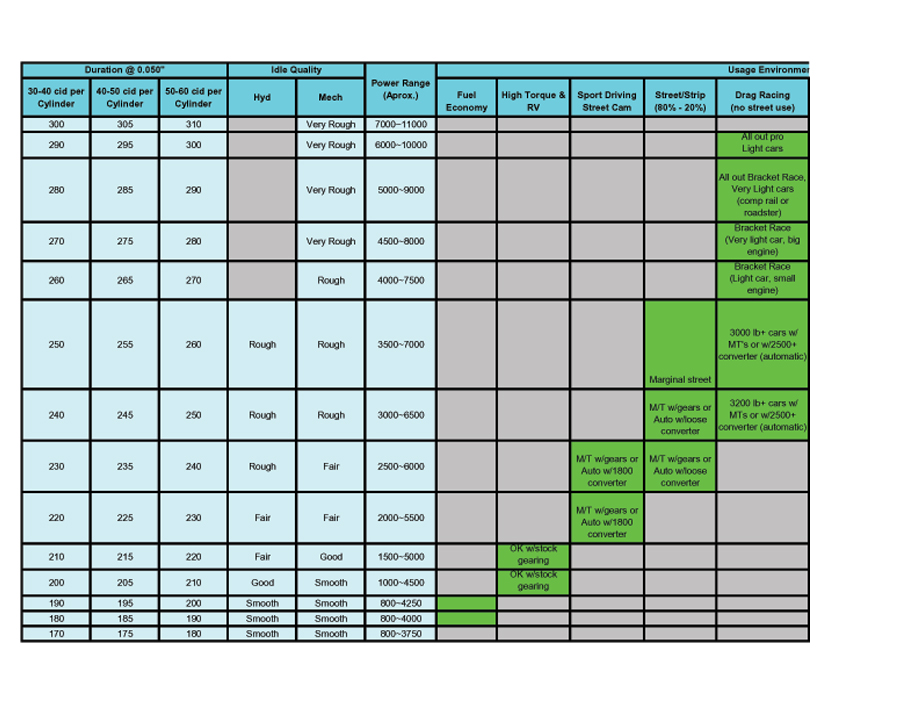

AS your displacement per cylinder increases the effective valve size per cubic inch decreases so you need a slightly tighter LSA and these charts should help.

of course you'll want to match the heads you select,

to the intended rpm/power range and application and match the cam timing, compression ratio, and drive train gearing, etc.

so lets discus the current car/truck weight, transmission, tire size, rear gear ratio and what your intended goals and budget limitations are, as a start point.

the last thing you'll want to do is select parts that may cripple or restrict the engine performance by mis-matching components or selecting parts on price alone, we all work on limited budgets,

but its will pay big dividends in power produced too carefully select matched components

and generally the biggest mistake is mis-matching heads, intake and cam combos or scrimping on the quality of the components used,

a couple extra hours or even days spent in detailed of research may prove critical, in fact anything less than buying and reading through several books and reading a couple dozen links and all the sub-links is very likely to leave you missing valuable and critical info youll need later, and thats usually going to cost you wasted time and cash.

the big mistake's most people make is in not selecting the correct cam, to match the displacement and compression and drive train gearing or selecting a restrictive cylinder head or intake that does not match the intended power range

yes it looks over whelming but youll be amazed at the detailed info and the mistakes you can avoid by reading carefully

http://garage.grumpysperformance.com/index.php?threads/sellecting-cylinder-heads.796/

http://garage.grumpysperformance.com/index.php?threads/semi-fool-proof-cam-sellection.82/

http://garage.grumpysperformance.com/index.php?threads/first-hotrod-build.12902/#post-67005

http://garage.grumpysperformance.co...ing-a-383-sbc-combo-planing.12168/#post-58778

http://garage.grumpysperformance.com/index.php?threads/bare-minimum-tools.11026/#post-48785

http://garage.grumpysperformance.com/index.php?threads/matching-parts-and-a-logical-plan.7722/

http://garage.grumpysperformance.com/index.php?threads/what-to-look-for-in-a-good-engine-combo.9930/

http://garage.grumpysperformance.com/index.php?threads/another-383-build.12786/

http://garage.grumpysperformance.com/index.php?threads/383-information-overload.11137/

http://garage.grumpysperformance.com/index.php?threads/a-383-build.10991/

http://garage.grumpysperformance.com/index.php?threads/impersonator.9600/

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

http://garage.grumpysperformance.com/index.php?threads/port-speeds-and-area.333/

http://garage.grumpysperformance.com/index.php?threads/valve-seat-angles-and-air-flow.8460/

http://garage.grumpysperformance.com/index.php?threads/tbucket-engine-project-dart-shp.3814/