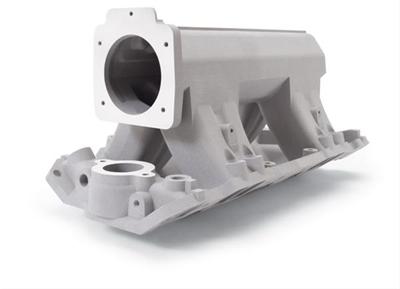

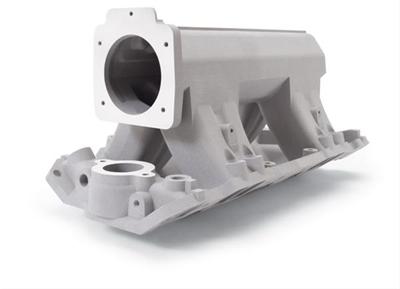

"GRUMPY? Ive got the Edelbrock Pro flo Xt Intake and E-Tec 200 Heads on our 388 Chevy. Try to get 400 hp out of that combo, still at only 350 hp. Have a 236/236 @ .050" solid roller in it. The Edelbrock crate engines have 242 @ .050" hyd. roller cams for 425 hp in it. But the Comp cams Camquest program tells me

1.: I´ll be better off with a 226 cam (more HP + Torque)

2.: Theres soooo much difference between selecting

a Tunnel ram Std or a LSfast intake /single plane intake.

The Tunnel ram makes 80hp more than the single plane. And Edelbrock uses hotter cams than camquest suggests.

So how realistic is this camquest program?

http://www.summitracing.com/parts/EDL-7137/?rtype=10

as always step one is verify EXACTLY what your working with before making guesses and random parts changes

the cam you select will depend a great deal on the rpm band you intend to make power in and your engine compression ratio must be matched to make the combo work, and BTW a 226 duration cam will usually be used with less compression and make noticeably less upper rpm power that a 236-245 duration cam.

viewtopic.php?f=52&t=1070

IF you assume either cam can make 1.1-1.2 ft lbs of torque DEPENDS mostly ON COMPRESSION,from your 388 sbc but that the 226 duration will make that at about 800rpm lower.....youll plug that info into the formula for horsepower and youll see the potential difference

if we say a 226 duration cam with a 110 lsa will require a 9.2:1 cpr and peak at about 5000rpm a 242 duration cam on a 110lsa will require about a 9.8:1 cpr and peak about 800rpm higher we get

450 x 5000/5252rpm=about 430hp

465 x 5800/5252rpm= about 510hp

or 60 plus extra hp

have you taken the time to measure the intakes vacuum readings, with and without an air filter, and exhaust back pressure in the header collectors at

every 1000rpm step, from idle to peak rpm and can you post pictures of your spark plugs?

whats your fuel air ratio?

whats your ignition advance curve?

have you verified it or just assume its correct?

whats your fuel pressure?

is it staying at 42 psi or dropping as the rpms increase?

what are the valve train clearances?

whats your engines true compression ratio? (get that wrong and a radical cam kills performance)

are the push rods the ideal length?

whats the coolant and oil temps?

whats the oil pressure?

any indication of a mis-firing ignition?

what size injectors?

have you done any testing to see the injectors flow correctly?

have you done a resistance and NOID test?

are there any trouble codes?

whats the spark plug gap?

whats the coil voltage?

whats the exhaust gas temp?

whats the cam lift, duration LSA and valve train clearances?

how are you measuring the horsepower?

(rear wheel hp is normally about 20% lower than flywheel hp)

did you degree the cam in or just install it DOT-TO-DOT?

how are the valves adjusted?

have you done a compression and leak-down test?

are you running a windage screen and 7-8 quart baffled oil pan?

HONESTLY I see stuff like this constantly and with checking and testing you don,t have the FACTS so you can,t expect to make valid choices.

first step is stop guessing and verify ALL the facts

Id strongly suggest using open headers and no air cleaner and a fuel air ratio meter on the next test or trip to the track, a restrictive exhaust and intake could very easily cost you 70 plus hp, but little things like having the valves adjusted to tightly or the ignition curve advance to slow or fast or a drop in fuel pressure will effect results

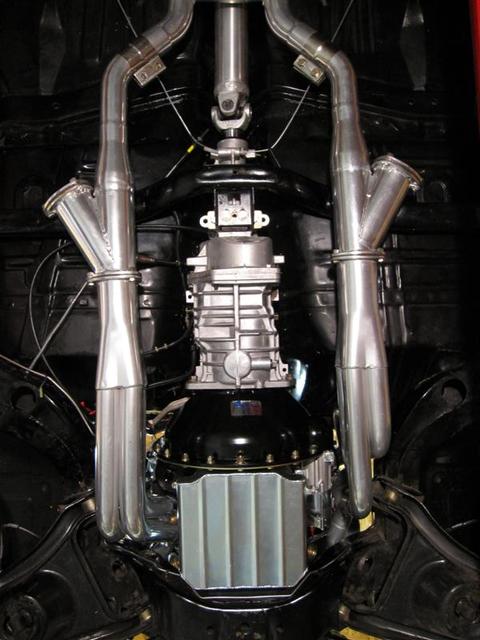

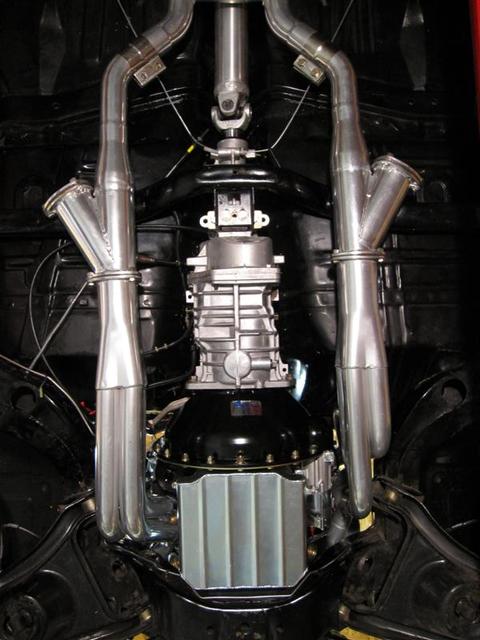

Id strongly suggest a minimum or 39-42 lb injectors and two 3" exhaust pipes with an (X) behind full length headers and an exhaust system that has less than 1 psi back pressure at peak power levels or at least track accessible cut outs

YEAH I KNOW YOU WON,T BELIEVE THIS BUT MOST OF THE ANSWERS ARE IN THE LINKS AND SUB LINKS

viewtopic.php?f=56&t=495

viewtopic.php?f=56&t=1503

viewtopic.php?f=56&t=961

viewtopic.php?f=56&t=185

viewtopic.php?f=55&t=1200

viewtopic.php?f=70&t=4683

viewtopic.php?f=52&t=5078&p=18194&hilit=dyno+software#p18194

viewtopic.php?f=69&t=2301&p=17297&hilit=dyno+software#p17297

you might be surprised but if you actually have some data on whats actually going on in the engine you can normally locate the potential problem area and correct it!

1.: I´ll be better off with a 226 cam (more HP + Torque)

2.: Theres soooo much difference between selecting

a Tunnel ram Std or a LSfast intake /single plane intake.

The Tunnel ram makes 80hp more than the single plane. And Edelbrock uses hotter cams than camquest suggests.

So how realistic is this camquest program?

http://www.summitracing.com/parts/EDL-7137/?rtype=10

as always step one is verify EXACTLY what your working with before making guesses and random parts changes

the cam you select will depend a great deal on the rpm band you intend to make power in and your engine compression ratio must be matched to make the combo work, and BTW a 226 duration cam will usually be used with less compression and make noticeably less upper rpm power that a 236-245 duration cam.

viewtopic.php?f=52&t=1070

IF you assume either cam can make 1.1-1.2 ft lbs of torque DEPENDS mostly ON COMPRESSION,from your 388 sbc but that the 226 duration will make that at about 800rpm lower.....youll plug that info into the formula for horsepower and youll see the potential difference

if we say a 226 duration cam with a 110 lsa will require a 9.2:1 cpr and peak at about 5000rpm a 242 duration cam on a 110lsa will require about a 9.8:1 cpr and peak about 800rpm higher we get

450 x 5000/5252rpm=about 430hp

465 x 5800/5252rpm= about 510hp

or 60 plus extra hp

have you taken the time to measure the intakes vacuum readings, with and without an air filter, and exhaust back pressure in the header collectors at

every 1000rpm step, from idle to peak rpm and can you post pictures of your spark plugs?

whats your fuel air ratio?

whats your ignition advance curve?

have you verified it or just assume its correct?

whats your fuel pressure?

is it staying at 42 psi or dropping as the rpms increase?

what are the valve train clearances?

whats your engines true compression ratio? (get that wrong and a radical cam kills performance)

are the push rods the ideal length?

whats the coolant and oil temps?

whats the oil pressure?

any indication of a mis-firing ignition?

what size injectors?

have you done any testing to see the injectors flow correctly?

have you done a resistance and NOID test?

are there any trouble codes?

whats the spark plug gap?

whats the coil voltage?

whats the exhaust gas temp?

whats the cam lift, duration LSA and valve train clearances?

how are you measuring the horsepower?

(rear wheel hp is normally about 20% lower than flywheel hp)

did you degree the cam in or just install it DOT-TO-DOT?

how are the valves adjusted?

have you done a compression and leak-down test?

are you running a windage screen and 7-8 quart baffled oil pan?

HONESTLY I see stuff like this constantly and with checking and testing you don,t have the FACTS so you can,t expect to make valid choices.

first step is stop guessing and verify ALL the facts

Id strongly suggest using open headers and no air cleaner and a fuel air ratio meter on the next test or trip to the track, a restrictive exhaust and intake could very easily cost you 70 plus hp, but little things like having the valves adjusted to tightly or the ignition curve advance to slow or fast or a drop in fuel pressure will effect results

Id strongly suggest a minimum or 39-42 lb injectors and two 3" exhaust pipes with an (X) behind full length headers and an exhaust system that has less than 1 psi back pressure at peak power levels or at least track accessible cut outs

YEAH I KNOW YOU WON,T BELIEVE THIS BUT MOST OF THE ANSWERS ARE IN THE LINKS AND SUB LINKS

viewtopic.php?f=56&t=495

viewtopic.php?f=56&t=1503

viewtopic.php?f=56&t=961

viewtopic.php?f=56&t=185

viewtopic.php?f=55&t=1200

viewtopic.php?f=70&t=4683

viewtopic.php?f=52&t=5078&p=18194&hilit=dyno+software#p18194

viewtopic.php?f=69&t=2301&p=17297&hilit=dyno+software#p17297

you might be surprised but if you actually have some data on whats actually going on in the engine you can normally locate the potential problem area and correct it!