You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Carb Cleaning

- Thread starter rlphvac

- Start date

8

87vette81big

Guest

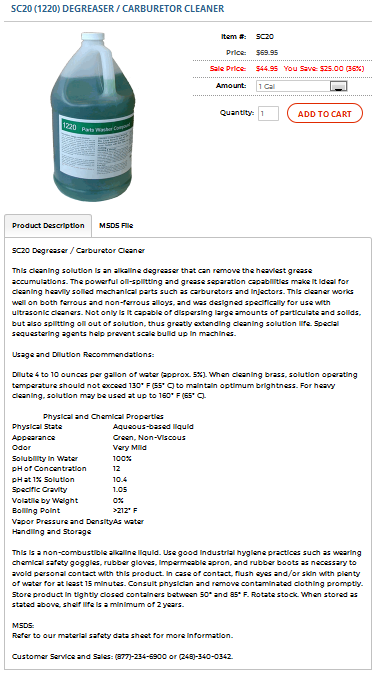

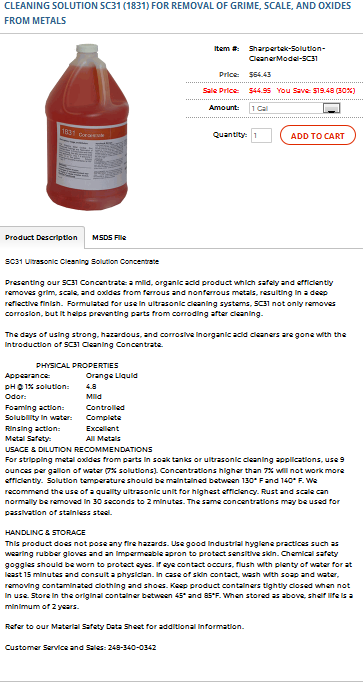

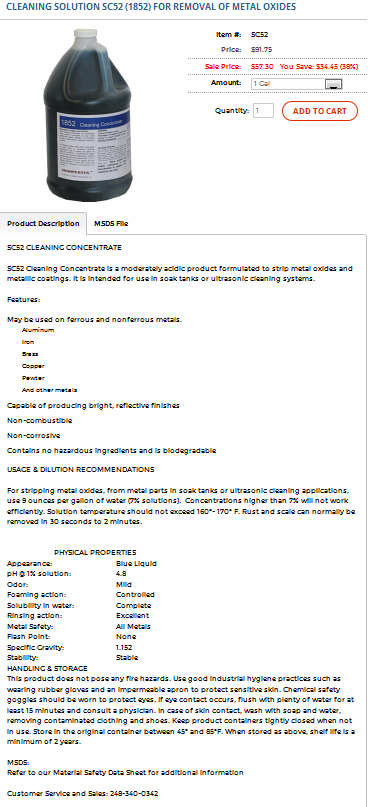

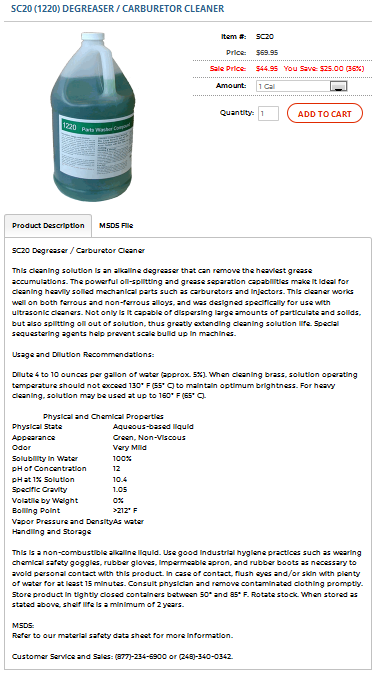

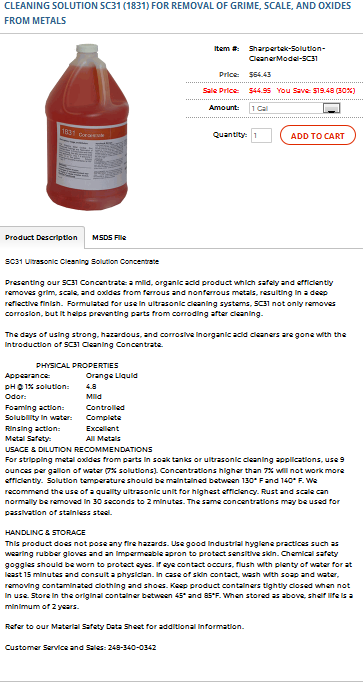

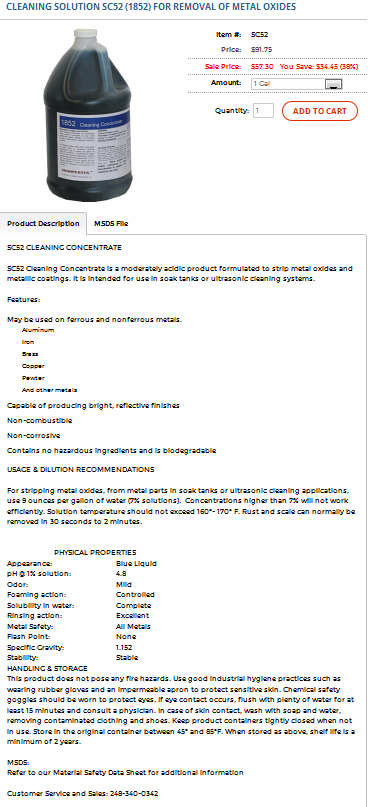

There are special Ultrasonic cleaning solutions you can use Ralph.

Woolite is supposed to be good stuff to clean with. Richard mentioned recently .

Woolite is supposed to be good stuff to clean with. Richard mentioned recently .

obviously what your willing to spend, the size limitations and how often you need to carefully clean parts,

has a huge effect on what ultra sonic cleaner your likely to want,

or can afford

most larger shops have a parts cleaner, soak parts in solvent , wash off and use the ultra sonic cleaner with approved cleaning liquids

high pressure air and some carb cleaner solvent can be very helpful

obviously ,like everything else quality varies and reading the fine print on the instructions and use of the correct cleaning fluid solution helps results IMMENSELY

http://ultrasonicsdirect.com/ultrasonic-cleaning-solution.html

http://ultrasonicsdirect.com/12decacl.html

http://ultrasonicsdirect.com/sharpertek-solution-cleaner-model-sh1831.html

http://ultrasonicsdirect.com/shclsoforreo.html

IF CASH IS TIGHT A GALLON OF WHITE VINEGAR WITH ONE OR TWO DROPS OF DAWN DISH SOAP WORKS AMAZINGLY WELL IN MANY ULTRA SONIC CLEANERS(don,t exceed that or you get a foamy mess )

AFTER YOU FIRST REMOVE GREASE WITH A SOLVENT WASH

http://www.northerntool.com/shop/tools/ ... _200365419

ULTRASONIC CLEANER?

Max. Capacity (gal.) 1

Tank Dimensions L x W x H (in.) 9 7/16 x 5 1/2 x 5 15/16 (Inside dimensions: 9 1/10 x 5 1/2 x 5 9/10) $250

http://www.yescomusa.com/products/3...5-1144287761&gclid=CPeD57itscwCFQUFaQodtdoLgA

Tank Size 9 1/2" L x 5 1/4" W x 4" H 3/4 gallon $168

http://www.ebay.com/itm/New-Stainle...540661?hash=item19f78f37b5:g:7TgAAOSwmLlX8IKx

http://ultrasonicsdirect.com/ultrasonic-cleaner-sh180-6l.html

HEATED WITH SWEEP AND DEGAS XPS360-6L 1.6 GAL. TANK DIMENSIONS 11.75" × 6" × 6" (TANK L × W × DEPTH) - MADE IN USA

Sale Price:

$477.00

related thread

http://garage.grumpysperformance.com/index.php?threads/parts-prep-cleaning.6255/#post-21692

http://garage.grumpysperformance.com/index.php?threads/bio-friendly-parts-cleaner.11547/#post-53360

has a huge effect on what ultra sonic cleaner your likely to want,

or can afford

most larger shops have a parts cleaner, soak parts in solvent , wash off and use the ultra sonic cleaner with approved cleaning liquids

high pressure air and some carb cleaner solvent can be very helpful

obviously ,like everything else quality varies and reading the fine print on the instructions and use of the correct cleaning fluid solution helps results IMMENSELY

http://ultrasonicsdirect.com/ultrasonic-cleaning-solution.html

http://ultrasonicsdirect.com/12decacl.html

http://ultrasonicsdirect.com/sharpertek-solution-cleaner-model-sh1831.html

http://ultrasonicsdirect.com/shclsoforreo.html

IF CASH IS TIGHT A GALLON OF WHITE VINEGAR WITH ONE OR TWO DROPS OF DAWN DISH SOAP WORKS AMAZINGLY WELL IN MANY ULTRA SONIC CLEANERS(don,t exceed that or you get a foamy mess )

AFTER YOU FIRST REMOVE GREASE WITH A SOLVENT WASH

http://www.northerntool.com/shop/tools/ ... _200365419

ULTRASONIC CLEANER?

Max. Capacity (gal.) 1

Tank Dimensions L x W x H (in.) 9 7/16 x 5 1/2 x 5 15/16 (Inside dimensions: 9 1/10 x 5 1/2 x 5 9/10) $250

http://www.yescomusa.com/products/3...5-1144287761&gclid=CPeD57itscwCFQUFaQodtdoLgA

Tank Size 9 1/2" L x 5 1/4" W x 4" H 3/4 gallon $168

http://www.ebay.com/itm/New-Stainle...540661?hash=item19f78f37b5:g:7TgAAOSwmLlX8IKx

http://ultrasonicsdirect.com/ultrasonic-cleaner-sh180-6l.html

HEATED WITH SWEEP AND DEGAS XPS360-6L 1.6 GAL. TANK DIMENSIONS 11.75" × 6" × 6" (TANK L × W × DEPTH) - MADE IN USA

Sale Price:

$477.00

related thread

http://garage.grumpysperformance.com/index.php?threads/parts-prep-cleaning.6255/#post-21692

http://garage.grumpysperformance.com/index.php?threads/bio-friendly-parts-cleaner.11547/#post-53360

Last edited:

8

87vette81big

Guest

Yes Ralph.

I would soke parts in carb cleaner 1st.

Don't put Volatile flammable chemicals in an Ultrasonic sonic cleaner.

The theory how they work is that near microscopic bubbles of water implode or explode on the surface of parts cleaned. 10,000 degree F temps the exploding bubbles have.

Water with the supplied poweder for your ultrasonic cleaner should be fine for secondary cleaning.

I would soke parts in carb cleaner 1st.

Don't put Volatile flammable chemicals in an Ultrasonic sonic cleaner.

The theory how they work is that near microscopic bubbles of water implode or explode on the surface of parts cleaned. 10,000 degree F temps the exploding bubbles have.

Water with the supplied poweder for your ultrasonic cleaner should be fine for secondary cleaning.

First, there is no need for a sonic cleaner to clean any carb, if you want to use one, this is some sensible advice. For the plating shop we have a large tank for effective cleaning of large truck radiators and a small Igersoll Rand commercial sonic cleaners for old and delicate parts.

Everybody likes their favorite name brand cleaning solutions but when using any good sonic cleaner there is no need to get crazy about any special products, you're just wasting good money.

Use any carb cleaner to degrease and flush away large visible deposits, this is the level of a standard quick cleaning for average reassembly (steam cleaning can do the same but without need for any cleaning products).

Deep cleaning and cleaning metals to attain a uniform color, and one of a couple very good methods of removing soaked in petroleum salts to assure long metal plating life starts with any good water-wetter. Woolite (40 ml/5 gal water) works as good as any commercial chemicals but to kill 2 birds with one stone use Tide "high efficiency" low suds (60 ml /gal of hot water) does both, penetrates the surface of non polished, or casted metals and breaks down petroleum distillates. One last benefit, as distillates break down they breaking the chemical bonds of wax, alaphatic and aromatic compounds (the dirty grease and carbon scale) that can coat the smallest of passages and finely machined parts of carbureters and valve bodies.

Everybody likes their favorite name brand cleaning solutions but when using any good sonic cleaner there is no need to get crazy about any special products, you're just wasting good money.

Use any carb cleaner to degrease and flush away large visible deposits, this is the level of a standard quick cleaning for average reassembly (steam cleaning can do the same but without need for any cleaning products).

Deep cleaning and cleaning metals to attain a uniform color, and one of a couple very good methods of removing soaked in petroleum salts to assure long metal plating life starts with any good water-wetter. Woolite (40 ml/5 gal water) works as good as any commercial chemicals but to kill 2 birds with one stone use Tide "high efficiency" low suds (60 ml /gal of hot water) does both, penetrates the surface of non polished, or casted metals and breaks down petroleum distillates. One last benefit, as distillates break down they breaking the chemical bonds of wax, alaphatic and aromatic compounds (the dirty grease and carbon scale) that can coat the smallest of passages and finely machined parts of carbureters and valve bodies.

Brian's right, don't ever use combustible/flammable liquids in any sonic type machine.

Those bubbles, called cavitation bubbles are propagated by high frequency pressure sound waves agitating the water. The agitation produces high forces (pounding) on contaminants adhering to substrates like metals, plastics, glass, rubber, and ceramics. This action also penetrates deep within passages, cracks, and recesses.

One great benifit is that you don't have to disassemble all the parts of a carb to clean using ultra sonic cleaning.

Most Important: DO NOT REST OBJECTS TO CLEAN ON ANY TANK SURFACE. TOUCHING WILL NOT ALLOW CAVITATION.

Contamination cleaned: Dirt, oil, pigments, rust, grease, algae, fungus, bacteria, lime scale, polishing compounds, flux agents, fingerprints, soot wax and mold release agents, biologics like blood are easily removed.

Those bubbles, called cavitation bubbles are propagated by high frequency pressure sound waves agitating the water. The agitation produces high forces (pounding) on contaminants adhering to substrates like metals, plastics, glass, rubber, and ceramics. This action also penetrates deep within passages, cracks, and recesses.

One great benifit is that you don't have to disassemble all the parts of a carb to clean using ultra sonic cleaning.

Most Important: DO NOT REST OBJECTS TO CLEAN ON ANY TANK SURFACE. TOUCHING WILL NOT ALLOW CAVITATION.

Contamination cleaned: Dirt, oil, pigments, rust, grease, algae, fungus, bacteria, lime scale, polishing compounds, flux agents, fingerprints, soot wax and mold release agents, biologics like blood are easily removed.

You don't need to use any chemicals, just might want to change water.Should I soak the carb in some acetone to pre clean I also have some powder I got from Harbor Freight with my sonic cleaner

The very reason Ultra-Sonic or "Sonic" cleaning devices were invented was to eliminate any need for solvents or cleaning distillates.

while thats mostly true adding a mild, solvent, acid, or detergent to the fluid, being used,

can and in many cases does speed up and increase the cleaning effect of the ultrasonic bath cleaner.

you don,t need HARSH chemicals, for example adding a cup of a detergent like WINDEX and a cup of white vinegar,

to a gallon of warn water seems to help a good deal on many things I clean.

can and in many cases does speed up and increase the cleaning effect of the ultrasonic bath cleaner.

you don,t need HARSH chemicals, for example adding a cup of a detergent like WINDEX and a cup of white vinegar,

to a gallon of warn water seems to help a good deal on many things I clean.

Strictly Attitude

solid fixture here in the forum

There are chemicals designed to work in ultra sonic cleaners I work in a lab and use one daily. A decent one has adjustment for tempature and has a degas cycle. If I wanted to use chemicals in one I would used one designed for it.

Strictly Attitude

solid fixture here in the forum

This is the proper product to use

https://www.coleparmer.com/i/branso...1s6CxiZDnSQqkyG4a4xlfIplJX3o5CpZR8aAk9S8P8HAQ

https://www.coleparmer.com/i/branso...1s6CxiZDnSQqkyG4a4xlfIplJX3o5CpZR8aAk9S8P8HAQ

Strictly Attitude

solid fixture here in the forum

http://www.emersonindustrial.com/en...-solutions/metal-cleaner-1/Pages/default.aspx

All the cleaners on this page are designed to be used in an ultrasonic if you read descriptions it will tell you what they are for exactly. There are allot of great products here.

All the cleaners on this page are designed to be used in an ultrasonic if you read descriptions it will tell you what they are for exactly. There are allot of great products here.

Strictly Attitude

solid fixture here in the forum

I did see some of the others you posted after the fact