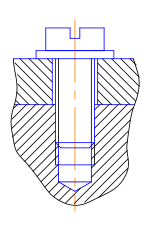

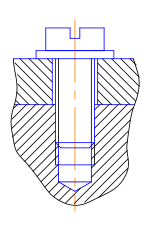

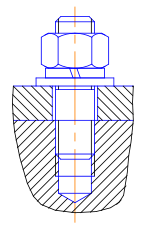

You can use whatever you want but the 2 main advantages to using studs are less strain and more longevity on the threads in an aluminum intakes carburetor mount area and you can get more uniform clamping action with the fine threads vs coarse in the intake., your A LOT less likely to have problems with threads stripping on the intake or the mount pad cracking with correctly installed studs. Id suggest use of LOCTITE thread sealer on the intake threads and NYLOC nuts on the nuts holding the carburetor to the pad, compressing the gasket.

BTW they come in a dozen lengths and threads but the 5/16" diam. and either 1.5",1.75" or 2" length size fits most applications, with the smaller two lengths being most common, if your NOT using a carburetor spacer under the carburetor.

http://store.summitracing.com/partdetai ... toview=sku

http://www.summitracing.com/expertadvic ... Calculator

viewtopic.php?f=52&t=1717&p=4255#p4255

HEY GRUMPY??

What is the reason for the carb intake studs having 2 different threads? Specifically, since the coarse thread is for the intake, why does the carb nut have a fine thread?

HEY GRUMPY??

What is the reason for the carb intake studs having 2 different threads? Specifically, since the coarse thread is for the intake, why does the carb nut have a fine thread?

Good question. Steel fine threads are stronger than steel course threads of the same diameter. Also, steel fine thread nuts are a less likely to vibrate loose than steel course thread nuts. But, there is no sense in using the stronger fine thread on the stud in order to gain greater resistance to thread stripping if the coarse thread part of the stud sees the higher torque and can then fail (cast iron fine threads are weaker than steel fine threads). As far as the fine thread nut being more resistant to vibration loosening, my question is, what stops the stud from loosening at the coarse thread end, unless the cast iron manifold/steel stud interface makes for a tighter bond?

thread depth in relation to both the material used and bolt diam. effect max hold or clamping strength,assuming both the bolts and material threaded are approximately equal strength, in steel, a depth of 1 times the diam of the bolt should provide a grip on the thread section equal to or exceeding the elastic limit of the bolts diam. but in steel, 1.5 times diam. is a really safe minimum,(example a 5/16" bolt threaded 5/8"" deep should hold the max tension the bolts capable of holding) but 2-2.5 times diam. should never fail.with either type threads.

in aluminum the safe minimum thread engagement is about 2.5 times the bolt diam. but 3 times is a really safe minimum.

fine threads can usually hold a higher clamp load than course threads

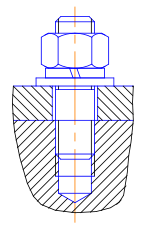

ok, the coarse threads are supposed to be installed full length or at least to about 3 times their diam. MINIMUM depth in aluminum with a sealant like loc-tite on the threads, because theres zero stress loads being applied to the studs while they are being installed and tension stress is only applied after the threads are fully engaged over at least 3 times the diam. theres no strength advantage to using the finer thread pitch, because stress is only applied after the threads fully engaged.

on the fine thread upper end your applying both torque loads and tension stress loads while clamping, and the finer thread allow higher clamping loads, remember the NUT seldom had more than 1.2 times the thread diam. to apply that clamp load , and a washer should be under the nut to help equalize the clamp force

Fine Thread Vs Coarse Thread

Fine threads have a larger Tensile Stress Area than coarse threads.

Example 1/4-28 - 0.0364

1/4-20 - 0.0318

Everything else being equal - bolts with fine threads are stronger in tension than bolts with coarse threads.

http://www.engineersedge.com/calculator ... gement.htm

http://www.boltscience.com/pages/strength.htm

http://www.boltplanet.com/Un/un.asp?txtseries_page=UN

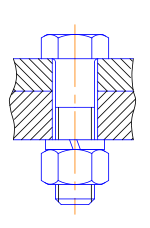

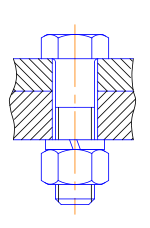

these style nuts PREVENT vibration from loosening carb stud nuts

obviously theres options to nyloc nuts

use of loctite thread locker sealant on the carb to stud threads is an excellent idea

A nyloc nut, also known nylon insert lock nut, polymer insert lock nut or elastic stop nut (although incorrectly, as an elastic stop nut is broad class of locking nuts), is a kind of nut that includes a nylon collar insert. The insert is placed at the end of the nut and its inner diameter (ID) is slightly smaller than the major diameter of the screw. The insert deforms elastically over the threads of the screw, but threads are not cut into the nylon. The nylon insert locks the nut in two ways. First, it forces the bottom face of the screw threads against the top face of the nut threads, increasing the friction between the two. Second, the nylon applies a compressive force against the screw itself. Nyloc nuts retain their locking ability up to 250 °F

Fine Thread Vs Coarse Thread

Fine threads have a larger Tensile Stress Area than coarse threads.

Example 1/4-28 - 0.0364

1/4-20 - 0.0318

Everything else being equal - bolts with fine threads are stronger in tension than bolts with coarse threads.

http://www.engineersedge.com/calculator ... gement.htm

http://www.boltscience.com/pages/strength.htm

viewtopic.php?f=50&t=50&p=12563&hilit=studs#p12563

http://www.boltplanet.com/Un/un.asp?txtseries_page=UN

http://en.wikipedia.org/wiki/Bolted_joint

viewtopic.php?f=51&t=2851&p=7376&hilit=studs#p7376

viewtopic.php?f=52&t=2746&p=7513&hilit=studs#p7513

http://www.mechanicsupport.com/articleB ... ength.html

BTW they come in a dozen lengths and threads but the 5/16" diam. and either 1.5",1.75" or 2" length size fits most applications, with the smaller two lengths being most common, if your NOT using a carburetor spacer under the carburetor.

http://store.summitracing.com/partdetai ... toview=sku

http://www.summitracing.com/expertadvic ... Calculator

viewtopic.php?f=52&t=1717&p=4255#p4255

HEY GRUMPY??

What is the reason for the carb intake studs having 2 different threads? Specifically, since the coarse thread is for the intake, why does the carb nut have a fine thread?

HEY GRUMPY??

What is the reason for the carb intake studs having 2 different threads? Specifically, since the coarse thread is for the intake, why does the carb nut have a fine thread?

Good question. Steel fine threads are stronger than steel course threads of the same diameter. Also, steel fine thread nuts are a less likely to vibrate loose than steel course thread nuts. But, there is no sense in using the stronger fine thread on the stud in order to gain greater resistance to thread stripping if the coarse thread part of the stud sees the higher torque and can then fail (cast iron fine threads are weaker than steel fine threads). As far as the fine thread nut being more resistant to vibration loosening, my question is, what stops the stud from loosening at the coarse thread end, unless the cast iron manifold/steel stud interface makes for a tighter bond?

thread depth in relation to both the material used and bolt diam. effect max hold or clamping strength,assuming both the bolts and material threaded are approximately equal strength, in steel, a depth of 1 times the diam of the bolt should provide a grip on the thread section equal to or exceeding the elastic limit of the bolts diam. but in steel, 1.5 times diam. is a really safe minimum,(example a 5/16" bolt threaded 5/8"" deep should hold the max tension the bolts capable of holding) but 2-2.5 times diam. should never fail.with either type threads.

in aluminum the safe minimum thread engagement is about 2.5 times the bolt diam. but 3 times is a really safe minimum.

fine threads can usually hold a higher clamp load than course threads

ok, the coarse threads are supposed to be installed full length or at least to about 3 times their diam. MINIMUM depth in aluminum with a sealant like loc-tite on the threads, because theres zero stress loads being applied to the studs while they are being installed and tension stress is only applied after the threads are fully engaged over at least 3 times the diam. theres no strength advantage to using the finer thread pitch, because stress is only applied after the threads fully engaged.

on the fine thread upper end your applying both torque loads and tension stress loads while clamping, and the finer thread allow higher clamping loads, remember the NUT seldom had more than 1.2 times the thread diam. to apply that clamp load , and a washer should be under the nut to help equalize the clamp force

Fine Thread Vs Coarse Thread

Fine threads have a larger Tensile Stress Area than coarse threads.

Example 1/4-28 - 0.0364

1/4-20 - 0.0318

Everything else being equal - bolts with fine threads are stronger in tension than bolts with coarse threads.

http://www.engineersedge.com/calculator ... gement.htm

http://www.boltscience.com/pages/strength.htm

http://www.boltplanet.com/Un/un.asp?txtseries_page=UN

these style nuts PREVENT vibration from loosening carb stud nuts

obviously theres options to nyloc nuts

use of loctite thread locker sealant on the carb to stud threads is an excellent idea

A nyloc nut, also known nylon insert lock nut, polymer insert lock nut or elastic stop nut (although incorrectly, as an elastic stop nut is broad class of locking nuts), is a kind of nut that includes a nylon collar insert. The insert is placed at the end of the nut and its inner diameter (ID) is slightly smaller than the major diameter of the screw. The insert deforms elastically over the threads of the screw, but threads are not cut into the nylon. The nylon insert locks the nut in two ways. First, it forces the bottom face of the screw threads against the top face of the nut threads, increasing the friction between the two. Second, the nylon applies a compressive force against the screw itself. Nyloc nuts retain their locking ability up to 250 °F

Fine Thread Vs Coarse Thread

Fine threads have a larger Tensile Stress Area than coarse threads.

Example 1/4-28 - 0.0364

1/4-20 - 0.0318

Everything else being equal - bolts with fine threads are stronger in tension than bolts with coarse threads.

http://www.engineersedge.com/calculator ... gement.htm

http://www.boltscience.com/pages/strength.htm

viewtopic.php?f=50&t=50&p=12563&hilit=studs#p12563

http://www.boltplanet.com/Un/un.asp?txtseries_page=UN

http://en.wikipedia.org/wiki/Bolted_joint

viewtopic.php?f=51&t=2851&p=7376&hilit=studs#p7376

viewtopic.php?f=52&t=2746&p=7513&hilit=studs#p7513

http://www.mechanicsupport.com/articleB ... ength.html