the larger the plenum volume (up to about 1/3- 1/2 of the engines displacement, the better the peak horsepower potential tends to be PROVIDED the runner and plenum design is near optimal. as the plenum volume is reduced the engine tends to become more responsive due to higher port flow speeds to throttle position changes and the mid and low rpm torque tends to improve, up to the point the runners cross sectional area or plenum size or carb venturies feeding them become a restriction to flow

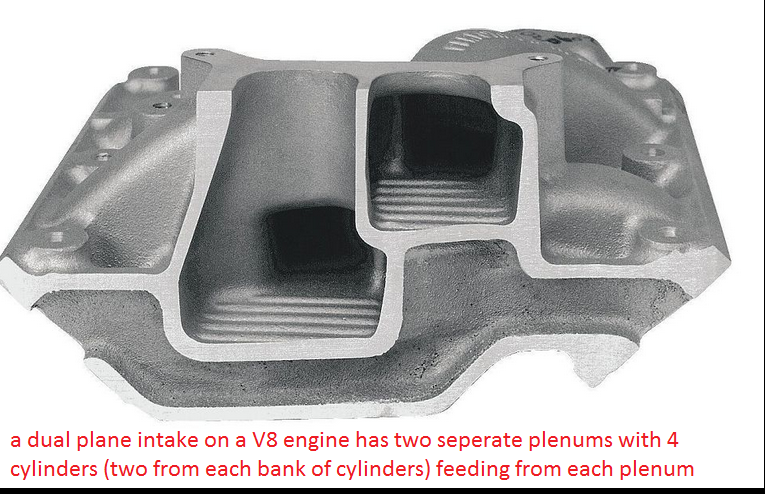

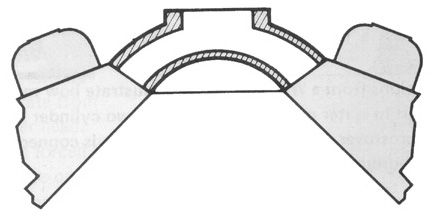

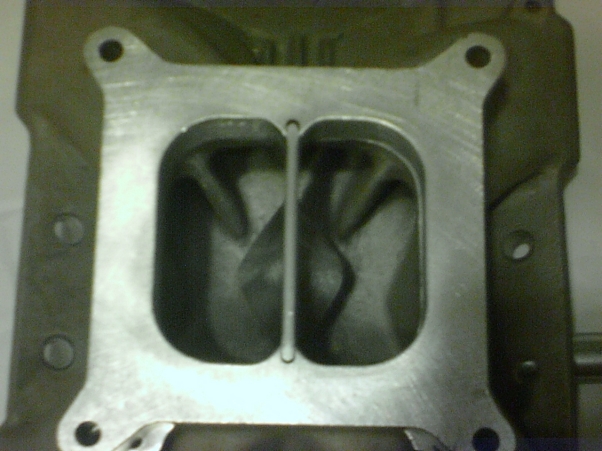

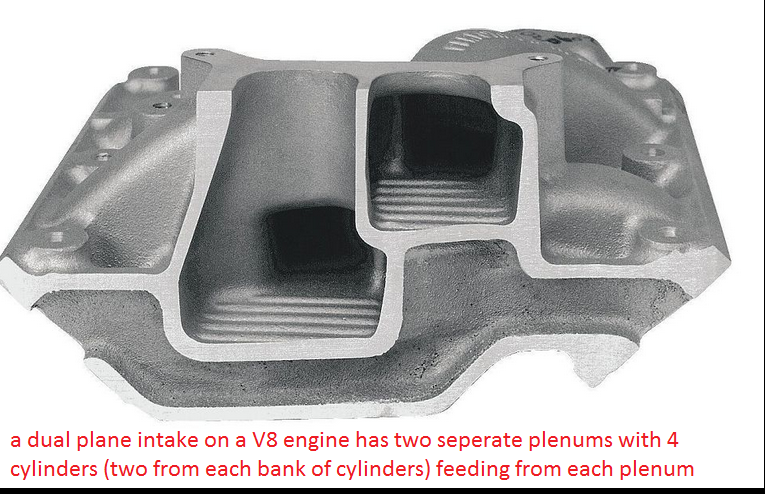

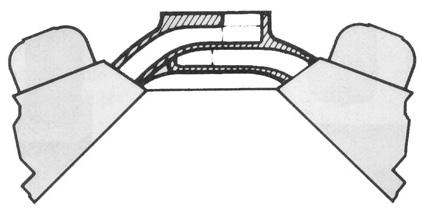

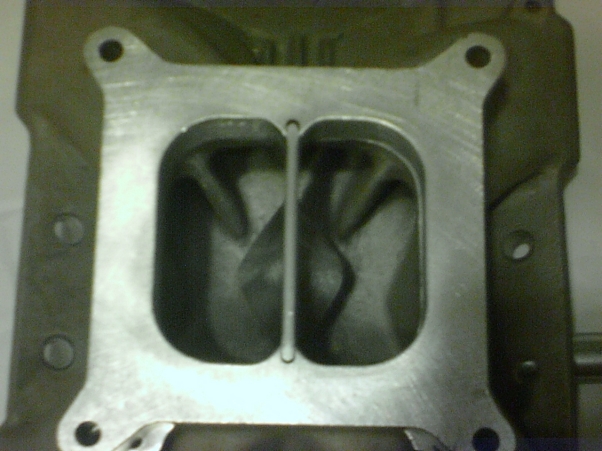

on a dual plane intake design a single primary and secondary venturie in the carburetor feeds four individual intake runners from 1 of two common plenums

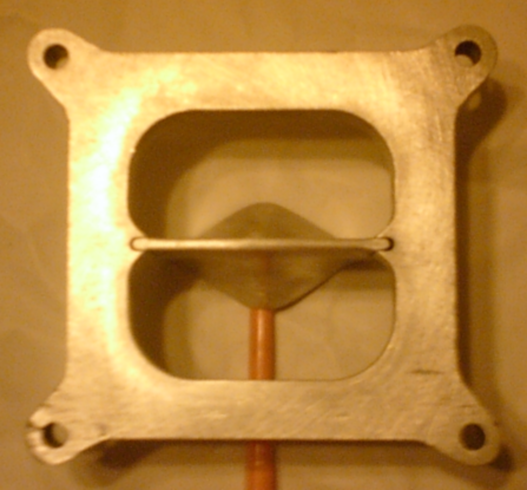

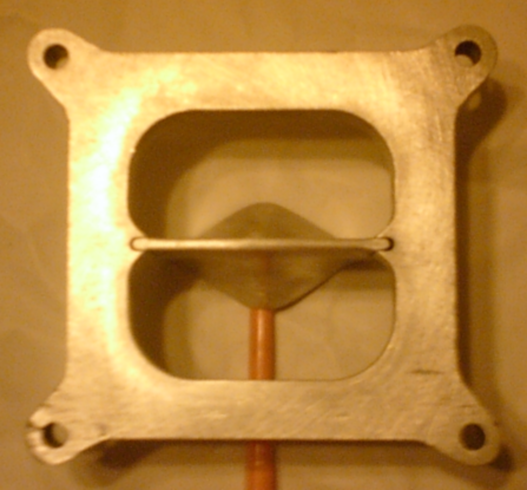

open carburetor spacers under a carburetor are designed for and generally used with single plane common plenum intakes to increase plenum volume

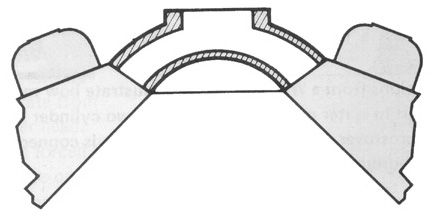

dual plane intakes have twin plenums designed to increase low and mid rpm port flow speeds and work best "in MANY CASES" with 4 hole or divided spacers, that maintain the high port flow speeds but allow more room under the carb to reduce the transition of direction as the air flow enters the individual intake runners, in some cases where the engine is very restricted a single open spacer or lowering the plenum divider wall helps improve flow rates on a dual plenum intake but if it proves to be a huge improvement in that application its almost a guarntee that a properly designed single plane intake would do even better

common dual plain divided dual plenum

viewtopic.php?f=55&t=4362&p=11826&hilit=volumetric#p11826

this mod effectively doubles the plenum volume, and effectively converts the intake into a semi-single plane design, but the modification tends to reduce low rpm engine torque and engine low and mid rpm responsiveness, because the added plenum volume tends to slow the low rpm port speeds , because the individual cylinders now can pull from a larger common volume of fuel/air mix in that larger plenum area.

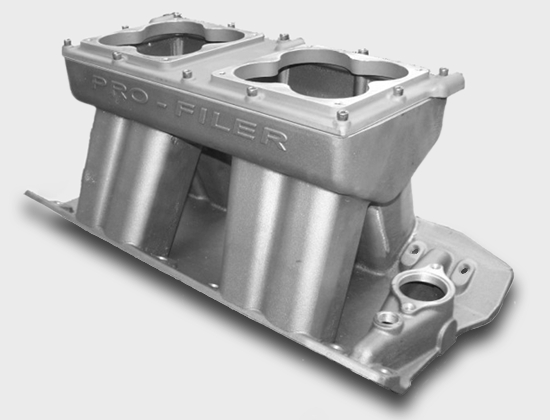

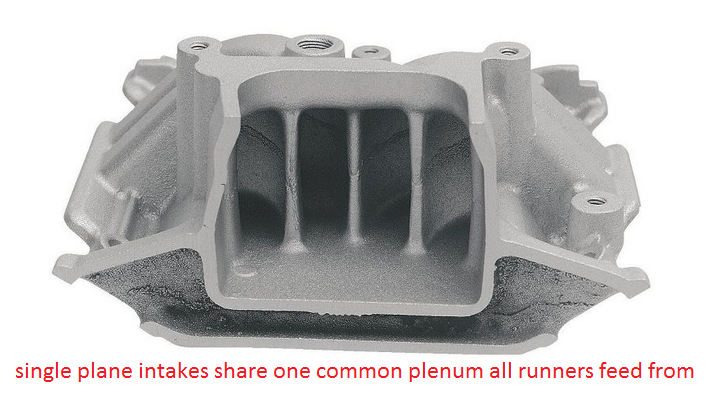

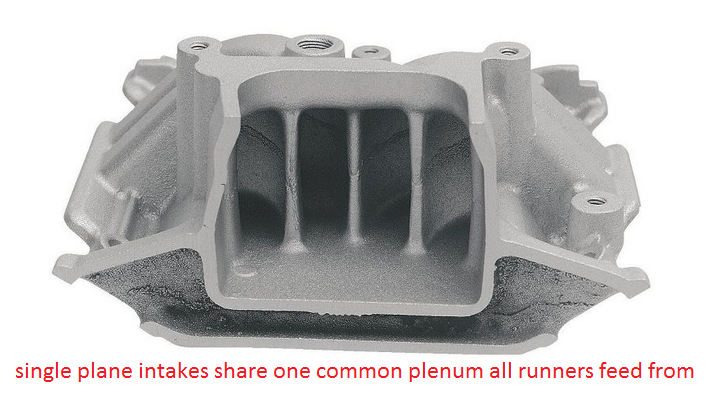

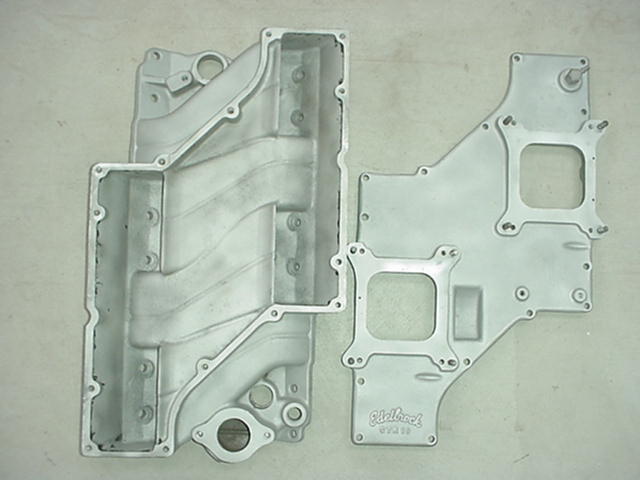

on a single plane intake design a pair of primary and a pair of secondary venturies in the carburetor feeds eight individual intake runners from 1 common plenum

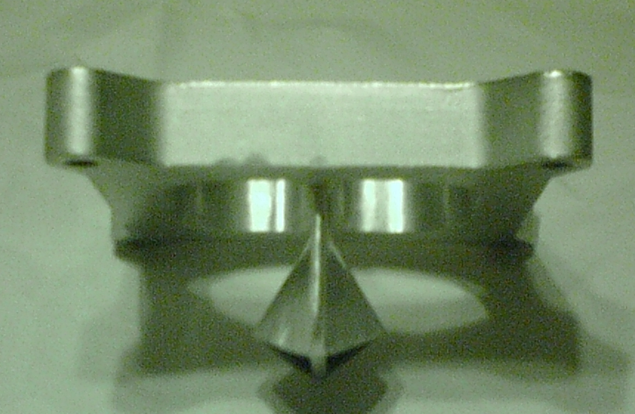

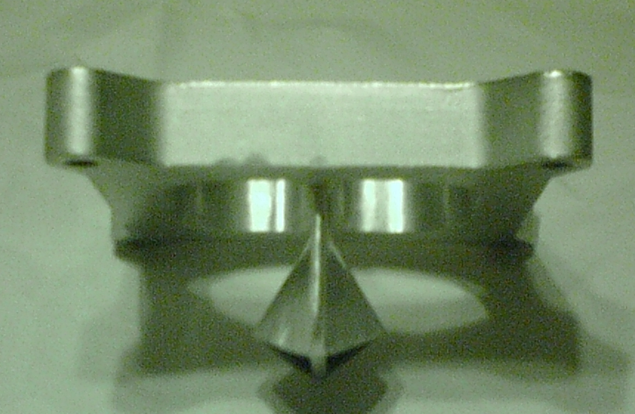

you can fabricate or in some cases modify intake plenums or add on spacers with plenum dividers, or "TURTLES" to get the air flow characteristics you desire

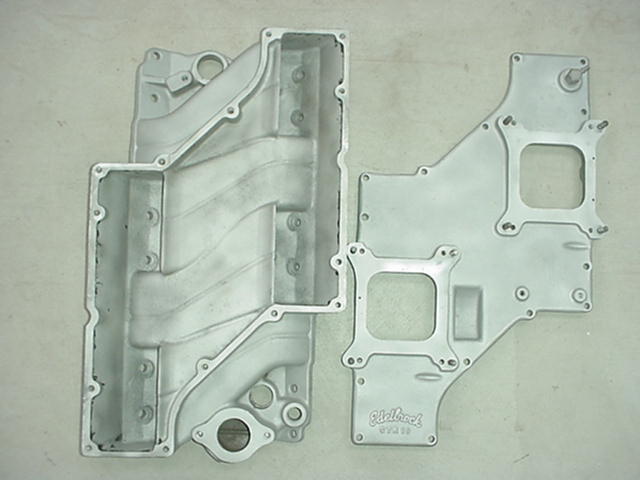

common single plane common single plenum

dual carb single common plenum cross ram

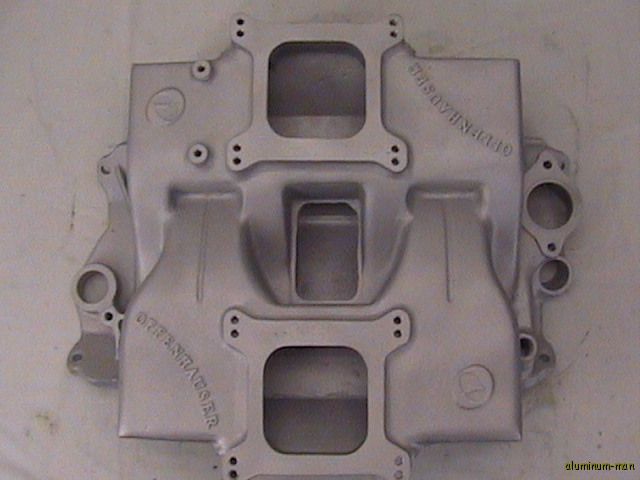

dual carb ,dual plenum single plane intake

single plenum dual carb tunnel ram intake

CIRCLE TRACK MAG HAD THIS INFO

Carburetor Spacers

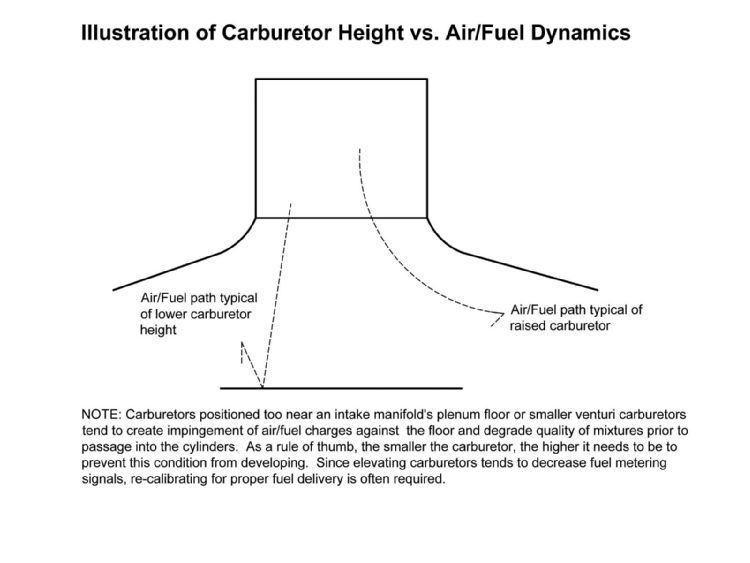

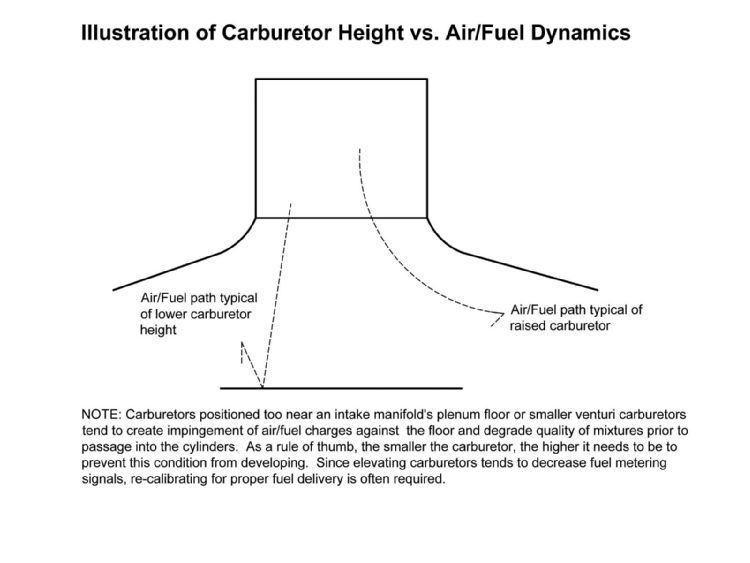

You've likely read or heard about an assortment of consequences when a carburetor is raised (or lowered) relative to an intake manifold's plenum floor. More plenum volume helps high rpm, for example. Or maybe, smaller carburetors like more spacer. This isn't to say these analogies are incorrect, but maybe the reasons are a bit obscure.

For example, let's look at it this way. A carburetor is a pressure differential device. It delivers fuel into a region that's designed to be at less than atmospheric pressure. It's a fuel metering "signal" that allows atmospheric pressure to force fuel into the incoming airstream, acting through the carburetor's bowl vents. By elevating a carburetor, all else being equal, it becomes more remote to runner entries and thus can experience a weaker metering signal. The carburetor tends to act "leaner" in the presence of a decreased signal. Aggregate airflow tends to be the same but there's less fuel flow, so fuel enrichment is decreased.

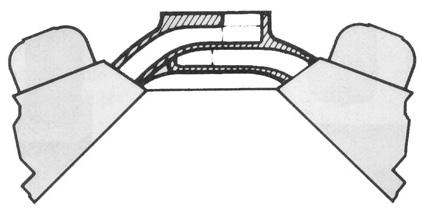

However, as Smokey often said, "there's one more little item." Once discharged from the carburetor, air/fuel charges are required to make a relatively abrupt turn into the manifold's runners. Air, being compressible can navigate this sudden change more easily than fuel. Increasing carburetor height allows air/fuel charges more time to slow down and make the turn more effectively, often reducing the possibility of air and fuel separation. As carburetor size is decreased and no spacer is used, the problem becomes more critical. In fact, carburetors placed too near a plenum floor can be akin to sticking a hose in a bucket with fuel impingement materially upsetting proper air/fuel mixtures.

One key here is to map brake specific fuel consumption (BSFC) data as carburetor height is changed, assuming carburetor sizing remains the same. If a disproportionate amount of fuel is required for best power and BSFC data are trending higher and higher, chances are good mixture quality is being upset and raising the carburetor is a potential solution.

On the other hand, if you discover that a four-hole spacer is beneficial, possible reasons include the fact the fuel metering signals were insufficient (for the calibration or jetting being used) and stronger signals provided by the spacer helped deliver additional fuel. But in virtually any case, power changes from raising or lowering a carburetor affect more areas than plenum volume.

READ THESE LINKS

http://victorylibrary.com/mopar/intake-tech-c.htm#new

viewtopic.php?f=55&t=858&p=1338&hilit=spacer+plenum#p1338

viewtopic.php?f=55&t=1038&p=1932#p1932

viewtopic.php?f=55&t=624&p=11125&hilit=intake+test+result#p11125

viewtopic.php?f=44&t=392

viewtopic.php?f=52&t=322

on a dual plane intake design a single primary and secondary venturie in the carburetor feeds four individual intake runners from 1 of two common plenums

open carburetor spacers under a carburetor are designed for and generally used with single plane common plenum intakes to increase plenum volume

dual plane intakes have twin plenums designed to increase low and mid rpm port flow speeds and work best "in MANY CASES" with 4 hole or divided spacers, that maintain the high port flow speeds but allow more room under the carb to reduce the transition of direction as the air flow enters the individual intake runners, in some cases where the engine is very restricted a single open spacer or lowering the plenum divider wall helps improve flow rates on a dual plenum intake but if it proves to be a huge improvement in that application its almost a guarntee that a properly designed single plane intake would do even better

common dual plain divided dual plenum

viewtopic.php?f=55&t=4362&p=11826&hilit=volumetric#p11826

this mod effectively doubles the plenum volume, and effectively converts the intake into a semi-single plane design, but the modification tends to reduce low rpm engine torque and engine low and mid rpm responsiveness, because the added plenum volume tends to slow the low rpm port speeds , because the individual cylinders now can pull from a larger common volume of fuel/air mix in that larger plenum area.

on a single plane intake design a pair of primary and a pair of secondary venturies in the carburetor feeds eight individual intake runners from 1 common plenum

you can fabricate or in some cases modify intake plenums or add on spacers with plenum dividers, or "TURTLES" to get the air flow characteristics you desire

common single plane common single plenum

dual carb single common plenum cross ram

dual carb ,dual plenum single plane intake

single plenum dual carb tunnel ram intake

CIRCLE TRACK MAG HAD THIS INFO

Carburetor Spacers

You've likely read or heard about an assortment of consequences when a carburetor is raised (or lowered) relative to an intake manifold's plenum floor. More plenum volume helps high rpm, for example. Or maybe, smaller carburetors like more spacer. This isn't to say these analogies are incorrect, but maybe the reasons are a bit obscure.

For example, let's look at it this way. A carburetor is a pressure differential device. It delivers fuel into a region that's designed to be at less than atmospheric pressure. It's a fuel metering "signal" that allows atmospheric pressure to force fuel into the incoming airstream, acting through the carburetor's bowl vents. By elevating a carburetor, all else being equal, it becomes more remote to runner entries and thus can experience a weaker metering signal. The carburetor tends to act "leaner" in the presence of a decreased signal. Aggregate airflow tends to be the same but there's less fuel flow, so fuel enrichment is decreased.

However, as Smokey often said, "there's one more little item." Once discharged from the carburetor, air/fuel charges are required to make a relatively abrupt turn into the manifold's runners. Air, being compressible can navigate this sudden change more easily than fuel. Increasing carburetor height allows air/fuel charges more time to slow down and make the turn more effectively, often reducing the possibility of air and fuel separation. As carburetor size is decreased and no spacer is used, the problem becomes more critical. In fact, carburetors placed too near a plenum floor can be akin to sticking a hose in a bucket with fuel impingement materially upsetting proper air/fuel mixtures.

One key here is to map brake specific fuel consumption (BSFC) data as carburetor height is changed, assuming carburetor sizing remains the same. If a disproportionate amount of fuel is required for best power and BSFC data are trending higher and higher, chances are good mixture quality is being upset and raising the carburetor is a potential solution.

On the other hand, if you discover that a four-hole spacer is beneficial, possible reasons include the fact the fuel metering signals were insufficient (for the calibration or jetting being used) and stronger signals provided by the spacer helped deliver additional fuel. But in virtually any case, power changes from raising or lowering a carburetor affect more areas than plenum volume.

READ THESE LINKS

http://victorylibrary.com/mopar/intake-tech-c.htm#new

viewtopic.php?f=55&t=858&p=1338&hilit=spacer+plenum#p1338

viewtopic.php?f=55&t=1038&p=1932#p1932

viewtopic.php?f=55&t=624&p=11125&hilit=intake+test+result#p11125

viewtopic.php?f=44&t=392

viewtopic.php?f=52&t=322

Last edited by a moderator: