now theres obviously two totally different types of valve covers , and theres several types, and many guys prefer one or the other of both major kinds, tall and standard heights and some have interior baffles or rocker arm lube drippers etc.

THERES VALVE COVER SPACERS IF YOU JUST NEED TO INCREASE HEIGHT ON YOUR CURRENT VALVE COVERS TO GAIN CLEARANCE FOR ROLLER ROCKERS ETC>

http://www.jegs.com/i/B-B/128/63910/100 ... tId=747514

http://garage.grumpysperformance.co...to-fit-roller-rockers-and-stud-girdles.12208/

or obviously a wide selection of taller valve cover designs

the stamped steel style are generally cheaper and CHROME finish is rather common.

stamped covers tend to be lighter in weight, and they can, have a tendency to warp if over tightened.

on the plus side stamped covers are usually easier to keep clean, and tend to cost a good deal less and if you need to weld on an oil return or some other accessory there several options, but theres obviously a wide range in quality between manufacturers

most TALL valve covers actually do provide some extra surface area for hot oil to radiate heat from, they radiate some extra heat because although the engine bay may be 150F or more its still cooler than the 215F-245F the oil running over them is so they absorb and transfer heat from the oil,and tend to reduce oil temperatures a few degrees

http://www.summitracing.com/parts/EDL-4480/

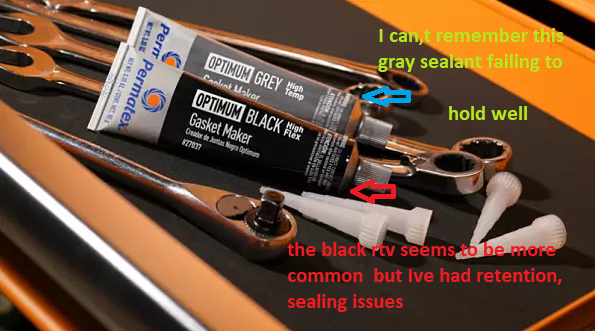

For more information, check out www.permatex.com. You’ll find product specs, technical data sheets, and instructional videos to help you learn more about which Permatex Gasket Maker is right for your job.

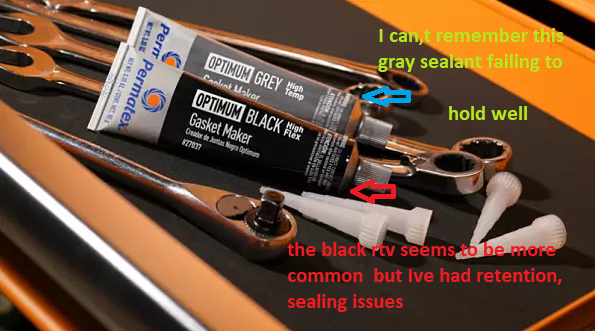

In my experience, the black rtv works ok,

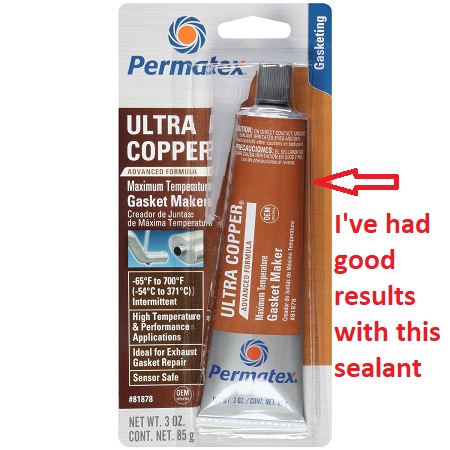

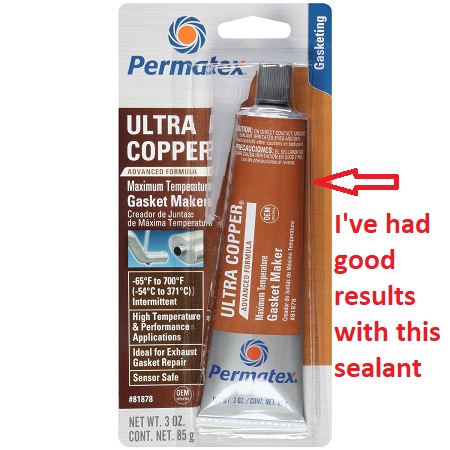

but the high heat gray or copper gasket sealant has always worked a bit better

I prefer this for most of the jobs where silicone type gasket sealants get used like intake gaskets and valve cover gaskets

http://garage.grumpysperformance.com/index.php?threads/sealants-and-threads.805/#post-71928

truthfully all three sealants work in a wide range odf applications, they work , best,if the surfaces were cleaned and de-greased prior to the sealants application,

of the sealant you select, so I doubt you,ll have any issues,

given a choice, Id have selected the high temp copper or as a back-up the high temp gray,

but like I stated I doubt any of the three would fail to do the job.

the key is proper surface, prep, de- greasing and cleaning, prior to the sealant application, and not over tightening the bolts.

On oil pans I prefer studs, and an oil pan back plate

you might want to Use with P/N 12553058 RH and P/N 12553059 LH oil pan reinforcement plates to distribute the bolt stress on the oil pan rail for 1985 and earlier oil pans P/N 14088501 (LH) and P/N 14088502 (RH).1986 and newer

http://www.summitracing.com/parts/MOR-68112/

http://www.summitracing.com/parts/DRT-6 ... /?rtype=10

stamped covers generally require load spreaders to equalize the gasket seal pressures to reduce leaks

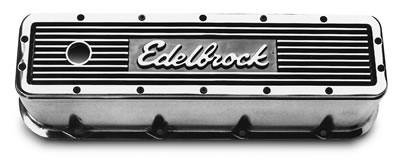

I think youll find that cast aluminum valve covers like these

,( rather than the less expensive and flimsy stamped steel valve covers)

with the bolt support holes cast into the side of the height spreads the load much more effectively,

and are also much more ridgid and less likely to warp or bent and thus less likely to leak.

http://www.summitracing.com/parts/MIL-85320/?rtype=10

personally Ive always preferred the TALL cast valve covers for the extra interior room that allows a rocker stud girdle and less chance of oil leaks, but chrome valve covers do look impressive on most cars

the CAST ZINK or ALUMINUM designs are generally stiffer or more rigid and higher quality (and cost 3-7 times more) but generally don,t have a CHROME finish, either polished aluminum, of powder coating tends to be more common on cast valve covers, and most don,t weld well as oil returns for turbos etc, need to be attached with a different method.

http://www.summitracing.com/parts/DRT-6 ... /?rtype=10

http://www.summitracing.com/parts/BRO-VC200/

http://www.summitracing.com/parts/EDL-4280/?rtype=10

http://www.summitracing.com/parts/NAL-25534323/

http://www.summitracing.com/parts/PRO-141-141/?rtype=10

http://www.summitracing.com/parts/NAL-12499200/

FABRICATED aluminum valve covers are relatively new to the hobby and can be quite expensive.

http://www.summitracing.com/parts/HAM-1086/?rtype=10

http://www.racerswholesale.com/product.cfm?InvKey=66017

http://www.southernrods.com/categories/ ... -2169.html

but there ARE DEALS IF YOU SHOP

THERES VALVE COVER SPACERS IF YOU JUST NEED TO INCREASE HEIGHT ON YOUR CURRENT VALVE COVERS TO GAIN CLEARANCE FOR ROLLER ROCKERS ETC>

My Cam Research for the Experts Eye

Test fit of intake/gaskets, it all fits like a glove. When I first built the engine I had done some mild chamber and port match on the heads. I'm happy with the current gasket. I set lifter preload, with everything locked down it looks like my original M/T valve covers will fit after all...

garage.grumpysperformance.com

does synthetic oil cause leaky gaskets?

hey grumpyvette? as far as synthetic in old cars. does anyone actually have any proof that synthetic oil eats seals or is it one of those wives tale things. BTW I have on several occasions seen guys who complain about various oil leaks on valve covers and rear seals ETC. Used, engine...

garage.grumpysperformance.com

taller valve covers?

most guys with corvettes/ or muscle cars tend too stay with the stock valve covers unless forced into swapping , due to clearance issues caused by the use of roller rockers, stud girdles or other aftermarket valve train accessories. On some corvettes or muscle cars theres serious clearance...

garage.grumpysperformance.com

http://garage.grumpysperformance.co...to-fit-roller-rockers-and-stud-girdles.12208/

or obviously a wide selection of taller valve cover designs

the stamped steel style are generally cheaper and CHROME finish is rather common.

stamped covers tend to be lighter in weight, and they can, have a tendency to warp if over tightened.

on the plus side stamped covers are usually easier to keep clean, and tend to cost a good deal less and if you need to weld on an oil return or some other accessory there several options, but theres obviously a wide range in quality between manufacturers

most TALL valve covers actually do provide some extra surface area for hot oil to radiate heat from, they radiate some extra heat because although the engine bay may be 150F or more its still cooler than the 215F-245F the oil running over them is so they absorb and transfer heat from the oil,and tend to reduce oil temperatures a few degrees

http://www.summitracing.com/parts/EDL-4480/

For more information, check out www.permatex.com. You’ll find product specs, technical data sheets, and instructional videos to help you learn more about which Permatex Gasket Maker is right for your job.

In my experience, the black rtv works ok,

but the high heat gray or copper gasket sealant has always worked a bit better

I prefer this for most of the jobs where silicone type gasket sealants get used like intake gaskets and valve cover gaskets

http://garage.grumpysperformance.com/index.php?threads/sealants-and-threads.805/#post-71928

truthfully all three sealants work in a wide range odf applications, they work , best,if the surfaces were cleaned and de-greased prior to the sealants application,

of the sealant you select, so I doubt you,ll have any issues,

given a choice, Id have selected the high temp copper or as a back-up the high temp gray,

but like I stated I doubt any of the three would fail to do the job.

the key is proper surface, prep, de- greasing and cleaning, prior to the sealant application, and not over tightening the bolts.

On oil pans I prefer studs, and an oil pan back plate

you might want to Use with P/N 12553058 RH and P/N 12553059 LH oil pan reinforcement plates to distribute the bolt stress on the oil pan rail for 1985 and earlier oil pans P/N 14088501 (LH) and P/N 14088502 (RH).1986 and newer

http://www.summitracing.com/parts/MOR-68112/

http://www.summitracing.com/parts/DRT-6 ... /?rtype=10

stamped covers generally require load spreaders to equalize the gasket seal pressures to reduce leaks

I think youll find that cast aluminum valve covers like these

,( rather than the less expensive and flimsy stamped steel valve covers)

with the bolt support holes cast into the side of the height spreads the load much more effectively,

and are also much more ridgid and less likely to warp or bent and thus less likely to leak.

http://www.summitracing.com/parts/MIL-85320/?rtype=10

personally Ive always preferred the TALL cast valve covers for the extra interior room that allows a rocker stud girdle and less chance of oil leaks, but chrome valve covers do look impressive on most cars

the CAST ZINK or ALUMINUM designs are generally stiffer or more rigid and higher quality (and cost 3-7 times more) but generally don,t have a CHROME finish, either polished aluminum, of powder coating tends to be more common on cast valve covers, and most don,t weld well as oil returns for turbos etc, need to be attached with a different method.

http://www.summitracing.com/parts/DRT-6 ... /?rtype=10

http://www.summitracing.com/parts/BRO-VC200/

http://www.summitracing.com/parts/EDL-4280/?rtype=10

http://www.summitracing.com/parts/NAL-25534323/

http://www.summitracing.com/parts/PRO-141-141/?rtype=10

http://www.summitracing.com/parts/NAL-12499200/

FABRICATED aluminum valve covers are relatively new to the hobby and can be quite expensive.

http://www.summitracing.com/parts/HAM-1086/?rtype=10

http://www.racerswholesale.com/product.cfm?InvKey=66017

http://www.southernrods.com/categories/ ... -2169.html

but there ARE DEALS IF YOU SHOP

Last edited by a moderator: