I stopped by the local "Regal Plastics" on a whim since I needed a plate to CC the combustion

chambers. I had no idea if they even dealt with the public, but it's usually not fatal

to try. They had a door labeled "Customer Entrance".....Hum looks good I'll try there first. They had

some example of some of the products they can make on site, they are not just materials but also fabrication.

He took me to the shop area to look thru the scrap pieces, there was plenty of the sizes in the range that

I needed.

Tip #1: Take cash for small purchases. They had a $10 minimum, but since I had cash, it only cost

$ 4.35 for what you see in the picture. Roughly 12 x 5.5 x 3/8.

Question: Once I got it home, I began to wonder if I should even cut it. Maybe it would be easier

if I CC'ed two chambers together. I know on a the scale of 1-10 of important questions, this rates

about a 2. Makes me wonder if you couldn't do all four cylinders, but you would need a different

plate for each type of head this way.

Oh well enough rambling, anyone try doing multiple chambers with one plate ???

Regal Plastic has multiple locations in the US.

http://www.regal-plastics.com/index.html

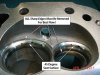

Tip #2: Get some old valves junk from your machine shop to protect the valve seats if you are going

to work on the combustion chambers, I plan on CC ing and polishing them. Since the 1.94" Intakes and 1.60 Exhausts

are very plentiful he gave a couple of each to see what I thought. It looks like these might

be helpful, but you can see how they don't quite cover the the 45 degree seat surface. I used

a Sharpie to identify the 45 degree cut. It's hard to see with all the shine.

Carter's Automotive Machine, where I took my pieces, said if I could wait a few days he probably had some junk

2.02 intakes and 1.60 exhaust or he could get some new cheap one for about $5 each. Looks like I

need some.

I will need to get really close the the seats to smooth out the sharp machine surfaces that will have a negative effect on flow and increase the chance of detonation.

chambers. I had no idea if they even dealt with the public, but it's usually not fatal

to try. They had a door labeled "Customer Entrance".....Hum looks good I'll try there first. They had

some example of some of the products they can make on site, they are not just materials but also fabrication.

He took me to the shop area to look thru the scrap pieces, there was plenty of the sizes in the range that

I needed.

Tip #1: Take cash for small purchases. They had a $10 minimum, but since I had cash, it only cost

$ 4.35 for what you see in the picture. Roughly 12 x 5.5 x 3/8.

Question: Once I got it home, I began to wonder if I should even cut it. Maybe it would be easier

if I CC'ed two chambers together. I know on a the scale of 1-10 of important questions, this rates

about a 2. Makes me wonder if you couldn't do all four cylinders, but you would need a different

plate for each type of head this way.

Oh well enough rambling, anyone try doing multiple chambers with one plate ???

Regal Plastic has multiple locations in the US.

http://www.regal-plastics.com/index.html

Tip #2: Get some old valves junk from your machine shop to protect the valve seats if you are going

to work on the combustion chambers, I plan on CC ing and polishing them. Since the 1.94" Intakes and 1.60 Exhausts

are very plentiful he gave a couple of each to see what I thought. It looks like these might

be helpful, but you can see how they don't quite cover the the 45 degree seat surface. I used

a Sharpie to identify the 45 degree cut. It's hard to see with all the shine.

Carter's Automotive Machine, where I took my pieces, said if I could wait a few days he probably had some junk

2.02 intakes and 1.60 exhaust or he could get some new cheap one for about $5 each. Looks like I

need some.

I will need to get really close the the seats to smooth out the sharp machine surfaces that will have a negative effect on flow and increase the chance of detonation.