Dart iron eagle 200 runner 49cc vs Edelbrock rpm 185 runner 64cc

350 standard bore

Edelbrock air gap intake

750 Proform carb

1" spacer

Isky 288 hyd cam

.244 / .244 dur

.450 / .450 lift with 1.5 rockers

But I'm running 1.6 rockers

So should bring up the lift to around

.475 / .475 lift

350 trans

4000 stall

410 gears

This combo now has the

Edelbrock rpm heads in it

My best time

12.05 @ 111mph

Question is would the Dart heads help or hurt my combo?

Wt is 3180lbs with driver

USE THE CALCULATORS

http://www.rbracing-rsr.com/runnertorquecalc.html

http://www.wallaceracing.com/chokepoint.php

http://www.wallaceracing.com/header_length.php

http://www.wallaceracing.com/chokepoint.php

http://www.rbracing-rsr.com/runnertorquecalc.html

http://www.velocity-of-sound.com/velocity_of_sound/calculator1.htm

Im always rather amused , at similar questions and the inevitable rather vague answers that youll see posted on various sites, that always make it seem like its some black magic art form, to calculate the port velocity. the truth is that its rather easy to calculate the port stall speed and at least get some idea on the potential changes that would result.youll also need to know your cam lift, duration, and port flow numbers,and it helps to understand pressure drop, in the plenum and in the header collectors.

simply measuring and a few calculations will give you a very good idea as to the potential change the intake port size should make.

viewtopic.php?f=52&t=333&p=407&hilit=cross+sectional+area#p407

http://www.rbracing-rsr.com/runnertorquecalc.html

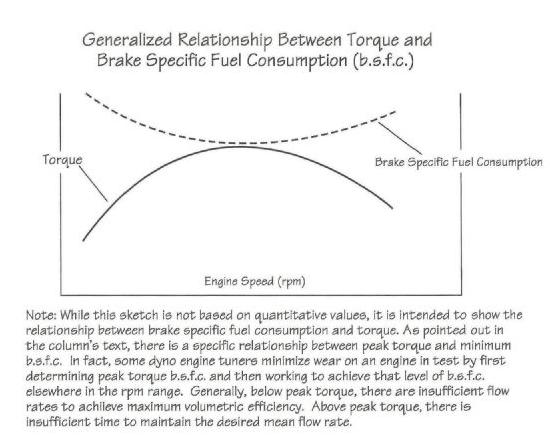

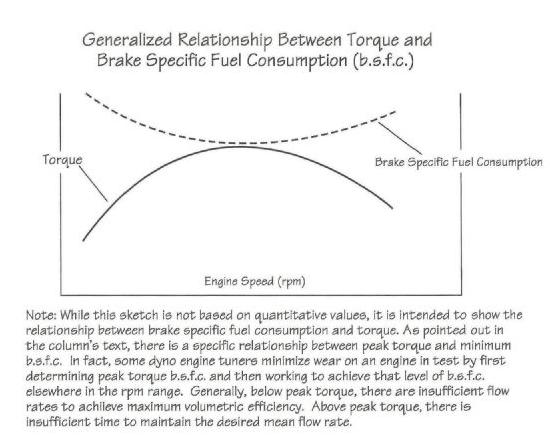

if the cross sectional area of the runner changed by 5% than you can expect the torque peak to move a similar percentage, but there are several other factors like port shape and cam timing, exhaust scavenging etc, that also effect the results.

lets say your current port is 1.93 sq inches at the narrowest point near the push rod and your new head has a 2.07 sq inch area , thats about a 7% change so you could see the power curve move up about 250 rpm if everything were ideally matched to take advantage of the change, in the real world Id expect a 150rpm change at best.

so if your currently making lets say 450 ft lbs of torque at 4500rpm (386 hp at peak torque)and it moved your torque peak 150 rpm, to 450 ft lbs at 4650rpm,(thats 398 hp at peak torque ) is a potential gain of about 12 hp at that point in your power band IF the heads were flowing similar flow numbers

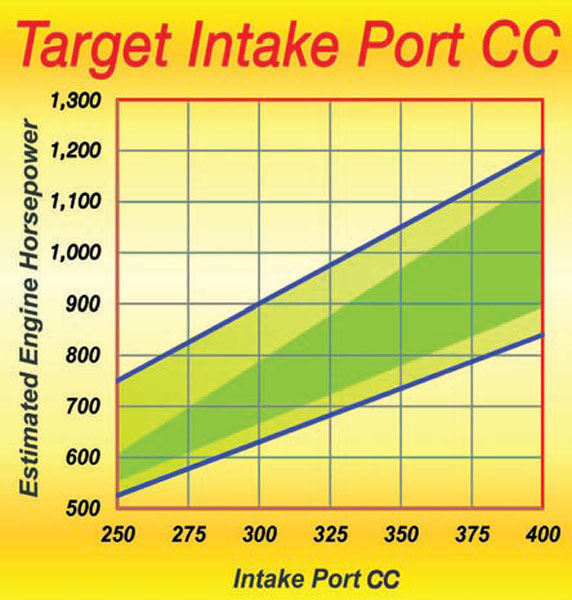

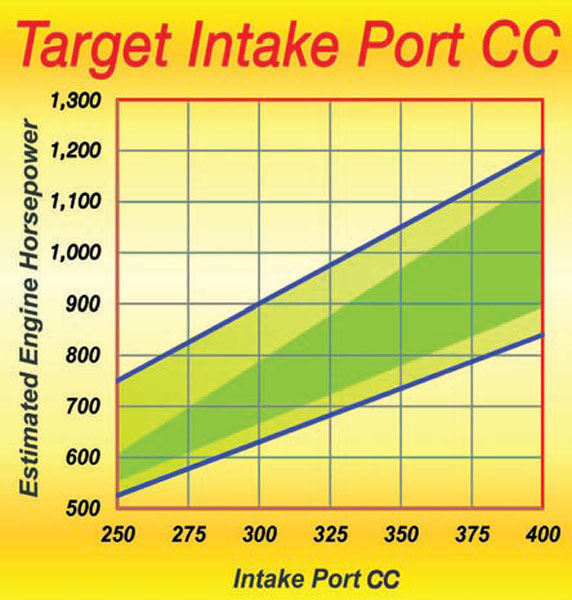

you can expect a torque gain of about 3% for every ratio increase in compression, swapping from a 64cc head to a 49cc head on a 350 should jump compression noticeably, on a flat top piston 350 with average specs your now running about a 9.9:1 compression ratio, swapping to a 49cc combustion chamber boosts that to near 11.8:1 so you could expect to be forced to run race fuel and gain about another 24hp,PLUS so yeah, in theory 36 hp PLUS GAIN, is possible from the swap, but swapping from aluminum heads to iron heads and several other factors makes me think the head swap will benefit from a slightly more aggressive SOLID LIFTER cam swap also like the cam below so you could dependably run that combo up to 7400rpm, and your going to need much better valve springs to run any where near 7000rpm

http://www.cranecams.com/product/cart.p ... il&p=24416

why not talk to the tech guys at crane, crower, lunati erson.

MUCH MORE INFO

viewtopic.php?f=52&t=240&p=285&hilit=cross+sectional+area#p285

viewtopic.php?f=52&t=181

viewtopic.php?f=52&t=148&p=182&hilit=cross+sectional+area#p182

viewtopic.php?f=52&t=322&p=516&hilit=cross+sectional+area#p516

350 standard bore

Edelbrock air gap intake

750 Proform carb

1" spacer

Isky 288 hyd cam

.244 / .244 dur

.450 / .450 lift with 1.5 rockers

But I'm running 1.6 rockers

So should bring up the lift to around

.475 / .475 lift

350 trans

4000 stall

410 gears

This combo now has the

Edelbrock rpm heads in it

My best time

12.05 @ 111mph

Question is would the Dart heads help or hurt my combo?

Wt is 3180lbs with driver

USE THE CALCULATORS

http://www.rbracing-rsr.com/runnertorquecalc.html

http://www.wallaceracing.com/chokepoint.php

http://www.wallaceracing.com/header_length.php

http://www.wallaceracing.com/chokepoint.php

http://www.rbracing-rsr.com/runnertorquecalc.html

http://www.velocity-of-sound.com/velocity_of_sound/calculator1.htm

Im always rather amused , at similar questions and the inevitable rather vague answers that youll see posted on various sites, that always make it seem like its some black magic art form, to calculate the port velocity. the truth is that its rather easy to calculate the port stall speed and at least get some idea on the potential changes that would result.youll also need to know your cam lift, duration, and port flow numbers,and it helps to understand pressure drop, in the plenum and in the header collectors.

simply measuring and a few calculations will give you a very good idea as to the potential change the intake port size should make.

viewtopic.php?f=52&t=333&p=407&hilit=cross+sectional+area#p407

http://www.rbracing-rsr.com/runnertorquecalc.html

if the cross sectional area of the runner changed by 5% than you can expect the torque peak to move a similar percentage, but there are several other factors like port shape and cam timing, exhaust scavenging etc, that also effect the results.

lets say your current port is 1.93 sq inches at the narrowest point near the push rod and your new head has a 2.07 sq inch area , thats about a 7% change so you could see the power curve move up about 250 rpm if everything were ideally matched to take advantage of the change, in the real world Id expect a 150rpm change at best.

so if your currently making lets say 450 ft lbs of torque at 4500rpm (386 hp at peak torque)and it moved your torque peak 150 rpm, to 450 ft lbs at 4650rpm,(thats 398 hp at peak torque ) is a potential gain of about 12 hp at that point in your power band IF the heads were flowing similar flow numbers

you can expect a torque gain of about 3% for every ratio increase in compression, swapping from a 64cc head to a 49cc head on a 350 should jump compression noticeably, on a flat top piston 350 with average specs your now running about a 9.9:1 compression ratio, swapping to a 49cc combustion chamber boosts that to near 11.8:1 so you could expect to be forced to run race fuel and gain about another 24hp,PLUS so yeah, in theory 36 hp PLUS GAIN, is possible from the swap, but swapping from aluminum heads to iron heads and several other factors makes me think the head swap will benefit from a slightly more aggressive SOLID LIFTER cam swap also like the cam below so you could dependably run that combo up to 7400rpm, and your going to need much better valve springs to run any where near 7000rpm

http://www.cranecams.com/product/cart.p ... il&p=24416

why not talk to the tech guys at crane, crower, lunati erson.

MUCH MORE INFO

viewtopic.php?f=52&t=240&p=285&hilit=cross+sectional+area#p285

viewtopic.php?f=52&t=181

viewtopic.php?f=52&t=148&p=182&hilit=cross+sectional+area#p182

viewtopic.php?f=52&t=322&p=516&hilit=cross+sectional+area#p516

Last edited by a moderator: