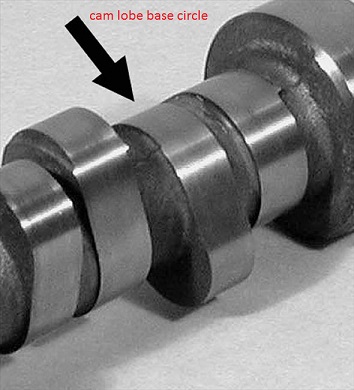

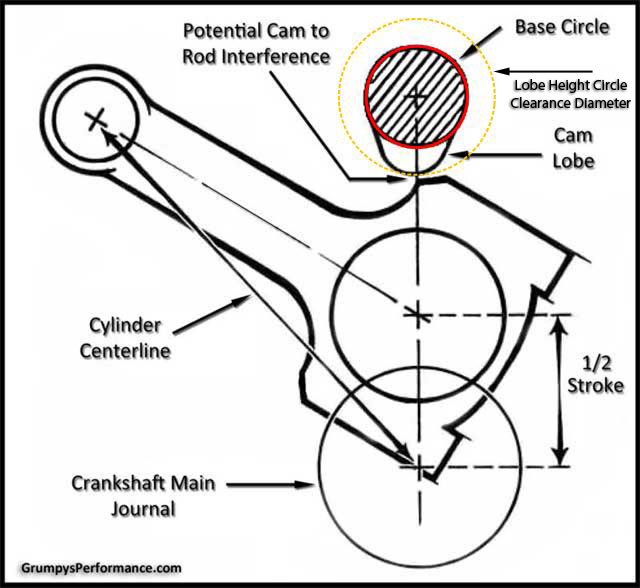

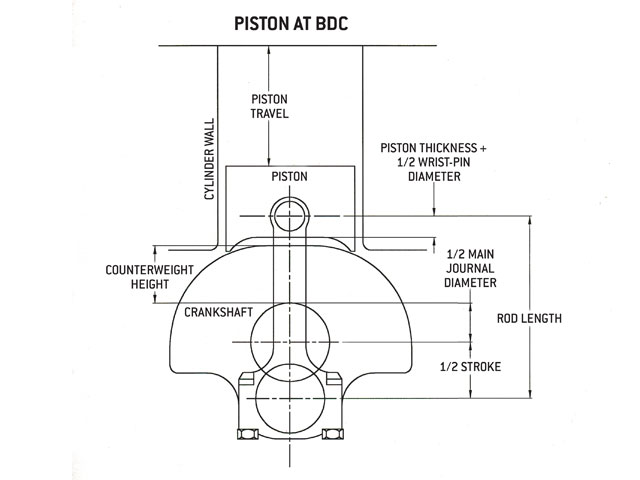

I want to to do a cam swap on my 434 SBC in a 9.025 deck height block. I currently run a ".900 base circle camshaft", the new camshaft does not come in a .900 base circle. Is there a way I can figure out if the new camshaft base circle and lobe lift will have clearance issues before I purchase the cam? I am changing to hydraulic and it doesn't come in a .900 base circle.

Thanks for your assistance,

Steve

Thanks for your assistance,

Steve