read the links

http://en.wikipedia.org/wiki/Differenti ... _device%29

http://en.wikipedia.org/wiki/Limited_slip_differential

http://www.artmorrison.com/multi-link-IRS.php

http://www.offroaders.com/tech/limited- ... ntials.htm

http://www.quickperformance.com/Technic ... easure.htm

http://www.drivetrain.com/parts_catalog ... s_lsd.html

http://www.f150online.com/forums/other- ... uburn.html

http://www.chevytrucks.org/tech/ifs&rearend.htm

POSITRACTIONS / LIMITED SLIPS

Auburn Gear (AG)

The Auburn Gear limited slip uses a cone style clutch that wears directly against the carrier case and provides the friction force to make the unit work. This design is not rebuildable. Once the cone clutch or case wears out, the entire unit must be replaced. Even with this shortcoming, this design works well for occasional use where extra traction is needed. They have good impact strength in passenger cars and trucks up to 1 ton. They will hold up well to high horse power, but will not last long if there is a lot of tire spinning. (aftermarket ) 1 yr warranty

Auburn Gear PRO (AG)

Also cone style & not rebuildable. Designed with more lockup force than regular Auburn Gear limited slips. Will provide better high performance traction than regular Auburn Gear, but still wears out under extreme off-road use and heavy wheel spin. This design tends to chatter a lot and is not recommended if the customer is looking for a smooth unit. (aftermarket ) 1 yr warranty

Detroit Locker (DET)

Heavy duty. Probably the most durable design available, the king of traction differentials. Usually causes banging and clunking, but gives 100% lock-up whenever traction is needed. Unlocks when negotiating a turn so that the outer wheel can turn faster than the ring gear is turning and the inside wheel are turning. Does not need any interaction from the driver. New Sof-Locker design has damping device to reduce banging and clunking. Includes carrier case that is stronger than stock except in 2 applications where the original factory carrier case is used. Only the 10.5" 14 bolt truck and the Nissan V6 designs use the factory carrier case and these cases are both very strong. (aftermarket ) 1 yr warranty

Eaton (EAT)

Clutch type, similar to Trac-Lok in design, yet far stronger like a Power-Lok, and, more aggressive and better lock-up similar to the Power-Lok design. These units came as an original equipment option in 65-72 12T (12 bolt GM truck), 12P (12 bolt GM passenger), 8.2" GM pass, 63-79 Cast Iron Corvettes. The original OEM 12T case was very weak, but the new design replacement from Eaton is very strong. 4 preload springs and 2 steel preload spring plates. Latest design uses HD nodular iron case, forged side and pinion gears, no-chatter, race-bred, carbon fiber clutches for extreme strength and longevity. Old design, all steel clutches which are still available in 18 or 22 clutch designs for those who need more lock-up and are not bothered by clutch chatter. For even more lockup customization, there are also 4 levels of spring pressure available (3 from Eaton and a fourth from GM) that can be used to vary the clutch preload from 200 lbs. to 800 lbs. Originally used in mid sixties GM muscle cars and trucks. This unit is now available for Ford applications and soon will be available for Dana Spicer, AMC, and Chrysler applications. They have a high tolerance for abuse in high horsepower vehicles. Recommended for everyday driving and severe off-road use (factory GM )

Detroit Truetrac (TT)

Based on the worm gear principal and works like clutch type positraction. Does not wear out, not recommended for tall tires over 33".

Detroit Truetracs are similar in design to the Gleason Torsen®, only the Truetracs hold up well with reasonably tall tires. They use worm wheel gears that work on the same principle as a worm gear. When the unit is loaded, the worm wheels are forced away from each other and against the case. They develop locking torque by the light friction between the worm wheels and the case. This light friction is multiplied by the ratio of the worm wheel which depends on the size of the worm wheel relative to the size of the side gear. The manufacturer can change the amount of torque biasing or lockup by simply changing the diameter of the gears, or the pitch and spiral of the teeth. A larger difference in the size for the worm wheels and side gears (smaller worm wheels and larger side gears) will increase the lockup force. Increasing the pitch and spiral of the teeth will also increase the lockup forces. Like everything, there is a limit as to how much lockup force is reasonable. Making the unit too "aggressive" will cause tire scrub during everyday driving and will cause the unit to wear out too quickly. All of the feedback that I have received from customers indicates that the unit works very well for mud and snow, while going unnoticed during every day driving. When used in situations like rocky trails where one wheel gets off the ground, the unit will not lock up 100%. Light application of the brakes will help the differential engage more transferring power to the tire that is still on the ground. For extreme situations where the vehicle will have one wheel in the air often a locking differential provides better power transfer to the wheel on the ground.

Detroit Truetracs are designed for medium duty 2WD and 4WD applications. They work well in the front and rear, and are so smooth that there is little or no hint of resistance in the steering wheel when used in front drive steering axles. Like the Gleason Torsen®, the Detroit Truetrac does not bang or clunk, has no clutch chatter, does not wear out like clutch type positractions, does not need limited slip additive, and needs no preload or clearance adjustments.

Almost sounds too good to be true doesn't it? The only drawbacks to the Truetracs are their inability to provide lockup 100% like a locking differential can. Although Gleason no longer makes the Torsen® differential, the Detroit Truetrac is a proven design that is available for many popular applications. (aftermarket) 1 yr warranty

http://www.ringpinion.com/ContentFrame. ... action.inc

An Improved Eaton Positraction An Improved Eaton Positraction In the early 1970s, real muscle cars were fading away, and average Americans were becoming more concerned with a plush ride than with high performance. In the 1973 model year, General Motors decided to start using the Gov-Lock in trucks, in an effort to eliminate positraction chatter associated with conventional spring preload clutch type positractions. This was the one of the few solutions available using 1970's technology. Thus, for GM trucks produced after 1972, the only traction-enhancing option was the Gov-Lock (still produced by Eaton) which does not even begin to compare to Eaton's 4 spring positraction. These governor actuated units provide a locking differential without chatter. Great for the average truck owner, but not for those who really use their trucks off-road. Often referred to as a "time bomb" or "Timex Posi". These locking differentials work fairly well for occasional use when traction is of small concern, but not when power transfer and traction are the main goal. The Gov-Lock can fail in any number of ways, and often does. Usually, the case will break in half, but sometimes small internal parts will break. I have no intention of defending them except to say that the Gov-Locks used in 3/4 & 1 ton trucks hold up fairly well due to their sheer size, and especially well when compared to the smaller designs.

For readers looking for something stronger, Eaton makes redesigned units are worth showing off. They are not actually a "new" design so much as a vast improvement on the old design. The basis for their new units is the heavy-duty positraction that they originally produced for big block GM muscle cars in the 60s and early 70s.

The latest Eaton Posi Limited Slips now come with race-bred pyrolytic carbon fiber clutches that are more durable than their steel counterparts. These virtually indestructible clutches do not chatter and have a high tolerance for abuse such as tall tires and constant off-road use.

New units also use stronger spider gears produced with Net Form Forging technology. These stronger spider gears look very different compared to standard cut gears. They are made from 8620 steel, and are carbonized to increase strength and durability. Net Form Forged gears perform at least 20% better than standard cut gears in both impact testing, and testing for fatigue under heavy loading.

In addition to the other improvements, Eaton has improved the case designs. The original 12-bolt truck positraction was very similar to the passenger car design but was not nearly as strong as it's passenger car counterpart. The new 12-bolt truck cases are about three times stronger than the original ones used in the early 1970s, and all Eaton Posi cases are now made of nodular cast iron with increased material thickness in critical areas. The new 10-bolt cases now have larger bearing journals that increase the case strength and use bearings with more rollers than stock.

Overall, the new Eaton Posi's are superior to the admired and sought after original OEM GM positraction. By using 90's technology, Eaton has built a stranger, harder working positraction that does not chatter.

Eaton has developed positraction differentials for 7.5" GM, 9.5" GM, 8.8" Ford, Dana 44, and Dana 60.

http://www.hotrod.com/techarticles/driv ... index.html

Improve Your 10- And 12-Bolt Positraction

Ways To Improve The Effectiveness Of Both The Eaton Plate-Style And The Auburn Cone-Design Limited-Slip Units

From the February, 2009 issue of Hot Rod

By Jeff Smith

Photography by Jeff Smith

|

Tweet

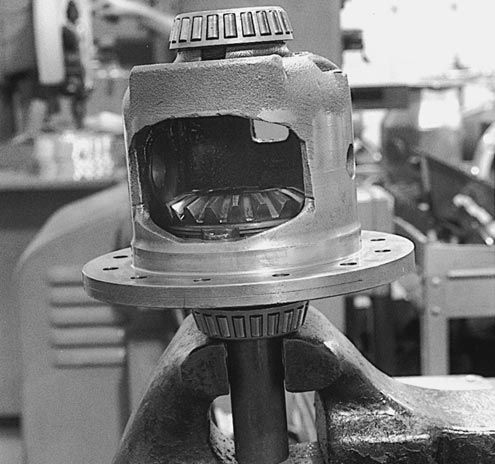

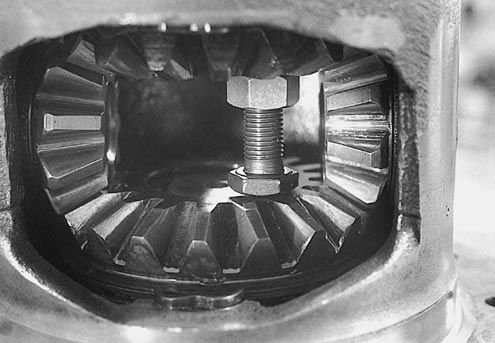

The best way to rework a posi...

read full caption

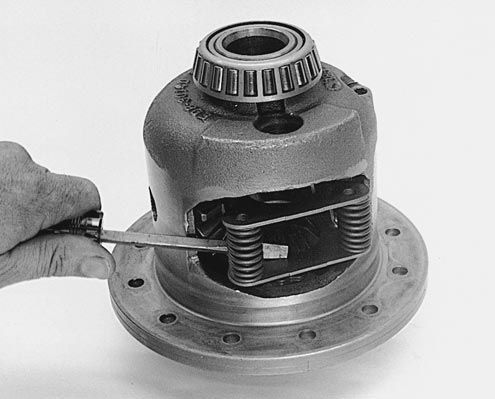

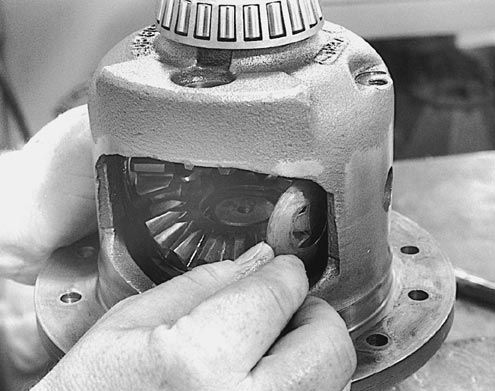

With the center pin removed,...

read full caption

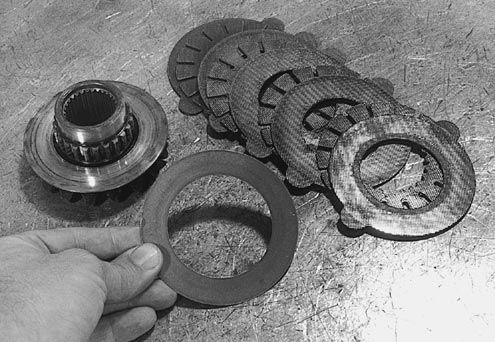

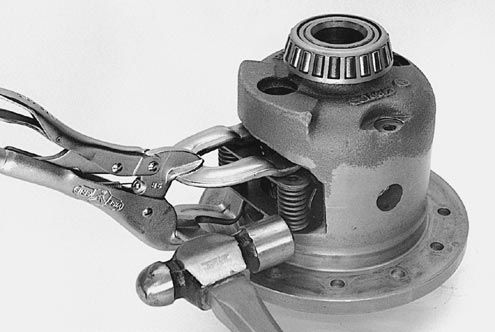

Once the spider gears are...

read full caption

Inspect the clutches and replace...

read full caption

The hard part comes when you...

read full caption

Chrisman found that this 1-inch-long...

read full caption

Test fit the large center...

read full caption

A C-clamp or large pliers...

read full caption

The posi is now ready to be...

read full caption

This is the posi breakaway...

read full caption

The only thing more frustrating than not having the power to spin the tires is smoking the right rear when you,d rather be accelerating. Single-tire spin occurs with either an open differential or a dead posi-traction unit. Since two legs are better than one in any kind of butt-kicking contest, we,ll take a look at a couple of ways to improve the effectiveness of both the Eaton plate-style and the Auburn cone-design limited-slip units.

The purpose of a posi-traction unit is to tie the two drive axles together for more efficient traction under acceleration. Originally designed to improve traction in mud, snow and icy conditions, such traction improvers were soon adopted to limit tire spin. Under hard acceleration in a rear-wheel-drive car, torque tries to rotate the rearend housing, lifting the right rear tire while planting the left one. While a posi-traction device does nothing to counteract that motion, it does connect the two drive tires with a friction device to prevent the right rear tire from spinning. The effectiveness of the unit can be measured by the amount of torque it takes to break the right rear tire loose from the left rear.

At this point, you might think that the simplest way to permanently tie the two wheels together would be with a solid link between the two axles. Drag racers often employ just such a device, known as a spool. Low-buck hot rodders sometimes weld the spider and side gears together to create an inexpensive spool. Unfortunately, both of those alternatives are dangerous for street use. The reason for the differential in any vehicle is to accommodate the different distances the inside and outside tires must travel in a turn (the outside tire travels a significantly greater distance than the inside tire). If the outside tire is not allowed to travel the greater distance, the axles twist and the outside tire tends to bounce and chirp. That eventually leads to broken axles. When the axle breaks in a GM 10- or 12-bolt rearend, the tire, wheel and axle combination exits the car, tearing up the rear sheetmetal in the process.

A limited-slip unit allows some slippage between the axles in a turn, which means that the device will eventually wear to the point where it cannot prevent torque from spinning the right rear tire under straight-line acceleration or the inside tire when accelerating out of a turn. That,s when you know it,s time to rebuild the posi.

We won,t cover removing the posi from the rearend in this story. If you need more information on that, you can consult a shop manual. Once the differential is removed from the housing, it can be easily disassembled and the clutch plates inspected for wear. To help us detail this rebuild, we enlisted the help of Steve Chrisman at Jack Chrisman Enterprises. In the case of the Eaton-style unit, a Posi-traction rebuild kit with new clutch plates is available through any Chevrolet dealer. If the friction facing on the clutches is worn, you might consider replacing the clutches. The rebuild kit is not expensive.

Usually, the clutch plates are not significantly worn even though the posi slips easily. That can be rectified by adding thicker shims to preload the posi with a higher breakaway torque. The shims are placed either between the clutch pack and the case or between the clutch pack and the large side gear. Chevrolet sells shims ranging in thickness from .007 to .030 inch that will increase the clutch-pack stack thickness and increase the torque required to make the unit slip. That is the most common way to improve the preload of a used posi-traction unit. Too thick of a washer stack will prevent you from assembling the spider gears in the posi unit. Start by using a .010-inch-thicker shim for each clutch pack (for a total of .020 inch). In our unit, that was all we could squeeze into the clutch packs and still assemble the unit. This procedure can be used to increase the preload on an Auburn cone-style posi as well.

Most posi units also employ a spring pack that puts additional load on the clutch packs. Two steel plates locate four springs that can be replaced. Chevrolet offers two different springs for the 12-bolt Eaton posi. The stock replacement springs are rated at 50 pounds per inch, while the high-performance springs are rated at 75 pounds per inch. The heavier springs can be tried, but they also may create a popping sound as they preload and then release the clutch plates, especially in tight, slow turns. Auburn also offers higher rate competition-only posi springs, but the company doesn,t recommend them for the street.

One way to measure the effectiveness of the changes you make to a posi is with a homemade torque adapter. The one we used was built by SCCA autocross racer Dan Livezey. The adapter is simply a flat steel plate drilled with the appropriate wheel bolt pattern and a 1-inch nut welded in the center. To use it we placed the car on jackstands and removed one wheel. We used the right rear since it more closely approximates a tire-spin situation. We blocked the left rear tire and slipped the adapter onto the right rear axle. With the parking brake released, we used a torque wrench to measure the amount of torque required to turn the axle. Our autocross racer sources tell us that a breakaway torque of between 110 and 140 pounds of torque will work well on the street and prevent inboard tire spin even in a tight, slow turn when the power is applied. It is possible to create more breakaway torque in a posi, but excessive torque only creates a bind in the posi that could decrease component life.

Improving your limited-slip probably doesn,t rate style points compared to bolting on a supercharger, but when it comes to putting the power to the ground, two legs are always better than one.