the pistons quench area or flat deck is supposed to come within a few thousands of an inch of the deck in most combos (.038-.044) and its not unusually for the piston quench area to reach the deck or even stick out above the deck a couple thousands, this deck or quench area is a set distance from the piston PIN center line ,the dome on a high compression piston reaches well up into the combustion chamber, at times easily 3/8" or more on some big block engines

BTW, When a head gasket thickness is listed its supposed to be the compressed gasket thickness

keep in mind it assumes you use the factory heads with the matched factory head bolts torqued to the factory suggested torque settings,this can be important in determining quench distance.

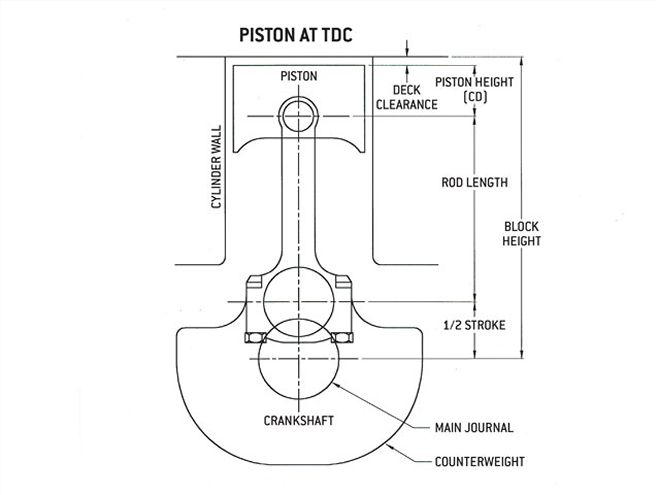

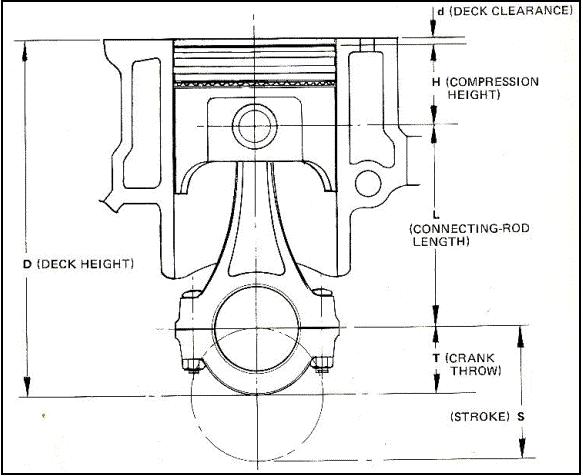

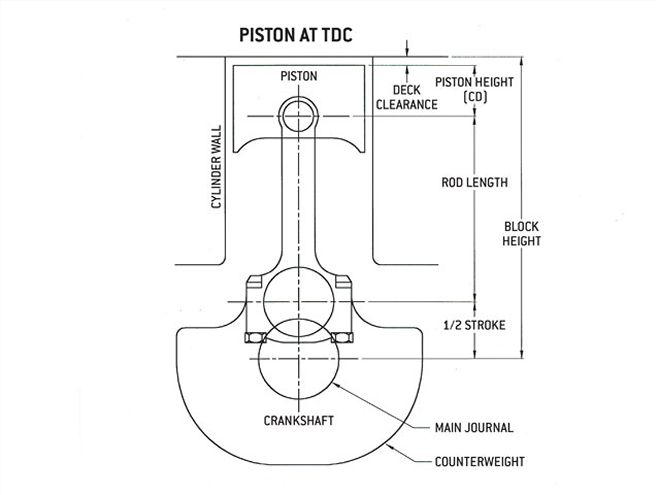

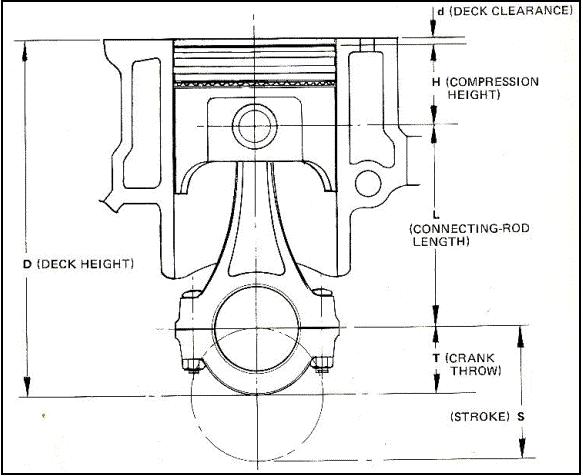

you figure the COMPRESSION HEIGHT by subtracting 1/2 of the crank stroke plus the rod length measured from piston pin center line to crank pin centerline subtracted from the blocks deck height, to get the piston compression height

if you wonder why I suggest using SCAT (H) beam style cap screw connecting rods vs stock or most (I) beam designs this picture should show the increased cam to connecting rod clearance

notice the pin height in the pistons pictured above allow a longer or shorter connecting rod length

heres a selection of commonly available big block chevy connecting rod lengths

now I may be in the small minority here, but I have always given away 3/8" bolt sbc or bbc rods rather than use them and purchased the 7/16" versions or aftermarket 7/16" cap screw rods, WITH the L19 bolt upgrade,the 7/16" rods ARE significantly stronger. rod bolts are critical, high stress items and one of the areas most likely to cause problems at high rpms and loads.

cross sectional area of a 3/8" bolt is approx .11 sq inches, a 7/16" bolt is approx .15 sq inches BTW when you go to buy a ring compressor....this type works far better than the others

EXAMPLE

on a small block chevy the deck height is 9" -9.023 if its never been deck milled

if you use a 6" rod and are building a 383 with its 3.75" stroke your dealing with a 6" plus 1.875" stroke subtracted from a 9"-9.023" deck height that results in a piston deck height of 1.125-1.130" compression height being correct

http://kb-silvolite.com/forged.php?action=details&P_id=391

remember the QUENCH distance should be between about .037 and .044 (thats the distance between the cylinder head and the piston deck) and theres a compressed GASKET between the two so you need to measure, lets say your decks never been milled and you have a block measuring 9.021 for the deck, the piston sticks up to within .015 thousands of the deck in this example (6" rod,1.875 stroke, 1.130 compression height = 9.005 subtracted from 9.021" so the quench WITHOUT a gasket would be .015 so you need to add about a .028 thick gasket

http://kb-silvolite.com/forged.php?action=details&P_id=352

"the piston was PERFECTLY clean in that area, so was the head"

THATS a GOOD indicator that the QUENCH/SQUISH function is working correctly AS its SUPPOSED TOO! the idea is to force the fuel/air mix at very high speeds into the center of the cylinder to speed up the burn rate and lower both emmisions and increase the potential HP because youll expend far less of the cylinders pressure curve resisting the piston as it approaches TDC on the compression stroke and use a larger percentage of the pressure that results from the fuel air mix being ignited durring the power stroke where it produces usefull TORQUE

BTW, When a head gasket thickness is listed its supposed to be the compressed gasket thickness

keep in mind it assumes you use the factory heads with the matched factory head bolts torqued to the factory suggested torque settings,this can be important in determining quench distance.

you figure the COMPRESSION HEIGHT by subtracting 1/2 of the crank stroke plus the rod length measured from piston pin center line to crank pin centerline subtracted from the blocks deck height, to get the piston compression height

if you wonder why I suggest using SCAT (H) beam style cap screw connecting rods vs stock or most (I) beam designs this picture should show the increased cam to connecting rod clearance

notice the pin height in the pistons pictured above allow a longer or shorter connecting rod length

heres a selection of commonly available big block chevy connecting rod lengths

now I may be in the small minority here, but I have always given away 3/8" bolt sbc or bbc rods rather than use them and purchased the 7/16" versions or aftermarket 7/16" cap screw rods, WITH the L19 bolt upgrade,the 7/16" rods ARE significantly stronger. rod bolts are critical, high stress items and one of the areas most likely to cause problems at high rpms and loads.

cross sectional area of a 3/8" bolt is approx .11 sq inches, a 7/16" bolt is approx .15 sq inches BTW when you go to buy a ring compressor....this type works far better than the others

EXAMPLE

on a small block chevy the deck height is 9" -9.023 if its never been deck milled

if you use a 6" rod and are building a 383 with its 3.75" stroke your dealing with a 6" plus 1.875" stroke subtracted from a 9"-9.023" deck height that results in a piston deck height of 1.125-1.130" compression height being correct

http://kb-silvolite.com/forged.php?action=details&P_id=391

remember the QUENCH distance should be between about .037 and .044 (thats the distance between the cylinder head and the piston deck) and theres a compressed GASKET between the two so you need to measure, lets say your decks never been milled and you have a block measuring 9.021 for the deck, the piston sticks up to within .015 thousands of the deck in this example (6" rod,1.875 stroke, 1.130 compression height = 9.005 subtracted from 9.021" so the quench WITHOUT a gasket would be .015 so you need to add about a .028 thick gasket

http://kb-silvolite.com/forged.php?action=details&P_id=352

"the piston was PERFECTLY clean in that area, so was the head"

THATS a GOOD indicator that the QUENCH/SQUISH function is working correctly AS its SUPPOSED TOO! the idea is to force the fuel/air mix at very high speeds into the center of the cylinder to speed up the burn rate and lower both emmisions and increase the potential HP because youll expend far less of the cylinders pressure curve resisting the piston as it approaches TDC on the compression stroke and use a larger percentage of the pressure that results from the fuel air mix being ignited durring the power stroke where it produces usefull TORQUE

Last edited by a moderator: