69 chevelle

New Member

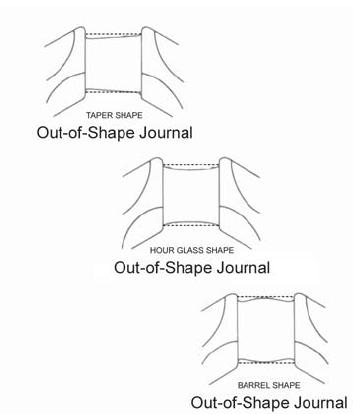

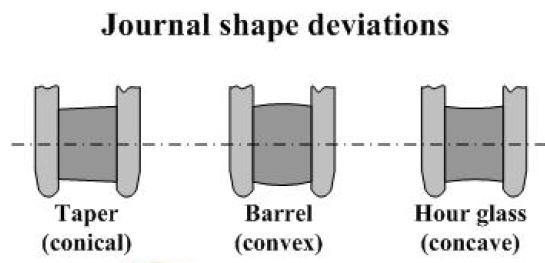

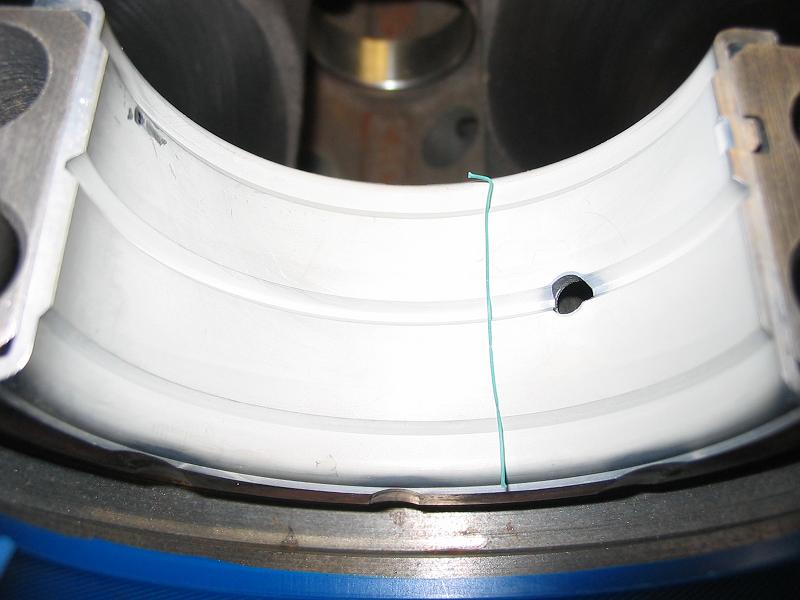

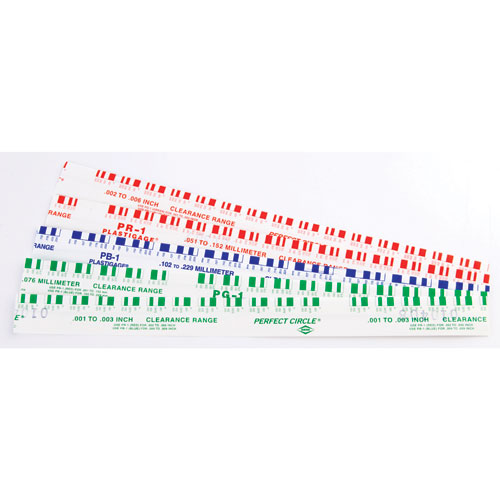

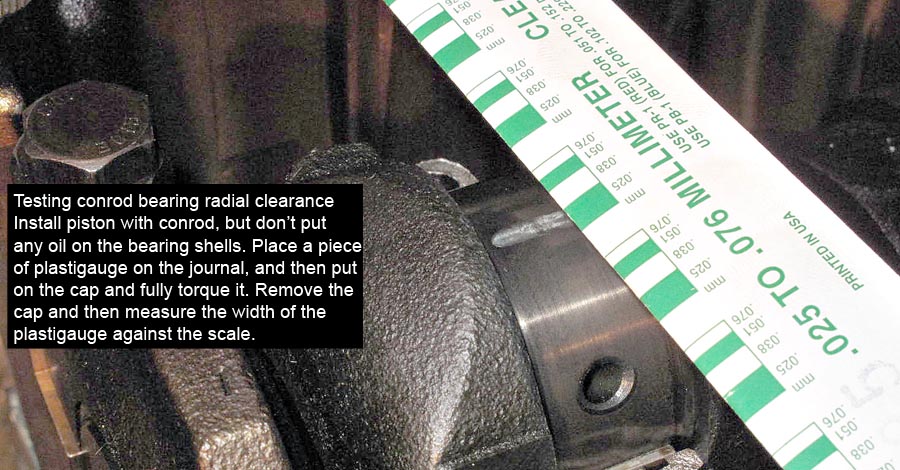

hey everyone don't know if I have a problem or not but hear goes,building 402 l78 big block,had crank shaft ground .010 under ,had rotating Assy, dynamic balanced ,in the process of assembly and miked the crank shaft journals and they have a taper to them especially the rod journals as Mitch as .001 from one side to the other. It's know it's not wright but will it cause problems or do I need to take it back to machine shop ,Bering clearance .003 on one side .002 on other.thanks for info in advance.