100% Chevy

Member

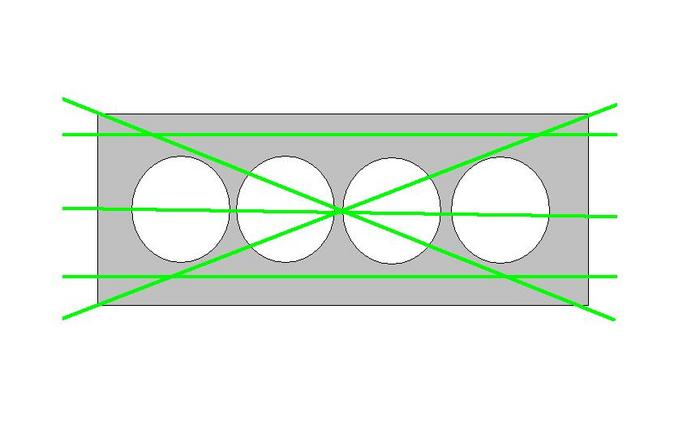

I have a 350 engine that I assume has been decked(no numbers).

What is the usual amount shaved?

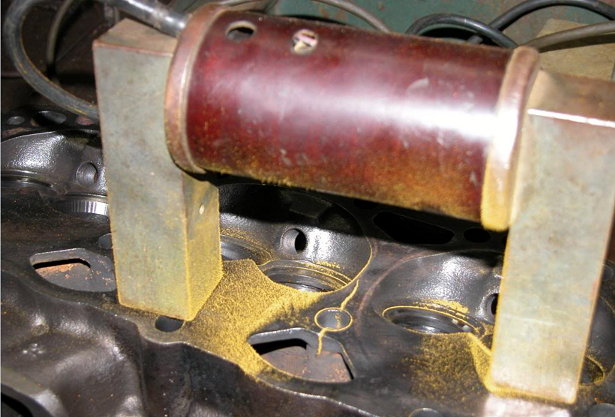

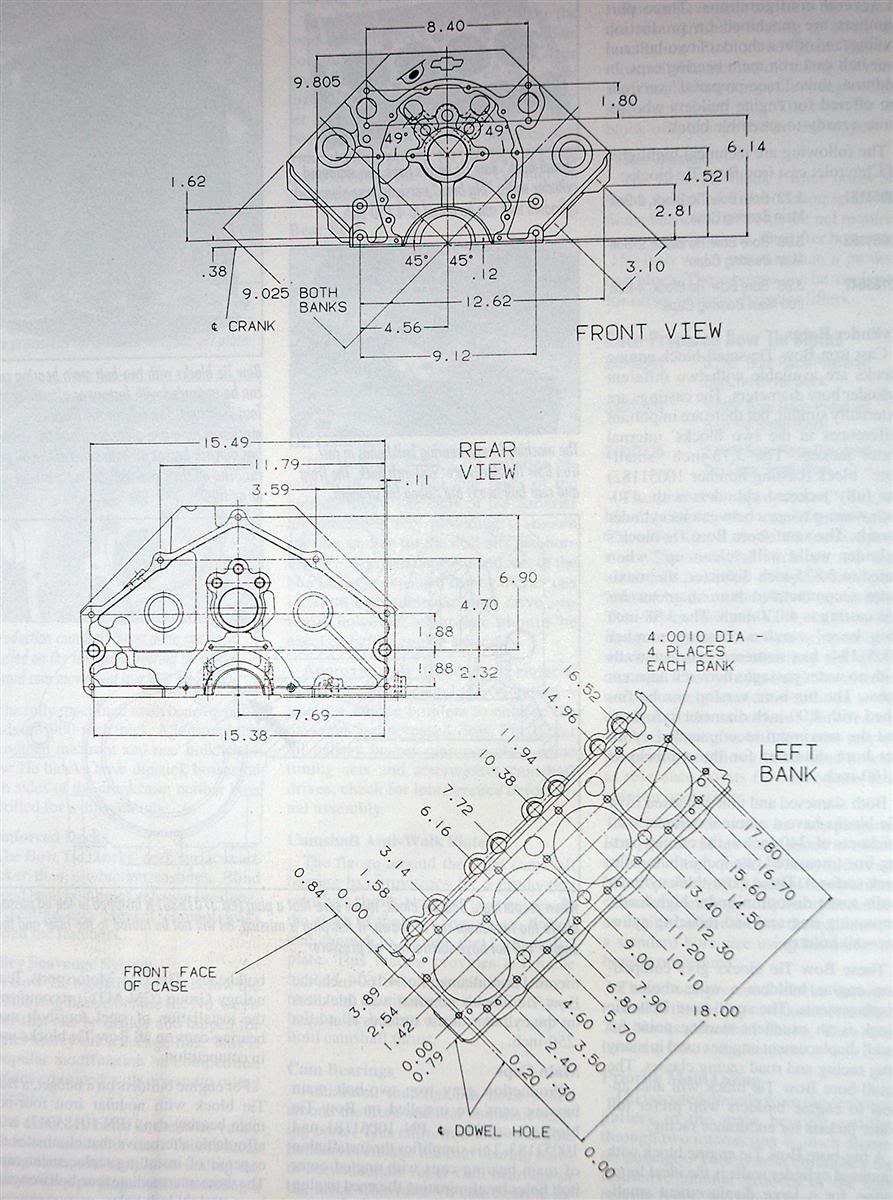

Reason I ask brings up another question-If the block is decked,do I need a thicker intake to head gasket?Or,just add more sealer?

I'm trying to determine why my vacuum is so low-15"hg at idle,and rough idle.

Thanks,Mike.

What is the usual amount shaved?

Reason I ask brings up another question-If the block is decked,do I need a thicker intake to head gasket?Or,just add more sealer?

I'm trying to determine why my vacuum is so low-15"hg at idle,and rough idle.

Thanks,Mike.