mathd

solid fixture here in the forum

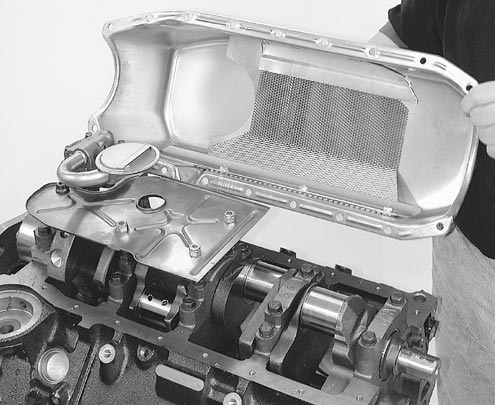

Today i found out that most people dont know there should be a lower dipstick tube extension in the block and many people (like me) dont have one in there engine

Is it really necessary?(i use a deep oil pan), when pulling it out there is no sign of contact with the rotating assembly to the dipstick.

Is it really necessary?(i use a deep oil pan), when pulling it out there is no sign of contact with the rotating assembly to the dipstick.