I want to add an oil cooler to my motor. I don't think I have room for a sandwich adapter and a oil filter because my exhaust runs directly under the filter, so I want to add a remote filter as well. If I add a cooler, remote filter and all the lines associated with it, will my oil pump be able to keep up? Or is it necessary to add a higher flow, higher pressure, pump to push the oil through the newly added accessories?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Does a cooler and remote filter require a new pump?

- Thread starter LLave

- Start date

the components, and fittings and line size, you use, the distance your pumping the oil ,where and how you set up the cooler will all effect its efficiency, and the rate of the oil flow.

pressure drops with remote coolers or filter mounts are almost always the result of using hydraulic lines AND hydraulic line connections with too small an INTERNAL cross sectional area, anything less than AN#8 is bound to be restrictive and AN#10 is far better, and much less likely to cause issues with pressure drops, obviously the adapters and fittings used for fluid transmission must also have at least AN# 8 OR PREFERABLY AN#10 CONNECTIONS , if you run 3/8" OR AN#6 LINES YOUR BOUND TO FIND IT DROPS RETURN LINE PRESSURE, and just as obviously this would mean the passage or tube size of the oil cooler must be at least AN#8 as the coolers with AN#6 internal passages tend to restrict flow so read carefully before you buy an oil or trans cooler

hooking up an oil cooler can be beneficial, reading sub links can be critical

https://www.summitracing.com/parts/prm-184?rrec=true#overview (for remote engine oil coolers)

BTW HERES AN IMPORTANT TIP, IF YOUR INSTALLING A REMOTE OIL COOLER, IT is really common for guys to use lines that are far too small, that restrict flow oil flow or select a transmission or oil cooler that has to small of internal passages, shop carefully you want a MINIMUM of 1/2, or AN8 line size and 5/8" or AN10 is BETTER.

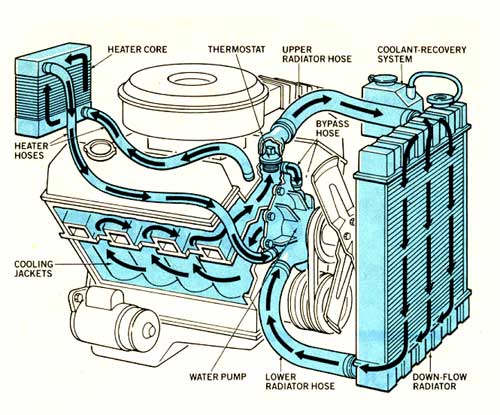

many guys don't realize that adding an oil and/or a transmission fluid cooler, with its own fan and radiator that allows those liquids to be cooled separately, to your engine and drive train, significantly reduces the heat load on the radiator, and generally allows the engine temps to decline noticeably. in fact just adding a high volume oil pan and a transmission cooler can drop your engine coolant temps 20F-30F in many cases

http://www.superchevy.com/how-to/15044-1991-chevrolet-corvette-oil-cooler-maintenance/

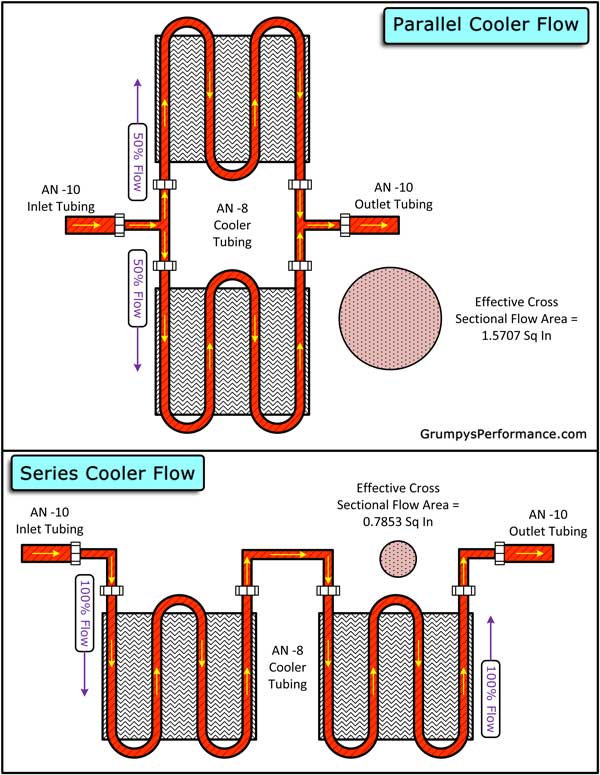

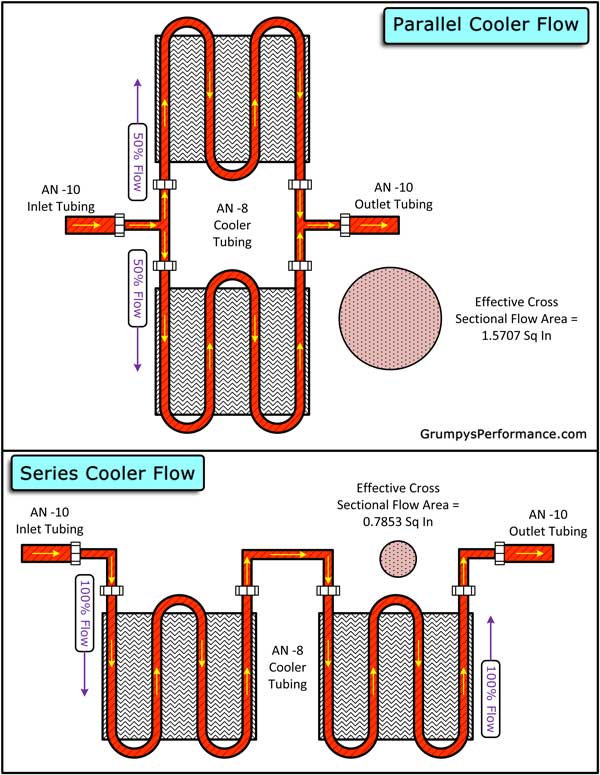

a rather common issue with adding oil coolers, is that many of the coolers available can significantly restrict fluid flow because of the small restrictive internal cross section of the internal tubing, AN #6 and 3/8" tube coolers can be quite restrictive, the AN#8 are better but DUAL AN#8 coolers and AN#10 lines generally work the best, and there's also frequently limited space to position a cooler in the outside cool air flow mandating a powered fans.

the solution to both issues can and frequently does require use of two different oil coolers but placed in series this can further increase flow restrictions, the solution is in use of larger internal cross sectional area,transfer lines and mounting the twin coolers in parallel thus doubling the effective cross sectional area reducing the flow restriction the cooler potentially could produce if used in series

http://www.summitracing.com/parts/der-1 ... dia/images

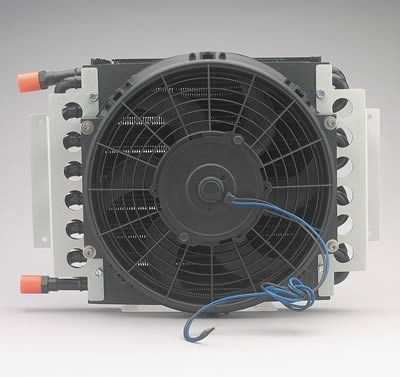

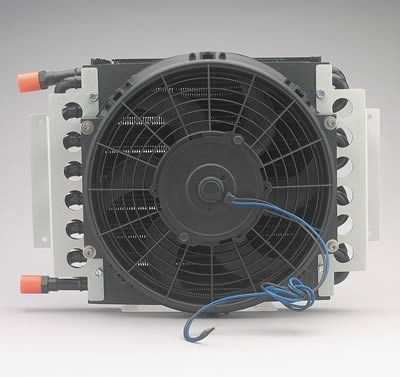

if you install an oil cooler like this that has larger AN#8 or 1/2" lines and a powered auxiliary electric fan its going to far more effective and less restrictive

http://www.summitracing.com/parts/flx-3818/media/images

if you install an oil cooler like this that has small AN#6 or 3/8" lines and no auxiliary electric fan its going to far less effective and more restrictive

BTW HERES AN IMPORTANT TIP, IT is really common for guys to use lines that are far to small, that restrict flow oil flow or select a transmission or oil cooler that has to small of internal passages, shop carefully you want a MINIMUM of 1/2, or AN8 line size and 5/8" or AN10 is BETTER

If properly set up with reasonably large lines and AN fittings on your hydraulic lines, the stock pump should be adequate, but most guys find a high volume pump tends to work slightly better.

Ive seen several cars using stock pumps and getting good results but the general feeling seems to be that a high volume oil pump helps with a remote filter and oil cooler

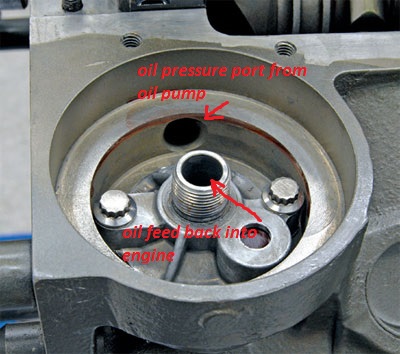

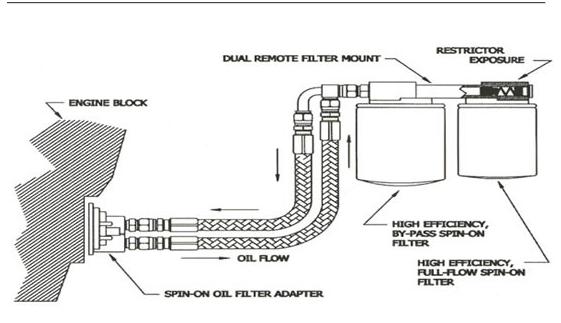

you'll generally have something like this replacing the oil filter at the stock location

the oil pressure out line will flow thru a remote filter mount like this

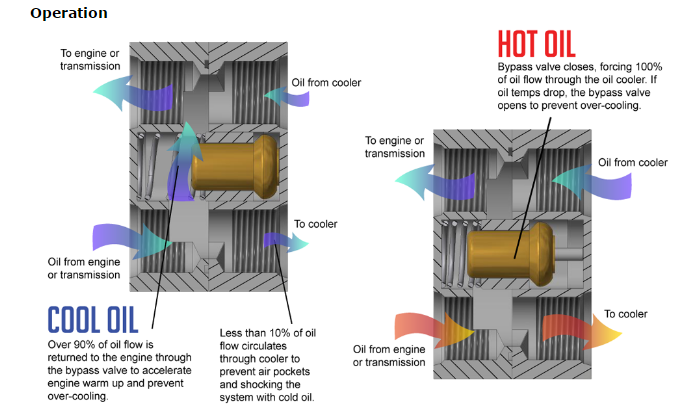

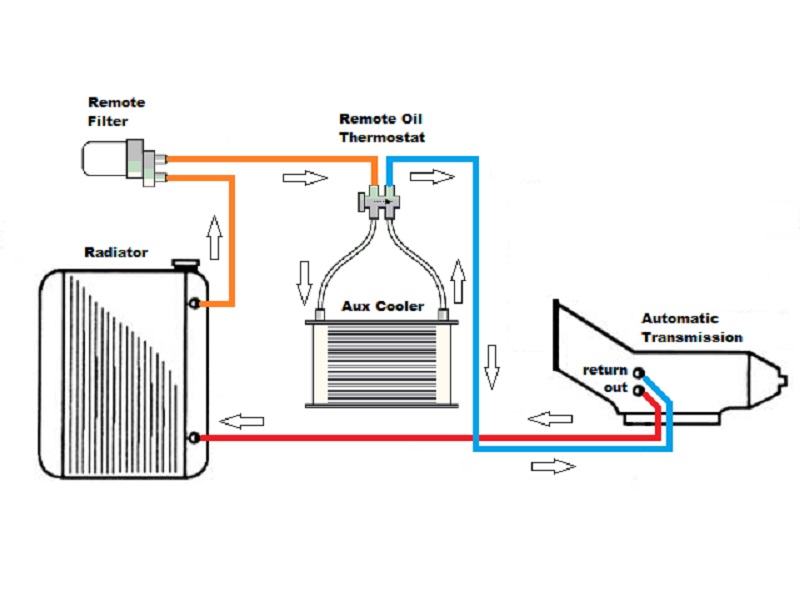

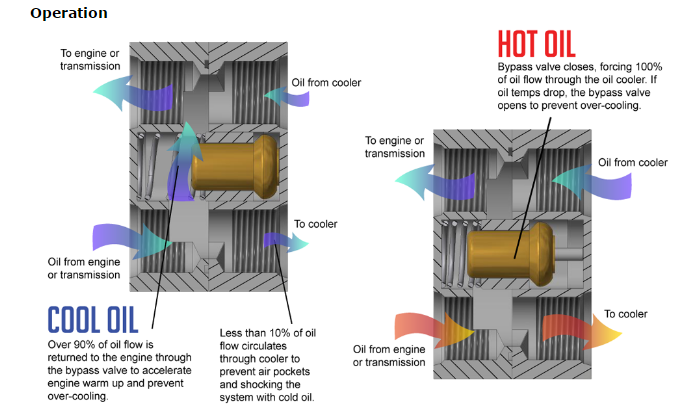

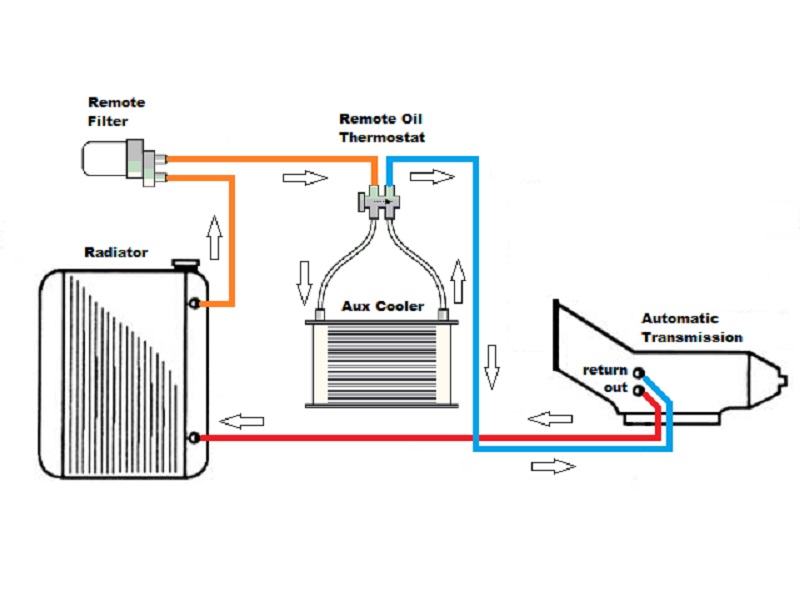

the out line gets routed to a thermostatically controlled valve like this that has four lines , two lines (feed and return) to the oil cooler mounted beyond it

and the pressure feed from the oil filter and the out line feeding oil back to the engine

then to a cooler like this

oil route

theres only one filter, one valve and one oil cooler

engine oil pressure out from old filter location>>>>>>>>>engine oil filter>>>>>>>>>thermostatic control valve>>>>>>>>>>>>oil cooler

engine oil passage and bearings <<<<<<<<<<<<<<<<<<<<<thermostatic control valve<<<<<<<<<<<<<oil cooler<<<<<

I know several people that ran those coolers , on their cars

and while they do work, they don,t work really well , at dropping the transmission fluid or oil temps and they don't tend to remove or transfer to the air a good deal of the fluid heat, the problem is that the surface area and air flow rates over that surface area don't work as effectively as the more effective coolers like these, certainly not well enough to bye-pass the in radiator trans cooler, and rely on that to cool your trans fluid.

Id suspect you would need about 6-8 of those coolers to equal the heat transfer rates of the single large radiator style fluid coolers with the electric fans if both designs are properly installed

'

Ive been using this recently on my transmission, as my 10 qt custom oil pan seems to provide adequate oil cooling by it self

http://www.summitracing.com/parts/PRM-12318/

heres a similar dual trans fluid & separate engine oil cooler

http://www.summitracing.com/parts/PRM-13311/?rtype=10

IVE RARELY found these VERTICAL adapters for remote mount oil filters as useful as the horizontal design adapters

you can mount the filter almost any place its easily accessed

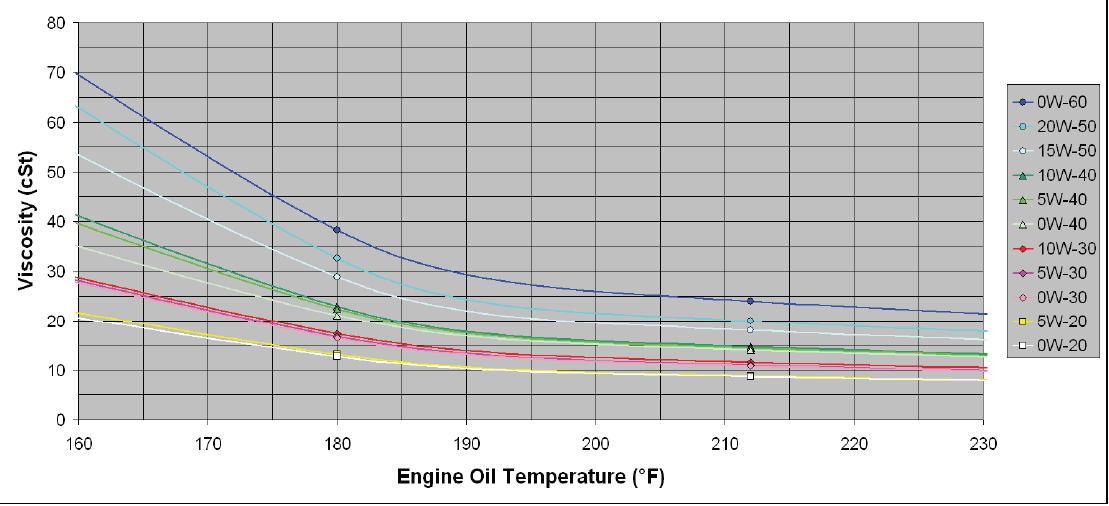

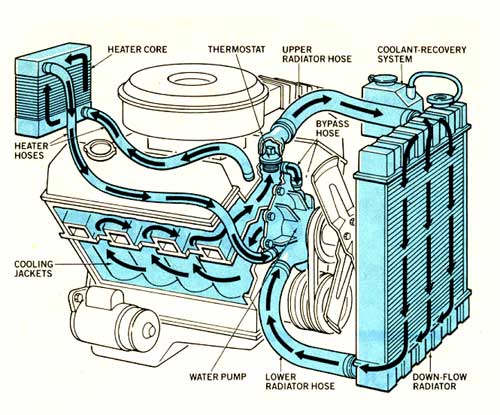

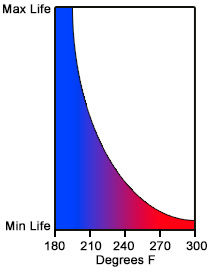

oil temps SHOULD reach 215F occasionally during engine operation,

to insure all moisture is boiled off

but keep in mind , oil in the sump is going to be significantly cooler than,

oil flowing over,

rocker pivot balls,

cam lobes,

bearings,

valve springs lifters,

piston skirts and rings

ETC.

oil, flowing over the moving and sliding components absorbs a great deal of heat,

that hot oil flowing over the engine block and heads has,

its heat load rapidly absorbed and transferred too coolant,

flowing through the major components, that coolant absorbs heat from the hot oil,

and transfers it to the outside air flow ,

and air flowing over the oil pan and valve covers is easily 40F-100F cooler than the oil,

this is how much of the initial heat is transferred,now oil in your oil pan will be by design cooler than it is in other locations,

and oil flow cycles endlessly so while your engine may only hold 4-8 quarts, theres 2-7 gallons a minute passing through the oil pump,

that flow changes, depending on clearances and rpms of course, so the longer any engine runs the more passes,

the individual oil molecules have of being repeatedly heated and cooled, thus moisture boiled out, but moisture will not be totally removed unless,

oil reaches about 215F repeatedly,

this almost mandates a 190F-205F oil pan oil temp.

www.supergen.in

www.supergen.in

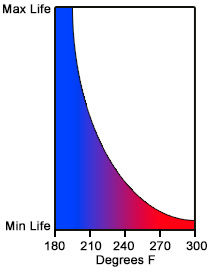

the safe zone for oil temperature is 190-220F. Anything lower and you risk not getting all the moisture out. Anything higher and you're oil is going to degrade faster.

Cold engine oil causes excessive frictional drag on the bearings and cylinder walls.

A quality conventional motor oil will tolerate oil sump temperatures of up to 250 degrees,

but starts breaking down over 275 degrees.

The traditional approach is to try to hold max oil temperatures ,

between 230 and no higher than 260 degree for brief time periods.

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/

www.elephantracing.com

www.elephantracing.com

the safe zone for oil temperature is 190-220F.

Anything lower and you risk not getting all the moisture out.

Anything consistently run higher and you're oil is going to degrade faster.

http://garage.grumpysperformance.co...sion-and-oil-cooler-increases-durability.176/

http://garage.grumpysperformance.com/index.php?threads/bearings-and-oil-flow.150/

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/

http://garage.grumpysperformance.co...gine-project-dart-shp.3814/page-23#post-21571

http://garage.grumpysperformance.com/index.php?threads/basic-info-on-your-v8-lube-system.52/

http://garage.grumpysperformance.com/index.php?threads/bearings-and-oil-flow.150/

http://garage.grumpysperformance.com/index.php?threads/oil-accumulator.1280/

http://garage.grumpysperformance.co...te-filter-require-a-new-pump.3144/#post-62980

http://garage.grumpysperformance.co...l-cooler-increases-durability.176/#post-48374

http://garage.grumpysperformance.co...y-in-building-a-good-engine.11682/#post-54682

http://forum.grumpysperformance.com/viewtopic.php?f=54&t=3536&p=9372#p9372

http://garage.grumpysperformance.co...g-up-oil-feed-holes-in-bearings-shells.10750/

http://garage.grumpysperformance.co...ng-clearances-engine-builders-magazine.11965/

http://garage.grumpysperformance.com/index.php?threads/valve-spring-cooling-via-engine-oil.6491/

http://garage.grumpysperformance.co...oil-passages-and-improved-oil-flow-mods.3834/

http://garage.grumpysperformance.co...m-sure-your-convinced-its-the-oil-pump.11085/

http://garage.grumpysperformance.com/index.php?threads/reducing-friction-and-pumping-losses.8966/

as a general rule you select .001 bearing clearance for every inch of bearing journal diameter,

Rod bearings 0.002 - 0.025" , side clearance 0.010 - 0.020"

Main bearings 0.002 - 0.003" for most engines ( 0.020-0.025 bearing clearance on small blocks, .025-.027 bearing clearance is about ideal, on big blocks ), 0.005 - 0.007 crankshaft end play

http://garage.grumpysperformance.co...ting-resistance-to-look-for.11312/#post-51472

http://garage.grumpysperformance.co...uring-crank-bearing-journals.5478/#post-16429

http://garage.grumpysperformance.co...ng-clearances-engine-builders-magazine.11965/

http://garage.grumpysperformance.com/index.php?threads/can-i-get-it-polished.9214/#post-43456

http://www.competitionproducts.com/Bearings-Bearing-Spacers/departments/179/

http://garage.grumpysperformance.co...shaft-journal-surface-finnish.2728/#post-9886

http://garage.grumpysperformance.com/index.php?threads/bearing-install-tips.3449/

http://garage.grumpysperformance.com/index.php?threads/which-torque-wrench.342/#post-59396

http://garage.grumpysperformance.co...guess-on-clearances-and-journal-surface.9955/

http://garage.grumpysperformance.com/index.php?threads/bearing-install-tips.3449/

pressure drops with remote coolers or filter mounts are almost always the result of using hydraulic lines AND hydraulic line connections with too small an INTERNAL cross sectional area, anything less than AN#8 is bound to be restrictive and AN#10 is far better, and much less likely to cause issues with pressure drops, obviously the adapters and fittings used for fluid transmission must also have at least AN# 8 OR PREFERABLY AN#10 CONNECTIONS , if you run 3/8" OR AN#6 LINES YOUR BOUND TO FIND IT DROPS RETURN LINE PRESSURE, and just as obviously this would mean the passage or tube size of the oil cooler must be at least AN#8 as the coolers with AN#6 internal passages tend to restrict flow so read carefully before you buy an oil or trans cooler

hooking up an oil cooler can be beneficial, reading sub links can be critical

https://www.summitracing.com/parts/prm-184?rrec=true#overview (for remote engine oil coolers)

BTW HERES AN IMPORTANT TIP, IF YOUR INSTALLING A REMOTE OIL COOLER, IT is really common for guys to use lines that are far too small, that restrict flow oil flow or select a transmission or oil cooler that has to small of internal passages, shop carefully you want a MINIMUM of 1/2, or AN8 line size and 5/8" or AN10 is BETTER.

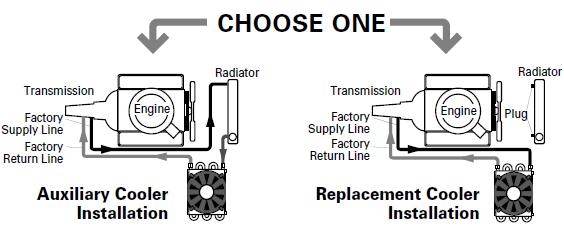

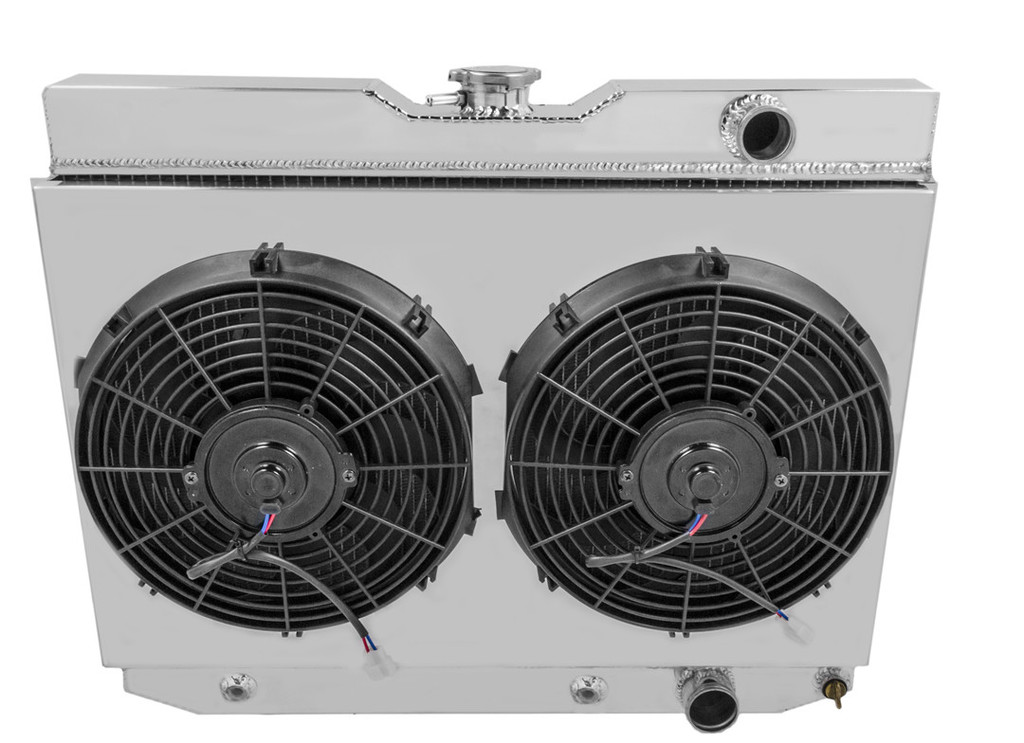

many guys don't realize that adding an oil and/or a transmission fluid cooler, with its own fan and radiator that allows those liquids to be cooled separately, to your engine and drive train, significantly reduces the heat load on the radiator, and generally allows the engine temps to decline noticeably. in fact just adding a high volume oil pan and a transmission cooler can drop your engine coolant temps 20F-30F in many cases

http://www.superchevy.com/how-to/15044-1991-chevrolet-corvette-oil-cooler-maintenance/

a rather common issue with adding oil coolers, is that many of the coolers available can significantly restrict fluid flow because of the small restrictive internal cross section of the internal tubing, AN #6 and 3/8" tube coolers can be quite restrictive, the AN#8 are better but DUAL AN#8 coolers and AN#10 lines generally work the best, and there's also frequently limited space to position a cooler in the outside cool air flow mandating a powered fans.

the solution to both issues can and frequently does require use of two different oil coolers but placed in series this can further increase flow restrictions, the solution is in use of larger internal cross sectional area,transfer lines and mounting the twin coolers in parallel thus doubling the effective cross sectional area reducing the flow restriction the cooler potentially could produce if used in series

http://www.summitracing.com/parts/der-1 ... dia/images

if you install an oil cooler like this that has larger AN#8 or 1/2" lines and a powered auxiliary electric fan its going to far more effective and less restrictive

http://www.summitracing.com/parts/flx-3818/media/images

if you install an oil cooler like this that has small AN#6 or 3/8" lines and no auxiliary electric fan its going to far less effective and more restrictive

BTW HERES AN IMPORTANT TIP, IT is really common for guys to use lines that are far to small, that restrict flow oil flow or select a transmission or oil cooler that has to small of internal passages, shop carefully you want a MINIMUM of 1/2, or AN8 line size and 5/8" or AN10 is BETTER

If properly set up with reasonably large lines and AN fittings on your hydraulic lines, the stock pump should be adequate, but most guys find a high volume pump tends to work slightly better.

Ive seen several cars using stock pumps and getting good results but the general feeling seems to be that a high volume oil pump helps with a remote filter and oil cooler

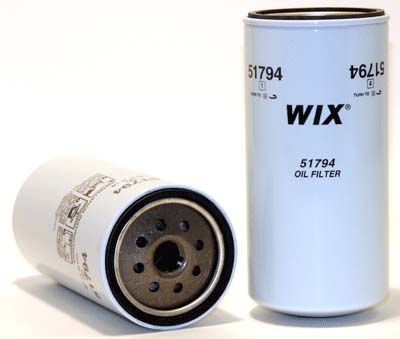

you'll generally have something like this replacing the oil filter at the stock location

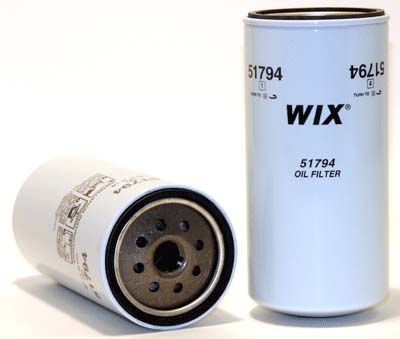

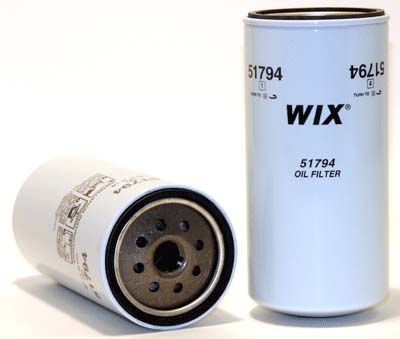

the oil pressure out line will flow thru a remote filter mount like this

the out line gets routed to a thermostatically controlled valve like this that has four lines , two lines (feed and return) to the oil cooler mounted beyond it

and the pressure feed from the oil filter and the out line feeding oil back to the engine

then to a cooler like this

oil route

theres only one filter, one valve and one oil cooler

engine oil pressure out from old filter location>>>>>>>>>engine oil filter>>>>>>>>>thermostatic control valve>>>>>>>>>>>>oil cooler

engine oil passage and bearings <<<<<<<<<<<<<<<<<<<<<thermostatic control valve<<<<<<<<<<<<<oil cooler<<<<<

I know several people that ran those coolers , on their cars

and while they do work, they don,t work really well , at dropping the transmission fluid or oil temps and they don't tend to remove or transfer to the air a good deal of the fluid heat, the problem is that the surface area and air flow rates over that surface area don't work as effectively as the more effective coolers like these, certainly not well enough to bye-pass the in radiator trans cooler, and rely on that to cool your trans fluid.

Id suspect you would need about 6-8 of those coolers to equal the heat transfer rates of the single large radiator style fluid coolers with the electric fans if both designs are properly installed

'

Ive been using this recently on my transmission, as my 10 qt custom oil pan seems to provide adequate oil cooling by it self

http://www.summitracing.com/parts/PRM-12318/

heres a similar dual trans fluid & separate engine oil cooler

http://www.summitracing.com/parts/PRM-13311/?rtype=10

IVE RARELY found these VERTICAL adapters for remote mount oil filters as useful as the horizontal design adapters

you can mount the filter almost any place its easily accessed

no!when you say 215F do you mean the normal rise in temp after shut-down?

oil temps SHOULD reach 215F occasionally during engine operation,

to insure all moisture is boiled off

but keep in mind , oil in the sump is going to be significantly cooler than,

oil flowing over,

rocker pivot balls,

cam lobes,

bearings,

valve springs lifters,

piston skirts and rings

ETC.

oil, flowing over the moving and sliding components absorbs a great deal of heat,

that hot oil flowing over the engine block and heads has,

its heat load rapidly absorbed and transferred too coolant,

flowing through the major components, that coolant absorbs heat from the hot oil,

and transfers it to the outside air flow ,

and air flowing over the oil pan and valve covers is easily 40F-100F cooler than the oil,

this is how much of the initial heat is transferred,now oil in your oil pan will be by design cooler than it is in other locations,

and oil flow cycles endlessly so while your engine may only hold 4-8 quarts, theres 2-7 gallons a minute passing through the oil pump,

that flow changes, depending on clearances and rpms of course, so the longer any engine runs the more passes,

the individual oil molecules have of being repeatedly heated and cooled, thus moisture boiled out, but moisture will not be totally removed unless,

oil reaches about 215F repeatedly,

this almost mandates a 190F-205F oil pan oil temp.

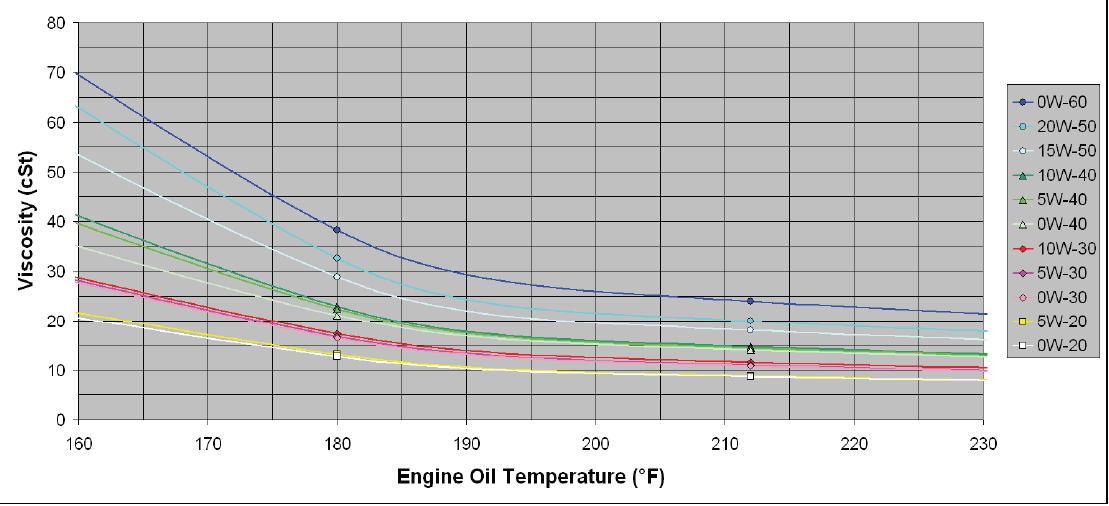

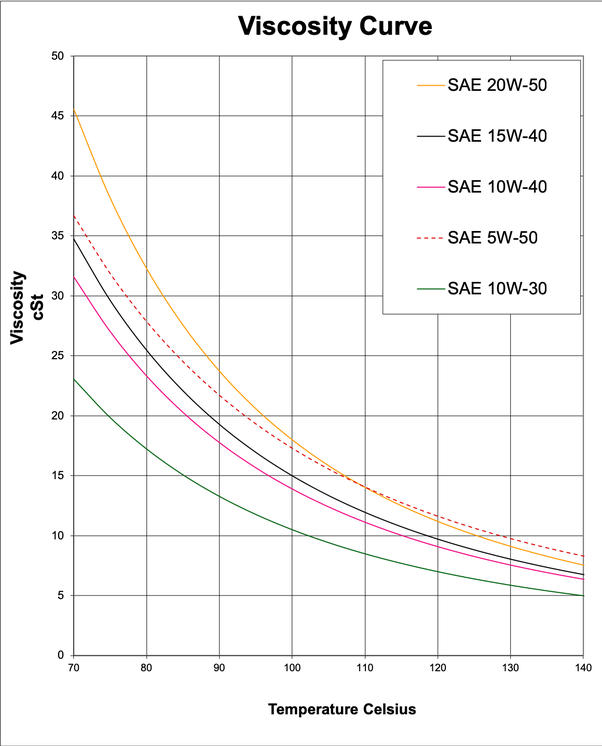

How Oil Viscosity & Temperature Influence Bearing Function

Some will know from their experience with automobiles that thicker oils, such as Society of Automotive Engineers (SAE) 30, are more appropriate for warm summer months. But thinner oils, perhaps SAE 10, can help prepare a vehicle for winter driving. Figure 1 illustrates where these motor oils fit...

www.pumpsandsystems.com

HOW TO CHOOSE THE RIGHT ENGINE OIL FOR YOUR VEHICLE?

Ever wondered how to choose the right engine oil for your bike or car? If yes, we have explained the different types & uses of engine oils

www.supergen.in

www.supergen.in

the safe zone for oil temperature is 190-220F. Anything lower and you risk not getting all the moisture out. Anything higher and you're oil is going to degrade faster.

Cold engine oil causes excessive frictional drag on the bearings and cylinder walls.

A quality conventional motor oil will tolerate oil sump temperatures of up to 250 degrees,

but starts breaking down over 275 degrees.

The traditional approach is to try to hold max oil temperatures ,

between 230 and no higher than 260 degree for brief time periods.

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/

Elephant Racing • Oil Temperature and Engine Life: Why is proper temperature so important?

Why is proper temperature so important?

www.elephantracing.com

www.elephantracing.com

the safe zone for oil temperature is 190-220F.

Anything lower and you risk not getting all the moisture out.

Anything consistently run higher and you're oil is going to degrade faster.

http://garage.grumpysperformance.co...sion-and-oil-cooler-increases-durability.176/

http://garage.grumpysperformance.com/index.php?threads/bearings-and-oil-flow.150/

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/

http://garage.grumpysperformance.co...gine-project-dart-shp.3814/page-23#post-21571

http://garage.grumpysperformance.com/index.php?threads/basic-info-on-your-v8-lube-system.52/

http://garage.grumpysperformance.com/index.php?threads/bearings-and-oil-flow.150/

http://garage.grumpysperformance.com/index.php?threads/oil-accumulator.1280/

http://garage.grumpysperformance.co...te-filter-require-a-new-pump.3144/#post-62980

http://garage.grumpysperformance.co...l-cooler-increases-durability.176/#post-48374

http://garage.grumpysperformance.co...y-in-building-a-good-engine.11682/#post-54682

http://forum.grumpysperformance.com/viewtopic.php?f=54&t=3536&p=9372#p9372

http://garage.grumpysperformance.co...g-up-oil-feed-holes-in-bearings-shells.10750/

http://garage.grumpysperformance.co...ng-clearances-engine-builders-magazine.11965/

http://garage.grumpysperformance.com/index.php?threads/valve-spring-cooling-via-engine-oil.6491/

http://garage.grumpysperformance.co...oil-passages-and-improved-oil-flow-mods.3834/

http://garage.grumpysperformance.co...m-sure-your-convinced-its-the-oil-pump.11085/

http://garage.grumpysperformance.com/index.php?threads/reducing-friction-and-pumping-losses.8966/

as a general rule you select .001 bearing clearance for every inch of bearing journal diameter,

Rod bearings 0.002 - 0.025" , side clearance 0.010 - 0.020"

Main bearings 0.002 - 0.003" for most engines ( 0.020-0.025 bearing clearance on small blocks, .025-.027 bearing clearance is about ideal, on big blocks ), 0.005 - 0.007 crankshaft end play

http://garage.grumpysperformance.co...ting-resistance-to-look-for.11312/#post-51472

http://garage.grumpysperformance.co...uring-crank-bearing-journals.5478/#post-16429

http://garage.grumpysperformance.co...ng-clearances-engine-builders-magazine.11965/

http://garage.grumpysperformance.com/index.php?threads/can-i-get-it-polished.9214/#post-43456

http://www.competitionproducts.com/Bearings-Bearing-Spacers/departments/179/

http://garage.grumpysperformance.co...shaft-journal-surface-finnish.2728/#post-9886

http://garage.grumpysperformance.com/index.php?threads/bearing-install-tips.3449/

http://garage.grumpysperformance.com/index.php?threads/which-torque-wrench.342/#post-59396

http://garage.grumpysperformance.co...guess-on-clearances-and-journal-surface.9955/

http://garage.grumpysperformance.com/index.php?threads/bearing-install-tips.3449/

Last edited by a moderator:

one factor thats frequently over looked is the oil feed and return line internal size and line heat rating,THINK IT THRU, now it should be obvious that fittings tend to have smaller more restrictive holes thru them than the hose internal dimensions of the fittings used with that hose, a fitting designed for 3/8" hose wont allow full 3/8"hose or component oil flow rates, AN-6 is normally considered about equal to 3/8" but thats doesn,t tend to be true, AN-8 size fittings are usually used to get decent flow in a 3/8" oil cooler , if your oil cooler has 3/8" internal passages youll want an AN#8 line size to insure the MINIMUM 3/8" internal passage size is maintained and not restricted by use of the internal passage size of AN#6 fittings

EXAMPLE

if your oil or transmission cooler has 3/8" internal passages you would think theres not a great deal gained in using larger lines than a MATCHING AN-8 or 1/2 OUTSIDE DIAM. LINE with its 3/8" INTERNAL DIAMETER.

routing transmission cooler lines, should be thought thru carefully so engine exhaust or vibration won,t damage the lines, a restriction to trans fluid or oil flow will generally be the part of the connecting lines with the smallest cross sectional area, if you look at most automotive oil or transmission coolers they have AN#6 (3/8")or AN#8 (1/2")connections, so lines significantly larger in cross sectional interior area,won,t do much for increasing flow rates

http://garage.grumpysperformance.co...ans-cooler-on-a-c4-corvette.10514/#post-70073

OR

if your oil or transmission cooler has 1/2" passages you would think theres not a great deal gained in using larger lines than a MATCHING AN-10 or 5/8 OUTSIDE DIAM. LINE with its 1/2" INTERNAL DIAMETER

but you'll frequently see guys running smaller lines than would be ideal that are restrictive that wonder why they have problems maintaining oil flow rates, they forget that the fittings tend to be restrictive , a 3/8" passage oil cooler tends to have slightly less restrictive flow if AN-10 lines are routed to and from it as the internal fittings on AN-10 tend to be a bit less restrictive on a 3/8" internal passage oil cooler, so its usually a good idea to step up the feed and return line size one step larger than you might think is required. this becomes even more important if the line length tends to be longer than average

EXAMPLE

one of my friends installed a really nice oil cooler with 1/2" oil passages and a large electric fan behind his rear axle on a pick-up truck, replacing his factory rear tire holder, he had a significant loss in oil pressure with the AN-8 lines it was first installed with, once the cooler and remote oil filter was originally installed, UNTIL he upgraded the line size on the advice of the hydraulic supply shop and installed AN-12 HYDRAULIC LINES and fittings on his BIG BLOCK off road pick-up, too cool his 4L80E transmission fluid

youll also want a 400F PLUS temp rating and at least a 400PSI minimum pressure rating, on hose used for hot oil or trans fluid, and its best to measure carefully and have the hydraulic shop fabricate the custom length hoses with ends installed

http://aeroquip.cc/fbc20002807-20aeroqu ... eflon.aspx

http://aeroquip.cc/aeroquipsupergemfitt ... 2hose.aspx

http://static.summitracing.com/global/i ... 5_4590.pdf

viewtopic.php?f=55&t=4381&p=16285&hilit=flex+line#p16285

Dash size is in 1/16 of an inch. So

-2 (2/16) 1/8 inch,

-6 (6/16) 3/8 inch,

-8 (8/16) 1/2 inch and so on.

But be careful, this does not mean that a -6 hose has an inside diameter of 3/8 inch. In fact, it can be anywhere from .298 to .359 inch, depending upon the hose type.

Common aircraft hose dash sizes are:

-2 Smallest hose size. Used as an instrument gage line

-3 Also used as an instrument gage line

-4 Common hydraulic line. Some smaller fuel line

-6 Common size for fuel delivery lines

-8 Fuel delivery and oil cooler lines

-10 Larger aircraft, oil and fuel

-12 Larger aircraft, oil and fuel

-16 Larger aircraft, oil and fuel

The inside diameter of each hose and fitting dash size is found in size charts. A common mistake is to think all hose of the same dash size has the same inside diameter. There not

A common mistake is to think that all fittings of the same dash size have the same inside diameter. They do not.

A common mistake is to think that a straight -6 fitting and a 90 -6 fitting of used on the same hose should both have the same inside diameter. They do not. A hose with a straight fitting on one end and an angle fitting on the other end will have different inside diameters.

read these threads and sub links

viewtopic.php?f=55&t=3172&p=8456#p8456

viewtopic.php?f=50&t=1660&p=4484&hilit=+bending+tube#p4484

viewtopic.php?f=55&t=635

viewtopic.php?f=55&t=1030

viewtopic.php?f=55&t=1939

viewtopic.php?f=55&t=1442

viewtopic.php?f=55&t=1860

viewtopic.php?f=55&t=733&p=3587&hilit=cell#p3587

The latest I found is this:

----------------------------------------------------------------------

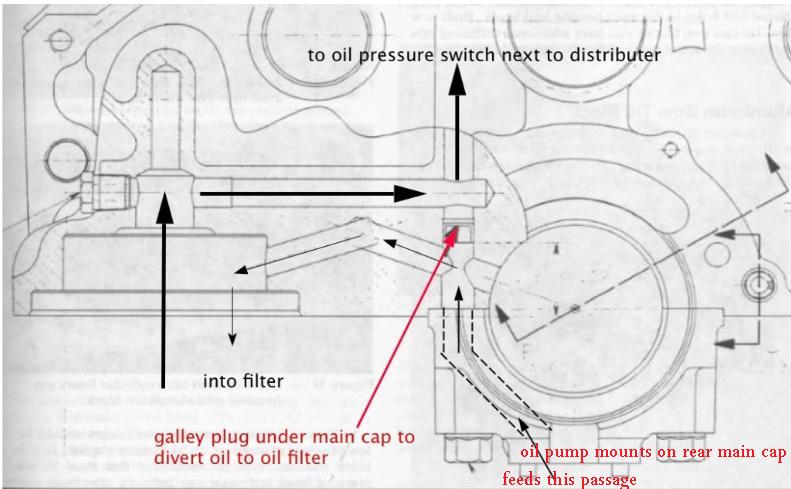

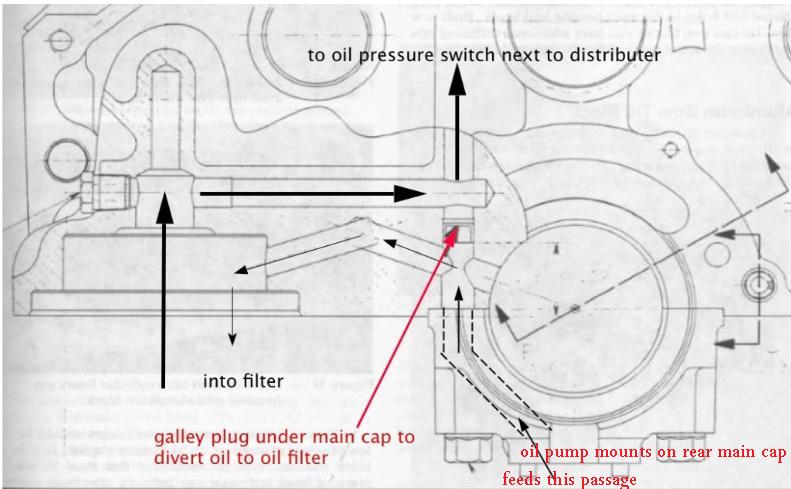

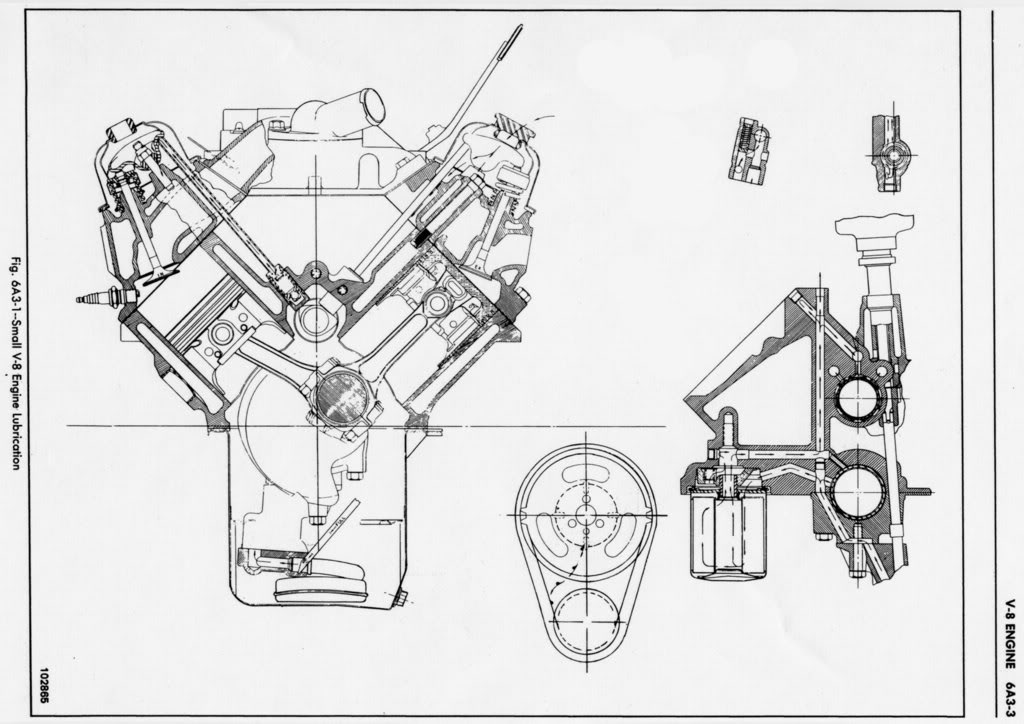

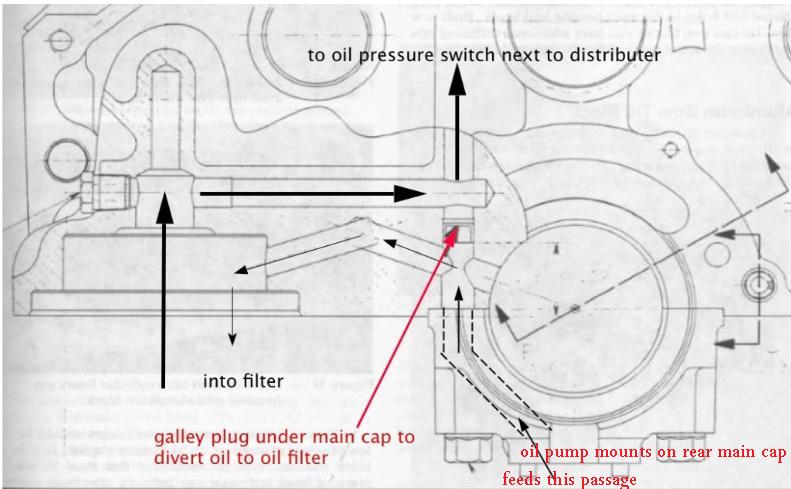

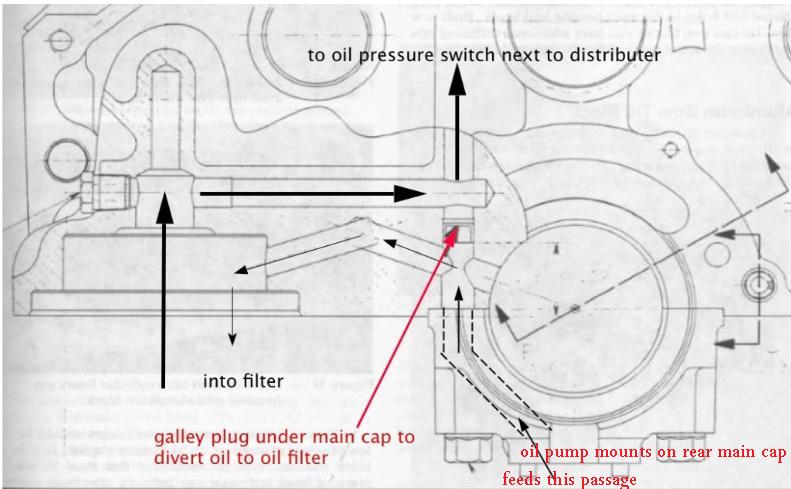

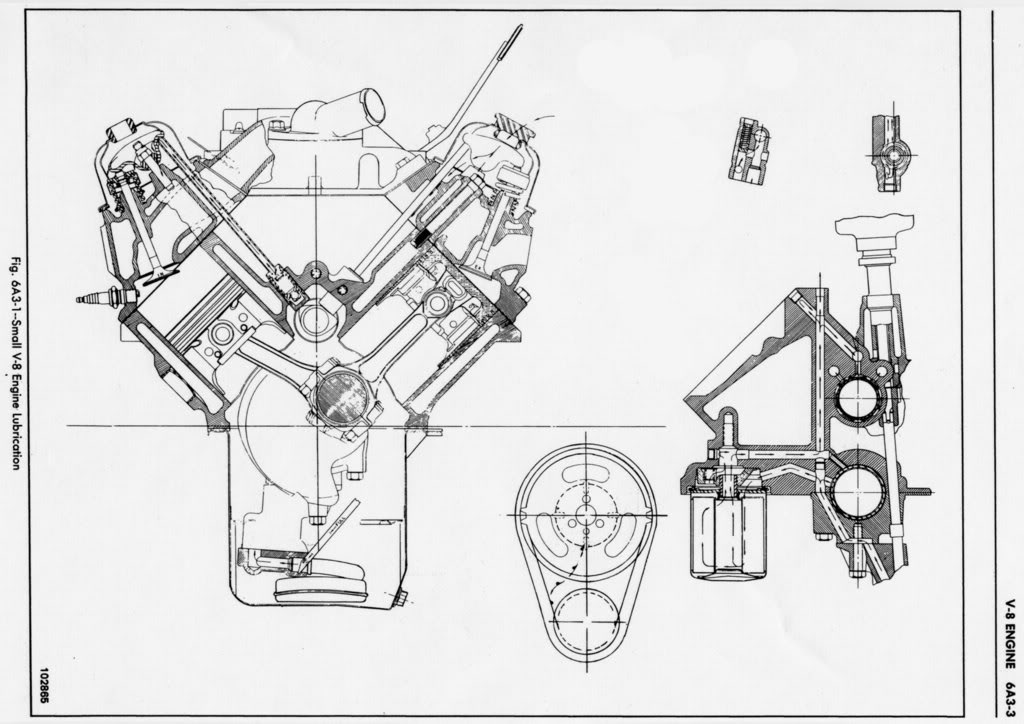

Big Block Chevrolet Gen V and Gen VI Oiling SystemSolving the mystery of the Gen V and Gen VI Priority Main Oiling system

Priority Main Oiling System

The Generation V and VI big block Chevrolet blocks feature a priority main oiling system where the main oil supply passage is located adjacent to the camshaft tunnel. Drilled passages which intersect this large oil tunnel carry oil directly to the main bearings. If you are facing the front of the block with the engine in the upright position, this main oil supply tunnel is located in the 2 o’clock position just below the right hand lifter oil supply line.

Oil Cooler Plumbing

Located along the oil pan rail just ahead of the oil filter pad are two drilled and tapped (3/8” NPT) oil passages for routing oil to an external oil cooler. The hole located closest to the oil filter pad (#2) is for the outgoing supply line to the oil cooler. The front passage (#1), which is farthest from the filter pad, is the return line from the oil cooler.

Careful examination reveals that these two passages intersect the same return line that feeds oil back to the main oil tunnel. This requires that a special fitting be used in the #2 supply line to prevent oil from short circuiting the oil cooler.

Part number SD1540 provides the necessary diverter basket to prevent the supply oil from entering the return line before going to the oil cooler. This fitting has a dash 10AN thread to allow the use of aftermarket components to plumb your external oil cooler. The front passage #1 will require a 3/8” NPT by dash 10AN adapter (#FCM2185), which is available from Scoggin-Dickey.

Understanding By-pass Valve Locations

Factory assembled 454, 502 engines and short blocks have two by-pass valves installed in the block. These factory installed by-pass valves (#25013759) will open at an 11 psi pressure differential. One by-pass valve is installed in the center hole on the oil filter pad (#4). This hole is the oil return passage from the oil filter. The second by-pass valve is installed in the adjacent hole (#3). The egg shaped hole (#5) is the high pressure oil supply passage from the oil pump.

For all racing application that will NOT use an oil cooler but will maintain the stock oil filter location, you must remove the center by-pass valve in location #4. Removing this valve eliminates three redundant right runs in the oil system. However, if you leave this by-pass in place the oil system will still function as it was intended, but a loss of oil pressure can result from the four right angle turns required for oil to return to the main oil tunnel.

If you intend to use a remote oil filter, a high pressure by-pass valve part number 25161284 must be installed in position #3. This valve will open at a 30 psi pressure differential. A plug will be installed in position #4 to prevent oil flow thru this passage. Oil should be returned to the block in the 3/8” hole located just able the oil filter pad. An oil filter block off plate kit (#SD3891) can be purchased from Scoggin-Dickey for Gen V and VI blocks to plumb your external oil filter.

If you intend to maintain the stock filter location and will use the factory provided oil cooler passages to install your oil cooler, then you must install two high pressure by-pass valves (#25161284). One will be installed in location #3 and the second in location #4. Happy oiling!

Here's the one from GM:

Excerpt from Speed Reading written by Wade Hajek of GM Performance Parts :

"Gen V and Gen VI big-block crate engines come with two oil pressure bypass valves installed in the engine blocks. Both of these valves are rated at 11 psi pressure differential. One valve is for the oil filter and the other is for the production oil cooler. If you install an aftermarket oil cooler or remote oil filter that attaches to the oil filter pad on the engine block, you should be aware that you need to change the oil filter bypass valve in the engine block. The aftermarket oil lines add resistance which will cause the bypass valve to bypass the aftermarket oil cooler and/or oil filter all the time. Obviously, if the cooler and filter are bypassed the oil will be dirty and hot. Your engine could run hotter and could be damaged by dirt in the oil. If you choose to use an aftermarket cooler or remote oil filter that attaches to the pad, you should change the bypass valve to one with a higher differential pressure rating. A good choice would be GM# 25161284 which is rated at 30 psi. Remove the valve that is closest to the crankshaft and replace it with the new valve. Press the new valve into the engine block and stake it in three places. You should note that the bypass valves don't need to be changed if you use a production oil cooler which uses the production holes in the engine block and you don't use a remote oil filter. Also, if you use an adapter that just angles the filter for clearance you don't need to change the bypass valves."

EXAMPLE

if your oil or transmission cooler has 3/8" internal passages you would think theres not a great deal gained in using larger lines than a MATCHING AN-8 or 1/2 OUTSIDE DIAM. LINE with its 3/8" INTERNAL DIAMETER.

routing transmission cooler lines, should be thought thru carefully so engine exhaust or vibration won,t damage the lines, a restriction to trans fluid or oil flow will generally be the part of the connecting lines with the smallest cross sectional area, if you look at most automotive oil or transmission coolers they have AN#6 (3/8")or AN#8 (1/2")connections, so lines significantly larger in cross sectional interior area,won,t do much for increasing flow rates

http://garage.grumpysperformance.co...ans-cooler-on-a-c4-corvette.10514/#post-70073

OR

if your oil or transmission cooler has 1/2" passages you would think theres not a great deal gained in using larger lines than a MATCHING AN-10 or 5/8 OUTSIDE DIAM. LINE with its 1/2" INTERNAL DIAMETER

but you'll frequently see guys running smaller lines than would be ideal that are restrictive that wonder why they have problems maintaining oil flow rates, they forget that the fittings tend to be restrictive , a 3/8" passage oil cooler tends to have slightly less restrictive flow if AN-10 lines are routed to and from it as the internal fittings on AN-10 tend to be a bit less restrictive on a 3/8" internal passage oil cooler, so its usually a good idea to step up the feed and return line size one step larger than you might think is required. this becomes even more important if the line length tends to be longer than average

EXAMPLE

one of my friends installed a really nice oil cooler with 1/2" oil passages and a large electric fan behind his rear axle on a pick-up truck, replacing his factory rear tire holder, he had a significant loss in oil pressure with the AN-8 lines it was first installed with, once the cooler and remote oil filter was originally installed, UNTIL he upgraded the line size on the advice of the hydraulic supply shop and installed AN-12 HYDRAULIC LINES and fittings on his BIG BLOCK off road pick-up, too cool his 4L80E transmission fluid

youll also want a 400F PLUS temp rating and at least a 400PSI minimum pressure rating, on hose used for hot oil or trans fluid, and its best to measure carefully and have the hydraulic shop fabricate the custom length hoses with ends installed

http://aeroquip.cc/fbc20002807-20aeroqu ... eflon.aspx

http://aeroquip.cc/aeroquipsupergemfitt ... 2hose.aspx

http://static.summitracing.com/global/i ... 5_4590.pdf

viewtopic.php?f=55&t=4381&p=16285&hilit=flex+line#p16285

Dash size is in 1/16 of an inch. So

-2 (2/16) 1/8 inch,

-6 (6/16) 3/8 inch,

-8 (8/16) 1/2 inch and so on.

But be careful, this does not mean that a -6 hose has an inside diameter of 3/8 inch. In fact, it can be anywhere from .298 to .359 inch, depending upon the hose type.

Common aircraft hose dash sizes are:

-2 Smallest hose size. Used as an instrument gage line

-3 Also used as an instrument gage line

-4 Common hydraulic line. Some smaller fuel line

-6 Common size for fuel delivery lines

-8 Fuel delivery and oil cooler lines

-10 Larger aircraft, oil and fuel

-12 Larger aircraft, oil and fuel

-16 Larger aircraft, oil and fuel

The inside diameter of each hose and fitting dash size is found in size charts. A common mistake is to think all hose of the same dash size has the same inside diameter. There not

A common mistake is to think that all fittings of the same dash size have the same inside diameter. They do not.

A common mistake is to think that a straight -6 fitting and a 90 -6 fitting of used on the same hose should both have the same inside diameter. They do not. A hose with a straight fitting on one end and an angle fitting on the other end will have different inside diameters.

read these threads and sub links

viewtopic.php?f=55&t=3172&p=8456#p8456

viewtopic.php?f=50&t=1660&p=4484&hilit=+bending+tube#p4484

viewtopic.php?f=55&t=635

viewtopic.php?f=55&t=1030

viewtopic.php?f=55&t=1939

viewtopic.php?f=55&t=1442

viewtopic.php?f=55&t=1860

viewtopic.php?f=55&t=733&p=3587&hilit=cell#p3587

The latest I found is this:

----------------------------------------------------------------------

Big Block Chevrolet Gen V and Gen VI Oiling SystemSolving the mystery of the Gen V and Gen VI Priority Main Oiling system

Priority Main Oiling System

The Generation V and VI big block Chevrolet blocks feature a priority main oiling system where the main oil supply passage is located adjacent to the camshaft tunnel. Drilled passages which intersect this large oil tunnel carry oil directly to the main bearings. If you are facing the front of the block with the engine in the upright position, this main oil supply tunnel is located in the 2 o’clock position just below the right hand lifter oil supply line.

Oil Cooler Plumbing

Located along the oil pan rail just ahead of the oil filter pad are two drilled and tapped (3/8” NPT) oil passages for routing oil to an external oil cooler. The hole located closest to the oil filter pad (#2) is for the outgoing supply line to the oil cooler. The front passage (#1), which is farthest from the filter pad, is the return line from the oil cooler.

Careful examination reveals that these two passages intersect the same return line that feeds oil back to the main oil tunnel. This requires that a special fitting be used in the #2 supply line to prevent oil from short circuiting the oil cooler.

Part number SD1540 provides the necessary diverter basket to prevent the supply oil from entering the return line before going to the oil cooler. This fitting has a dash 10AN thread to allow the use of aftermarket components to plumb your external oil cooler. The front passage #1 will require a 3/8” NPT by dash 10AN adapter (#FCM2185), which is available from Scoggin-Dickey.

Understanding By-pass Valve Locations

Factory assembled 454, 502 engines and short blocks have two by-pass valves installed in the block. These factory installed by-pass valves (#25013759) will open at an 11 psi pressure differential. One by-pass valve is installed in the center hole on the oil filter pad (#4). This hole is the oil return passage from the oil filter. The second by-pass valve is installed in the adjacent hole (#3). The egg shaped hole (#5) is the high pressure oil supply passage from the oil pump.

For all racing application that will NOT use an oil cooler but will maintain the stock oil filter location, you must remove the center by-pass valve in location #4. Removing this valve eliminates three redundant right runs in the oil system. However, if you leave this by-pass in place the oil system will still function as it was intended, but a loss of oil pressure can result from the four right angle turns required for oil to return to the main oil tunnel.

If you intend to use a remote oil filter, a high pressure by-pass valve part number 25161284 must be installed in position #3. This valve will open at a 30 psi pressure differential. A plug will be installed in position #4 to prevent oil flow thru this passage. Oil should be returned to the block in the 3/8” hole located just able the oil filter pad. An oil filter block off plate kit (#SD3891) can be purchased from Scoggin-Dickey for Gen V and VI blocks to plumb your external oil filter.

If you intend to maintain the stock filter location and will use the factory provided oil cooler passages to install your oil cooler, then you must install two high pressure by-pass valves (#25161284). One will be installed in location #3 and the second in location #4. Happy oiling!

Here's the one from GM:

Excerpt from Speed Reading written by Wade Hajek of GM Performance Parts :

"Gen V and Gen VI big-block crate engines come with two oil pressure bypass valves installed in the engine blocks. Both of these valves are rated at 11 psi pressure differential. One valve is for the oil filter and the other is for the production oil cooler. If you install an aftermarket oil cooler or remote oil filter that attaches to the oil filter pad on the engine block, you should be aware that you need to change the oil filter bypass valve in the engine block. The aftermarket oil lines add resistance which will cause the bypass valve to bypass the aftermarket oil cooler and/or oil filter all the time. Obviously, if the cooler and filter are bypassed the oil will be dirty and hot. Your engine could run hotter and could be damaged by dirt in the oil. If you choose to use an aftermarket cooler or remote oil filter that attaches to the pad, you should change the bypass valve to one with a higher differential pressure rating. A good choice would be GM# 25161284 which is rated at 30 psi. Remove the valve that is closest to the crankshaft and replace it with the new valve. Press the new valve into the engine block and stake it in three places. You should note that the bypass valves don't need to be changed if you use a production oil cooler which uses the production holes in the engine block and you don't use a remote oil filter. Also, if you use an adapter that just angles the filter for clearance you don't need to change the bypass valves."

Last edited by a moderator:

Crusty66 said:I have an oil cooler adapter I wish to use on my 496, BBC ENGINE but the standard oil filter will then be too long. Is there a short oil filter available?

The usual oil filter will stick well below the oil pan with this adapter

http://www.superchevy.com/how-to/15044-1991-chevrolet-corvette-oil-cooler-maintenance/

I think your looking at the issue , of installing the adapter you have that requires a shorter and more compact oil filter to maintain the required clearance around the oil filter with that adapter and your goals in using it incorrectly here, the last thing you want too do is put a SMALLER and potentially more restrictive oil filter on a BIG BLOCK PERFORMANCE ENGINE APPLICATION WITH A REMOTE OIL COOLER,

if your using that particular oil filter adapter its designed to allow a remote oil cooler ,

and its generally used on trucks that have a good deal of ground clearance, where the use of a deep sump oil pan and that adapter with a standard oil filter is considered a workable combo.

keep in mind there are other options, many guys start with an adapter similar to this,

followed by an adapter like this

READ THIS RELATED INFO, ITS WELL WORTH THE TIME AND EFFORT

http://garage.grumpysperformance.com/index.php?threads/oil-filters-related-info.2080/#post-54352

http://garage.grumpysperformance.co...l-cooler-increases-durability.176/#post-48374

http://garage.grumpysperformance.co...ilter-you-sellect-does-make-a-differance.117/

this set-up allows you to have a very effective oil line connection point that can be and usually is routed to both an oil cooler and a remotely mounted full length or extended length oil filter or even dual extended length oil filters ,

that way you have, a greatly increased filter surface area surface that significantly reduces the resistance to oil flow rates and a significantly larger surface area on the filter medium, that will in theory allow longer use before the filter medium starts to clog with debris .

remember the goal here is two fold, effective cooling of the oil and low flow rate restriction, which a remotely mounted oil filter(s) can supply, plus the option of selecting an easily accessed remote mount filter location

Last edited:

8

87vette81big

Guest

That's a Really Slick Dual Oil Filter Layout pictured above Grumpy.

Its in a 2 nd Generation Camaro.

I recognize the Swoopy Curved Body Lines like the Trans Am.

Oil lines and block filter adapter running off the Drivers Side with a SBC Engine.

Pontiac V8 is opposite With oil filter adapter off the Passengers side.

I.never have seen those real nice aluminium stand mounts going into the Front Fender.

Look Billet almost but they are Precision. cast aluminium or Extruded aluminium .

Like to do a Stacked pil plate Cooler - Earls Brand, #10 AN Teflon lined Stainless braided hoses, Dual Oil filter layout , & Moroso oil accumulator.

Have to save up put away $1k.

Would be to my benifit on the Trans Am.

At least extend my oil change intervels.

When I run my TA hard I change oil every 50-100 miles for peace of mind.

That Camaro is a Drag Racer.

Front Skinnies MOROSO DS-2 Front Runners.

Front steel fender wells removed to save weight and get instant front end rise and weight transfer to the back tires.

Its in a 2 nd Generation Camaro.

I recognize the Swoopy Curved Body Lines like the Trans Am.

Oil lines and block filter adapter running off the Drivers Side with a SBC Engine.

Pontiac V8 is opposite With oil filter adapter off the Passengers side.

I.never have seen those real nice aluminium stand mounts going into the Front Fender.

Look Billet almost but they are Precision. cast aluminium or Extruded aluminium .

Like to do a Stacked pil plate Cooler - Earls Brand, #10 AN Teflon lined Stainless braided hoses, Dual Oil filter layout , & Moroso oil accumulator.

Have to save up put away $1k.

Would be to my benifit on the Trans Am.

At least extend my oil change intervels.

When I run my TA hard I change oil every 50-100 miles for peace of mind.

That Camaro is a Drag Racer.

Front Skinnies MOROSO DS-2 Front Runners.

Front steel fender wells removed to save weight and get instant front end rise and weight transfer to the back tires.

one of the guys I went too college with has a 1985 corvette thats been rather extensively modified , hes installed a much modified LS aluminum engine that makes in excess of 700 hp, I was discussing his list of mods and he mentioned he has multiple fluid coolers in use, now you might want to pay attention to what I'm describing because he found this works the best after several years of trial & error testing and he has the budget and resources to test a great many configurations and in this case it took him several seasons to find what worked out almost ideally.

keep in mind he has three separate oil and engine coolant temp gauges measuring oil pan oil temps, oil cooler return line oil temps and engine coolant temps, I found his approch of a multi layer cooler rather ingenious

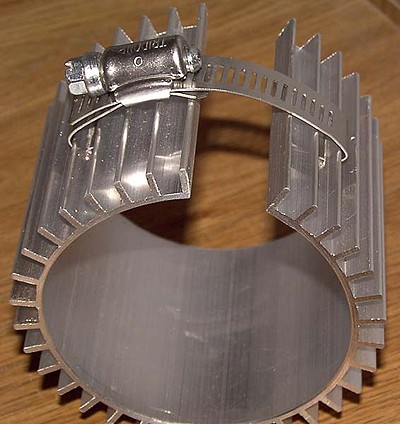

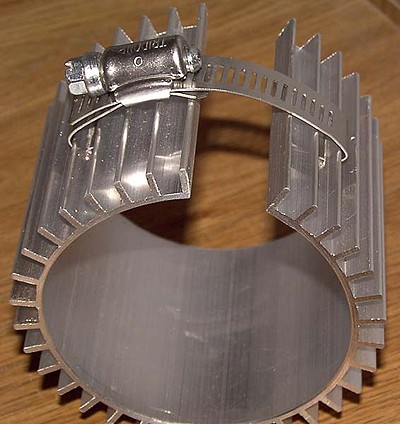

Id also suggest you install a long higher capacity oil filter if you have the clearance to do so, as both the extra oil capacity and the fact that the larger oil filter with its greater surface area constantly exposed to outside air flow, (especially if you have an oil filter finned cooler) can in many cases reduce oil temps 5 degrees or more, and keep in mind you can remotely mount oil filters and coolers in dozens of varied configs, and various sizes can be used.

I don,t know where they sell these, finned aluminum filter covers now ,a few years back these were $20 each and significantly longer that this picture shows,

in fact they were the length of the long oil filter ,and believe it or not the combo of the longer oil filter and finned cover dropped my oil temps an additional 5 deg F , EASY TO PROVE by simply removing and replacing the slip on finned cover several times after keeping detailed records while cruising the interstate at a steady 70 mph (not a big difference but for $20 well worth it!

yes you can get a bit more creative and build or buy something with significantly more surface area for increased cooling capacity if you might feel inclined

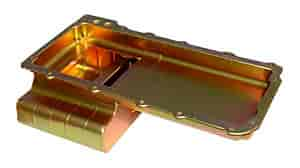

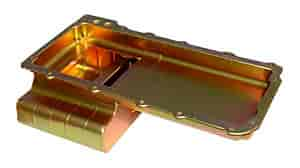

he started out with a decent 7 quart oil pan

http://www.jegs.com/i/Milodon/697/31527/10002/-1?parentProductId=748533

he installed a coolant too oil cooler with AN#10 lines to the oil cooler from the engine so there would be no flow restriction in the line , the reason he used a coolant to oil cooler set-up was to insure that engine oil heated up more rapidly and consistently as the engine was being used, it does a decent job of reducing the oil temp but its efficiency is changed as engine coolant temps change, but, knowing that , would be the case, he installed an additional air to oil cooler in series with a thermal bye-pass switch, set to open the coolant lines to the second cooler, rather than bye-pass oil back to the engine, through the thermal routing switch,

http://www.improvedracing.com/oil-t...uct_search&utm_source=googleproductsearchusen

that kicks in if the oil leaving the coolant too oil cooler ,reaches 220-225 deg F (which it seldom does until he is actually racing)

https://www.summitracing.com/parts/ear-45000erl/overview/

and he uses a 195F engine coolant t-stat , the result is engine oil fairly rapidly heats to about 210f while engine coolant rarely exceed 200F when hes cruising ,

but under hard racing the engine temps occasionally climb.

he found he needed the oil cooler because with just the 7 quart oil pan his oil temps would slowly build to 255-260F , once the oil to coolant cooler was installed he rarely saw oil temps exceed 235F for more than a minute or so. and then only when engine coolant temps went up briefly to 220-225F under hard road racing conditions ,

where he had to keep the rpms in the 4700-rpm-7000-rpm range most of the time,

adding the second oil cooler seemed to take some of the thermal load off both the engine and oil too coolant oil cooler because the second cooler in series drops the oil temps of oil returning to the engine to WELL under 215F, until the engine oil entering the thermal bye-pass switch shuts and stops routing oil through the second cooler, keep in mind the second oil to air cooler always has a small volume of oil flow through it, and once the engines being raced hard its seldom not in the oil line flow routing.

the answer too what cooling system is most likely to both cool the car/truck efficiently and fit your budget,would mostly depend on your budget limitations,

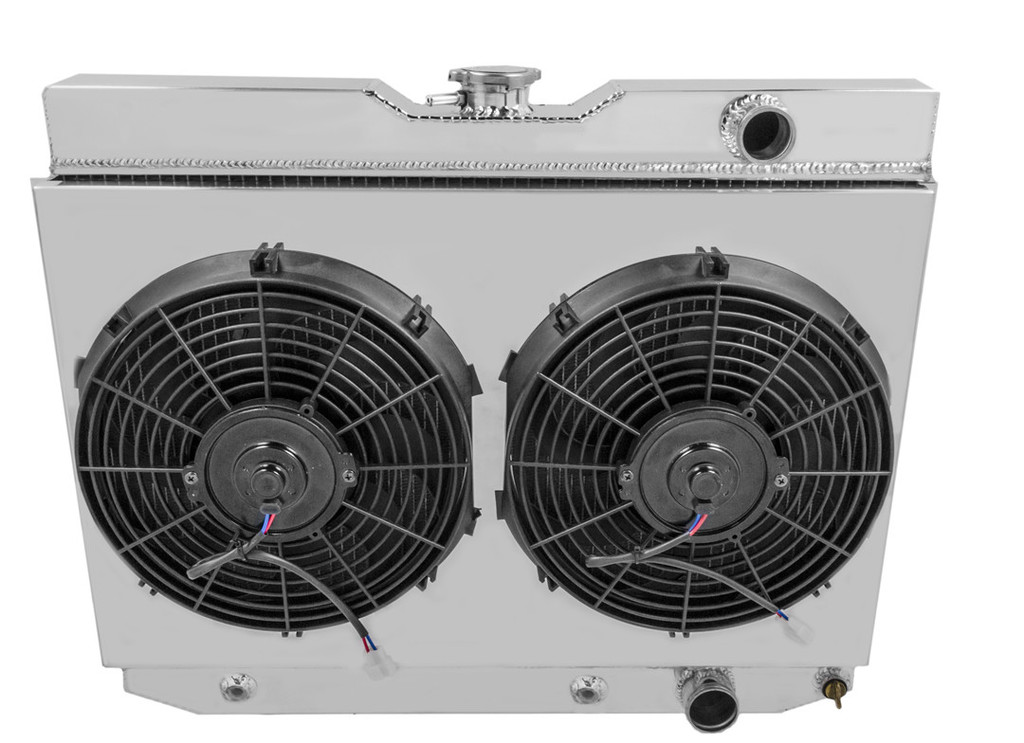

but a large 3-4 tube aluminum radiator with a a 140-to-200 amp alternator

https://www.dbelectrical.com/produc...0-5-7l-7-4l-chevy-truck-93-94-95-200-amp.html

https://www.summitracing.com/parts/tff-8173nep/applications/year/1996

http://garage.grumpysperformance.com/index.php?threads/building-a-custom-wet-sump-oil-pan.65/

taking advantage of all your options is a smart way to reproach the issue of correctly controlling, and maintaining a stable and predictable engine heat level, thus installing a larger capacity racing style oil pan and an auxiliary oil cooler with an electrical fan, will significantly increase the engines ability to rapidly dissipate heat even before that engine heat is absorbed by the engines cooling systems coolant. oil flow over a few of the hottest components like valve springs, bearing surfaces,and rocker arms absorb and transfer heat to the block, and oil pan as it flows, thus a larger oil capacity and a baffled oil pan with an extended sump is a good idea as the increased oil capacity and larger surface area of an enlarged sump area exposed too outside air flow can stabilize and allow a good deal of heat to dissipate to that outside air flow, as the air which can be well over 130F-170 plus F cooler that the engine oil that can be up to 250F plus in a racing engine

I'd point out that a 7-8 quart baffled oil pan helps cool an engine.

and dual or a large single electric fan with a matched ducted shroud and the ability to move,

2500 fcm-3000 cfm of air should provide adequate cooling for most engines.

adding an auxiliary oil cooler certainly helps

I'm forced to point out the oil cooler or trans fluid transfer line internal cross sectional area has a potential effect on flow resistance and efficiency,

if you select 1/2" or AN#8 lines they are large enough in cross sectional area too make the transfer line size and length basically non-restrictive.

Id also suggest selecting the longer length, dual oil filters mounted vertically in a rather easy to access area of your choice making replacement easy and less likely to be a messy process.

the longer length oil filters, pleated filtration medium, provide much greater surface area for filtration reducing the flow restriction.

http://garage.grumpysperformance.co...ubing-fuel-lines-and-flaring.1030/#post-35905

http://garage.grumpysperformance.co...ion-remote-filter-flow-rate.14621/#post-78235

http://garage.grumpysperformance.com/index.php?threads/thoughts-on-cooling.149/#post-70002

http://garage.grumpysperformance.com/index.php?threads/transmission-over-temp.12832/

http://garage.grumpysperformance.co...il-cooler-increases-durability.176/#post-3620

http://garage.grumpysperformance.co...il-cooler-increases-durability.176/#post-3620

Keep in mind a well designed 7-8 quart baffled oil pan adds both durability and helps reduce cooling issues

and if you have an automatic transmission Id add a electrical fan cooled trans fluid cooler

RELATED INFO

http://garage.grumpysperformance.co...lternators-and-oil-all-here.12628/#post-69303

http://garage.grumpysperformance.co...sion-and-oil-cooler-increases-durability.176/

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/

http://garage.grumpysperformance.co...-choose-an-electric-fan-in-4-easy-steps.7774/

http://garage.grumpysperformance.co...tting-out-low-voltage.12221/page-2#post-59599

http://garage.grumpysperformance.co...uys-don-t-look-at-the-clues.11176/#post-50125

http://garage.grumpysperformance.com/index.php?threads/aluminum-radiator-sources.755/

http://garage.grumpysperformance.co...ing-system-flow-rates-and-heat-transfer.9880/

http://garage.grumpysperformance.com/index.php?threads/copper-vs-aluminum-in-radiators.4230/

http://garage.grumpysperformance.com/index.php?threads/setting-up-electric-fans-correctly.7150/

http://garage.grumpysperformance.co...r-transmission-fluid-cooler.15375/#post-90261

related info

http://garage.grumpysperformance.co...hy-is-the-ls-engine-so-good.11713/#post-59455

http://garage.grumpysperformance.com/index.php?threads/chevy-ls1-related-info.3918/#post-42797

http://garage.grumpysperformance.com/index.php?threads/big-block-or-ls-series-motor.6866/#post-22294

keep in mind he has three separate oil and engine coolant temp gauges measuring oil pan oil temps, oil cooler return line oil temps and engine coolant temps, I found his approch of a multi layer cooler rather ingenious

Id also suggest you install a long higher capacity oil filter if you have the clearance to do so, as both the extra oil capacity and the fact that the larger oil filter with its greater surface area constantly exposed to outside air flow, (especially if you have an oil filter finned cooler) can in many cases reduce oil temps 5 degrees or more, and keep in mind you can remotely mount oil filters and coolers in dozens of varied configs, and various sizes can be used.

I don,t know where they sell these, finned aluminum filter covers now ,a few years back these were $20 each and significantly longer that this picture shows,

in fact they were the length of the long oil filter ,and believe it or not the combo of the longer oil filter and finned cover dropped my oil temps an additional 5 deg F , EASY TO PROVE by simply removing and replacing the slip on finned cover several times after keeping detailed records while cruising the interstate at a steady 70 mph (not a big difference but for $20 well worth it!

yes you can get a bit more creative and build or buy something with significantly more surface area for increased cooling capacity if you might feel inclined

he started out with a decent 7 quart oil pan

http://www.jegs.com/i/Milodon/697/31527/10002/-1?parentProductId=748533

he installed a coolant too oil cooler with AN#10 lines to the oil cooler from the engine so there would be no flow restriction in the line , the reason he used a coolant to oil cooler set-up was to insure that engine oil heated up more rapidly and consistently as the engine was being used, it does a decent job of reducing the oil temp but its efficiency is changed as engine coolant temps change, but, knowing that , would be the case, he installed an additional air to oil cooler in series with a thermal bye-pass switch, set to open the coolant lines to the second cooler, rather than bye-pass oil back to the engine, through the thermal routing switch,

http://www.improvedracing.com/oil-t...uct_search&utm_source=googleproductsearchusen

that kicks in if the oil leaving the coolant too oil cooler ,reaches 220-225 deg F (which it seldom does until he is actually racing)

https://www.summitracing.com/parts/ear-45000erl/overview/

and he uses a 195F engine coolant t-stat , the result is engine oil fairly rapidly heats to about 210f while engine coolant rarely exceed 200F when hes cruising ,

but under hard racing the engine temps occasionally climb.

he found he needed the oil cooler because with just the 7 quart oil pan his oil temps would slowly build to 255-260F , once the oil to coolant cooler was installed he rarely saw oil temps exceed 235F for more than a minute or so. and then only when engine coolant temps went up briefly to 220-225F under hard road racing conditions ,

where he had to keep the rpms in the 4700-rpm-7000-rpm range most of the time,

adding the second oil cooler seemed to take some of the thermal load off both the engine and oil too coolant oil cooler because the second cooler in series drops the oil temps of oil returning to the engine to WELL under 215F, until the engine oil entering the thermal bye-pass switch shuts and stops routing oil through the second cooler, keep in mind the second oil to air cooler always has a small volume of oil flow through it, and once the engines being raced hard its seldom not in the oil line flow routing.

the answer too what cooling system is most likely to both cool the car/truck efficiently and fit your budget,would mostly depend on your budget limitations,

but a large 3-4 tube aluminum radiator with a a 140-to-200 amp alternator

https://www.dbelectrical.com/produc...0-5-7l-7-4l-chevy-truck-93-94-95-200-amp.html

https://www.summitracing.com/parts/tff-8173nep/applications/year/1996

http://garage.grumpysperformance.com/index.php?threads/building-a-custom-wet-sump-oil-pan.65/

taking advantage of all your options is a smart way to reproach the issue of correctly controlling, and maintaining a stable and predictable engine heat level, thus installing a larger capacity racing style oil pan and an auxiliary oil cooler with an electrical fan, will significantly increase the engines ability to rapidly dissipate heat even before that engine heat is absorbed by the engines cooling systems coolant. oil flow over a few of the hottest components like valve springs, bearing surfaces,and rocker arms absorb and transfer heat to the block, and oil pan as it flows, thus a larger oil capacity and a baffled oil pan with an extended sump is a good idea as the increased oil capacity and larger surface area of an enlarged sump area exposed too outside air flow can stabilize and allow a good deal of heat to dissipate to that outside air flow, as the air which can be well over 130F-170 plus F cooler that the engine oil that can be up to 250F plus in a racing engine

I'd point out that a 7-8 quart baffled oil pan helps cool an engine.

and dual or a large single electric fan with a matched ducted shroud and the ability to move,

2500 fcm-3000 cfm of air should provide adequate cooling for most engines.

adding an auxiliary oil cooler certainly helps

I'm forced to point out the oil cooler or trans fluid transfer line internal cross sectional area has a potential effect on flow resistance and efficiency,

if you select 1/2" or AN#8 lines they are large enough in cross sectional area too make the transfer line size and length basically non-restrictive.

Id also suggest selecting the longer length, dual oil filters mounted vertically in a rather easy to access area of your choice making replacement easy and less likely to be a messy process.

the longer length oil filters, pleated filtration medium, provide much greater surface area for filtration reducing the flow restriction.

http://garage.grumpysperformance.co...ubing-fuel-lines-and-flaring.1030/#post-35905

http://garage.grumpysperformance.co...ion-remote-filter-flow-rate.14621/#post-78235

http://garage.grumpysperformance.com/index.php?threads/thoughts-on-cooling.149/#post-70002

http://garage.grumpysperformance.com/index.php?threads/transmission-over-temp.12832/

http://garage.grumpysperformance.co...il-cooler-increases-durability.176/#post-3620

http://garage.grumpysperformance.co...il-cooler-increases-durability.176/#post-3620

Keep in mind a well designed 7-8 quart baffled oil pan adds both durability and helps reduce cooling issues

and if you have an automatic transmission Id add a electrical fan cooled trans fluid cooler

RELATED INFO

http://garage.grumpysperformance.co...lternators-and-oil-all-here.12628/#post-69303

http://garage.grumpysperformance.co...sion-and-oil-cooler-increases-durability.176/

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/

http://garage.grumpysperformance.co...-choose-an-electric-fan-in-4-easy-steps.7774/

http://garage.grumpysperformance.co...tting-out-low-voltage.12221/page-2#post-59599

http://garage.grumpysperformance.co...uys-don-t-look-at-the-clues.11176/#post-50125

http://garage.grumpysperformance.com/index.php?threads/aluminum-radiator-sources.755/

http://garage.grumpysperformance.co...ing-system-flow-rates-and-heat-transfer.9880/

http://garage.grumpysperformance.com/index.php?threads/copper-vs-aluminum-in-radiators.4230/

http://garage.grumpysperformance.com/index.php?threads/setting-up-electric-fans-correctly.7150/

http://garage.grumpysperformance.co...r-transmission-fluid-cooler.15375/#post-90261

related info

http://garage.grumpysperformance.co...hy-is-the-ls-engine-so-good.11713/#post-59455

http://garage.grumpysperformance.com/index.php?threads/chevy-ls1-related-info.3918/#post-42797

http://garage.grumpysperformance.com/index.php?threads/big-block-or-ls-series-motor.6866/#post-22294

Last edited: