" GRUMPY? does comps lifter bore groove tool really work?

which side of the bore do you put the groove on? I'd assume that you want the oil to spray down on the lobe right before it goes under the lifter, so all 16 of the grooves would be on the passenger side of the bores- pointed towards the even numbered cylinders- correct?

READ THRU THIS THREAD

viewtopic.php?f=54&t=2187

yes thats correct!

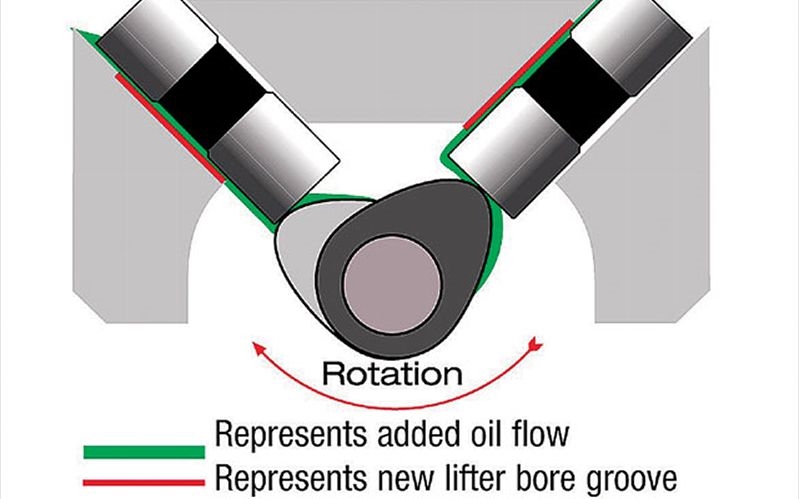

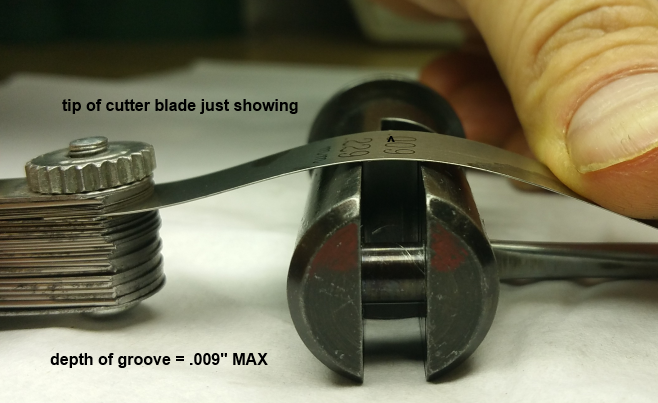

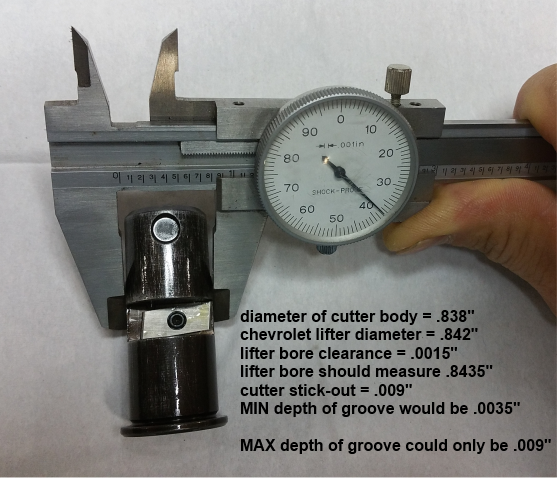

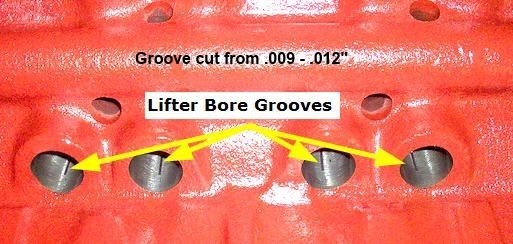

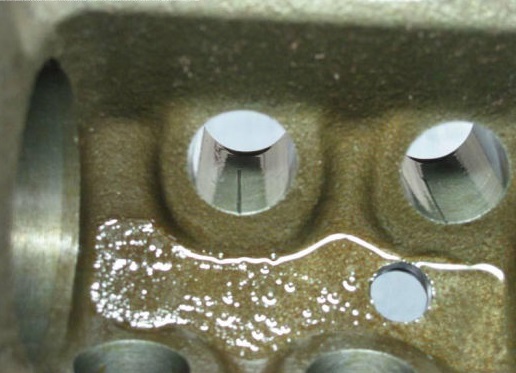

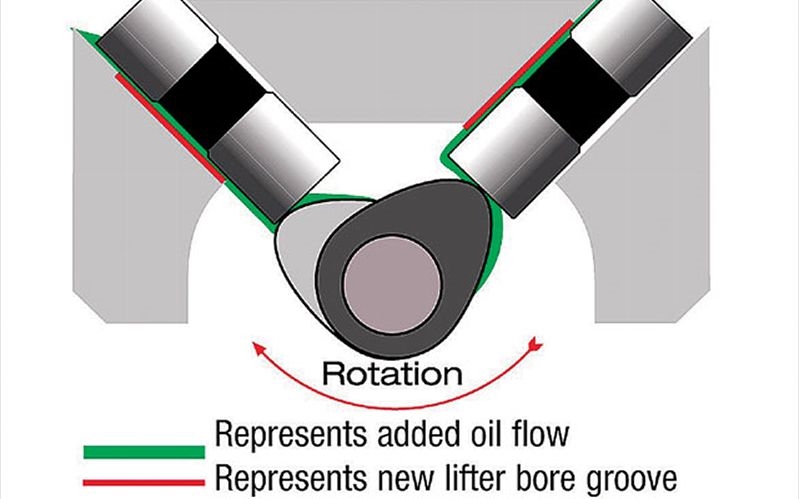

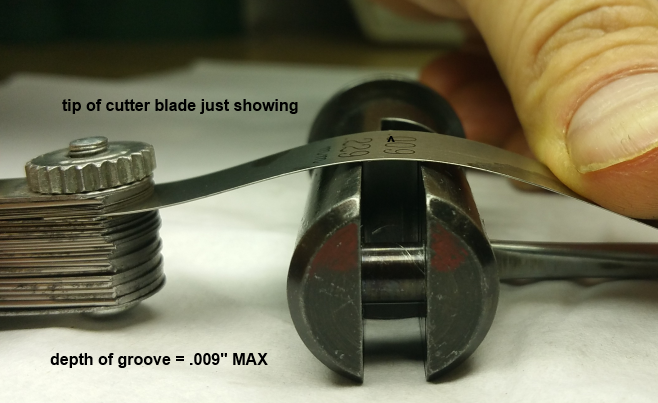

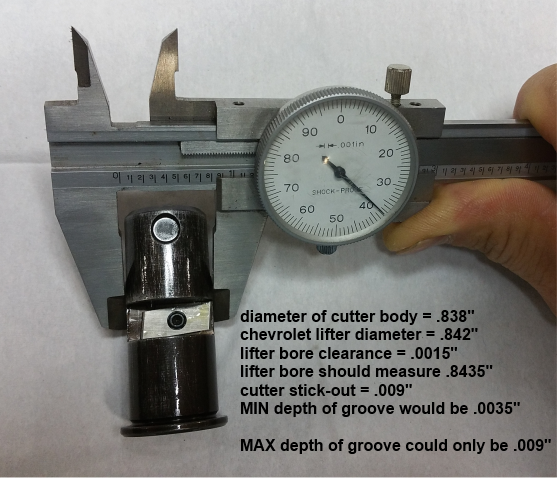

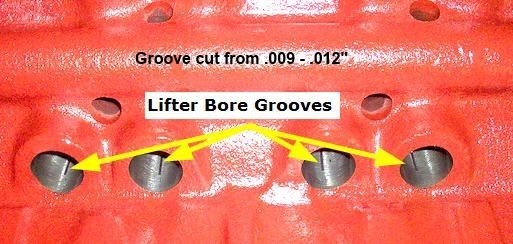

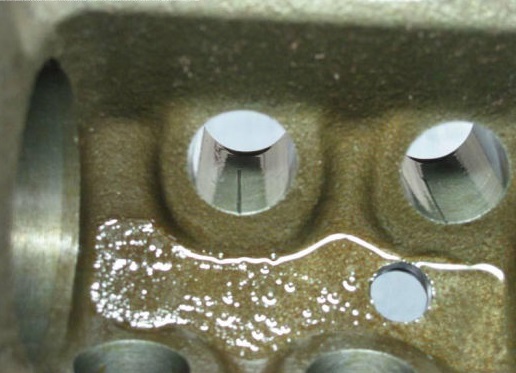

yes it is as simple as it sounds, you just put a small oil groove in the lower 1/2 of the lifter bore per the instructions, look at the picture below, its just cutting a .005-.007 deep groove

You do have to go back in & hone the lifter bore or at the least hit the groove with your finger & some Emory paper to be sure there is not a raised burr or groove edge

yes I have and use the tool, be aware your probably going to want to use a 7-8 quart baffled oil pan, a windage screen, with a crank scraper and a high volume oil pump, as those little grooves in the lower lifter bores,along with grooving the lower distributor to increase oil flow to the cam gear,will drop the at idle oil pressure slightly, but I have also never YET lost a cam lobe on a flat tappet cam on an engine so modified

COMP SELLS A TOOL TO GROOVE LIFTER BORES

COMP SELLS A TOOL TO GROOVE LIFTER BORES

which side of the bore do you put the groove on? I'd assume that you want the oil to spray down on the lobe right before it goes under the lifter, so all 16 of the grooves would be on the passenger side of the bores- pointed towards the even numbered cylinders- correct?

READ THRU THIS THREAD

viewtopic.php?f=54&t=2187

yes thats correct!

yes it is as simple as it sounds, you just put a small oil groove in the lower 1/2 of the lifter bore per the instructions, look at the picture below, its just cutting a .005-.007 deep groove

You do have to go back in & hone the lifter bore or at the least hit the groove with your finger & some Emory paper to be sure there is not a raised burr or groove edge

yes I have and use the tool, be aware your probably going to want to use a 7-8 quart baffled oil pan, a windage screen, with a crank scraper and a high volume oil pump, as those little grooves in the lower lifter bores,along with grooving the lower distributor to increase oil flow to the cam gear,will drop the at idle oil pressure slightly, but I have also never YET lost a cam lobe on a flat tappet cam on an engine so modified

Last edited by a moderator: