http://www.wallaceracing.com/driveshaftspeed.php

http://www.dennysdriveshaft.com/c976_combination_universal_joints.html

http://pstds.com/critical-speed-chart/

http://www.wolferacecraft.com/pinionangle.aspx

http://azdriveshaft.com/

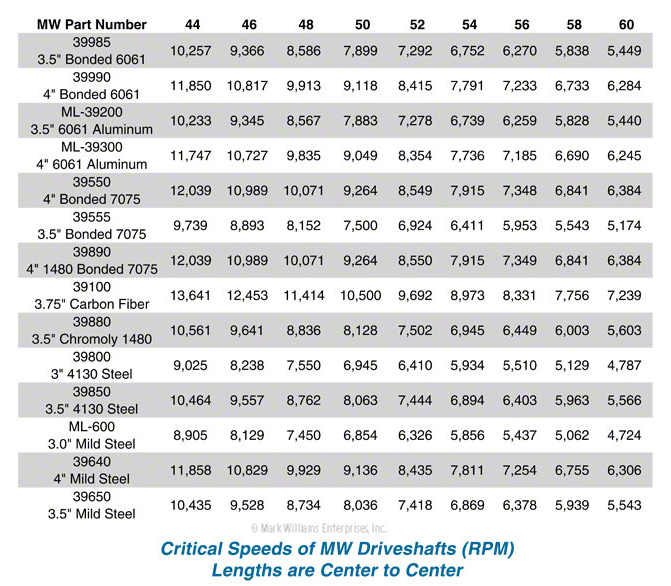

the diameter of the drive shaft tube,

and the torque loads its expected to handle, and rpms it will need too transmit as it turns

, naturally as both torque, loads, and rpms increase the strength,

of the materials and yoke and bearing size and resulting cost to build it from quality materials,increases.

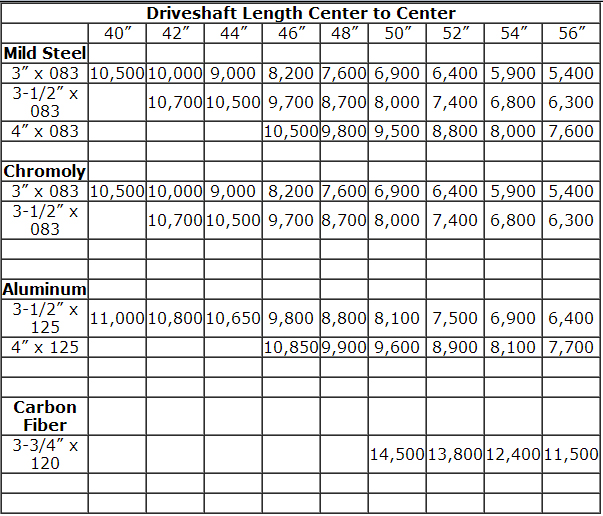

As you will see looking over the chart below,a 44"-60" increase in length , results in a very large reduction in the recommended rpm range, as the length increased,and its a big mistake to assume youll get by with inferior materials or workmanship or without having the drive shaft properly balanced.

youll see few performance cars with two piece drice shafts but at times its required.

heres a bit of related info below

Driveshaft Tech and FAQ

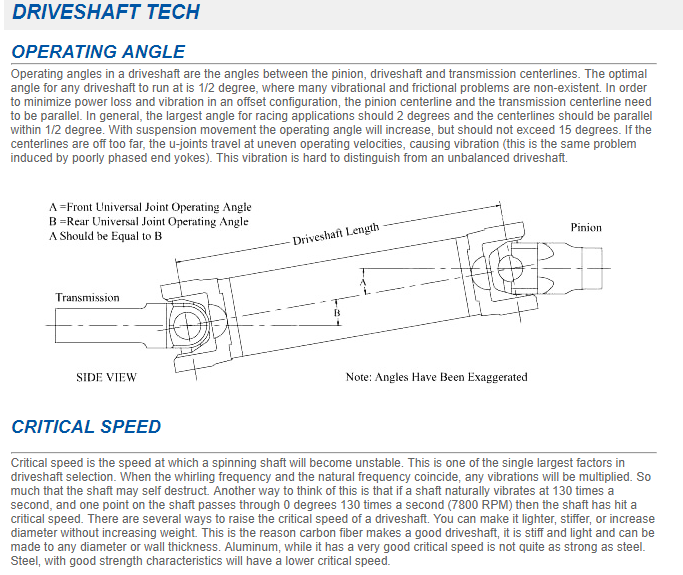

Operating Angle

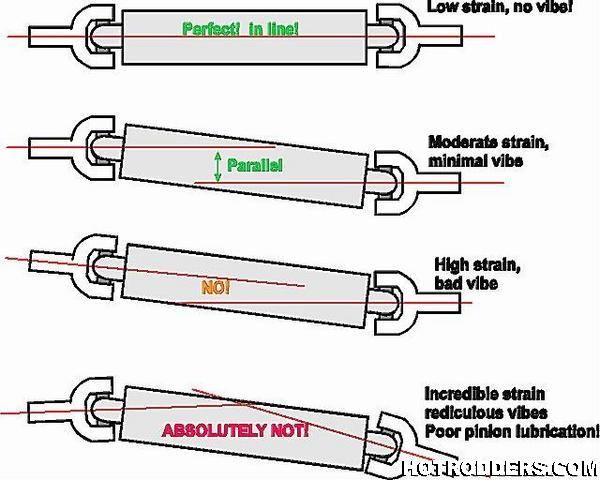

Operating angles in a driveshaft are the angles between the pinion, driveshaft and transmission centerlines. The optimal angle for any driveshaft to run at is 1/2 degree, where many vibrational and frictional problems are non-existent. In order to minimize power loss and vibration in an offset configuration, the pinion centerline and the transmission centerline need to be parallel. In general, the largest angle for racing applications should 2 degrees and the centerlines should be parallel within 1/2 degree. With suspension movement the operating angle will increase, but should not exceed 15 degrees. If the centerlines are off too far, the u-joints travel at uneven operating velocities, causing vibration (this is the same problem induced by poorly phased end yokes). This vibration is hard to distinguish from an unbalanced driveshaft.

Critical Speed

Critical speed is the speed at which a spinning shaft will become unstable. This is one of the single largest factors in driveshaft selection. When the whirling frequency and the natural frequency coincide, any vibrations will be multiplied. So much that the shaft may self destruct. Another way to think of this is that if a shaft naturally vibrates at 130 times a second, and one point on the shaft passes through 0 degrees 130 times a second (7800 RPM) then the shaft has hit a critical speed. There are several ways to raise the critical speed of a driveshaft. You can make it lighter, stiffer, or increase diameter without increasing weight. This is the reason carbon fiber makes a good driveshaft, it is stiff and light and can be made to any diameter or wall thickness. Aluminum, while it has a very good critical speed is not quite as strong as steel. Steel, with good strength characteristics will have a lower critical speed.

http://www.dynotecheng.com/

http://www.hotrodhotline.com/conten...ancellation-jim-clark-hot-rod-md#.WRKEkfnyvcc

http://www.dennysdriveshaft.com/how_to_measure.html

http://garage.grumpysperformance.com/index.php?threads/physics-of-racing-series-info.372/

http://www2.dana.com/pdf/J3311-1-DSSP.pdf

http://www.4xshaft.com/driveline101.asp

http://www.carcraft.com/howto/91758/

http://www.dennysdriveshaft.com/c29_corvette.html

http://www.carcraft.com/techarticles/cc ... index.html

http://www.dennysdriveshaft.com/c36_tra ... yokes.html

http://www.drivetrain.com/jonts_yokes.htm

http://www.circletrack.com/drivetrainte ... index.html

http://www.arizonadrivelines.com/Drive_ ... spline.htm

http://www.pitstopusa.com/SearchResult. ... oryID=1872

http://www.moderndriveline.com/md_faqs/ ... ft_1.shtml

http://www.dickmillerracing.com/Driveshaft_page.htm

http://driveshaftmasters.com/

http://markwilliams.com/

viewtopic.php?f=71&t=1261&p=2709#p2709

viewtopic.php?f=71&t=1198&hilit=+angle

stock driveshafts ARE very unlikely to hold up to hard launches with sticky tires and high torque loads for long periods drive shaft ballance,is critical, and high performance engines usually require larger diam. and purpose built driveshafts, on some theres a faint seam along the side of the tube and having that line spiral around several degees is comon on stock driveshafts, KEEP in mind driveshafts can get twisted or bent, throwing them significantly out of ballance.

Last edited by a moderator: