EVERY SHOP needs a drill press, hydraulic press and a decent welder, I can,t imagine how you can work without basic tools,

Try to find a variable speed/adjustable speed and 3/4hp minimum, too-2 hp DRILL PRESS model with a built in adjustable vise ,and at least a 1/2" chuck ,if you can, locate one is a huge help in fabrication or repair jobs most garages.

a good USED American made drill press can usually be located at a good price looking thru the classifieds or craigs list.

A DRILL PRESS, and a decent welding machine IN A persons SHOP who is into the car hobby IS ALMOST 100% MANDATORY,

ITS far more useful than a hand held drill,

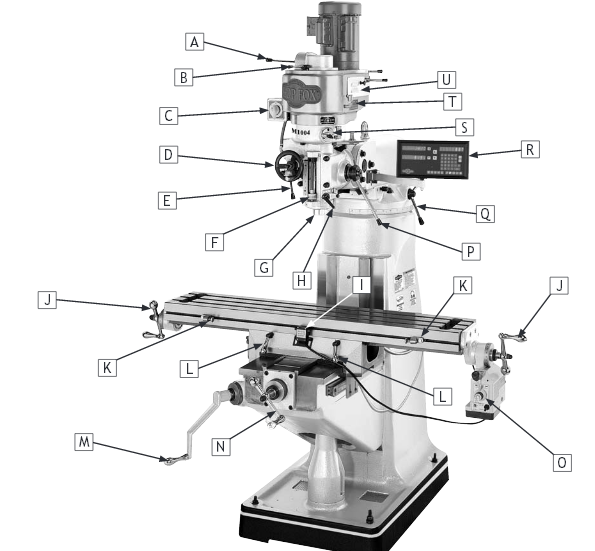

but even a good drill press is inferior to a good MILLING MACHINE

\

EVERY SHOP needs a drill press, hydraulic press and a decent welder, I can,t imagine how you can work without basic tools, now you don,t need the best one ever made but a decent floor mount drill press is a huge asset to any shop

http://www.grizzly.com/products/12-Spee ... ress/G7944

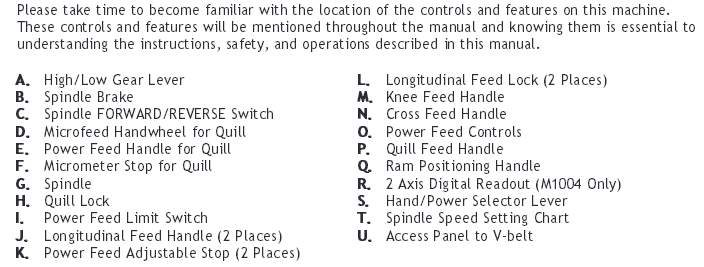

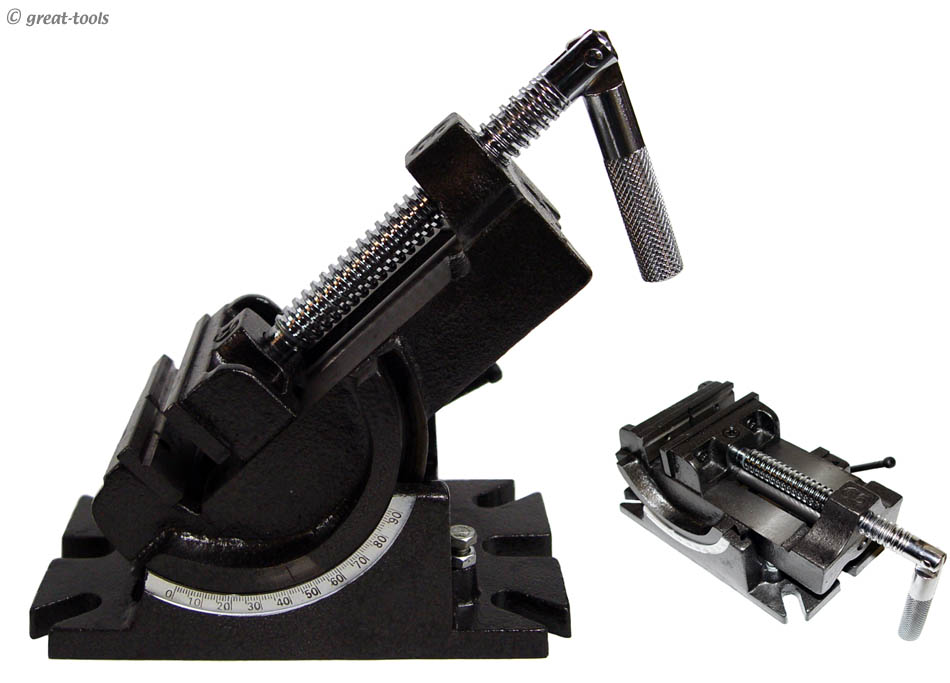

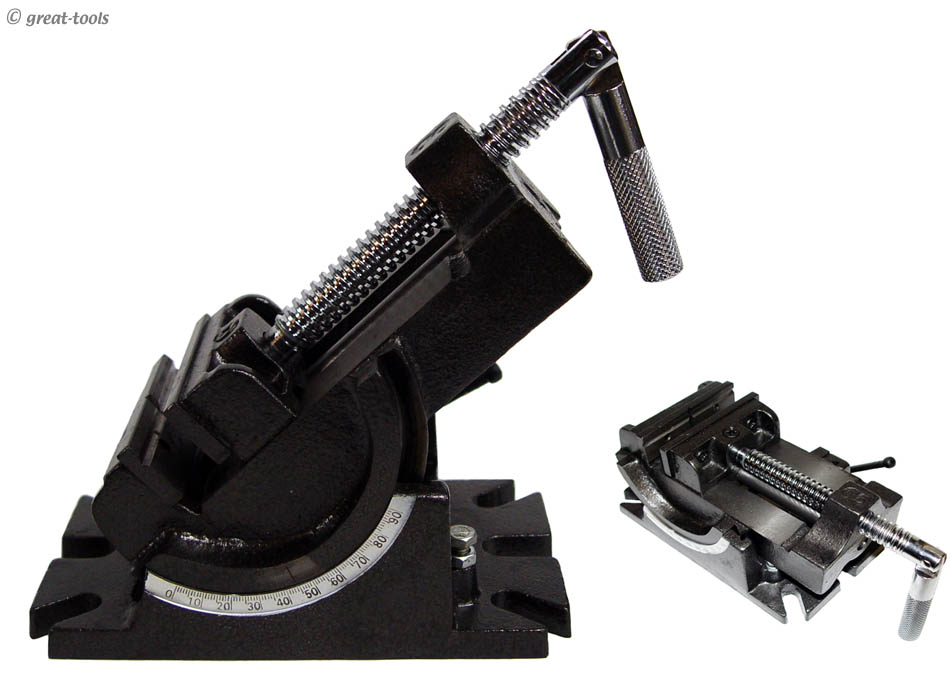

http://www.grizzly.com/products/Cross-S ... Vise/G1064

https://drillsandcutters.com/

https://www.homedepot.com/p/RIDGID-...VCr3ACh2fzgbHEAQYBCABEgL9yfD_BwE&gclsrc=aw.ds

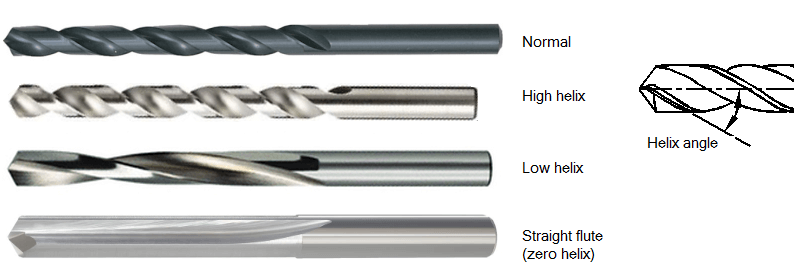

WATCH THE DRILL BIT VIDEO,s

yeah if you can swing the cost a decent MILL is even better

http://www.grizzly.com/products/5-Speed ... ress/G7946

viewtopic.php?f=27&t=4231&p=33023&hilit=milling#p33023

viewtopic.php?f=50&t=8340&p=28997&hilit=milling#p28997

viewtopic.php?f=27&t=993&p=10056&hilit=milling#p10056

FLOOR stand models tend to be better quality than the desk top versions simply because most desk top versions are designed for the hobby use sector while many stand alone versions are designed for shop use.

most of the 1/2hp and some of the 3/4 hp versions Ive inspected or used over the years are extremely cheaply made, and basically trash.

while its getting much harder to do, an AMERICAN MADE brand tends to be better made than those imported from china or india , etc. so look for local machine shops that might sell older equipment and while your in the market you might find a MILLING MACHINE at a good price

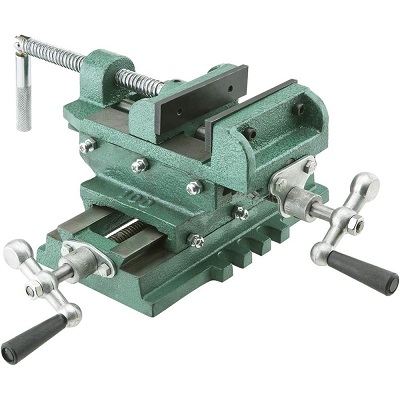

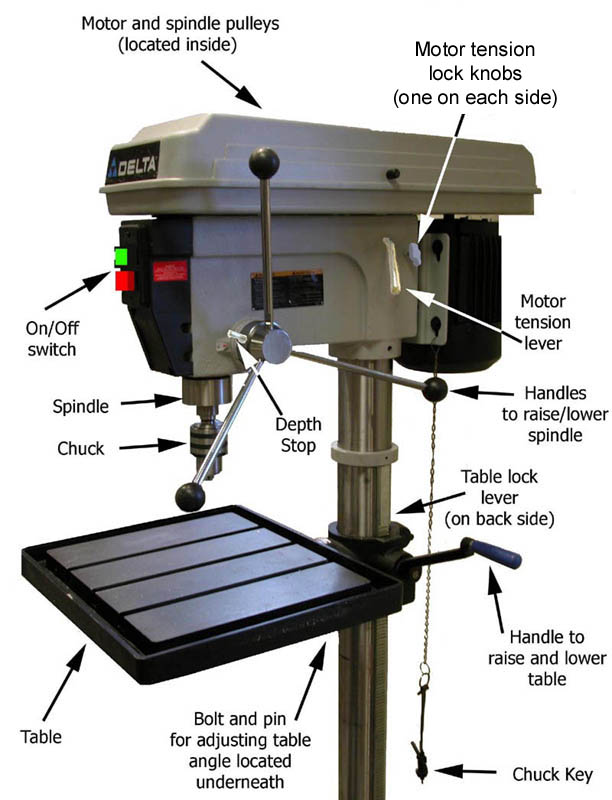

some drill presses allow the drill angle or table to be re-indexed to allow holes to be drilled at precise angles, but all drill presses require a good drill press vise to drill accurate holes

http://www.grizzly.com/products/5-Speed ... ress/G7946

READ THE LINKS THERES A WIDE VERITY IN QUALITY IN BITS

reading thru the sub linked info will help a great deal

http://store.curiousinventor.com/guides/drill_speed

http://its.fvtc.edu/MachShop1/coolant/cutfluids.htm

viewtopic.php?f=27&t=4714&p=12809&hilit=drill+sharpen#p12809

http://www.northerntool.com/shop/tools/ ... _200320247

viewtopic.php?f=27&t=1170

theres a tool that puts a professional quality re-sharpened tip on bits and yes even the best bits need to be touched up regularly to maintain a decent edge, and Id point out that hard metal must be drilled at low speed with constant flow of cutting & cooling oil

viewtopic.php?f=27&t=1170

http://www.popularmechanics.com/home_jo ... 74536.html

http://www.nextag.com/drill-press/shop-html

http://www.northerntool.com/webapp/wcs/ ... allpartial

http://www.northerntool.com/webapp/wcs/ ... _200365433

http://www.overstock.com/Home-Garden/16 ... oduct.html

http://www.taunton.com/finewoodworking/ ... px?id=5415

http://grizzley.com/products/5-Speed-Be ... ress/G7945

Last edited by a moderator: