every last person in this hobby does this frequently, yes far to many times we fail to step back and logically look over a problem , before assuming we know whats wrong or testing carefully, yes most of us gain experience and eventually get better at trouble shooting and diagnosing problems,but we see a problem or a symptom indicating a problem and initially ignore the indications that clearly point to the source of the problem.

when things don,t operate smoothly theres usually a reason and the first question I usually ask is what did you change lately,ID also look at the motor mount bolts and bell housing bolts as those can also cause noise at low rpms that goes away as rpms increase if the answers nothing then you do a compression check, use a timing light and multimeter , fuel pressure gauge and vacuum gauge to isolate the source of your problem, and don,t overlook the simple things, if the coils not getting any voltage, or theres no fuel pressure check grounds and fuses before attempting major engine surgery, read the spark plugs they provide you with a ton of info, look at the oil filter after you cut it open, check the oil pressure, and check the sensors and electrical connections

example

when I was about 19 years old I purchased a Mallory dual point distributor for a Pontiac, I installed it and the car ran no better than it did with the factory ignition,in fact it was worse at higher rpms, I took it to an older mechanic at the Pontiac, dealership I was working part time at at that time and he brought out a dwell meter and set the points, up until that time I had no idea what a dwell meter was or how to use one, id always set points with a feeler gauge, I should have realized something was wrong when the ignition would not allow the engine to run at over 5600rpm,but I had assumed the Mallory ignition was perfect right out of the box when I installed it, and set the timing. its the AMP load that heats and burns points, getting 20-25 k miles is very common before you notice any need to clean and reset points in my experience, but you need a dwell meter and a points file, if your going old school ignition.

example

one of my friends calls and says the car just "THREW A CONNECTING ROD" could I help him get the engine repaired, I got over there and it sure didn,t sound good but it also didn,t sound like a connecting rod knock, careful inspection showed the flex-plate bolts had worked loose and sheared off,, obviously not good but better than a thrown rod.

example

I once had a guys with a 1968 big block corvette that had installed a dual point distributor that had a rather annoying hiigh rpm ignition miss that was eventually traced to a severely worn cam on the distributor shaft that opened and closed the ignition points, if you were not aware of what the cam in the distributor was supposed to look like it appeared rather normal, it just had very small lift to open the points due to excess wear.

example

I get a call from a friend asking if I want to buy his old (BLOWN_UP 375hp 396 engine) dirt cheap, as hes just installed a new 454 crate engine

I get it for $200 which I figured I could break even on if just the heads or block was salvageable, close inspection shows theres nothing wrong with the (TOTALLY BLOWN ENGINE) except for three rocker arm balls heat welded to rockers due to lack of oil and three busted push rods

I replaced all the lifters,rockers, cam timing set, bearings and push rods and drove that engine for over a year with zero problems.

the orriginal owner had never even pulled a valve cover, the engine made a few bad sounds and stopped running so he relaced it without ever bothering to find out what had happened internally.

example

buddy calls and wants my help tuning his new dual quad equipped engine which he can,t get fired with a new cam installed, obviously I,m thinking hes screwed up the cam install or got the ignition timing all wrong, careful inspection shows hes got every last lifter adjusted way to tight, simply backing off each rocker nut several full turns gets it to fire up, then we adjust the valves and every things fine!

example

a neighbor calls up asked me to look at why his car runs like crap, starts, runs very badly for 2-3 seconds then makes grinding noises and won,t run at all, then several tries later it seems to want to fire up, again but won,t and repeats the cycle, I pull the distributor cap and notice very irregular rotation traced to a cam timing gear with most of the teeth worn off.

example

a few years later I get a similar call and the car has similar symptoms, I figure hes destroyed another timing set,but this time hes snapped a cam in two

example

a buddy changed spark plugs, and ignition wires on a 440 road runner, the car developed a ignition miss, careful checking shower he had somehow left one plug wire not plugged onto a spark plug but wedged in next to the plug

example

I helped a guy install a cam years ago, I get out the cam degree kit with the degree wheel and dial indicator and he says don,t bother, its a daily driver, just use the dot-to-dot indicator marks, so hey its his car......bad mistake! car runs like crap and its eventually found to be a cheap imported timing set in a blister pack, he picked up for $19 at some auto parts bargain bin,thats full 11 degrees out from the true cam location , if the index marks are used to locate the cam timing

I could post many dozens of these, examples,

but what problems have you found in the way of issues that took you some time to locate the cause and correct it because the cause was not instantly obvious

a good experienced tuner , and someone whose good at isolating and diagnosing problems, someone familiar with reading plugs,and using diagnosing cylinder pressure, heat levels and timing advance curves and fuel air ratios can make a huge difference in the results you see.....theres hours of reading in the links but for those willing to learn its time well spent

http://forum.grumpysperformance.com...=5615&p=17136&hilit=just+running+right#p17136

http://forum.grumpysperformance.com/viewtopic.php?f=50&t=5726&p=17448&hilit=leak+down#p17448

http://forum.grumpysperformance.com/viewtopic.php?f=87&t=332&p=14272&hilit=leak+down#p14272

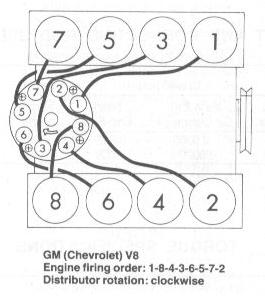

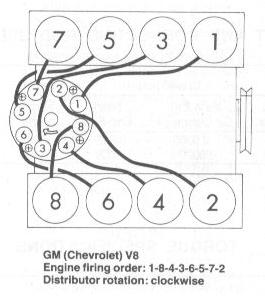

Id also label BOTH ends of each ignition wire, any decent label maker can produce sticky number tags far cheaper that the kits but even the kits are cheap

viewtopic.php?f=50&t=6098&p=18837&hilit=label#p18837

3M sells these really handy number tape tags

http://www.clarcorpindustrialsales.com/ ... -p/wmd.htm

at about $30- $45 for a fully loaded dispenser it seems expensive but its really a bargain

RELATED INFO

related links and sub links you can use to locate the source of your problem

viewtopic.php?f=87&t=3234&p=16012&hilit=fighting+correct#p16012

viewtopic.php?f=55&t=1639

viewtopic.php?f=55&t=109

viewtopic.php?f=55&t=635

viewtopic.php?f=55&t=1790

viewtopic.php?f=70&t=1015

viewtopic.php?f=70&t=202

viewtopic.php?f=70&t=4683

viewtopic.php?f=70&t=840

viewtopic.php?f=55&t=5229

viewtopic.php?f=87&t=3234

viewtopic.php?f=50&t=609

viewtopic.php?f=52&t=966

viewtopic.php?f=52&t=90

viewtopic.php?f=52&t=196

viewtopic.php?f=70&t=5428&p=16174&hilit=leak+down#p16174

viewtopic.php?f=87&t=332&p=14269&hilit=leak+down#p14269

viewtopic.php?f=52&t=181

viewtopic.php?f=70&t=1015

viewtopic.php?f=70&t=4683

viewtopic.php?f=70&t=2798

viewtopic.php?f=50&t=248&p=295&hilit=just+running#p295

viewtopic.php?f=87&t=3183&p=8477&hilit=+just+list+running+right#p8477

viewtopic.php?f=36&t=768&p=2762&hilit=+just+list+running+right#p2762

viewtopic.php?f=50&t=3110&p=16799&hilit=multi+meter#p16799

viewtopic.php?f=44&t=5615&p=17136#p17136

viewtopic.php?f=44&t=773

viewtopic.php?f=32&t=596

viewtopic.php?f=32&t=168

viewtopic.php?f=32&t=1773

viewtopic.php?f=70&t=202

viewtopic.php?f=55&t=211

viewtopic.php?f=70&t=2798

when things don,t operate smoothly theres usually a reason and the first question I usually ask is what did you change lately,ID also look at the motor mount bolts and bell housing bolts as those can also cause noise at low rpms that goes away as rpms increase if the answers nothing then you do a compression check, use a timing light and multimeter , fuel pressure gauge and vacuum gauge to isolate the source of your problem, and don,t overlook the simple things, if the coils not getting any voltage, or theres no fuel pressure check grounds and fuses before attempting major engine surgery, read the spark plugs they provide you with a ton of info, look at the oil filter after you cut it open, check the oil pressure, and check the sensors and electrical connections

example

when I was about 19 years old I purchased a Mallory dual point distributor for a Pontiac, I installed it and the car ran no better than it did with the factory ignition,in fact it was worse at higher rpms, I took it to an older mechanic at the Pontiac, dealership I was working part time at at that time and he brought out a dwell meter and set the points, up until that time I had no idea what a dwell meter was or how to use one, id always set points with a feeler gauge, I should have realized something was wrong when the ignition would not allow the engine to run at over 5600rpm,but I had assumed the Mallory ignition was perfect right out of the box when I installed it, and set the timing. its the AMP load that heats and burns points, getting 20-25 k miles is very common before you notice any need to clean and reset points in my experience, but you need a dwell meter and a points file, if your going old school ignition.

example

one of my friends calls and says the car just "THREW A CONNECTING ROD" could I help him get the engine repaired, I got over there and it sure didn,t sound good but it also didn,t sound like a connecting rod knock, careful inspection showed the flex-plate bolts had worked loose and sheared off,, obviously not good but better than a thrown rod.

example

I once had a guys with a 1968 big block corvette that had installed a dual point distributor that had a rather annoying hiigh rpm ignition miss that was eventually traced to a severely worn cam on the distributor shaft that opened and closed the ignition points, if you were not aware of what the cam in the distributor was supposed to look like it appeared rather normal, it just had very small lift to open the points due to excess wear.

example

I get a call from a friend asking if I want to buy his old (BLOWN_UP 375hp 396 engine) dirt cheap, as hes just installed a new 454 crate engine

I get it for $200 which I figured I could break even on if just the heads or block was salvageable, close inspection shows theres nothing wrong with the (TOTALLY BLOWN ENGINE) except for three rocker arm balls heat welded to rockers due to lack of oil and three busted push rods

I replaced all the lifters,rockers, cam timing set, bearings and push rods and drove that engine for over a year with zero problems.

the orriginal owner had never even pulled a valve cover, the engine made a few bad sounds and stopped running so he relaced it without ever bothering to find out what had happened internally.

example

buddy calls and wants my help tuning his new dual quad equipped engine which he can,t get fired with a new cam installed, obviously I,m thinking hes screwed up the cam install or got the ignition timing all wrong, careful inspection shows hes got every last lifter adjusted way to tight, simply backing off each rocker nut several full turns gets it to fire up, then we adjust the valves and every things fine!

example

a neighbor calls up asked me to look at why his car runs like crap, starts, runs very badly for 2-3 seconds then makes grinding noises and won,t run at all, then several tries later it seems to want to fire up, again but won,t and repeats the cycle, I pull the distributor cap and notice very irregular rotation traced to a cam timing gear with most of the teeth worn off.

example

a few years later I get a similar call and the car has similar symptoms, I figure hes destroyed another timing set,but this time hes snapped a cam in two

example

a buddy changed spark plugs, and ignition wires on a 440 road runner, the car developed a ignition miss, careful checking shower he had somehow left one plug wire not plugged onto a spark plug but wedged in next to the plug

example

I helped a guy install a cam years ago, I get out the cam degree kit with the degree wheel and dial indicator and he says don,t bother, its a daily driver, just use the dot-to-dot indicator marks, so hey its his car......bad mistake! car runs like crap and its eventually found to be a cheap imported timing set in a blister pack, he picked up for $19 at some auto parts bargain bin,thats full 11 degrees out from the true cam location , if the index marks are used to locate the cam timing

I could post many dozens of these, examples,

but what problems have you found in the way of issues that took you some time to locate the cause and correct it because the cause was not instantly obvious

a good experienced tuner , and someone whose good at isolating and diagnosing problems, someone familiar with reading plugs,and using diagnosing cylinder pressure, heat levels and timing advance curves and fuel air ratios can make a huge difference in the results you see.....theres hours of reading in the links but for those willing to learn its time well spent

http://forum.grumpysperformance.com...=5615&p=17136&hilit=just+running+right#p17136

http://forum.grumpysperformance.com/viewtopic.php?f=50&t=5726&p=17448&hilit=leak+down#p17448

http://forum.grumpysperformance.com/viewtopic.php?f=87&t=332&p=14272&hilit=leak+down#p14272

Id also label BOTH ends of each ignition wire, any decent label maker can produce sticky number tags far cheaper that the kits but even the kits are cheap

viewtopic.php?f=50&t=6098&p=18837&hilit=label#p18837

3M sells these really handy number tape tags

http://www.clarcorpindustrialsales.com/ ... -p/wmd.htm

at about $30- $45 for a fully loaded dispenser it seems expensive but its really a bargain

RELATED INFO

related links and sub links you can use to locate the source of your problem

viewtopic.php?f=87&t=3234&p=16012&hilit=fighting+correct#p16012

viewtopic.php?f=55&t=1639

viewtopic.php?f=55&t=109

viewtopic.php?f=55&t=635

viewtopic.php?f=55&t=1790

viewtopic.php?f=70&t=1015

viewtopic.php?f=70&t=202

viewtopic.php?f=70&t=4683

viewtopic.php?f=70&t=840

viewtopic.php?f=55&t=5229

viewtopic.php?f=87&t=3234

viewtopic.php?f=50&t=609

viewtopic.php?f=52&t=966

viewtopic.php?f=52&t=90

viewtopic.php?f=52&t=196

viewtopic.php?f=70&t=5428&p=16174&hilit=leak+down#p16174

viewtopic.php?f=87&t=332&p=14269&hilit=leak+down#p14269

viewtopic.php?f=52&t=181

viewtopic.php?f=70&t=1015

viewtopic.php?f=70&t=4683

viewtopic.php?f=70&t=2798

viewtopic.php?f=50&t=248&p=295&hilit=just+running#p295

viewtopic.php?f=87&t=3183&p=8477&hilit=+just+list+running+right#p8477

viewtopic.php?f=36&t=768&p=2762&hilit=+just+list+running+right#p2762

viewtopic.php?f=50&t=3110&p=16799&hilit=multi+meter#p16799

viewtopic.php?f=44&t=5615&p=17136#p17136

viewtopic.php?f=44&t=773

viewtopic.php?f=32&t=596

viewtopic.php?f=32&t=168

viewtopic.php?f=32&t=1773

viewtopic.php?f=70&t=202

viewtopic.php?f=55&t=211

viewtopic.php?f=70&t=2798