If the belts correctly installed and correctly adjusted ,it should be reasonably difficult to exceed 1/2" deflection over the fan belts unsupported length,PROVIDED the belt tensioned pulley is adjusted correctly (usually the alternator, on v-belts) and if you've got a belt tensioned (serpentine belts)is working correctly, but some FAN BELT DRESSING should add a bit of traction surface and cure the problem, its sprayed onto the belt at idle speeds so it covers both the belt and pulley surfaces,

approaching the problem logically with an isolate and test mentality would be the fastest way to cure the issue.

Id suggest he pull the belt and spin the accessories by hand to feel for bad bearings and listen for roughness, binding or squeaks, etc. in the search for the cause of that squealing on start-up,once youve eliminated the obvious accessory bearings, and replaced any accessory or idler you found defective or worn, Id certainly check for power steering pump leaks , loose or mis-aligned pulleys, and check the air conditioning compressor and alternator along with the water pump and idler pulley bearing,a worn serpentine belt is easily checked with a good spray down with belt traction spray,

and / or replacing the belt ( especially if it shows any sign of wear or cracks)and check for loose vacuum hoses or belt mis-alignment while your at the check and isolate process

http://www.supercheapauto.com.au/Product/CRC-Belt-Grip-400g/1444

so be careful not to get grabbed by the fan belt of get belt dressing thrown onto your shirt,etc. and NEVER EVER WEAR LOOSE CLOTHES OR A TIE while adjusting a running engine

http://www.moroso.com/catalog/categoryd ... code=29008

http://www.summitracing.com/parts/FLX-14528/

http://www.streetsideauto.com/p/moroso- ... ign=Nextag

http://garage.grumpysperformance.co...ng-serpentine-hoses-and-belts.3060/#post-8085

you can move the top pulley outward with shims that MOROSO SELLS

http://www.royalsupply.com/downloads/Gates/Belt_ID_Chart_bkmrks.pdf

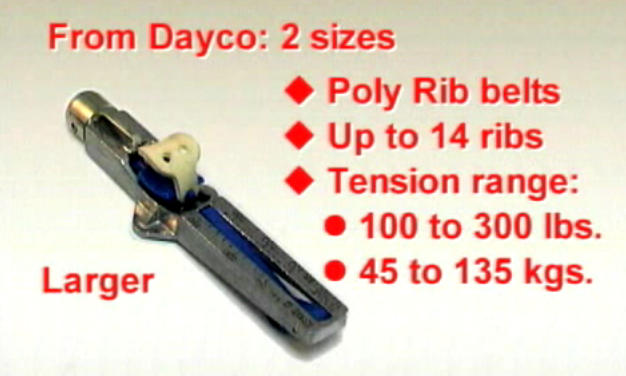

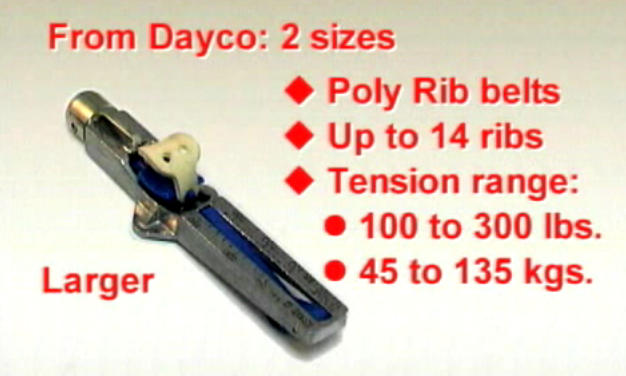

http://www.daycoproducts.com/dayco®-belt-tension-gauges

WATCH VIDEO

http://www.summitracing.com/parts/dac-93865

V_BELTS

SERPENTINE BELTS

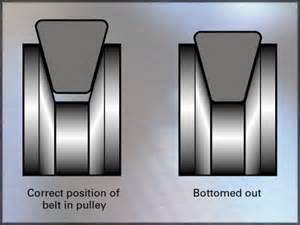

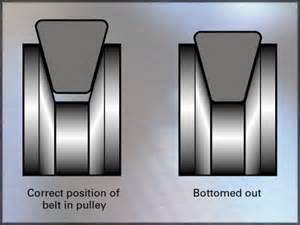

youll need to verify PROPER pulley and BELT alignment

http://www.waybuilder.net/sweethaven/Me ... &modNum=12

http://autorepair.about.com/od/quicktip ... essing.htm

swapping to a tooth belt is an option

http://www.stefs.com/products/gilmerbeltcharts.htm

these guys sell cog belt drives

http://www.millerspeed.com/

belts slip when resistance, required to spin accessories is greater than than the surface friction on the drive belt surface to the crank pulley surface, keep in mind reduced diameter crank pulleys have less surface area and a defective water pump,power steering pump, air conditioning compressor or alternator will substantially increase drag loads on the belt,

if your fan-belt squeaks CHECK ALL THE ACCESSORY BEARINGS AND FAN TENSION

some of my least favorite myths

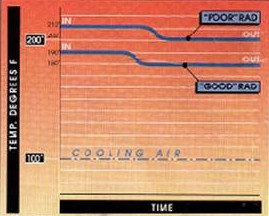

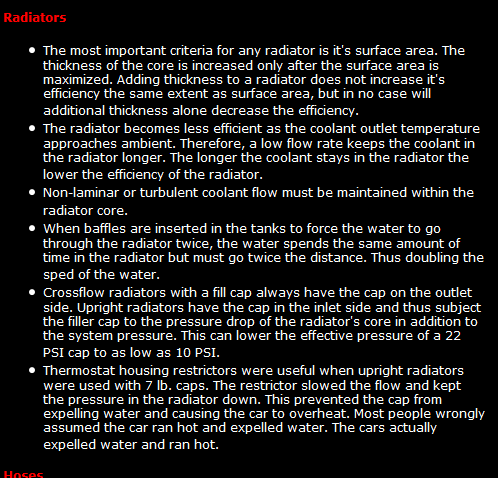

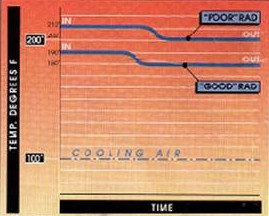

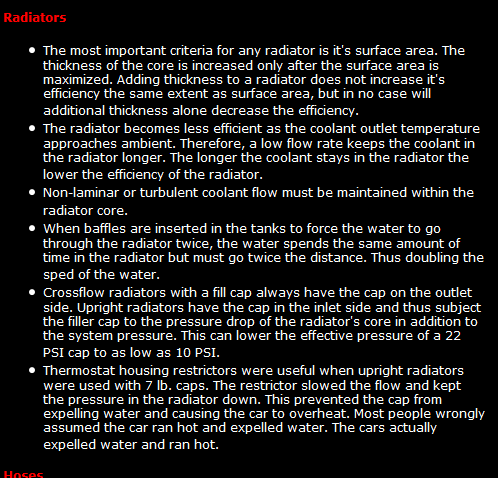

(1) you need to slow the coolant flow thru the radiator to allow time to cool the fluid moving thru it

(2) swapping from a 190F to a 160F T-stat will significantly reduce an engines tendency to over heat.

(3) removing the t-stat will cure over heating

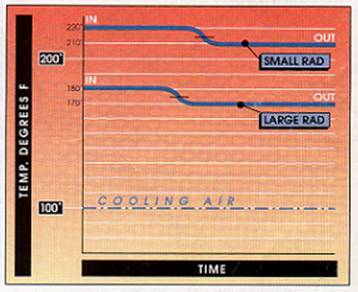

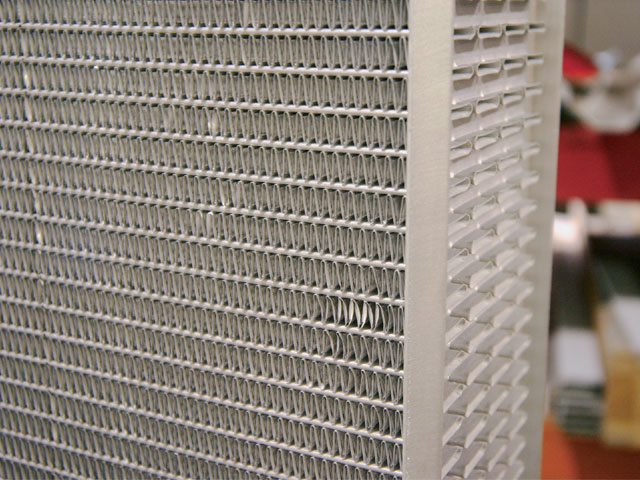

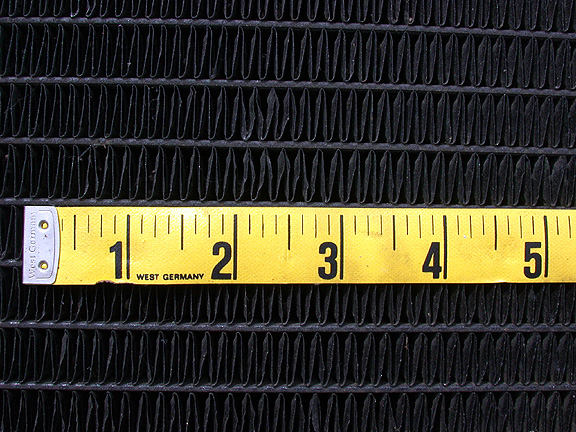

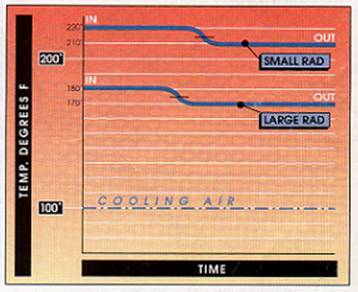

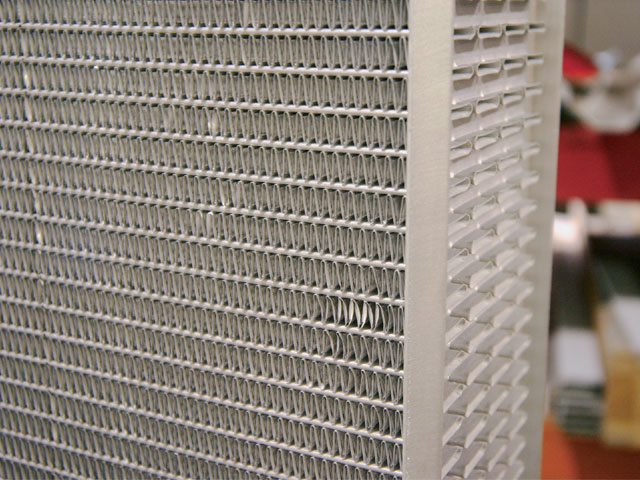

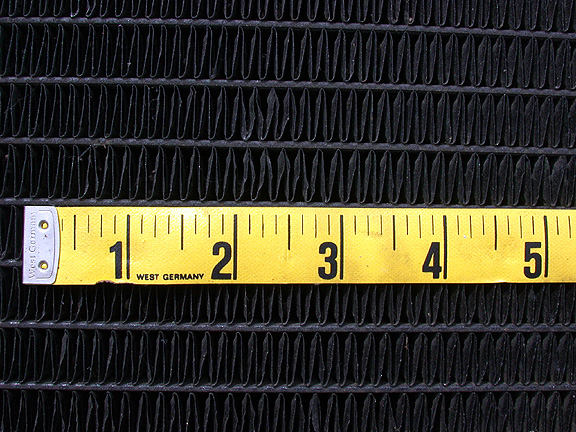

one fact often over looked is that radiator designs vary wildly, and the number of fins per inch of surface area and width of radiator coolant flow tubes can significantly increase or decrease thermal heat transfer efficiency., fin counts vary from 8 to 22 fins per inch on various radiator designs Ive seen.

thus a radiator might measure say 18" tall by 24" wide but depending on design, and fin and tube count, might actually have a radically more or less efficient heat transfer rate.obviously the best and surest way to find out if a radiator, shroud and fan combo cools the engine effectively will be to install and run the component parts you have under the current applications limitations for real world testing and if it needs upgrading your dealing in proven facts vs guessing

ID also point out that all radiators collect crud and become restrictive to flow and much less effective at transferring heat to outside air flow over time, especially if the wrong coolant or water containing excessive mineral content are used so you might want to have yours cleaned out, rebuilt or replaced, if thats needed, after taking it out, an inspection indicates the correct course, a new aluminum radiator, in the largest size quality, radiator, that fits you can afford, is usually a good idea, if it needs replacing

\

\

http://garage.grumpysperformance.com/index.php?threads/thoughts-on-cooling.149/

http://garage.grumpysperformance.com/index.php?threads/cylinder-cooling-and-tuning-consistency.4701/

http://garage.grumpysperformance.com/index.php?threads/how-the-cooling-system-works-basics.853/

http://garage.grumpysperformance.co...ing-system-flow-rates-and-heat-transfer.9880/

if the radiator or heater hose swells noticeably and feels spongy , or if the hose has obvious surface flaking or cracks the hose is deteriorated internally to the point mandatory replacement is required or your looking at it failing withing a few months, or just weeks time in most cases.

if a serpentine belt starts to show cracks in its ribs, or frayed edges, you also check the pulley alignment and condition of the pulley surfaces, as rust or mis-alignment will cause wear issues.

heat and age and in a few cases use of the wrong coolant , or exhaust leaks in head gaskets or getting misted with petroleum products from an oil, power steering or transmission fluid leak will deteriorate the hose , or belt rubber.

if its the result of oil age and heat you replace it and if its the result of a fluid leak you cure the leak source first and replace it and, you can assume all belts and hoses need to be replaced by the time they are about 5-6 years old or by about 90k-100k miles which ever comes first, as a normal maintenance replacement item if your not looking to get stranded

yes IM fully aware theres thousands of cars running original belts and hoses at 140k miles, many are pushing their luck, if not inspected frequently.

http://www.aa1car.com/library/belthose.htm

hose clamps also tend to rust or loose tension over time causing them to fail so use of new clamps when installing a hose is good maintenance, procedure

approaching the problem logically with an isolate and test mentality would be the fastest way to cure the issue.

Id suggest he pull the belt and spin the accessories by hand to feel for bad bearings and listen for roughness, binding or squeaks, etc. in the search for the cause of that squealing on start-up,once youve eliminated the obvious accessory bearings, and replaced any accessory or idler you found defective or worn, Id certainly check for power steering pump leaks , loose or mis-aligned pulleys, and check the air conditioning compressor and alternator along with the water pump and idler pulley bearing,a worn serpentine belt is easily checked with a good spray down with belt traction spray,

and / or replacing the belt ( especially if it shows any sign of wear or cracks)and check for loose vacuum hoses or belt mis-alignment while your at the check and isolate process

http://www.supercheapauto.com.au/Product/CRC-Belt-Grip-400g/1444

so be careful not to get grabbed by the fan belt of get belt dressing thrown onto your shirt,etc. and NEVER EVER WEAR LOOSE CLOTHES OR A TIE while adjusting a running engine

http://www.moroso.com/catalog/categoryd ... code=29008

http://www.summitracing.com/parts/FLX-14528/

http://www.streetsideauto.com/p/moroso- ... ign=Nextag

http://garage.grumpysperformance.co...ng-serpentine-hoses-and-belts.3060/#post-8085

you can move the top pulley outward with shims that MOROSO SELLS

http://www.royalsupply.com/downloads/Gates/Belt_ID_Chart_bkmrks.pdf

http://www.daycoproducts.com/dayco®-belt-tension-gauges

WATCH VIDEO

http://www.summitracing.com/parts/dac-93865

V_BELTS

SERPENTINE BELTS

youll need to verify PROPER pulley and BELT alignment

http://www.waybuilder.net/sweethaven/Me ... &modNum=12

http://autorepair.about.com/od/quicktip ... essing.htm

swapping to a tooth belt is an option

http://www.stefs.com/products/gilmerbeltcharts.htm

these guys sell cog belt drives

http://www.millerspeed.com/

belts slip when resistance, required to spin accessories is greater than than the surface friction on the drive belt surface to the crank pulley surface, keep in mind reduced diameter crank pulleys have less surface area and a defective water pump,power steering pump, air conditioning compressor or alternator will substantially increase drag loads on the belt,

if your fan-belt squeaks CHECK ALL THE ACCESSORY BEARINGS AND FAN TENSION

some of my least favorite myths

(1) you need to slow the coolant flow thru the radiator to allow time to cool the fluid moving thru it

(2) swapping from a 190F to a 160F T-stat will significantly reduce an engines tendency to over heat.

(3) removing the t-stat will cure over heating

one fact often over looked is that radiator designs vary wildly, and the number of fins per inch of surface area and width of radiator coolant flow tubes can significantly increase or decrease thermal heat transfer efficiency., fin counts vary from 8 to 22 fins per inch on various radiator designs Ive seen.

thus a radiator might measure say 18" tall by 24" wide but depending on design, and fin and tube count, might actually have a radically more or less efficient heat transfer rate.obviously the best and surest way to find out if a radiator, shroud and fan combo cools the engine effectively will be to install and run the component parts you have under the current applications limitations for real world testing and if it needs upgrading your dealing in proven facts vs guessing

ID also point out that all radiators collect crud and become restrictive to flow and much less effective at transferring heat to outside air flow over time, especially if the wrong coolant or water containing excessive mineral content are used so you might want to have yours cleaned out, rebuilt or replaced, if thats needed, after taking it out, an inspection indicates the correct course, a new aluminum radiator, in the largest size quality, radiator, that fits you can afford, is usually a good idea, if it needs replacing

http://garage.grumpysperformance.com/index.php?threads/thoughts-on-cooling.149/

http://garage.grumpysperformance.com/index.php?threads/cylinder-cooling-and-tuning-consistency.4701/

http://garage.grumpysperformance.com/index.php?threads/how-the-cooling-system-works-basics.853/

http://garage.grumpysperformance.co...ing-system-flow-rates-and-heat-transfer.9880/

if the radiator or heater hose swells noticeably and feels spongy , or if the hose has obvious surface flaking or cracks the hose is deteriorated internally to the point mandatory replacement is required or your looking at it failing withing a few months, or just weeks time in most cases.

if a serpentine belt starts to show cracks in its ribs, or frayed edges, you also check the pulley alignment and condition of the pulley surfaces, as rust or mis-alignment will cause wear issues.

heat and age and in a few cases use of the wrong coolant , or exhaust leaks in head gaskets or getting misted with petroleum products from an oil, power steering or transmission fluid leak will deteriorate the hose , or belt rubber.

if its the result of oil age and heat you replace it and if its the result of a fluid leak you cure the leak source first and replace it and, you can assume all belts and hoses need to be replaced by the time they are about 5-6 years old or by about 90k-100k miles which ever comes first, as a normal maintenance replacement item if your not looking to get stranded

yes IM fully aware theres thousands of cars running original belts and hoses at 140k miles, many are pushing their luck, if not inspected frequently.

http://www.aa1car.com/library/belthose.htm

hose clamps also tend to rust or loose tension over time causing them to fail so use of new clamps when installing a hose is good maintenance, procedure

Last edited by a moderator: