OBVIOUSLY If your building a custom engine you'll want to match the cam timing and compression to the intended application,IF YOUR ENGINE COMBO REQUIRES a certain compression ratio, for the cam to operate and produce the intended torque in a predetermined rpm band and your cylinder heads combustion chamber volume and design limits your compression ratio to a very limited range with a flat top piston you'll want to swap to a domed or dished piston design to change the effective compression ratio, heads can easily cost $800-$2500, and if you want to get into the really good flowing heads that are custom built and ported limited production designs a cost over $3000-$6000 a set is common, custom pistons usually cost a good deal less and many applications have good forged off the shelf designs available

http://www.carcraft.com/techarticles/ca ... index.html

http://www.csgnetwork.com/compcalc.html

viewtopic.php?f=53&t=110&p=1672&hilit=4032#p1672

http://www.circletrack.com/techarticles ... index.html

http://www.flatlanderracing.com/trwchevy350.html

viewtopic.php?f=52&t=2077

viewtopic.php?f=52&t=727

youll obviously need to know the piston dome or dish volume an CC your heads to get the combustion chamber volume, plus measure your deck height.

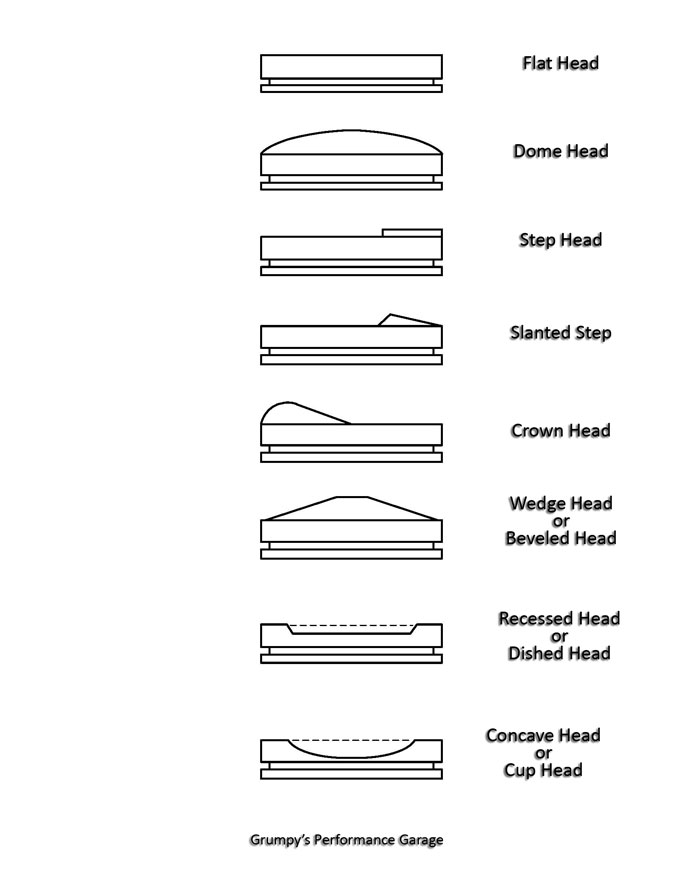

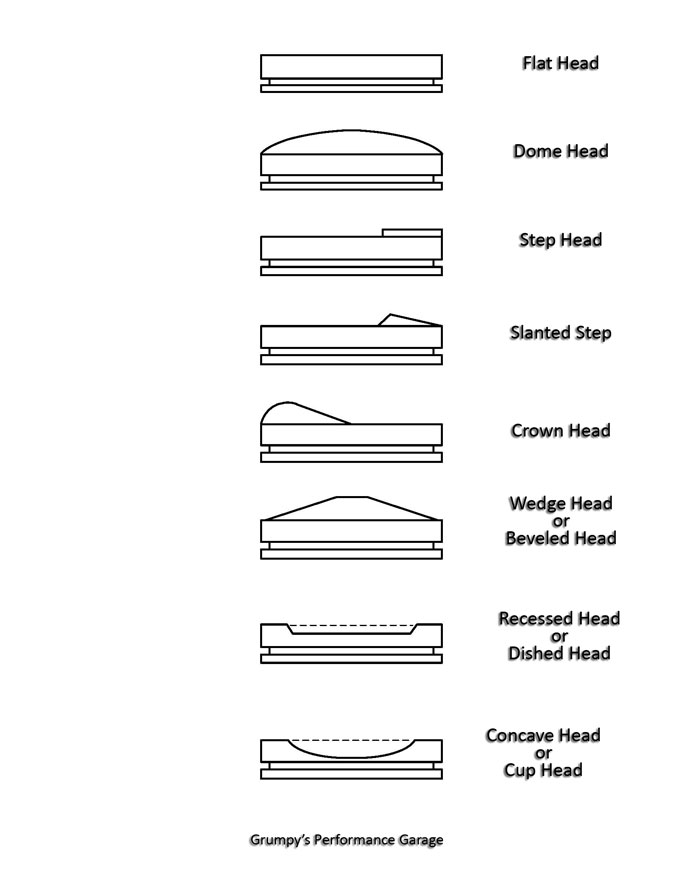

domed, used to significantly increase the effective compression ratio, by taking up a good deal of the combustion chamber volume, and tend to be a bit heavier than the other two designs

dished pistons, used to reduce or add to the effective combustion chamber volume, usually a bit heavier than the flat top designs but lighter than the domed designs

flat top pistons, generally provide the lightest piston and usually a good combustion but limit your compression

types of piston dome configurations

related info

these links, below will hold useful info

viewtopic.php?f=53&t=110&p=3631#p3631

viewtopic.php?f=53&t=1795

viewtopic.php?f=53&t=2795&p=7240#p7240

http://www.kb-silvolite.com/assets/auto ... ctions.pdf

viewtopic.php?f=53&t=2208

viewtopic.php?f=53&t=247

viewtopic.php?f=53&t=509

viewtopic.php?f=53&t=978

viewtopic.php?f=53&t=509

viewtopic.php?f=53&t=1797

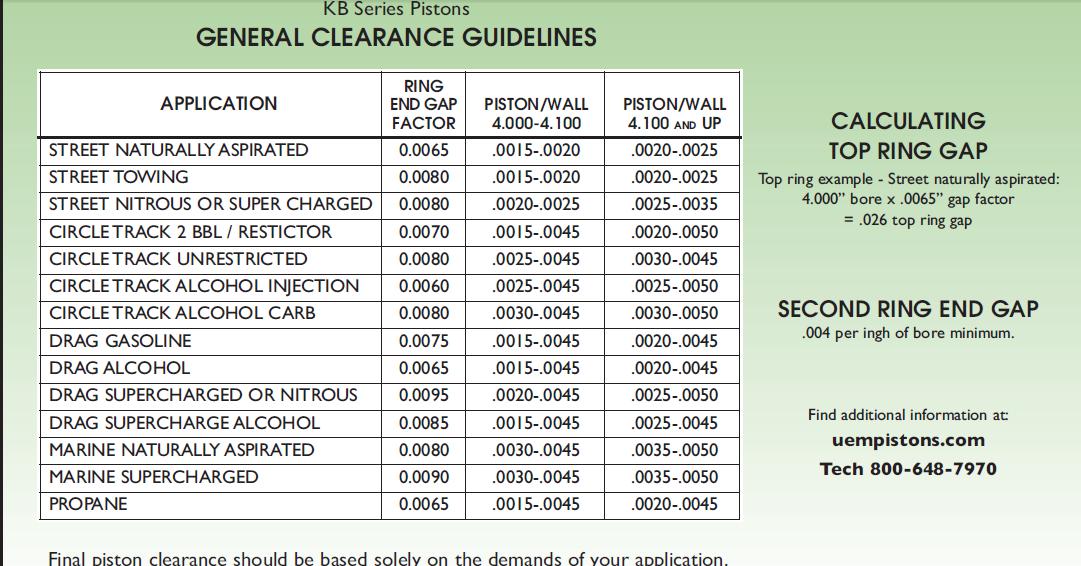

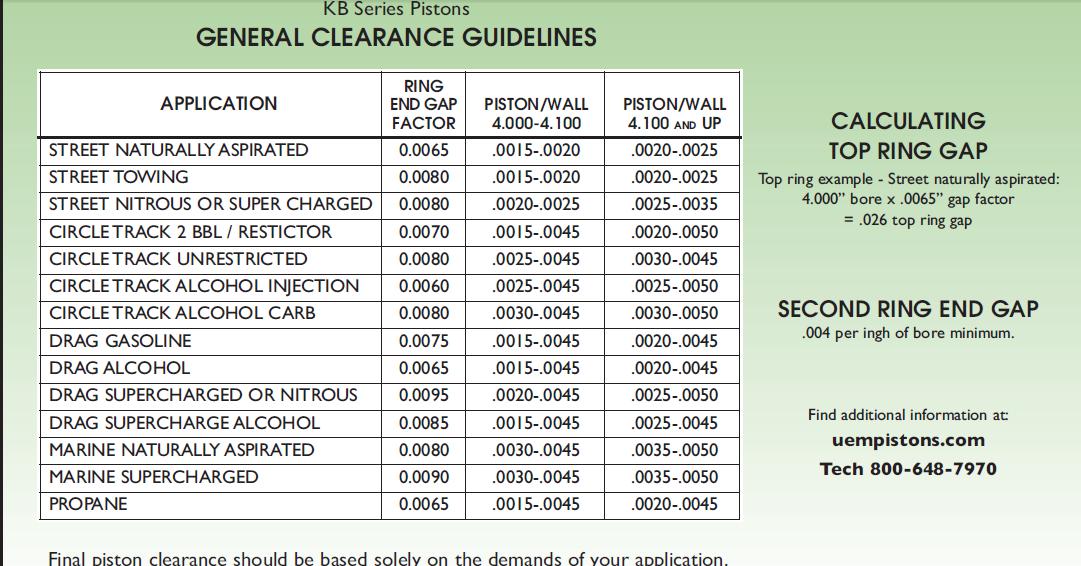

when ever you order parts like pistons that must be fitted precisely to a block,ok the first factor you need to know is the TRUE bore diam. of the block, and if its consistent between all cylinders, youll also need to know the deck height on the block, the connecting rod type, IE, is it set up for pressed or floating pin pistons and if the block ,decks parallel and square to the crank center line, you'll need to order pistons that fit the bore or in most cases you order pistons a bit larger than the current bore size and have your engine builder bore, hone and fit the pistons to your block with the correct side clearance, and order a matching ring set.

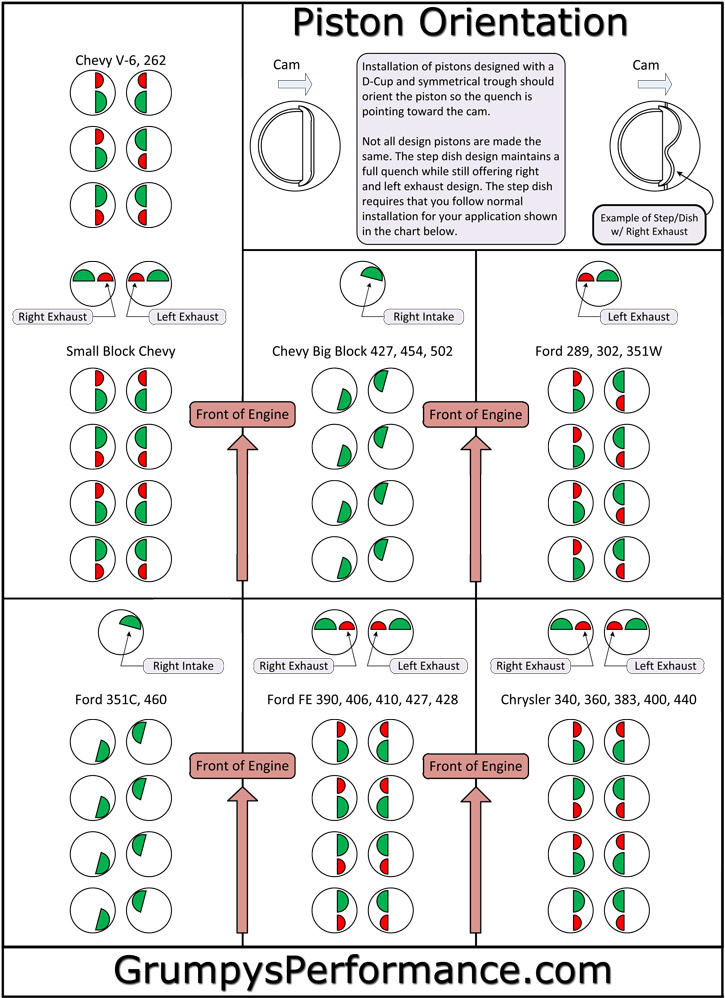

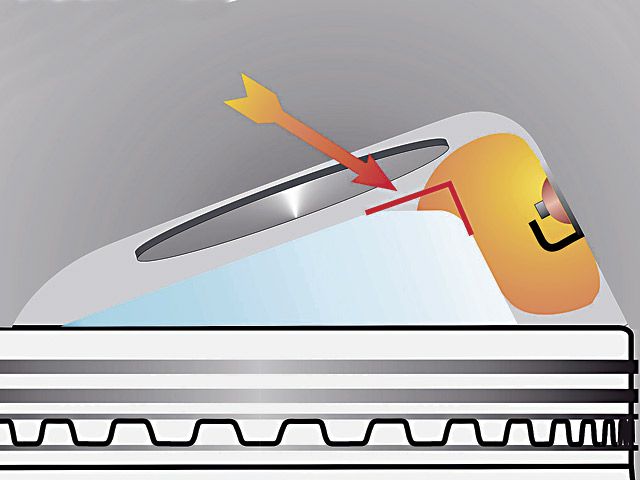

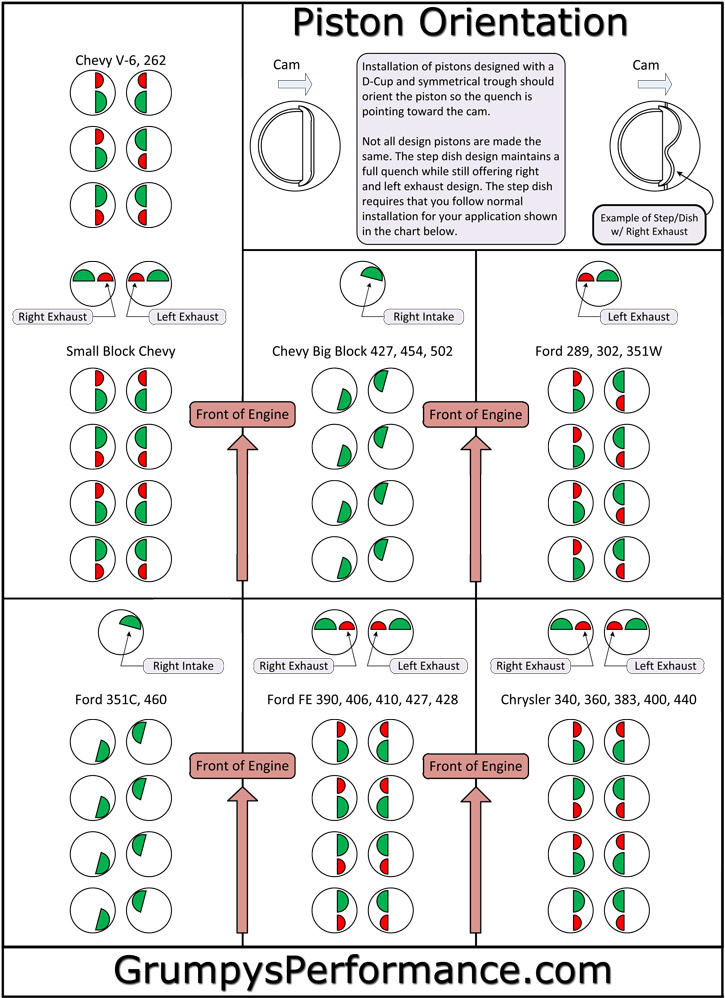

the cylinder heads combustion chamber shape , you chose to work with and location in the cylinder heads of that combustion chamber will determine BOTH the dome or dish size, the pistons require to function correctly and the valve clearance you need, along with the cam you select and the way you degree it in to the engine.

remember different piston materials expand at different rates and require different side clearance and ring gaps.(don,t forget that different rings will require a different surface Finnish on the bore surface)

as a general rule HYPER-EUTECTIC pistons will require a tighter bore clearance and more ring gap clearance than forged pistons as they tend to run hotter and expand less in the bore, but you MUST use the manufacturers suggested clearance requirements.

not all piston domes are located to clear all spark plugs, valve sizes or combustion chamber shapes, so ask both the piston and head manufacturers for info they might have on potential problems, most engine builder will know how to correct MINOR mis-matches,

but ordering the correct piston machined for the intended application, and carefully measuring components before and during assembly and NEVER taking ANYTHING FOR GRANTED goes a long way toward preventing problems.

factors like the piston pin length and diam. and the piston pin bore thru the piston, the method of locking the piston to the rod and the heat and rpm band your likely to run those pistons under will require some careful thought if you expect the engine to live a long life, surface finish, heat barrier coatings will also effect the choices.

AS LOTS of QUESTIONS before ordering and carefully check clearances during the assembly process.

Youll also want to keep in mind that swapping too new pistons will generally require re-balancing the rotating assembly

http://www.carcraft.com/techarticles/ca ... index.html

http://www.csgnetwork.com/compcalc.html

viewtopic.php?f=53&t=110&p=1672&hilit=4032#p1672

http://www.circletrack.com/techarticles ... index.html

http://www.flatlanderracing.com/trwchevy350.html

viewtopic.php?f=52&t=2077

viewtopic.php?f=52&t=727

youll obviously need to know the piston dome or dish volume an CC your heads to get the combustion chamber volume, plus measure your deck height.

domed, used to significantly increase the effective compression ratio, by taking up a good deal of the combustion chamber volume, and tend to be a bit heavier than the other two designs

dished pistons, used to reduce or add to the effective combustion chamber volume, usually a bit heavier than the flat top designs but lighter than the domed designs

flat top pistons, generally provide the lightest piston and usually a good combustion but limit your compression

types of piston dome configurations

related info

these links, below will hold useful info

viewtopic.php?f=53&t=110&p=3631#p3631

viewtopic.php?f=53&t=1795

viewtopic.php?f=53&t=2795&p=7240#p7240

http://www.kb-silvolite.com/assets/auto ... ctions.pdf

viewtopic.php?f=53&t=2208

viewtopic.php?f=53&t=247

viewtopic.php?f=53&t=509

viewtopic.php?f=53&t=978

viewtopic.php?f=53&t=509

viewtopic.php?f=53&t=1797

when ever you order parts like pistons that must be fitted precisely to a block,ok the first factor you need to know is the TRUE bore diam. of the block, and if its consistent between all cylinders, youll also need to know the deck height on the block, the connecting rod type, IE, is it set up for pressed or floating pin pistons and if the block ,decks parallel and square to the crank center line, you'll need to order pistons that fit the bore or in most cases you order pistons a bit larger than the current bore size and have your engine builder bore, hone and fit the pistons to your block with the correct side clearance, and order a matching ring set.

the cylinder heads combustion chamber shape , you chose to work with and location in the cylinder heads of that combustion chamber will determine BOTH the dome or dish size, the pistons require to function correctly and the valve clearance you need, along with the cam you select and the way you degree it in to the engine.

remember different piston materials expand at different rates and require different side clearance and ring gaps.(don,t forget that different rings will require a different surface Finnish on the bore surface)

as a general rule HYPER-EUTECTIC pistons will require a tighter bore clearance and more ring gap clearance than forged pistons as they tend to run hotter and expand less in the bore, but you MUST use the manufacturers suggested clearance requirements.

not all piston domes are located to clear all spark plugs, valve sizes or combustion chamber shapes, so ask both the piston and head manufacturers for info they might have on potential problems, most engine builder will know how to correct MINOR mis-matches,

but ordering the correct piston machined for the intended application, and carefully measuring components before and during assembly and NEVER taking ANYTHING FOR GRANTED goes a long way toward preventing problems.

factors like the piston pin length and diam. and the piston pin bore thru the piston, the method of locking the piston to the rod and the heat and rpm band your likely to run those pistons under will require some careful thought if you expect the engine to live a long life, surface finish, heat barrier coatings will also effect the choices.

AS LOTS of QUESTIONS before ordering and carefully check clearances during the assembly process.

Youll also want to keep in mind that swapping too new pistons will generally require re-balancing the rotating assembly