I took the valve covers off, Found that lifter "noise" and noticed the silver stain on the head around one of the rockers:

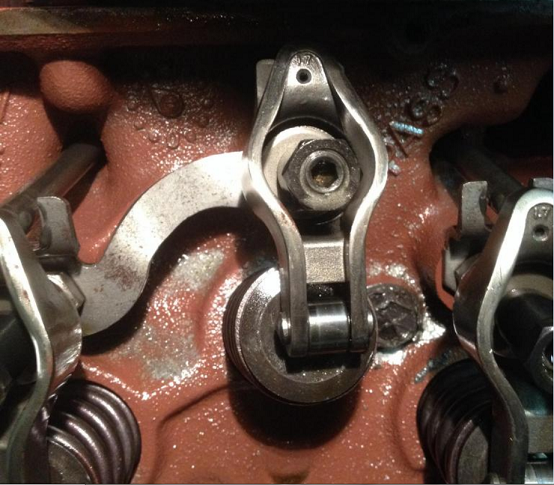

Took it apart and saw this:

Ground pushrod. What caused this? Did I have it too tight? Maybe the lifter is not pumping oil properly ? There was oil in the cup and rocker nut. Do you think the lifter is ok? The metal paste is limited to the head as best I can tell.

Thanks for any input.

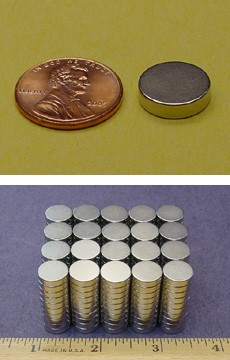

YES it looks like the valve adjustment was too tight or the lifters defective or the push rod was clogged,so make sure the new replacement parts pump oil thru the rocker weep holes on ALL the rockers, before the valve covers re-installed. adding a couple high heat tolerance magnets to the engine helps trap, the metallic debris,the finer stuff gets easily washed into the sump with the oil flow, any parts failure like that generates BEFORE the abrasive grit gets sucked thru the oil pump and be aware the oil filter won,t always prevent 100% of the grit reaching the bearings.

IVE typically used several of these magnets in any engine,Ive built, one in the rear oil drain on each cylinder head, one near each lifter gallery drain and 4 in the oil pan sump

http://www.kjmagnetics.com/proddetail.asp?prod=D82SH

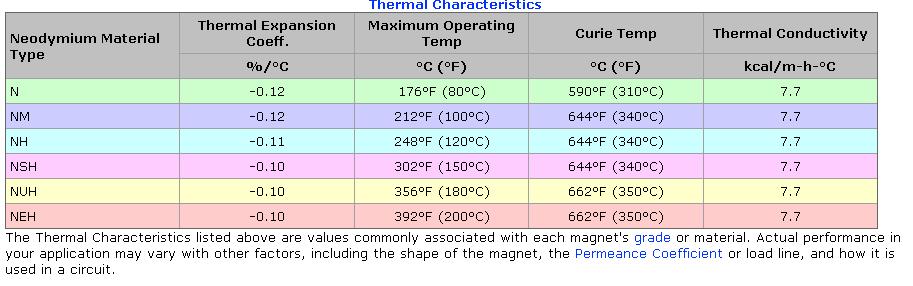

BE AWARE magnets heat tolerance differs so ask for and pay attention to the heat limitations, a MINIMUM of 300F for any magnet expected to be used bathed in hot engine oil would be smart

viewtopic.php?f=51&t=1458&p=22845&hilit=magnets+screens#p22845

viewtopic.php?f=54&t=2187