the first step, in isolating a problems source on these c4 corvettes is almost always to pull trouble codes, and to grab the factory shop manual, so ID be looking at those first. youll want to have a muli meter and a fuel pressure gauge and it certainly won,t hurt to have a diagnostic code reader/scanner

have you pulled trouble codes"

what is the resistance reading on the new injectors?

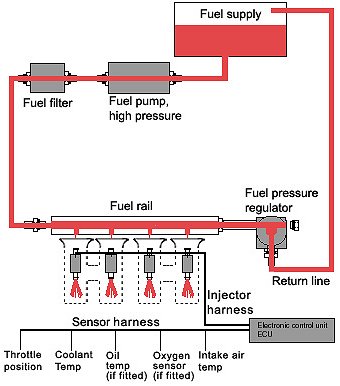

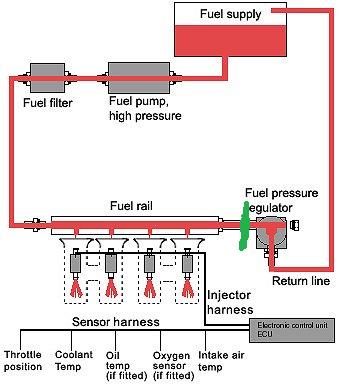

if the injectors still allow fuel flow without the electrical connectors attached ,to the injectors themselves, obviously theres either crud in the pindle seats that needs to be cleaned or the fuel pressure significantly exceeds the 40psi-44psi the stock TPI fuel rail system runs at.

Measured Value

Engine Coolant Temperature Sensor. 185 Ohms @ 210F, 3400 Ohms @ 68F, 7,500 Ohms @ 39 F.

Engine Oil Temperature Sensor. (lower sensor above oil filter) 185 Ohms @ 210 F, 3400 Ohms @ 68 F, 7,500 Ohms @39 F.

some early c4 vettes have the gauge and oil pressure switch on an adapter near the distributor base into the block

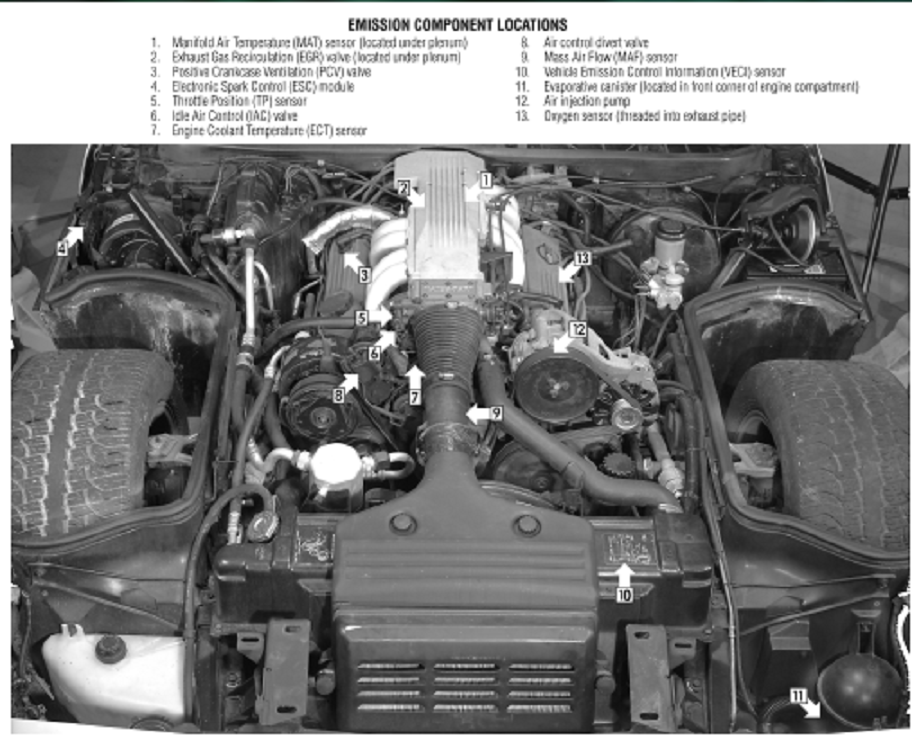

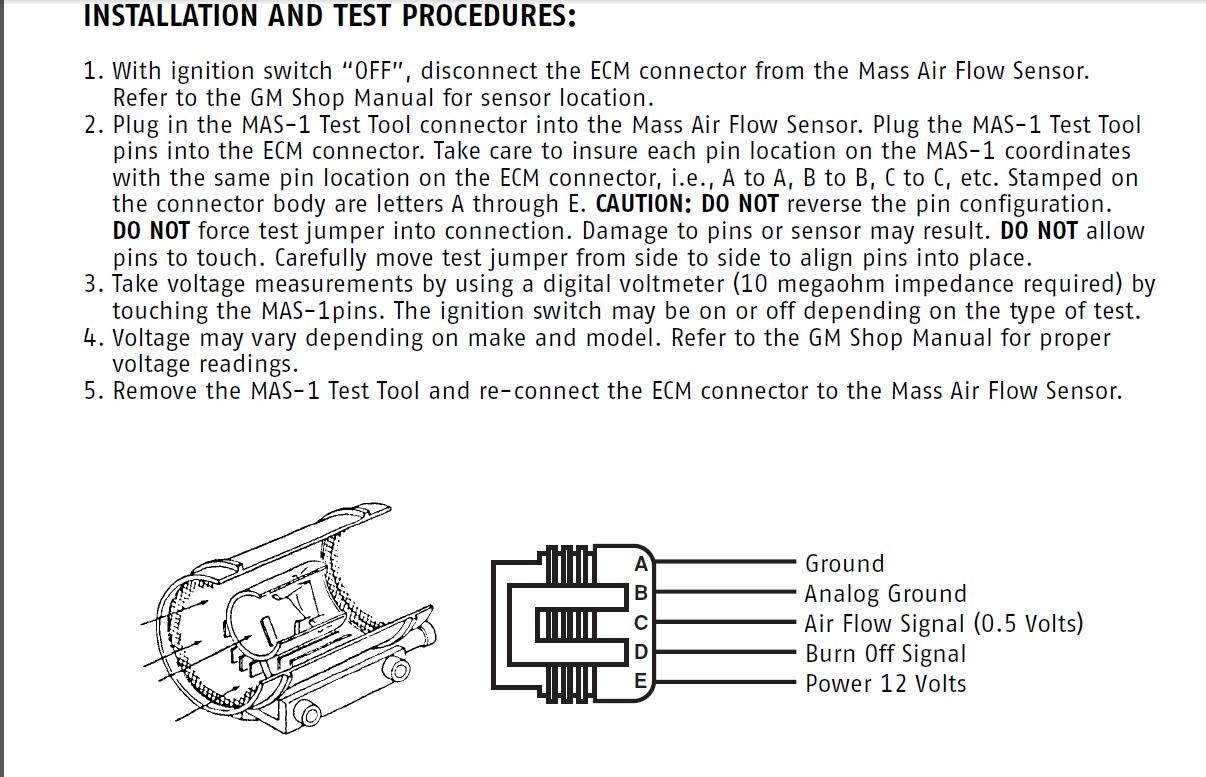

to add something to this that is often over looked regarding MAF codes, so here it is, a direct quote from my 87 FSM which is probably the same for 85,86,88,89.

Second paragraph on both code 33 and 34...interestingly not on code 36.

Code 33 page 6E3-A-42

"The oil pressure switch or the ECM, through control of the fuel pump relay, will provide 12 volts for the MAF power relay which provides the 12 volts needed by the MAF sensor".

I personally know a few guys who cured their MAF problem simply by either replacing the FP relay or repairing the wires going into the FP relay...these wires over time may have had the insulation shrink back (mine were bare 1-2 inches, and touching) not only dangerous , but can cause all types of problems.

Oil Pressure Sender/Switch. (top sensor in picture above) 1 Ohms @ 0 PSI, 43 Ohms @ 30 PSI, 86 Ohms @ 60 PSI.

Fuel Quantity Sender. 0 Ohms @ Empty, 45 Ohms @ 1/2 Full, 90 Ohms @ Full.

MAT (Manifold Absolute Temperature Sensor). 185 Ohms @ 210 F, 3400 Ohms @ 70 F,

the most likely source of your problem, that matches your stated symptoms, is a ruptured or leaking fuel pressure regulator diaphragm thats allowing fuel to flow up the vacuum hose into the plenum, as its very unlikely all 8 injectors are leaking, that would account for the fuel pressure drop and all 8 cylinders showing excess fuel contamination , if its a small leak the fuel bleeds down into the vacuum line and back into the plenum, when the cars shut down, fouling the plugs, but it may just run slightly rich once it starts as the oxygen sensors partly compensate by reducing the injector pulse duration

replacement diaphragm

stock FUEL PRESSURE REGULATOR

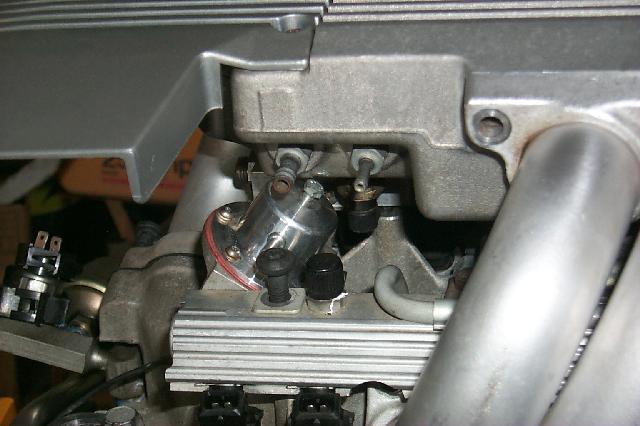

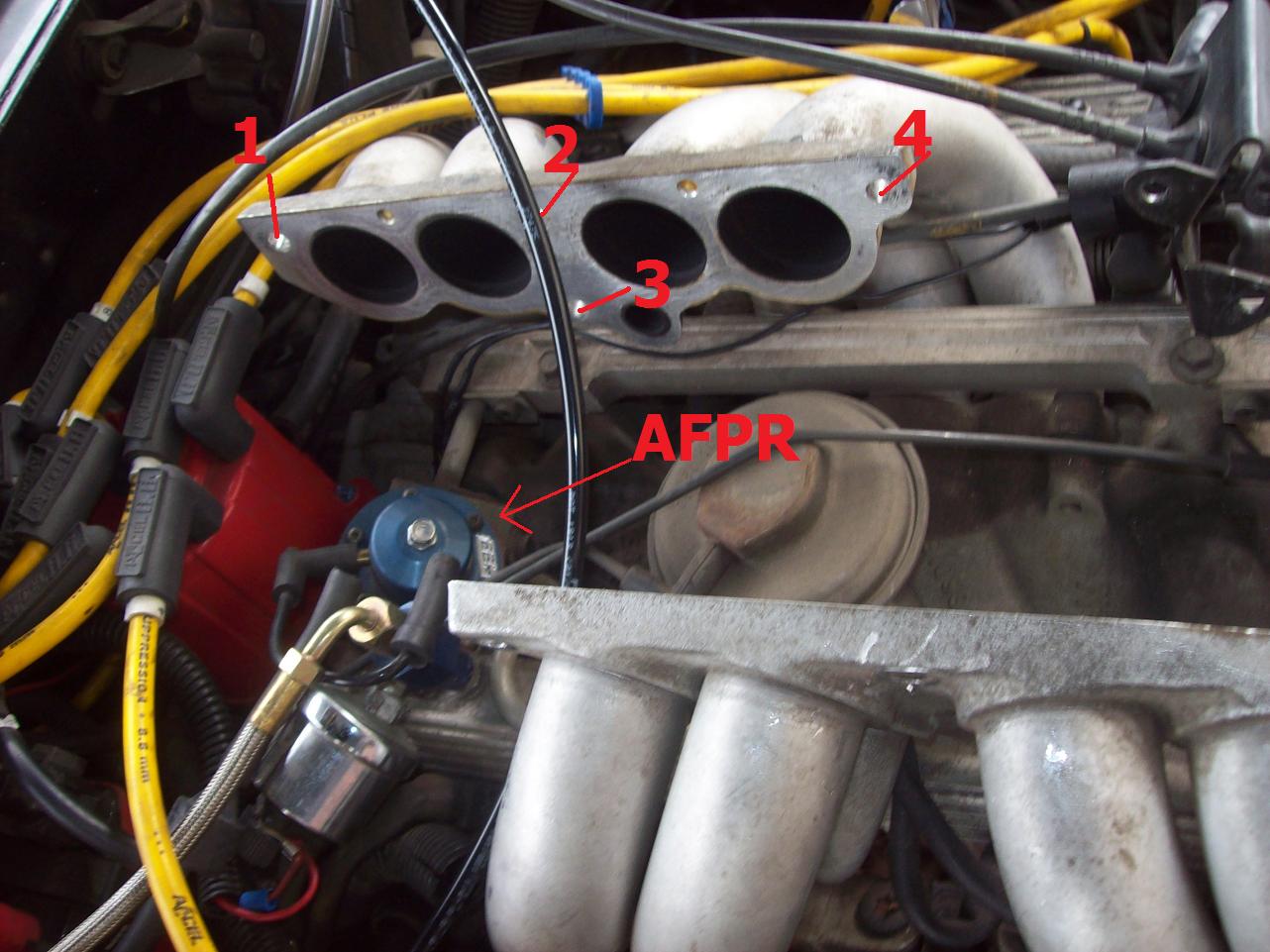

aftermarket fuel pressure regulator on tpi fuel rail pictures

if you have at lease 38 psi in the fuel rail, and it holds at or near at least 38 psi for at least a couple minutes after you stop cranking the engine, the fuel pressure regulator is most likely functioning correctly, but you state the injectors are not squirting fuel and the pump keeps running while you crank the engine?

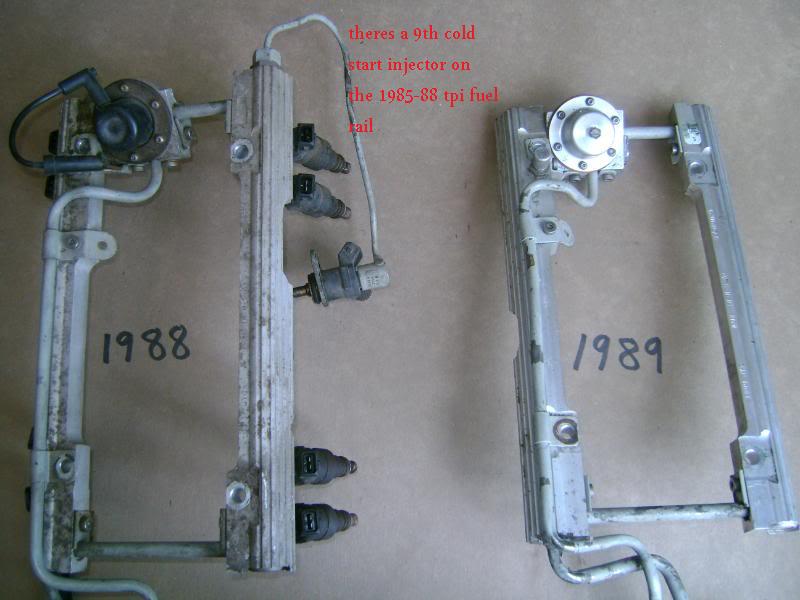

you can test the electrical connectors on the injectors with a noid test light to watch the electric pulse,at each injector location, ID verify timing injector resistance,and check for vacuum leaks while testing, and remember theres a 9th cold start injector on the 1985-88 TPI fuel rail

ADJUSTABLE AFTERMARKET FUEL PRESSURE REGULATOR

as always a simple, step bye step approach where you verify the function or failure of each related component in the system before assuming any components working correctly is the smart route to take. never assume you know some component functions or is at fault until its tested carefully, and remember to verify proper voltage, resistance OHMS and ELECTRICAL GROUNDS

MAF Problems

Faulty MAF sensors will normally light the check engine light on the drivers information center if the problem is constant and store a trouble code. If intermittent, a trouble code will still be stored as long as the battery is not disconnected.

Normally, the problem is a poor connection at the sensor and wiggling the wires, unplugging and reinserting the connector will often cure the problem.

A faulty MAF will normally cause a no start or difficult start condition and although you can eventually get the car into the "limp-home" mode in most cases, you need to attend to the problem ASAP.

AC/Delco sensors can become intermittent or give false readings if the wires become contaminated as explained above.

The MAF is a critical part of the emission control system and as such will cause the computer to react to problems very quickly, setting trouble codes and reducing performance in ways that cannot be ignored for long.

MAF Mods

The Bosch MAF is often modified by removing the two screens that are present in the front and rear of the cylinder. Removing these screens significantly increases the air flow through them and this results in more horsepower. Removing the screens is an old trick from the Corvette Challenge days in 1988 and 1989. It does work but is illegal in many states so be advised not to do anything that will get you arrested for a pollution violation.

The AC/Delco MAF is not readily modified. It is what it is but since it is a larger diameter than the Bosch, it responds well to changing the air filter to a free flowing type such as the K&N filter."

http://www.mamotorworks.com/corvette-c4 ... 6-893.html

http://content.mamotorworks.com/pdf/601096.pdf

THIS LINK WILL HELP

http://members.shaw.ca/corvette86/FuelS ... gnosis.pdf

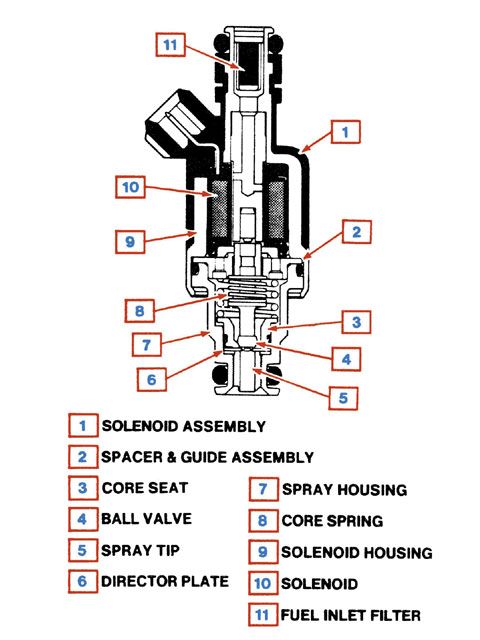

now keep in mind the, fuel pump supplies fuel flow, the fuel pressure regulator restricts fuel from leaving the fuel rails untill pressure exceeds about 42 psi, each injector is basically just an electric solenoid that controls an internal valve in the injector thats NORMALLY in a closed position, until, the electrical pulse OPENS the injector, if you removed the electrical connectors the solenoid should remain firmly shut.

(Id remove the aftermarket chip during testing as Ive seen a very high percentage of those aftermarket performance chips cause problems after a few weeks of run time as they seem overly prone to defects)

the injector is supposed to be effectively a sealed valve controlling flow of fuel until voltage is applied forcing the solenoid to open the injectors internal fuel passage, and no fuel should be able to drain thru the orifice,if it does, even though the injectors may be new ID be strongly suspecting that debris in the tank or lines has entered the injectors ,water carrying micro crud or rust into the fuel line, and into the injector is preventing its full closure, as thats the only logical way fuel can pass thru a disconnected injector receiving no electrical current.

it only takes a very small amount of rust/dust/crud in the fuel flowing thru an injector to let it leak or jam the pindle seat partly open, so don,t assume NEW injectors can swallow that sludge with impunity.

the factory fuel filters are BARELY adequate for clean fuel

the next step is to use a multi meter and verify injector resistance, it should be consistent within an OHM or two between all injectors depending on brand most c4 corvette injectors will read 12-15 OHMS resistance.

Id then check the fuses and use a NOID test kit

viewtopic.php?f=55&t=606&p=7969&hilit=noid#p7969

http://garage.grumpysperformance.com/index.php?threads/testing-1985-89-m-a-f-sensor.1475/#post-43635

to verify the injector gets an electrical pulse at the electrical connector, remember each bank is separately fused on some year c4 corvettes

Dirty or partially clogged injectors can show up in many ways and may include:

- "Check Engine" light or cylinder misfire code

- Poor idle

- Light throttle surging or bucking

- Denotation (knocking or pinging), causing possible engine damage

- Low speed hesitation and surging issues

- Emission problems

- Loss of performance

- Increased fuel consumption

Leaky injectors can cause:

- Hard starting, especially when hot

- Poor idle

- Emission problems

- Increased fuel consumption

- Exhaust odor

Theres a great deal of related info, in these links

viewtopic.php?f=32&t=1401

http://www.eficonnection.com/eficonnection/default.aspx

viewtopic.php?f=32&t=2697

viewtopic.php?f=32&t=596

viewtopic.php?f=32&t=168

viewtopic.php?f=32&t=302

viewtopic.php?f=55&t=1378

viewtopic.php?f=80&t=728&p=9217&hilit=code+reader#p9217

viewtopic.php?f=27&t=3096&p=8238&hilit=code+reader#p8238

viewtopic.php?f=55&t=7310

viewtopic.php?f=44&t=469&p=6061&hilit=code+reader#p6061

viewtopic.php?f=36&t=63&p=8435&hilit=aldl#p8435

viewtopic.php?f=32&t=6706&p=21505&hilit=noid#p21505

viewtopic.php?f=55&t=635&p=12710#p12710

viewtopic.php?f=55&t=606&p=7969&hilit=noid#p7969