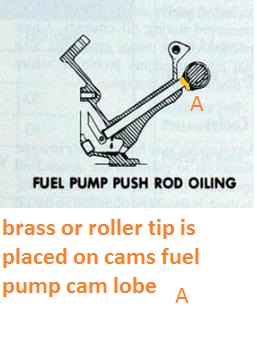

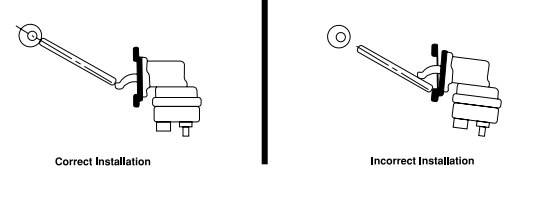

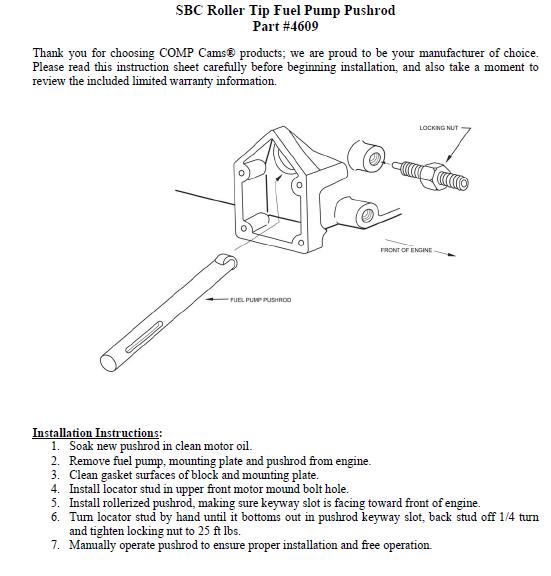

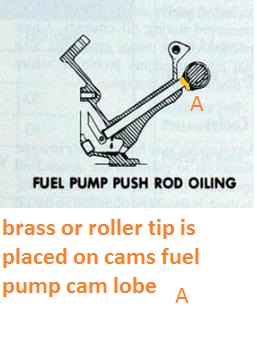

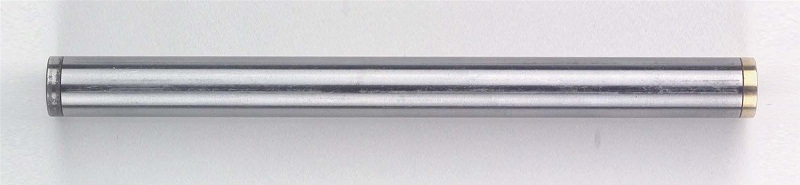

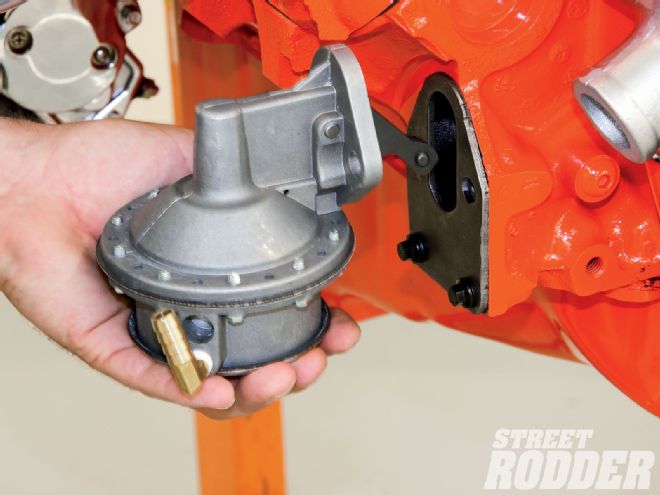

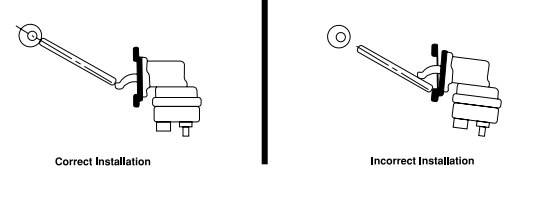

If your using a stock STYLE mechanical fuel pump the lever that works the pump with a push rod off the front cam fuel pump eccentric, you can use a light weight polymer push rod that has a lot less potential for friction and wear on both the cam eccentric and push rod lever is a low cost modification, OR if you choose to go with the much more expensive custom roller tip fuel pump push rod it can further reduce friction but a roller must be kept in alignment or it will quickly destroy the cam, so the alignment bolt and slot arrangement is required, personally Ive seen no advantage for the use of the roller push rod, in dyno results but that just indicated its friction level is not huge, but theres no doubt that at least in theory its potentially reducing friction

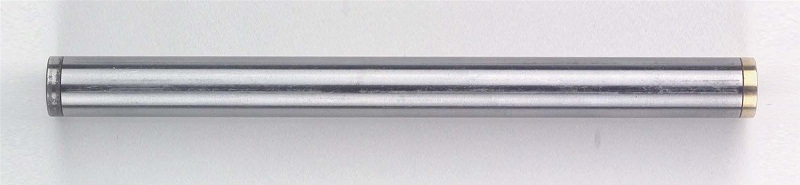

while your worrying about your new billet steel roller cam tearing up your old soft distributor gear, you might want to think about swapping to a bronze tip fuel pump push-rod to prevent excessive wear on that expensive billet steel cam core on the front end ,

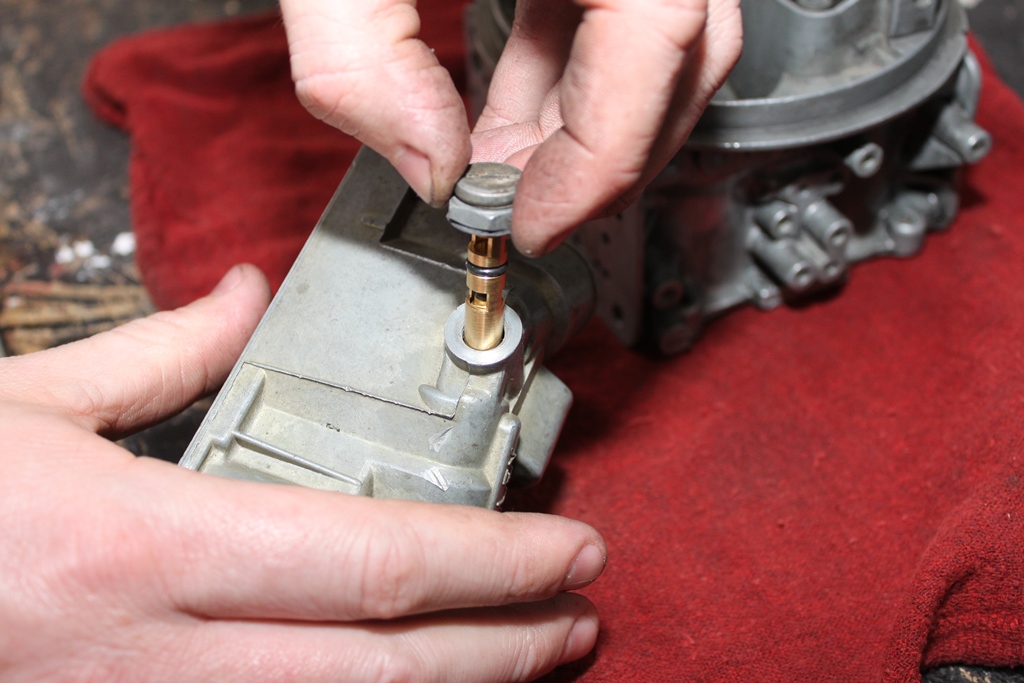

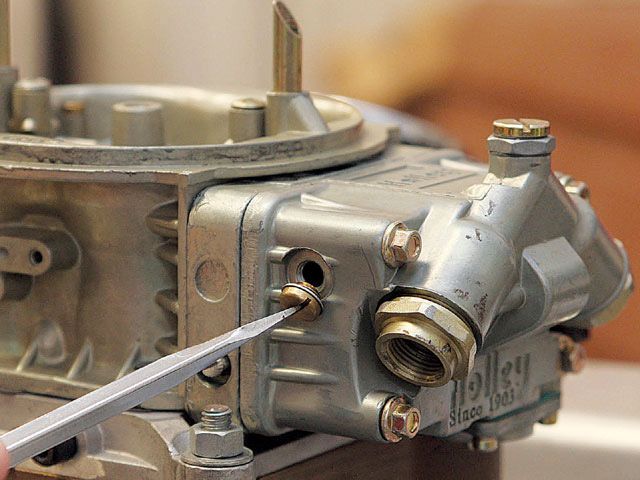

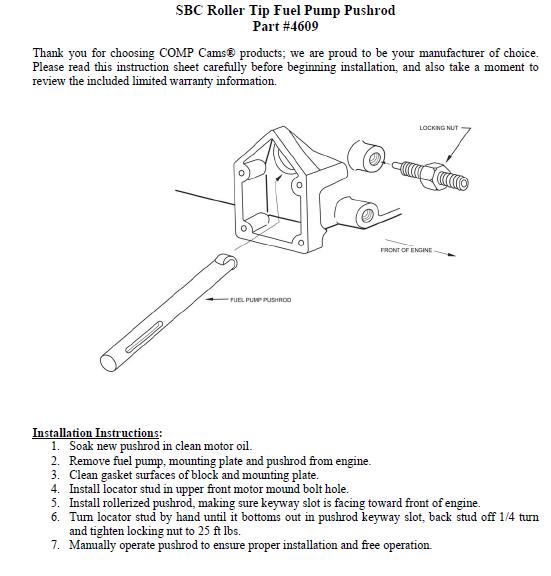

one end of the fuel pump push rod rides the cam surface on a roller wheel on the spinning cam eccentric lobe,that is ground off center of the cam center line, the other end of the fuel pump push rod rides on the fuel pump lever ,and pushes the fuel pump lever actuating the pump

http://www.summitracing.com/parts/RNB-03875/?rtype=10

http://www.summitracing.com/parts/HRS-94475/

http://www.summitracing.com/parts/cca-4609

http://www.summitracing.com/parts/trd-2310/overview/make/chevrolet

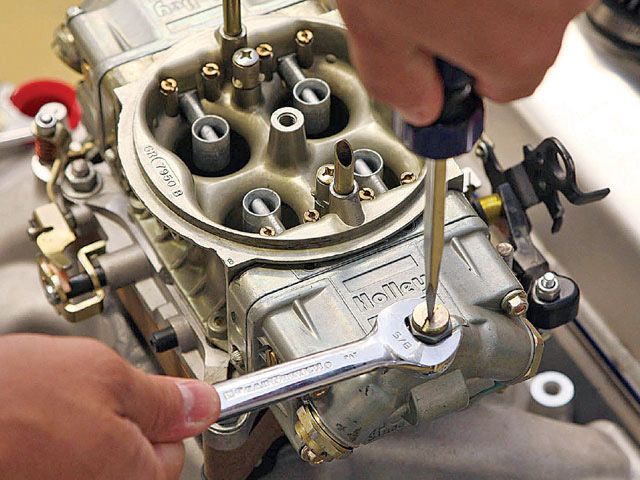

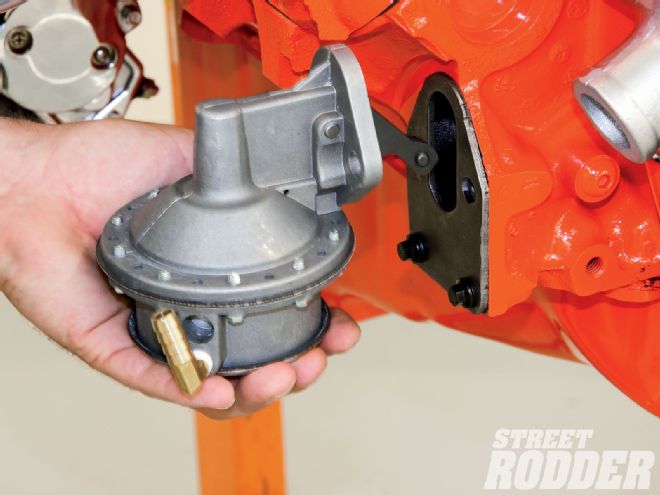

youll need the fuel pump mounting adapter plate and gaskets

http://www.summitracing.com/parts/spe-42493?seid=srese1&gclid=COWu1Lu61MYCFYsWHwodwNANjQ

watch this video

http://www.youtube.com/watch?v=8XiuiyBA ... ure=relmfu

read these links

viewtopic.php?f=55&t=5365&p=16067&hilit=fuel+pump+need#p16067

viewtopic.php?f=55&t=1939

viewtopic.php?f=55&t=211

viewtopic.php?f=55&t=5365&p=16067#p16067

while your worrying about your new billet steel roller cam tearing up your old soft distributor gear, you might want to think about swapping to a bronze tip fuel pump push-rod to prevent excessive wear on that expensive billet steel cam core on the front end ,

one end of the fuel pump push rod rides the cam surface on a roller wheel on the spinning cam eccentric lobe,that is ground off center of the cam center line, the other end of the fuel pump push rod rides on the fuel pump lever ,and pushes the fuel pump lever actuating the pump

http://www.summitracing.com/parts/RNB-03875/?rtype=10

http://www.summitracing.com/parts/HRS-94475/

http://www.summitracing.com/parts/cca-4609

http://www.summitracing.com/parts/trd-2310/overview/make/chevrolet

youll need the fuel pump mounting adapter plate and gaskets

http://www.summitracing.com/parts/spe-42493?seid=srese1&gclid=COWu1Lu61MYCFYsWHwodwNANjQ

watch this video

http://www.youtube.com/watch?v=8XiuiyBA ... ure=relmfu

read these links

viewtopic.php?f=55&t=5365&p=16067&hilit=fuel+pump+need#p16067

viewtopic.php?f=55&t=1939

viewtopic.php?f=55&t=211

viewtopic.php?f=55&t=5365&p=16067#p16067

Last edited by a moderator: