its not always a defective rod or main bearing!

stock fle plates are notorious for having cracks or center hub failures

the SFI certified FLEX PLATES are generally thicker heat treated steel thats both significantly thicker and less prone to failure under load.

EXAMPLE

http://www.summitracing.com/parts/SUM-G100SFI/

http://www.summitracing.com/parts/SUM-G102SFI/

U-JOINTS CAN FAIL

http://mgaguru.com/mgtech/propshaft/ps102.htm

http://www.procarcare.com/includes/cont ... shaft.html

http://dodgeram.org/tech/repair/U_joint/repair.htm

pressure plates can self destruct

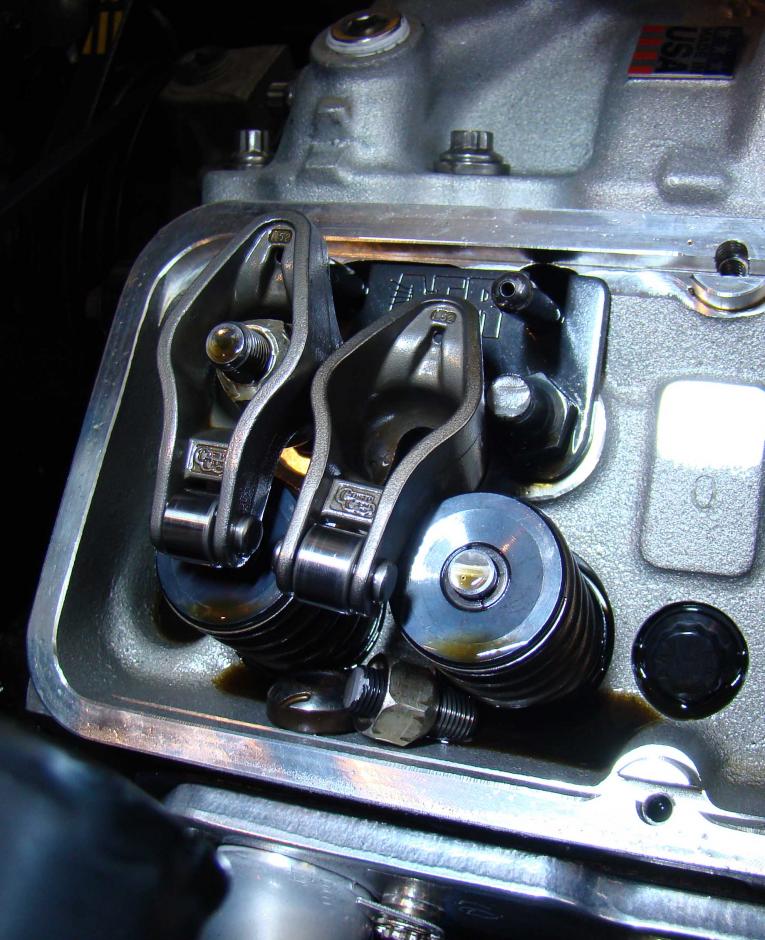

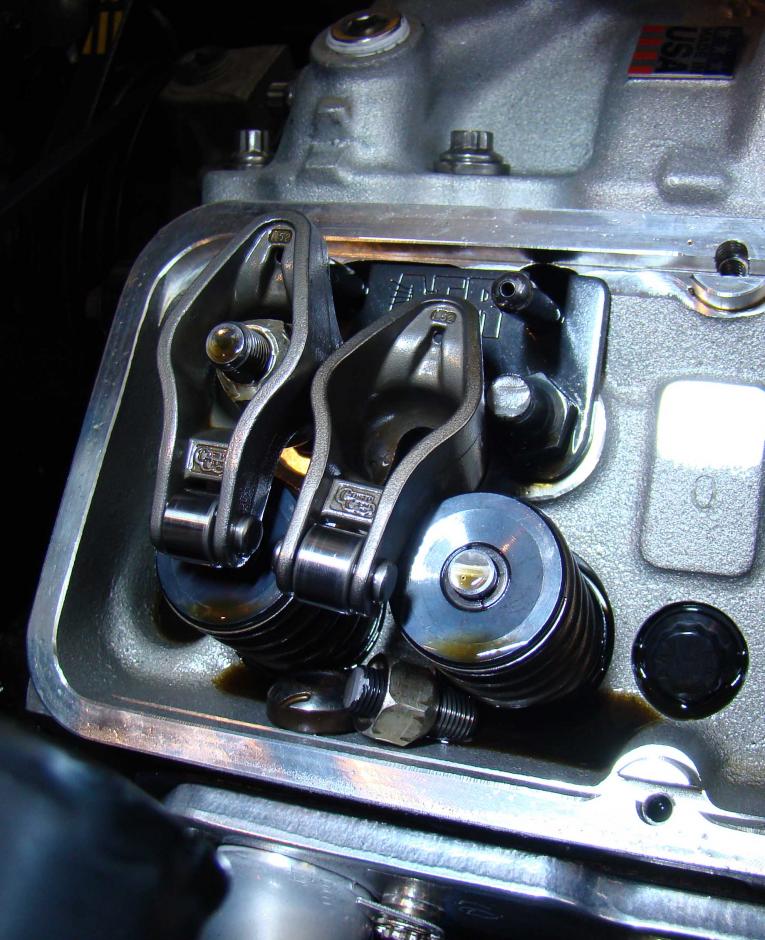

rocker balls can and do gall or wear, or friction weld in an amazingly short time if the oil flow is restricted

valve springs can and do break

rocker studs can bust really easily if clearances are not correctly set up,

thats obviously not normal wear,issue and it takes a huge amount of force to pressure shear the valve tip,in that short time,

Id bet you you find its a CLEARANCE issue, that type of damage usually indicates valve train binding, if your binding the valve train,pressure are immense, and parts fail rapidly, the most common on big blocks is the rocker slot binding on the rocker stud or spring bind or retainer to valve guide issues ESPECIALLY if the cam has more than about a .530 lift and your still using stock valve springs and rockers

but check the piston to valve clearance, verify the installed spring height,(you could have to many valve seat shims) and if you adjusted the pre-load or lash on the valves COLD ID strongly suggest AFTER VERIFYING CLEARANCES that you adjust the valves AT IDLE

read thru the links

viewtopic.php?f=52&t=181

viewtopic.php?f=52&t=282

viewtopic.php?f=52&t=1005&p=1818&hilit=+shims+spring#p1818

like Ive stated, many times youll need to verify ALL clearances, and the rocker stud to rocker slot clearance and the rocker polylocks to rocker body are usually overlooked

retainer to valve guide and retainer to rocker, coil bind and measuring the installed height are all required, its very common for some shops to just throw on valve springs without measuring the installed spring height and just reinstall seat shims., you can NEVER just assume your average machine shops done everything correctly...you need to verify, thats why you need a basic understanding of what your looking at and a few tools

[color]be very sure you check all the valve train clearances, having a rocker bind on a rocker stud can easily result in busted rockers or studs or bent pushrods[/color]

it should be obvious that the slot clearance in some rockers , especially with poly locks significantly limits rocker movement before clearances become an issue

BEEHIVE SPRINGS and FORGED STEEL ROCKERS GIVE A GOOD DEAL MORE ROCKER TO RETAINER CLEARANCE

cam lobes and lifters can wear very quickly if improper clearances, geometry or lubrication are a factor

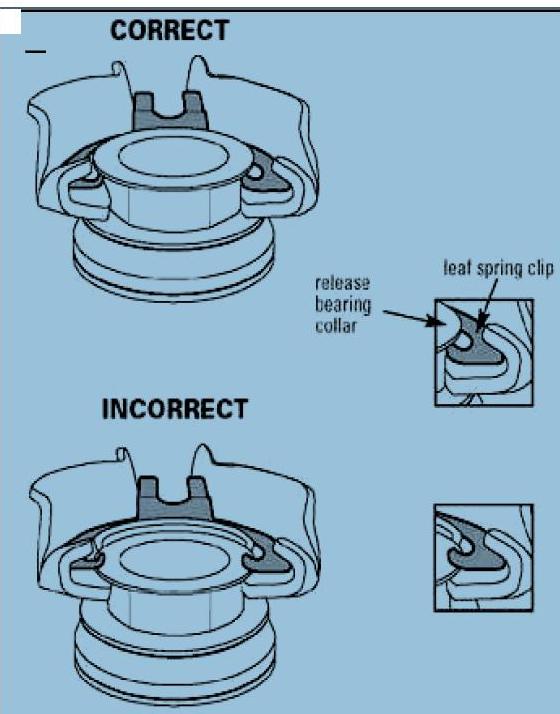

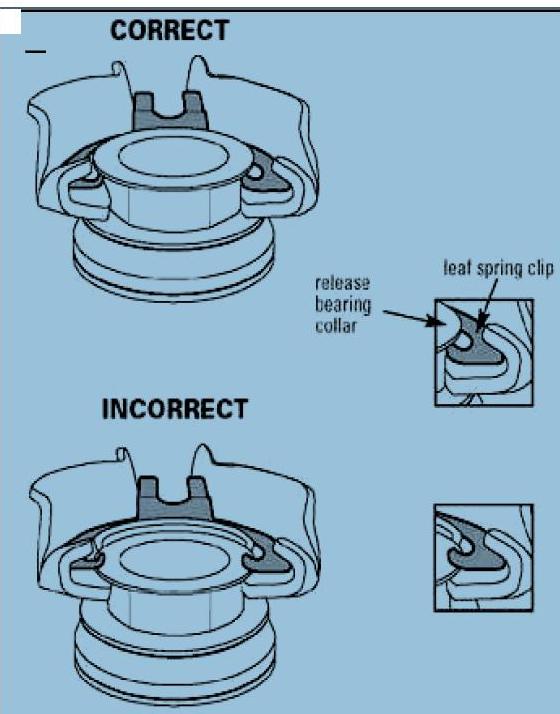

keep in mind theres three common throw out bearing heights and youll need the correct height for your particular application to get proper clutch function

remember theres two different designs, and use of the wrong one in your application will cause problems

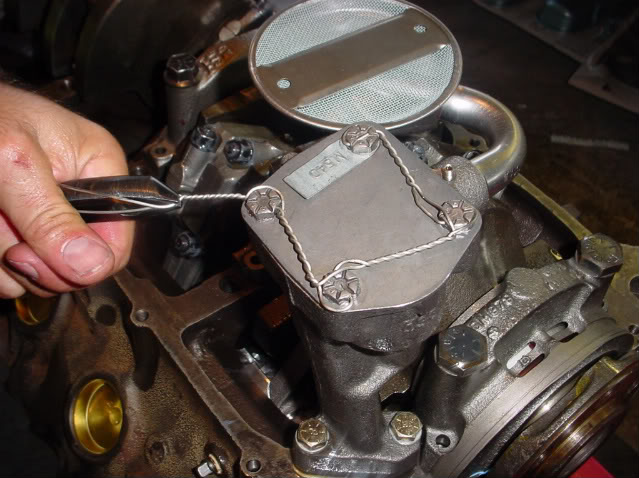

FOR ALL THE NEWER GUYS READING THIS,ANY TIME YOU INSTALL PARTS, LIKE SUSPENSION, STEERING OR DRIVE TRAIN COMPONENTS THAT MIGHT COME LOOSE WITH VIBRATION, ESPECIALLY IF IT COMING LOOSE , WHILE YOUR DRIVING COULD BE DANGEROUS ,

yes fasteners coming loose can also be a huge problem!

NOW I WOULD EXPECT THE EXPERIENCED GUYS TO HAVE ALREADY SEEN PARTS FAIL, AND KNOW TOO THINK THIS THRU ALREADY

I know you know this. SO THIS IS MOSTLY FOR THE NEW GUYS, and yes it takes some getting used to doing it, but I can,t imaging NOT doing this on critical fasteners

nyloc nuts work MOST OF THE TIME,but are very suspect if subjected to higher heat levels using THE CORRECT FORMULA FOR THE INTENDED APPLICATION, of loc-tite on the threads (yes theres several kinds so read instructions and follow directions ,and replacing the standard nuts on those studs with a lock washer and a NYLOC NUTS on each stud, or BOLT will usually cure the issue of a nut backing off , or bolt backing out.

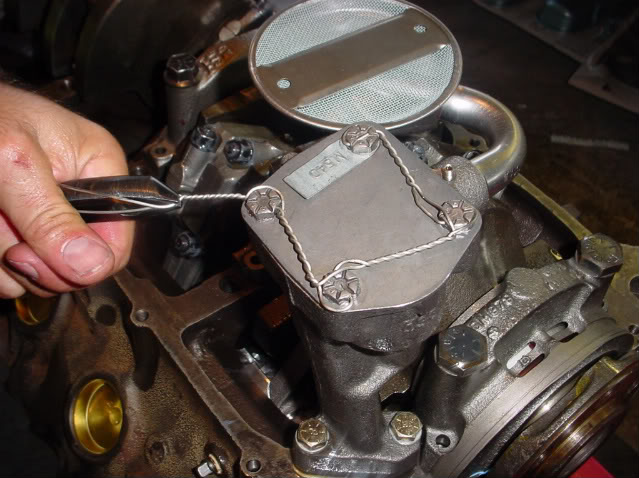

BUT IF YOUR 100% DEPENDENT ON THINGS STAYING AS YOU LEFT THEM USE LOCTITE AND SAFETY WIRE, as the COMBO PROPERLY USED WORKS 100% of the time

READ THRU THIS LINKED THREAD

viewtopic.php?f=50&t=4306&p=48044&hilit=+safety+wire#p48044

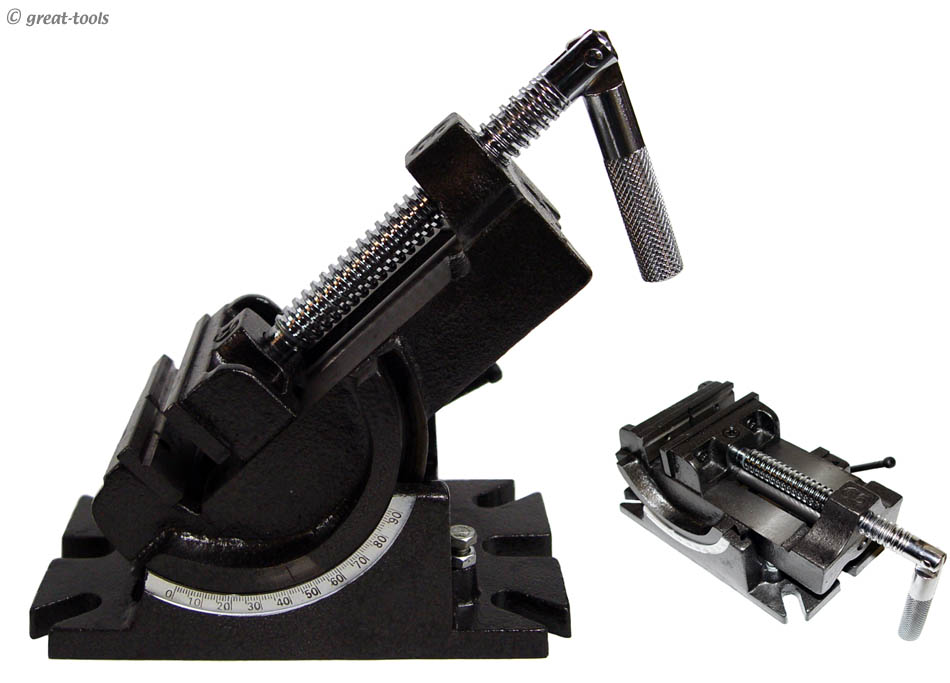

viewtopic.php?f=27&t=970&p=45483&hilit=drill+press#p45483

http://sprintparts.com/safety-wire-pliers/

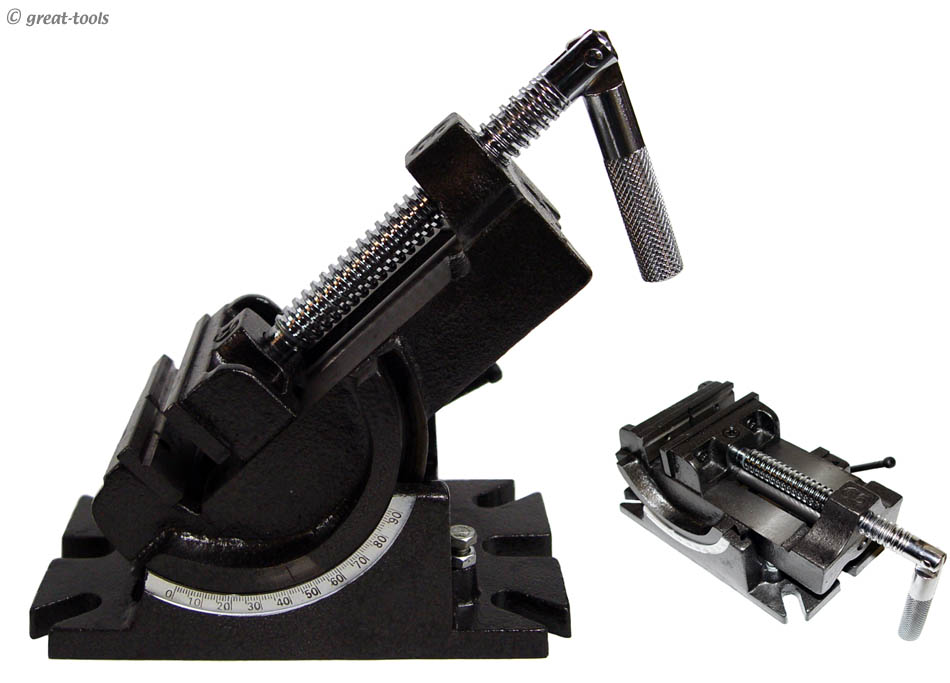

obviously having a drill press with a vise, the proper drill bits, assorted roll pins and an oil can for use when you cool the bits during the drill process helps

if you deal with safety wire and castle nuts and cotter pins youll find a drill press mandatory

stock fle plates are notorious for having cracks or center hub failures

the SFI certified FLEX PLATES are generally thicker heat treated steel thats both significantly thicker and less prone to failure under load.

EXAMPLE

http://www.summitracing.com/parts/SUM-G100SFI/

http://www.summitracing.com/parts/SUM-G102SFI/

U-JOINTS CAN FAIL

http://mgaguru.com/mgtech/propshaft/ps102.htm

http://www.procarcare.com/includes/cont ... shaft.html

http://dodgeram.org/tech/repair/U_joint/repair.htm

pressure plates can self destruct

rocker balls can and do gall or wear, or friction weld in an amazingly short time if the oil flow is restricted

valve springs can and do break

rocker studs can bust really easily if clearances are not correctly set up,

thats obviously not normal wear,issue and it takes a huge amount of force to pressure shear the valve tip,in that short time,

Id bet you you find its a CLEARANCE issue, that type of damage usually indicates valve train binding, if your binding the valve train,pressure are immense, and parts fail rapidly, the most common on big blocks is the rocker slot binding on the rocker stud or spring bind or retainer to valve guide issues ESPECIALLY if the cam has more than about a .530 lift and your still using stock valve springs and rockers

but check the piston to valve clearance, verify the installed spring height,(you could have to many valve seat shims) and if you adjusted the pre-load or lash on the valves COLD ID strongly suggest AFTER VERIFYING CLEARANCES that you adjust the valves AT IDLE

read thru the links

viewtopic.php?f=52&t=181

viewtopic.php?f=52&t=282

viewtopic.php?f=52&t=1005&p=1818&hilit=+shims+spring#p1818

like Ive stated, many times youll need to verify ALL clearances, and the rocker stud to rocker slot clearance and the rocker polylocks to rocker body are usually overlooked

retainer to valve guide and retainer to rocker, coil bind and measuring the installed height are all required, its very common for some shops to just throw on valve springs without measuring the installed spring height and just reinstall seat shims., you can NEVER just assume your average machine shops done everything correctly...you need to verify, thats why you need a basic understanding of what your looking at and a few tools

[color]be very sure you check all the valve train clearances, having a rocker bind on a rocker stud can easily result in busted rockers or studs or bent pushrods[/color]

it should be obvious that the slot clearance in some rockers , especially with poly locks significantly limits rocker movement before clearances become an issue

BEEHIVE SPRINGS and FORGED STEEL ROCKERS GIVE A GOOD DEAL MORE ROCKER TO RETAINER CLEARANCE

cam lobes and lifters can wear very quickly if improper clearances, geometry or lubrication are a factor

keep in mind theres three common throw out bearing heights and youll need the correct height for your particular application to get proper clutch function

remember theres two different designs, and use of the wrong one in your application will cause problems

FOR ALL THE NEWER GUYS READING THIS,ANY TIME YOU INSTALL PARTS, LIKE SUSPENSION, STEERING OR DRIVE TRAIN COMPONENTS THAT MIGHT COME LOOSE WITH VIBRATION, ESPECIALLY IF IT COMING LOOSE , WHILE YOUR DRIVING COULD BE DANGEROUS ,

yes fasteners coming loose can also be a huge problem!

NOW I WOULD EXPECT THE EXPERIENCED GUYS TO HAVE ALREADY SEEN PARTS FAIL, AND KNOW TOO THINK THIS THRU ALREADY

I know you know this. SO THIS IS MOSTLY FOR THE NEW GUYS, and yes it takes some getting used to doing it, but I can,t imaging NOT doing this on critical fasteners

nyloc nuts work MOST OF THE TIME,but are very suspect if subjected to higher heat levels using THE CORRECT FORMULA FOR THE INTENDED APPLICATION, of loc-tite on the threads (yes theres several kinds so read instructions and follow directions ,and replacing the standard nuts on those studs with a lock washer and a NYLOC NUTS on each stud, or BOLT will usually cure the issue of a nut backing off , or bolt backing out.

BUT IF YOUR 100% DEPENDENT ON THINGS STAYING AS YOU LEFT THEM USE LOCTITE AND SAFETY WIRE, as the COMBO PROPERLY USED WORKS 100% of the time

READ THRU THIS LINKED THREAD

viewtopic.php?f=50&t=4306&p=48044&hilit=+safety+wire#p48044

viewtopic.php?f=27&t=970&p=45483&hilit=drill+press#p45483

http://sprintparts.com/safety-wire-pliers/

obviously having a drill press with a vise, the proper drill bits, assorted roll pins and an oil can for use when you cool the bits during the drill process helps

if you deal with safety wire and castle nuts and cotter pins youll find a drill press mandatory

Last edited by a moderator: