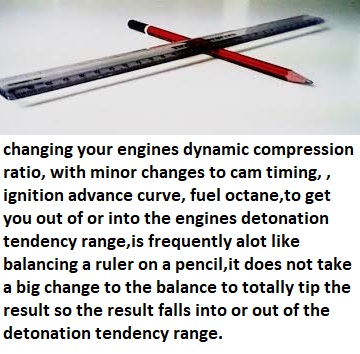

be aware that, the fuel octane, being used, alone is not the only factor here!Just got my heads back an cc'd them from being decked and checked for valve leaks. 5 were at 62cc and 3 at 63cc.

I would like to know the best place to grind out the 1 cc in the 5 chambers so they all match. Or is this to close to worry about it?

Vortecs are said to be very touchy so I don't want to upset the chamber dynamics.

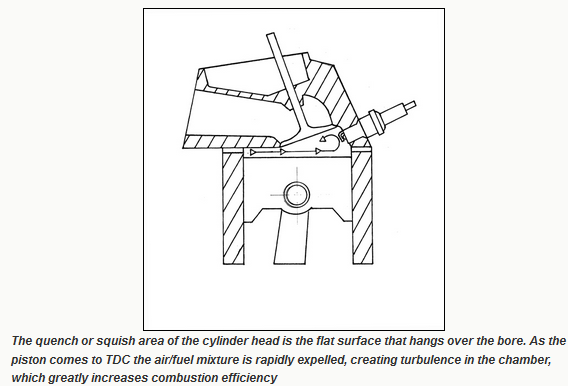

Going with flat tops with 4 reliefs, .015 shim gasket for a .040 quench. The 63cc puts me at 10.5:1 C/R total and a Dynamic C/R at 8.48:1

iron heads hold heat and transfer heat to coolant at a lower rate!

running a 180f -190f t-stat and use of a 7-8 quart oil pan, an oil cooler will tend too lower the effective operating temp.

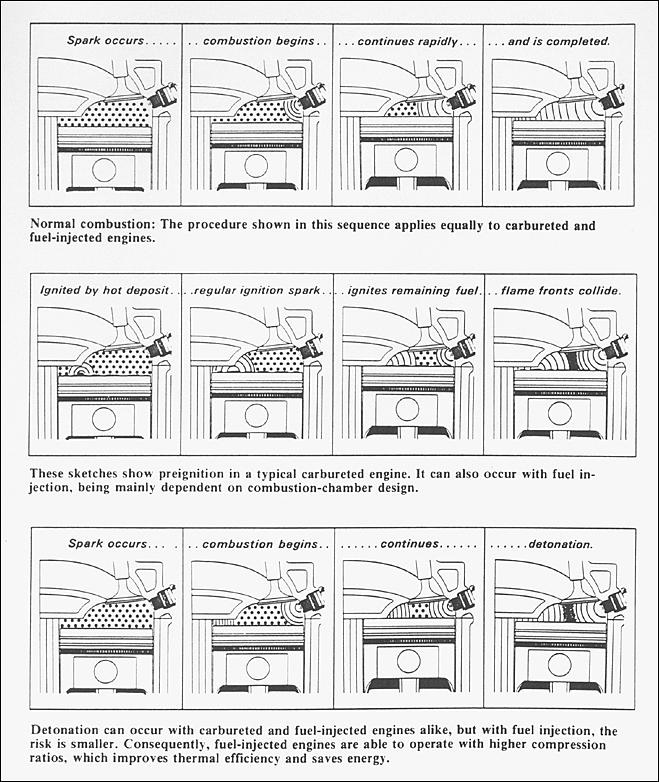

both the coolant and oil temps, and ignition advance curve, will effect the range where detonation will occur,richer fuel/air mixtures (12.5:1-13.5:1) tend to burn a bit cooler than lean mix ratios,(13.5:1-15.5:1)

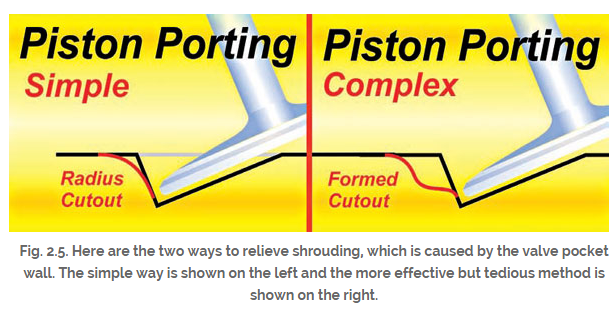

aluminum heads, transfer heat much faster, and benefit from, some, simple mods , like keeping the quench in the .040-.042 range, polishing the piston deck surface and combustion chamber and rounding the edges on the combustion chamber and piston valve notches, will reduce the tendency to get into detonation

keep in mind the depth of the valve seat surface and the thickness of the valves will tend to vary a bit between the combustion chambers, at times simply swapping two valves between different cylinder locations is all thats required to equalize the combustion chamber volume.

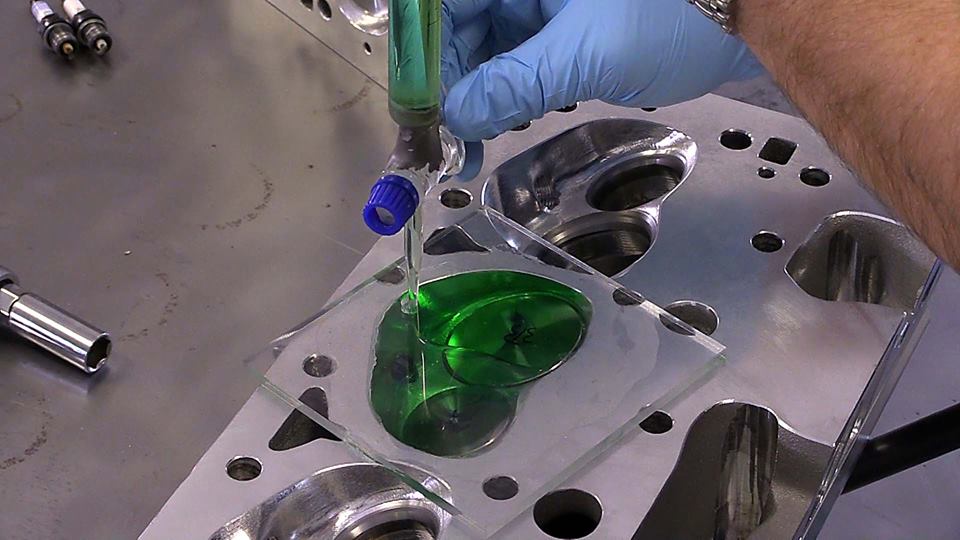

if your combustion chamber volumes are with-in 1 cc YOU may want to try swapping valve locations but keep in mind youll want to verify valve seat seal with a couple table spoons of solvent, like toluene, poured into each port to make sure all the valve seats seal and don,t leak into the combustion chamber, before running the engine.

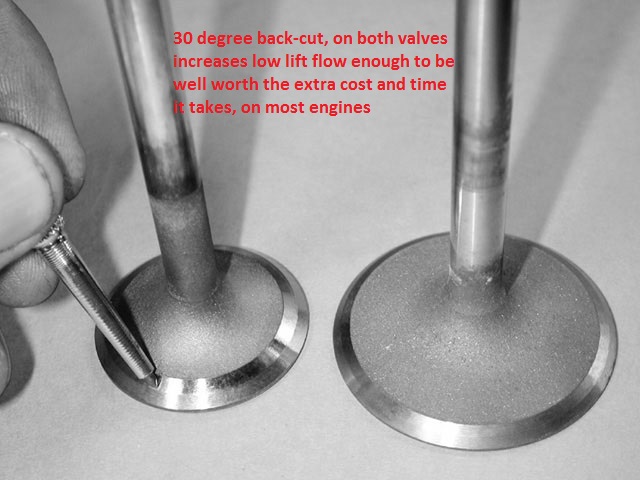

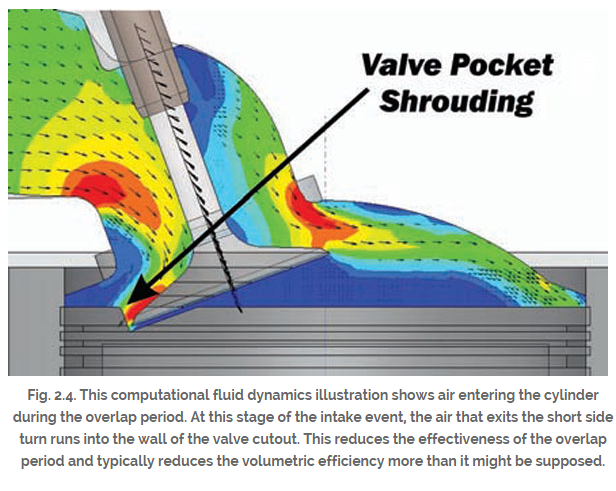

Ideally you'll want to maximize air flow rates, this would strongly suggest UN-shrouding the area near the intake calve out to the limits imposed by the head gasket being used on the engine would be a good place to start the chamber clean-up.

head gaskets are rarely completely round, nore are combustion chambers

you,ll want to place a head gasket you,ll use on the heads and mark the area inside the opening as the only areas you can change,

(notice the gasket fire ring is NOT a perfect circle like many people assume)

ideally you,ll want to un-shroud the valves while opening up the combustion chamber volume, but not extend the combustion chamber past the front edge of the gasket fire ring as that usually causes gasket failure

http://garage.grumpysperformance.com/index.php?threads/ccing-my-heads.14187/

http://garage.grumpysperformance.com/index.php?threads/iron-vs-aluminum-heads.389/#post-31684

http://garage.grumpysperformance.co...r-piston-dome-or-port-volume.2077/#post-60554

BlackoutSteve posted these pictures

What cylinder head?

With my 4.280" bore and AFR head, I am forced to use a 4.540" bore gasket because the chambers are wide and would otherwise allow the gasket to "hang" in the chamber.

For example..

laying a head gasket on the head and use machinist blue dye to show the areas inside the gasket fire-ring

http://www.skygeek.com/dymon-8000-s...MI8vPS24jm1gIVBolpCh2pnAoWEAQYAiABEgL2ZPD_BwE

thus the first logical step would be to carefully place a identical head gasket to what you'll use on the engine , properly lined up on the cylinder head and accurately scribe its inside dimensional limits on the cylinder head, a metal scribe , a dremel tool and machinist blue would be helpful here

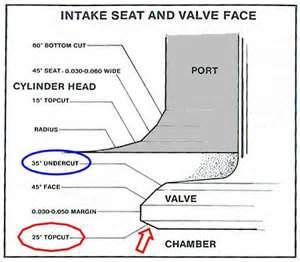

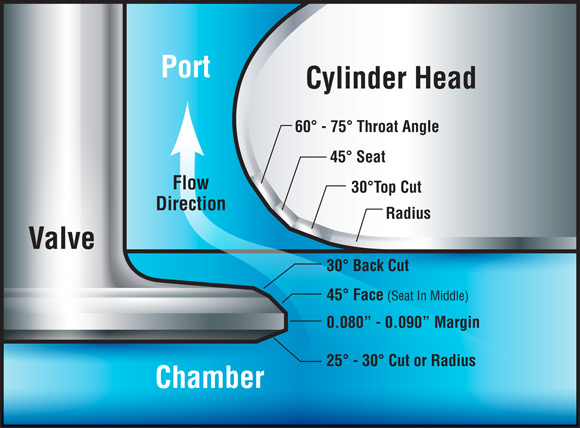

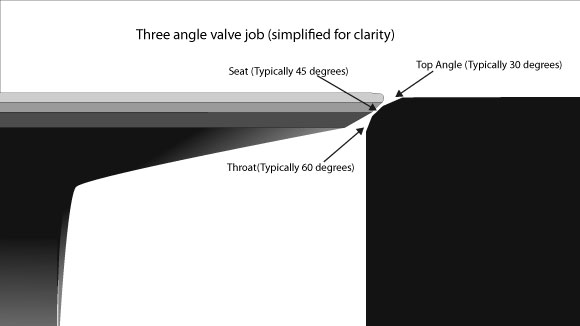

keep in mind its one of several factors working together, things like getting the quench correct, polishing and un-shrouding the combustion chamber, getting the ignition advance curve and fuel/air ratio correctly matched and taking the time to polish the piston, dome, removing sharp edges from valve clearance notches , and polishing and very slightly rounding sharp edges on the valves, use of the correct spark plug heat range, removing exposed threads in the combustion chamber after you test by inserting a correct spark plug, certainly helps reduce any potential hot spots.

obviously youll want to accurately CC the combustion chambers several times during the process to verify the combustion chamber then carefully cc each chamber once its cleaned up, and un-shrouded, and once you have those limitations carefully measured out and marked you can carefully and gradually remove material in the areas indicated

its generally a very good idea to keep all the cam, lifter,valve train and cylinder head components in matched sets, keep components in labeled matched sets, if you intend to reuse used parts in a rebuild. as each wears in, or laps in to its matched components a bit differently thus random assembly increases the chances of future parts

failures

https://www.summitracing.com/search?SortBy=BestKeywordMatch&SortOrder=Ascending&keyword=POW735002

btw, if the parts will be sitting on a shelf in the work shop while you wait, a good soak with wd 40, and wrapping a few criss crossed layers of saran wrap plastic over the loose parts is a good idea as it prevents moisture damage and tends to keep the parts in the correct location slots, and if your working on more than one engine type out some detailed info as to the build ID and place it under the saran wrap.

these links should help

http://garage.grumpysperformance.co...alves-and-polishing-combustion-chambers.2630/

http://garage.grumpysperformance.com/index.php?threads/porting-can-help.462/

http://garage.grumpysperformance.com/index.php?threads/more-port-flow-related-info.322/

http://garage.grumpysperformance.co...lve-seat-angles-and-air-flow.8460/#post-29682

http://garage.grumpysperformance.co...ur-cylinder-heads-or-piston-dome-volume.2077/

http://garage.grumpysperformance.com/index.php?threads/can-you-plan-for-quench.11298/

http://garage.grumpysperformance.com/index.php?threads/head-gasket-related.1859/#post-50617

http://garage.grumpysperformance.com/index.php?threads/quench-or.10951/

http://garage.grumpysperformance.co...r-piston-dome-or-port-volume.2077/#post-44568

http://garage.grumpysperformance.co...needs-clean-up-equalization.12474/#post-62647

http://garage.grumpysperformance.co...video-with-info-worth-watching-through.15999/

http://garage.grumpysperformance.co...ng-combustion-chambers.2630/page-2#post-55199

Last edited: