most guys in this spot have had a set of crappy looking rusted headers on a car at some time, and while thats almost UN-avoidable with cheap UN-coated headers there are ceramic coatings and paints that reduce or retard corrosion on headers.

now there are both company's that can professionally coat headers with a thin durable coat of ceramics, almost like porcelain, and paint or powder coat like products that can be self applied that are either baked on or cures with engine exhaust heat.

Ive seen several guys sand blast older sets of headers that looked like crap, and several have used several different brands of do it yourself paint on header coatings and while long term results varied wildly. between the products they all tended to look far better for at least a few weeks and in a few cases several years.

yes you tend to get better results from professionally re-coated headers, but think thru the price/value, it might make sense to recoat $1500 custom headers for $300-$600 but it would make no sense on standard cheap $300 headers and be a total waste of time and effort on $180 bargain cheap headers

like with most coatings its surface prep and following directions that pays in longer life on the headers

read this related thread and related links

https://www.facebook.com/pages/Dun-Righ ... 0691252371

viewtopic.php?f=56&t=5443

http://www.centralctcoatings.com/

http://www.performancecoatingsplus.com/ ... tings.html

http://www.performancecoatings.com/headercoatings.html

http://www.amr-coatings.com/x-style-headers.php

http://www.zircotec.com/page/performance-colours--2-/96

http://www.carcraft.com/techarticles/hi ... index.html

http://www.coolconceptspc.com/ceramic_coatings.html

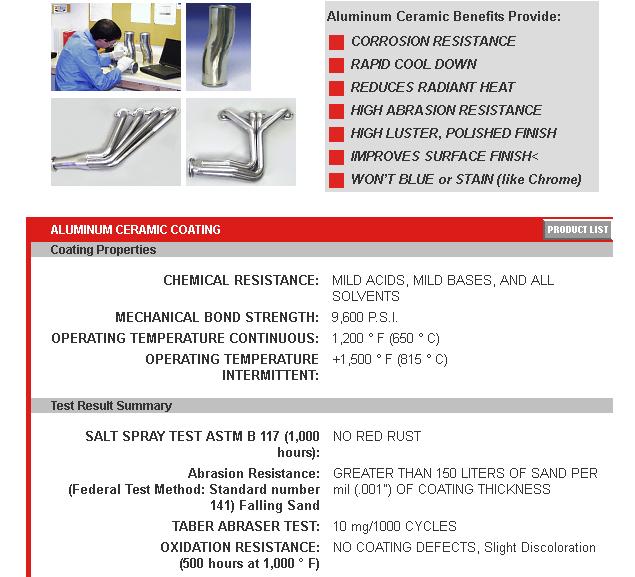

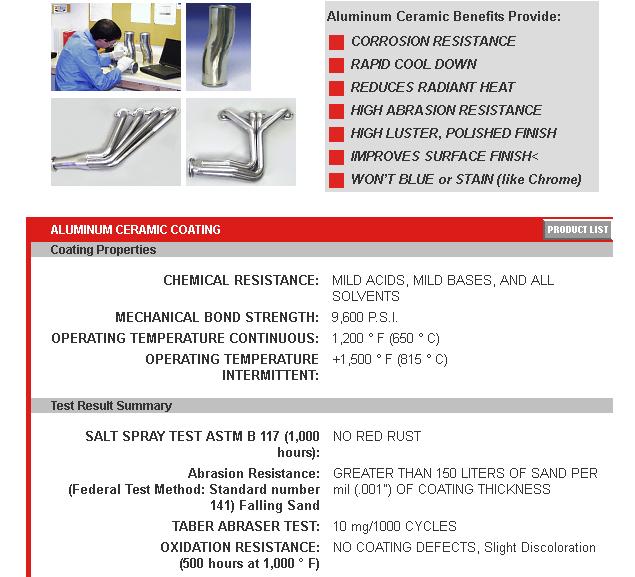

What are Ceramic Coatings?

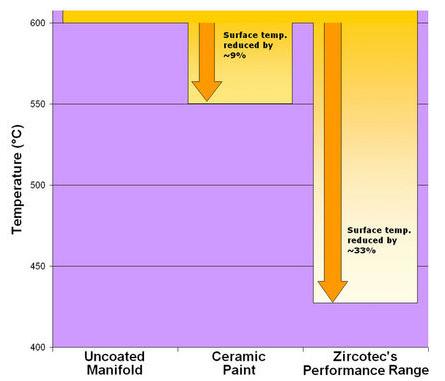

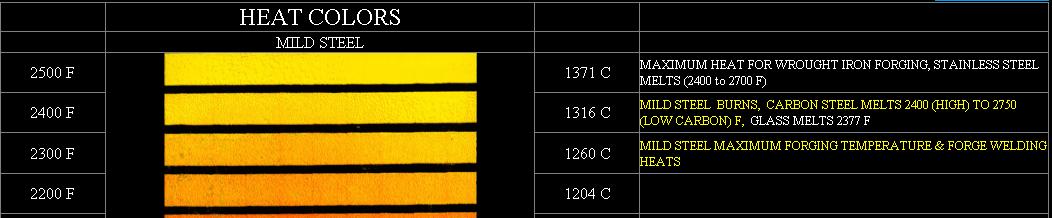

Ceramics are a “wet†process coating that, when properly applied, bar excessive heat radiation with a barrier that reflects the heat instead of absorbing it. This prevents the eventual destruction of the outer coating and the part itself. For instance, a ceramic coat applied to the inner and outer walls of tubular headers will seal the tube’s body with a thermal barrier and reduce heat transfer. This relieves the steel tube from excessive heat absorption and reduces cracking by preventing excessive expansion/contraction of the part. This barrier also protects the base metal itself, preserving the part and extending its service life. Today’s ceramic coatings are effective up to temperatures of 2000F and come in a variety of colors and finishes. Test data has shown radiated temperature drops in excess of 130F between coated and uncoated exhaust parts. Trade magazines, like HOT ROD, have done articles on ceramic coated headers, showing similar temperature drops when comparing coated and uncoated headers. A secondary benefit from ceramic coatings is its capability to seal the part from the elements. This creates a rust/corrosion resistant coat that rivals the best anti-rust coatings on the market. Ceramic coats, however, will outperform those coatings when high heat is applied.

How do Ceramics compare to Powdercoats?

Benefits of Powder Coating:

• Wide variety of colors to choose from. Virtually every color imaginable can be purchased, along with a variety of finishes, i.e. metallics, translucents, flats, gloss, wrinkle and hammered.

• Durable coats. Powder coats are very durable and chip-resistant and outperform paints in many ways.

• Multiple coats can be laid on, covering minor imperfections in the surface of the part.

• Powders are generally inexpensive compared to ceramics.

Drawbacks of Powder Coating:

• Powders cannot withstand high heat. Most powder coats begin to fail when the temperature of the part reaches 500F or more. There are some high temp powders available that can last up to 900F. We do not recommend any powdercoat on any exhaust component, or any part that will see heat above 500F.

• Powders do not contain a thermal barrier like ceramics do.

• When powdercoats fail, the coating comes off in big chunks.

Benefits of Ceramics:

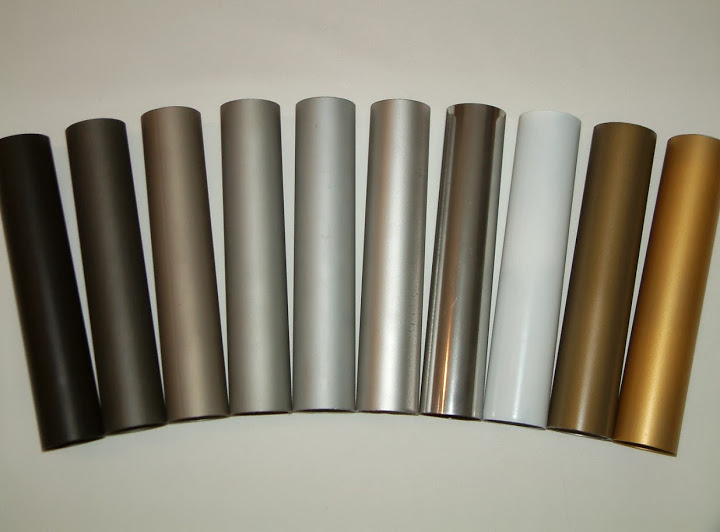

• Decent range of colors available, with more coming every year. The most popular colors available are a ceramic “chrome,†semi-gloss black, satin black and aluminum.

• Withstands a wide range of heat. Ceramics really shine where powders or paint cannot. Ceramics generally operate best in the 1100F – 2000F range and are considered “bulletproof†for cast iron manifolds.

• A ceramic coated set of header pipes will last many more years than ones with header paint. Powder coats will not last beyond the first engine start.

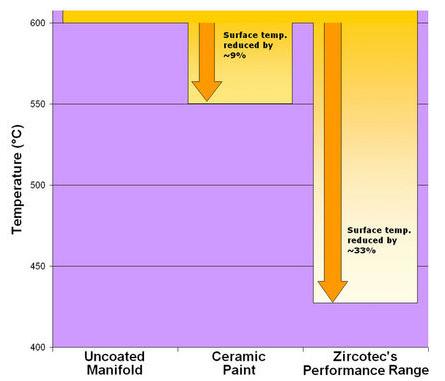

• Ceramics block excessive heat radiation, with 130F+ temperature drops recorded by major trade publications like HOT ROD magazine. The thermal protection provided by ceramic coatings will extend the life of other engine components, especially electronics, through reduced exposure to heat. Thermal barriers applied to complete exhaust systems will reduce floorboard and firewall heat.

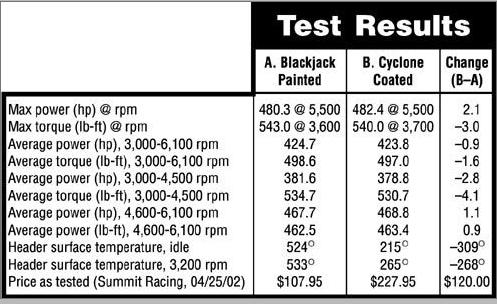

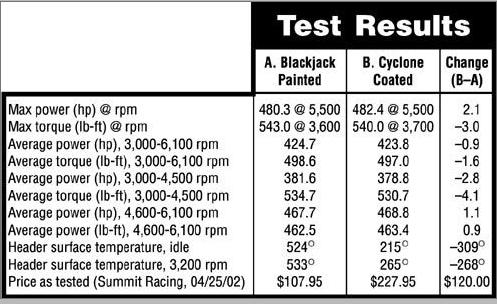

• Minor performance boost. Dyno tests have revealed power gains of 8-10 hp in a 550 hp engine. This is mainly due to the heat barriers trapping heat inside the header pipes and increasing exhaust velocity. It was also acknowledged that more gains could be had when installed in an engine bay, where hot air robs power. Ceramics may also be applied to internal engine parts, creating less drag and longer burn cycles during engine operation.

• Durable coats. Ceramics are much tougher than paints and match powder in durability.

• Rust protection. Select ceramics provide excellent rust protection against the elements.

• Good chemical resistance.

Drawbacks of Ceramics:

• Smaller selection of colors than powder. While there are many colors available, our experience has shown the silvers, blacks, polishable “chrome†and aluminums are the most reliable colors. There are some metallics, coppers, reds and blues that have recently come out, but as of now they are not very durable. They also hold a lower temperature rating, usually in the 1300F range. A general rule of thumb on ceramics: The prettier they are, the less heat they can take.

• Ceramic colors will go dull or flat. This is common for all ceramic coatings. This is not a failure of the coating. The thermal barriers will still be intact.

• Ceramics are not a high solids filler coat. Ceramics work best with a thin coat, as a thicker one will delaminate and flake off. Rough surfaces cannot not be filled to a smooth finish with ceramic coats. For best results, spend some time improving surface imperfections before bringing your parts in.

• Cost is generally higher than powdercoating.

• Ceramics aren’t appropriate for use on everything. Ceramics perform mainly as a heat barrier, so you wouldn’t want to use it on a part where it would lock heat in an area where you don’t want it.

What are Powder Coatings?

Air Cleaner Valve CoversPowder Clear Coat

• Chemical and corrosion resistant.

• Protects bare cast or a highly polished surface.

• Excellent for marine applications.

Powder Coating

• Wide array of colors available. Many colors in stock.

• Many types of finishes available: Hammered, wrinkle, gloss, flat, translucent, metallic.

• Excellent chemical and corrosion resistance with clear coat.

• Highly durable finish.

• Ideal for any engine part that will not reach 500F+ surface temps. Intake manifolds, water pumps, cylinder heads, brackets, alternator housings, power steering pump cases, valve covers, etc.

http://www.jegs.com/p/VHT/VHT-Flame-Pro ... 3/10002/-1

http://www.jegs.com/i/KBS%20Coatings/19 ... /-1?CT=999

http://www.jetcoat.com/alumcerm.html

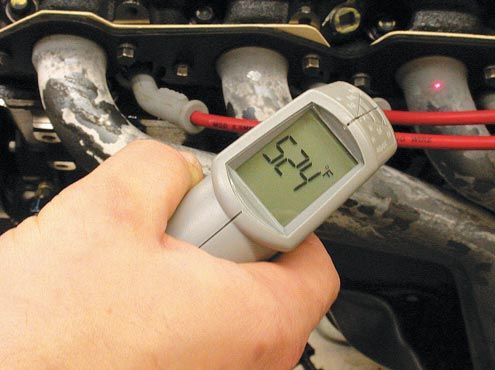

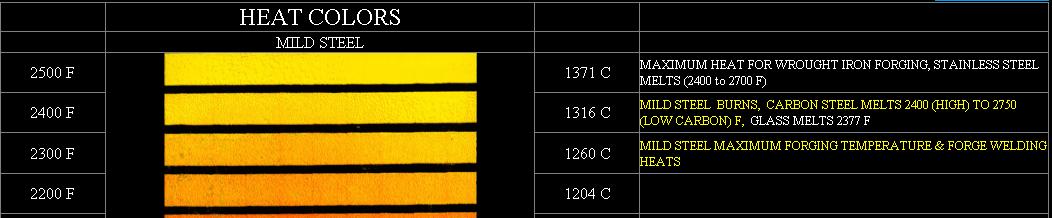

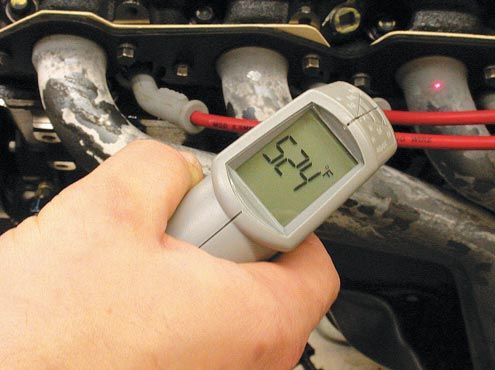

exhaust manifold temps commonly exceed 550F-850F and in many cases the exhaust manifolds, or headers are located very close to the heads and block in some header and manifold designs, so reflected heat is significantly higher than you might imagine near the headers[/b]

http://www.professionalequipment.com/ex ... ermometer/

now there are both company's that can professionally coat headers with a thin durable coat of ceramics, almost like porcelain, and paint or powder coat like products that can be self applied that are either baked on or cures with engine exhaust heat.

Ive seen several guys sand blast older sets of headers that looked like crap, and several have used several different brands of do it yourself paint on header coatings and while long term results varied wildly. between the products they all tended to look far better for at least a few weeks and in a few cases several years.

yes you tend to get better results from professionally re-coated headers, but think thru the price/value, it might make sense to recoat $1500 custom headers for $300-$600 but it would make no sense on standard cheap $300 headers and be a total waste of time and effort on $180 bargain cheap headers

like with most coatings its surface prep and following directions that pays in longer life on the headers

Rust From Plain Steel Headers Can Ruin Your New Engine

Check out this video, it should start at 30: 40 min:sec and see what Jon Kaase has to say about rust that develops in plain steel headers and how it can go thru your engine and collect on the throttle plates of your carburetor.

garage.grumpysperformance.com

read this related thread and related links

https://www.facebook.com/pages/Dun-Righ ... 0691252371

viewtopic.php?f=56&t=5443

http://www.centralctcoatings.com/

http://www.performancecoatingsplus.com/ ... tings.html

http://www.performancecoatings.com/headercoatings.html

http://www.amr-coatings.com/x-style-headers.php

http://www.zircotec.com/page/performance-colours--2-/96

http://www.carcraft.com/techarticles/hi ... index.html

http://www.coolconceptspc.com/ceramic_coatings.html

What are Ceramic Coatings?

Ceramics are a “wet†process coating that, when properly applied, bar excessive heat radiation with a barrier that reflects the heat instead of absorbing it. This prevents the eventual destruction of the outer coating and the part itself. For instance, a ceramic coat applied to the inner and outer walls of tubular headers will seal the tube’s body with a thermal barrier and reduce heat transfer. This relieves the steel tube from excessive heat absorption and reduces cracking by preventing excessive expansion/contraction of the part. This barrier also protects the base metal itself, preserving the part and extending its service life. Today’s ceramic coatings are effective up to temperatures of 2000F and come in a variety of colors and finishes. Test data has shown radiated temperature drops in excess of 130F between coated and uncoated exhaust parts. Trade magazines, like HOT ROD, have done articles on ceramic coated headers, showing similar temperature drops when comparing coated and uncoated headers. A secondary benefit from ceramic coatings is its capability to seal the part from the elements. This creates a rust/corrosion resistant coat that rivals the best anti-rust coatings on the market. Ceramic coats, however, will outperform those coatings when high heat is applied.

How do Ceramics compare to Powdercoats?

Benefits of Powder Coating:

• Wide variety of colors to choose from. Virtually every color imaginable can be purchased, along with a variety of finishes, i.e. metallics, translucents, flats, gloss, wrinkle and hammered.

• Durable coats. Powder coats are very durable and chip-resistant and outperform paints in many ways.

• Multiple coats can be laid on, covering minor imperfections in the surface of the part.

• Powders are generally inexpensive compared to ceramics.

Drawbacks of Powder Coating:

• Powders cannot withstand high heat. Most powder coats begin to fail when the temperature of the part reaches 500F or more. There are some high temp powders available that can last up to 900F. We do not recommend any powdercoat on any exhaust component, or any part that will see heat above 500F.

• Powders do not contain a thermal barrier like ceramics do.

• When powdercoats fail, the coating comes off in big chunks.

Benefits of Ceramics:

• Decent range of colors available, with more coming every year. The most popular colors available are a ceramic “chrome,†semi-gloss black, satin black and aluminum.

• Withstands a wide range of heat. Ceramics really shine where powders or paint cannot. Ceramics generally operate best in the 1100F – 2000F range and are considered “bulletproof†for cast iron manifolds.

• A ceramic coated set of header pipes will last many more years than ones with header paint. Powder coats will not last beyond the first engine start.

• Ceramics block excessive heat radiation, with 130F+ temperature drops recorded by major trade publications like HOT ROD magazine. The thermal protection provided by ceramic coatings will extend the life of other engine components, especially electronics, through reduced exposure to heat. Thermal barriers applied to complete exhaust systems will reduce floorboard and firewall heat.

• Minor performance boost. Dyno tests have revealed power gains of 8-10 hp in a 550 hp engine. This is mainly due to the heat barriers trapping heat inside the header pipes and increasing exhaust velocity. It was also acknowledged that more gains could be had when installed in an engine bay, where hot air robs power. Ceramics may also be applied to internal engine parts, creating less drag and longer burn cycles during engine operation.

• Durable coats. Ceramics are much tougher than paints and match powder in durability.

• Rust protection. Select ceramics provide excellent rust protection against the elements.

• Good chemical resistance.

Drawbacks of Ceramics:

• Smaller selection of colors than powder. While there are many colors available, our experience has shown the silvers, blacks, polishable “chrome†and aluminums are the most reliable colors. There are some metallics, coppers, reds and blues that have recently come out, but as of now they are not very durable. They also hold a lower temperature rating, usually in the 1300F range. A general rule of thumb on ceramics: The prettier they are, the less heat they can take.

• Ceramic colors will go dull or flat. This is common for all ceramic coatings. This is not a failure of the coating. The thermal barriers will still be intact.

• Ceramics are not a high solids filler coat. Ceramics work best with a thin coat, as a thicker one will delaminate and flake off. Rough surfaces cannot not be filled to a smooth finish with ceramic coats. For best results, spend some time improving surface imperfections before bringing your parts in.

• Cost is generally higher than powdercoating.

• Ceramics aren’t appropriate for use on everything. Ceramics perform mainly as a heat barrier, so you wouldn’t want to use it on a part where it would lock heat in an area where you don’t want it.

What are Powder Coatings?

Air Cleaner Valve CoversPowder Clear Coat

• Chemical and corrosion resistant.

• Protects bare cast or a highly polished surface.

• Excellent for marine applications.

Powder Coating

• Wide array of colors available. Many colors in stock.

• Many types of finishes available: Hammered, wrinkle, gloss, flat, translucent, metallic.

• Excellent chemical and corrosion resistance with clear coat.

• Highly durable finish.

• Ideal for any engine part that will not reach 500F+ surface temps. Intake manifolds, water pumps, cylinder heads, brackets, alternator housings, power steering pump cases, valve covers, etc.

http://www.jegs.com/p/VHT/VHT-Flame-Pro ... 3/10002/-1

http://www.jegs.com/i/KBS%20Coatings/19 ... /-1?CT=999

http://www.jetcoat.com/alumcerm.html

exhaust manifold temps commonly exceed 550F-850F and in many cases the exhaust manifolds, or headers are located very close to the heads and block in some header and manifold designs, so reflected heat is significantly higher than you might imagine near the headers[/b]

http://www.professionalequipment.com/ex ... ermometer/

Last edited by a moderator: