"hey grumpyvette?

I installed header wraps to lower engine compartment temps, once I started the car the wrap material really started smoking,so I turned the engine off? is this normal?"

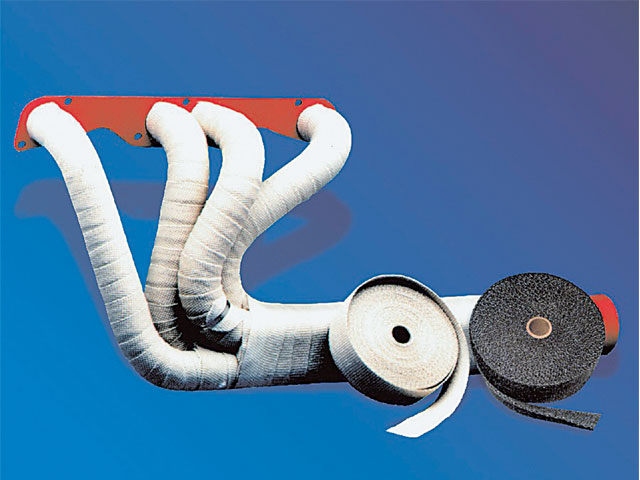

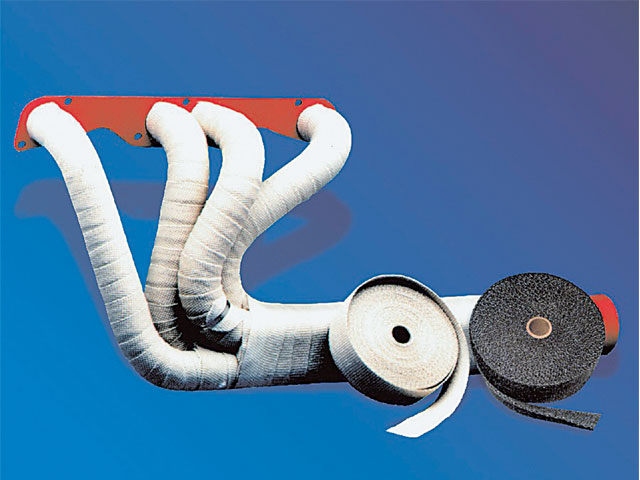

http://www.jegs.com/i/DEI/186/010127/10 ... 7AodwS8AXg

no header manufacturer ,I know of will warrant the damage to headers header wraps frequently cause,

most header wrap material reduces engine compartment heat,

while tends to increase exhaust scavenging efficiency very slightly it can and frequently does cause many header rust issues,

as the headers don,t tend to dry off quickly if the cars headers get splashed with water, and header wrap tends to act like a moisture magnet for condensation from the air moisture under some conditions.

the duration and amount of smoke , most header wraps tend to cause depends on the brand and how much crud was on the wraps, or got on the material during the install, but most smoke for the first few minutes, then stop after about 20 minutes, Id park the car well away from the house with the hood open, and keep a decent CO2 fire extinguisher and a running water hose handy in case of problems, with fire, during that first 30 minutes.

keep in mind the extra heat tends to reduce header life expectancy by about 30%-50% MINIMUM in my experience, and far faster on cheap non-coated headers

heres the pros and cons of wrapping

PRO:

Other areas of performance are Improved by the increased scavenging effect. Increasing the scavenging effect of the exhaust allows the engine to breathe more efficiently. A engine in many ways is like an air compressor, the pushing of exhaust gases from the combustion chamber creates a condition called pumping losses. This is the loss of power due to the piston pushing these exhaust gases Into the system and out of the system. Increased scavenging not only lowers pumping losses but also allows more efficient clearing of exhaust gases from the combustion chamber. This means cleaner air fuel mixture, this means power. The increased scavenging effect of the exhaust also benefits the intake of air & fuel during the overlap phase of the intake stroke. During the overlap phase, both the intake & exhaust valve are open. The exhaust gases create a vacuum effect which pulls the air fuel mixture at a higher velocity through the intake. As you can see, there are many benefits to the use of header wrap, lower cockpit temperatures, lower under hood temperatures. These all mean increased life of electric & electronic components as well.

CON:

Wrap can and frequently will hold moisture, oil, and grime next to the pipe to cause " header rotting."

Extra heat can cause the pipes to become brittle.....Cool air needs to be around the header, and insulating it with a wrap to hold exhaust heat in makes the header material temperatures near molten. When you wrap the header you trap the heat in the header, but also in the material that needs to breathe to dissipate heat for it's own survival.

READ THRU THIS LINK

(http://www.centuryperformance.com/ex...e-spg-138.html)

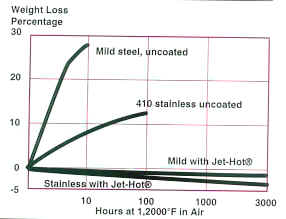

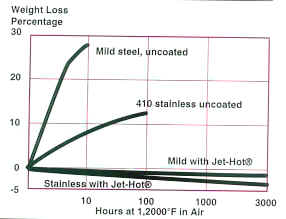

Headers Oxidize! the higher the heat the faster they degrade

Under normal use, and even more with higher EGTs and header surface temperatures, headers will oxidize and material is actually removed from the headers. This means they become lighter and weaker.

Try these actual test numbers:

Mild Steel (1010) uncoated header exposed to 1200º F. in normal air will have a weight loss percentage of roughly 25% with only 10 hours use at this temperature.

Stainless Steel (410) uncoated header will have roughly 8% weight loss in the same 10 hour period.

A coated mild steel header will have NO weight loss at temperatures up to 1200º F. In fact it will actually gain a bit of weight! Between 1300º F and 1600º F the coating will begin to show signs of mud cracking or like the look of lacquer checking. However, limited diffusion takes place between the coating and the substrate, producing a very thin film of iron aluminide, which continues to inhibit oxidation.

If I had some expensive headers , and wanted to reduce engine compartment heat, I would strongly suggest you go the good Ceramic Coating option route

personally a high quality ceramic coating on headers seems like a great option.

http://jet-hot.com/

http://www.moorepower.com/

http://www.moorepower.com/header_coatings/

http://www.prokoteindy.com/prokote2_003.htm

I installed header wraps to lower engine compartment temps, once I started the car the wrap material really started smoking,so I turned the engine off? is this normal?"

http://www.jegs.com/i/DEI/186/010127/10 ... 7AodwS8AXg

no header manufacturer ,I know of will warrant the damage to headers header wraps frequently cause,

most header wrap material reduces engine compartment heat,

while tends to increase exhaust scavenging efficiency very slightly it can and frequently does cause many header rust issues,

as the headers don,t tend to dry off quickly if the cars headers get splashed with water, and header wrap tends to act like a moisture magnet for condensation from the air moisture under some conditions.

the duration and amount of smoke , most header wraps tend to cause depends on the brand and how much crud was on the wraps, or got on the material during the install, but most smoke for the first few minutes, then stop after about 20 minutes, Id park the car well away from the house with the hood open, and keep a decent CO2 fire extinguisher and a running water hose handy in case of problems, with fire, during that first 30 minutes.

keep in mind the extra heat tends to reduce header life expectancy by about 30%-50% MINIMUM in my experience, and far faster on cheap non-coated headers

heres the pros and cons of wrapping

PRO:

Other areas of performance are Improved by the increased scavenging effect. Increasing the scavenging effect of the exhaust allows the engine to breathe more efficiently. A engine in many ways is like an air compressor, the pushing of exhaust gases from the combustion chamber creates a condition called pumping losses. This is the loss of power due to the piston pushing these exhaust gases Into the system and out of the system. Increased scavenging not only lowers pumping losses but also allows more efficient clearing of exhaust gases from the combustion chamber. This means cleaner air fuel mixture, this means power. The increased scavenging effect of the exhaust also benefits the intake of air & fuel during the overlap phase of the intake stroke. During the overlap phase, both the intake & exhaust valve are open. The exhaust gases create a vacuum effect which pulls the air fuel mixture at a higher velocity through the intake. As you can see, there are many benefits to the use of header wrap, lower cockpit temperatures, lower under hood temperatures. These all mean increased life of electric & electronic components as well.

CON:

Wrap can and frequently will hold moisture, oil, and grime next to the pipe to cause " header rotting."

Extra heat can cause the pipes to become brittle.....Cool air needs to be around the header, and insulating it with a wrap to hold exhaust heat in makes the header material temperatures near molten. When you wrap the header you trap the heat in the header, but also in the material that needs to breathe to dissipate heat for it's own survival.

READ THRU THIS LINK

(http://www.centuryperformance.com/ex...e-spg-138.html)

Headers Oxidize! the higher the heat the faster they degrade

Under normal use, and even more with higher EGTs and header surface temperatures, headers will oxidize and material is actually removed from the headers. This means they become lighter and weaker.

Try these actual test numbers:

Mild Steel (1010) uncoated header exposed to 1200º F. in normal air will have a weight loss percentage of roughly 25% with only 10 hours use at this temperature.

Stainless Steel (410) uncoated header will have roughly 8% weight loss in the same 10 hour period.

A coated mild steel header will have NO weight loss at temperatures up to 1200º F. In fact it will actually gain a bit of weight! Between 1300º F and 1600º F the coating will begin to show signs of mud cracking or like the look of lacquer checking. However, limited diffusion takes place between the coating and the substrate, producing a very thin film of iron aluminide, which continues to inhibit oxidation.

If I had some expensive headers , and wanted to reduce engine compartment heat, I would strongly suggest you go the good Ceramic Coating option route

personally a high quality ceramic coating on headers seems like a great option.

http://jet-hot.com/

http://www.moorepower.com/

http://www.moorepower.com/header_coatings/

http://www.prokoteindy.com/prokote2_003.htm

Last edited by a moderator: