Grumpy the heater hose nipple in my intake manifold seems to be corroded in place to the point I'm rather reluctant to force it as I.m fairly sure it will round off the hex surface the socket fits before it comes out as its already slightly rounded

while I saw this thread too late to be helpful here, let me introduce a bit of experience.

use of anti-seize paste on the threads , of sensors and spark plugs ,prior to instal tends to reduce the chances of this in the future

aluminum is significantly softer and weaker than cast iron, especially when its been repeatedly heat cycled or the spark plug threads were subjected of moisture that can cause corrosion to take place

anti seize paste, in many cases, is generally a mix of powdered aluminum,zinc,graphite and copper, suspended in high temp synthetic or lithium grease or waxes, that forms a effective film barrier to prevent threads corroding and binding, due to oxides forming in the thread gaps, it also tends to allow the threads to engage with less force or torque required, making it much easier for a hobbiest or mechanic to feel the plug bottom out and reduce the dendency to over tighten the plugs

copper or nickle based anti-corrosive paste (ANTI-SEIZE) on a sensor or spark plug threads, greatly reduces the chance of corrosion,locking the contacting surfaces

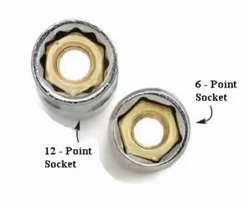

obviously a 6 point DEEP socket or wrench rather than a 12 point should be used here while applying force to the fitting.

I prefer a deep socket and the use of a tee wrench as it allows less off center torque on the threads

threads on fittings or spark plugs rusted into an intake or binding in a cylinder head can be freed with a fairly easy method,

step one clean the area with a wire brush to remove as much external corrosion as you can

HEAT WITH A TORCH, untill you know its hot, if you have a IR temp gun 300F-350F.

pure physics,

THINK ABOUT WHAT YOUR TRYING TO ACCOMPLISH!

your trying to break the bond, corrosion has formed between the two threaded surfaces, so a lubricating and corrosion breaking fluid can penetrate, thus greatly reducing the effort required to break loose and remove the part.

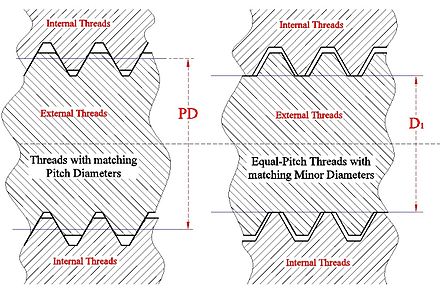

heat expands metal, rapidly cooling metal causes it to shrink, thedifferent metals both expand and shrink at different rates per degree of heat, thus the bond or gap between two dis-similar metals will tend to change as they are rapidly heated and cooled ,this tends to allow penetrating oils to seep into the micro gaps, and fissures the rapid change in physical dimensions caused by the change in temperature,especially if the process is cycled 5-7 times

there IS BY DESIGN, some thread clearance between the spark plug threads and cylinder head threads, use of anti-seize on those threads reduces the area moisture can cause corrosion on.

look over chart

http://www.engineeringtoolbox.com/thermal-expansion-metals-d_859.html

STEP two

spray with a 50%/50% mix of marvel mystery oil and ACETONE

until cool to the touch, then repeat, the acetone /MMO mix is thin viscosity and penetrates very small fissures easily drawing more in with each repeated cycle

whack the corroded fitting, or spark plug, medium lightly with a hammer a few dozen times as vibration helps the lubricant penetrate,(don,t hit hard enough to damage it)

step three REPEAT the first two steps 4-6 times as the CYCLING of heat expansion followed by cooling with the penetrating lubricant allows the penetrating lubricant to seep into the rusted threads

ITS ALSO A GREAT IDEA,too KEEP a FIRE extinguisher handy any time you use a torch

keep some penetrating oil (MARVEL MYSTERY OIL AND /ACETONE MIXED 50%/50% and a torch, and freeze spray plus the IR temp gun, in the shop

Some of you might appreciate this. Machinist's Workshop magazine

tested penetrants for break out torque on rusted nuts.

They are below, as forwarded by an ex-student and professional

machinist, Bud Baker.

They arranged a subjective test of all the popular penetrants

with the control being the torque required to remove the nut from

a "scientifically rusted" environment.

*Penetrating oil ..... Average load*

None ...................... 516 pounds

WD-40 ..................... 238 pounds

PB Blaster ................ 214 pounds

Liquid Wrench ............. 127 pounds

Kano Kroil ................ 106 pounds

ATF-Acetone mix..............53 pounds

The ATF-Acetone mix was a "home brew" mix of 50 - 50 automatic

transmission fluid and acetone,

( IN MY EXPERIENCE MARVEL MYSTERY OIL AND ACETONE MIXED 50%/50% works slightly better and faster).

Note the "home brew" was better

than any commercial product in this one particular test.AND ID POINT OUT THAT MMO/ACETONE MIX PENETRATES QUICKLY AND SEEMS TO WORK WHERE MANY OTHER PENETRATING OIL FAILS, heat and spray cycles over several cycles are the key prep here!

now let it sit for 30 minutes and soak,Like anything else, it was not immediate but it worked.

watch video

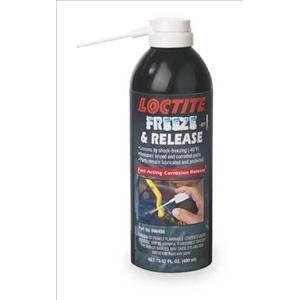

step 4 BUY LOC TITE FREEZE SPRAY

http://www.henkelna.com/industrial/product-search-1554.htm?nodeid=8797940809729

after you have prepped the part with several heat and cooling cycles spray the corroded threaded part for 20-30 seconds the freeze spray ,thermal shock , and the fact that rapidly cooling the bolt or spark plug will cause it to shrink in size further than it normally will at usually temperatures, it should and usually does shrink the threads away from the larger part its installed in enough for it to break free with noticeably less effort.

LOCTITE® Freeze & Release Penetrating Oil instantly freezes seized and rusted bolts, nuts and studs down to -38°F(-39°C). The exceptional shock-freeze effect of this penetrating oil causes microscopic cracks in the layer of rust, allowing the lubricating ingredient to wick directly into the rust by capillary action. The rusted bolt assembly can be easily dismantled after allowing only 1-2 minutes penetration time.

RELATED INFO

http://garage.grumpysperformance.com/index.php?threads/installing-hard-to-access-plugs.962/

don,t over complicate it,its just not all that difficult.

YEAH SOME PLASTICS AND ACETONE WON,T PLAY WELL TOGETHER, SO DON,T USE PLASTIC

youve got DOZENS OF OPTIONS, and MOST oil cans will not be effected with the mix and those that are ,USUALLY can be repaired with a new o-ring designed to not be effected by common solvents

OBVIOUSLY YOULL WANT TOO,LABEL THE CAN SO YOU DON,T MIX IT UP WITH REGULAR LUBRICANT OIL

BTW use of a 6 point socket and a sliding t-bar rather than a breaker bar, as it allows the torque too be applied to the fitting from both sides of the breaker bar handle to have the force applied directly on center while a traditional breaker bar or wrench applys a great deal of side torque thats counter productive.

theres been dozens of times Ive found that guys butchered and screwed up, spark plug or sensor threads, theres seldom an excuse other than they rushed and forced the job, follow the instructions above and in many cases the stuck threads will be reasonably easy to free with minimal damage resultying if any.

Last edited by a moderator: