NoTraction1970

Member

Grumpy,

Hi again.

Adrian, from Central Victoria in Australia.

New to registering on this site, but we've exchanged a little on ChevyTalk.

I am building a '38 Bedford truck into a rod, Big Block, TH400, 9", flat tray, airbag susp, chopped and channeled etc.

Just wondering if you might offer your opinion on this offering on eBay, quite close by to me here in Australia.

Seems to be reasonably priced, if the gear is not damaged.

I've decided to take your previous advice and make my new 427 tall deck into a 496 stroker.

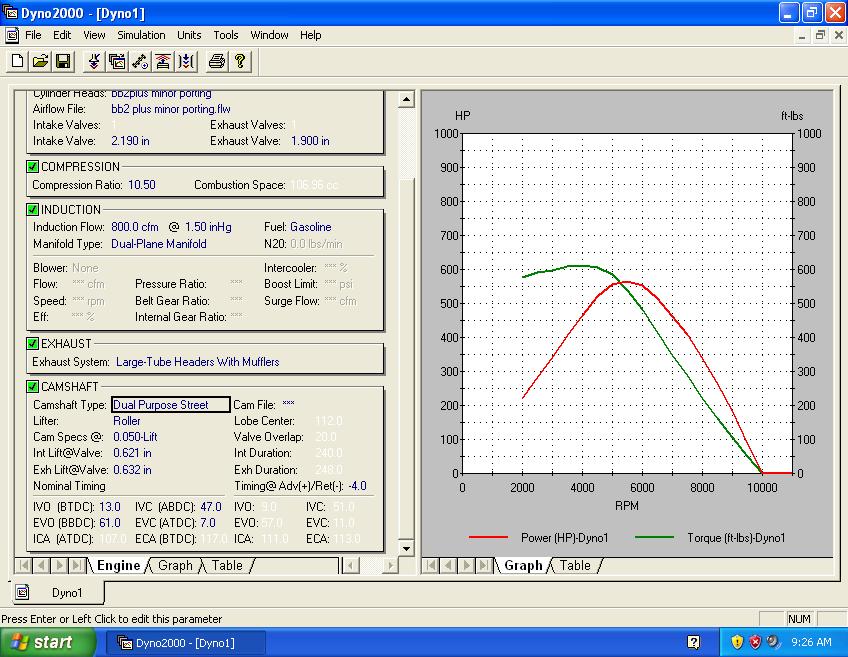

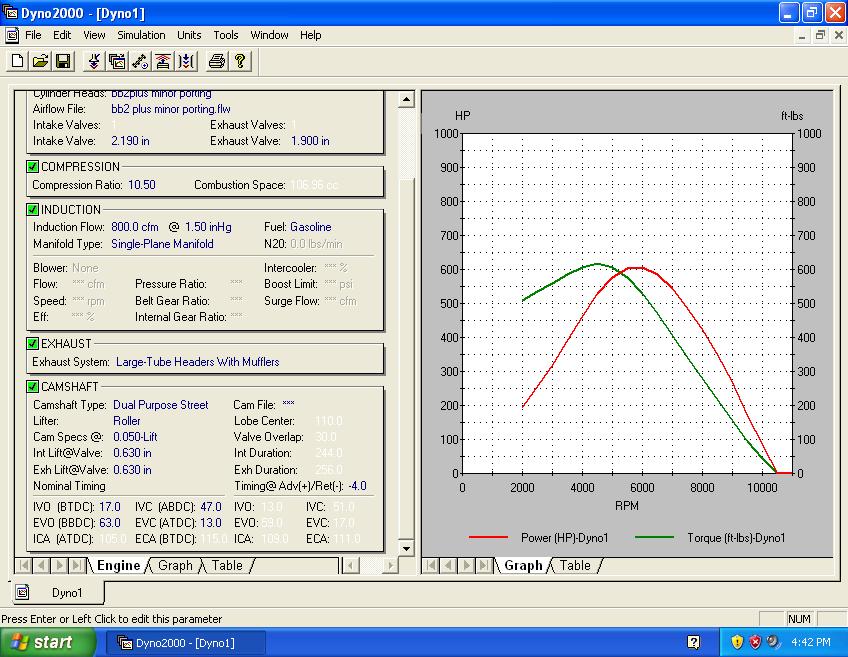

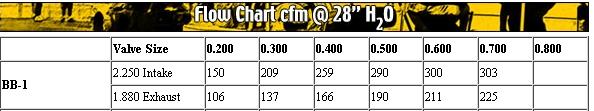

Will this pair of heads suit the 500hp I would like? and the manifold?

Or is it too much?

Hope to hear from you soon with your always interesting and informative comments.

http://www.ebay.com.au/itm/110748873445 ... 1436.l2649

Cheers,

Adrian.

Hi again.

Adrian, from Central Victoria in Australia.

New to registering on this site, but we've exchanged a little on ChevyTalk.

I am building a '38 Bedford truck into a rod, Big Block, TH400, 9", flat tray, airbag susp, chopped and channeled etc.

Just wondering if you might offer your opinion on this offering on eBay, quite close by to me here in Australia.

Seems to be reasonably priced, if the gear is not damaged.

I've decided to take your previous advice and make my new 427 tall deck into a 496 stroker.

Will this pair of heads suit the 500hp I would like? and the manifold?

Or is it too much?

Hope to hear from you soon with your always interesting and informative comments.

http://www.ebay.com.au/itm/110748873445 ... 1436.l2649

Cheers,

Adrian.